IS676 ECN4560

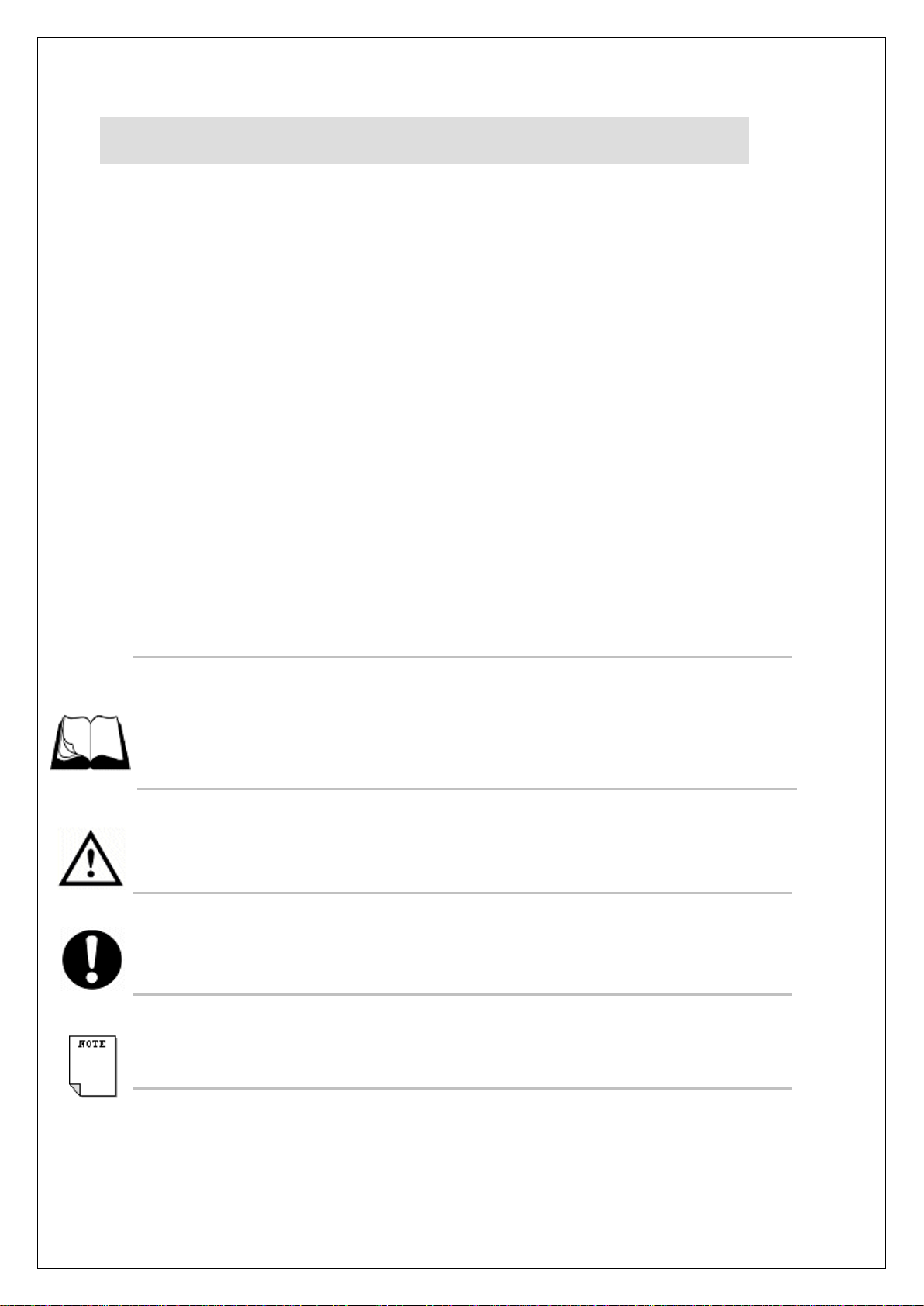

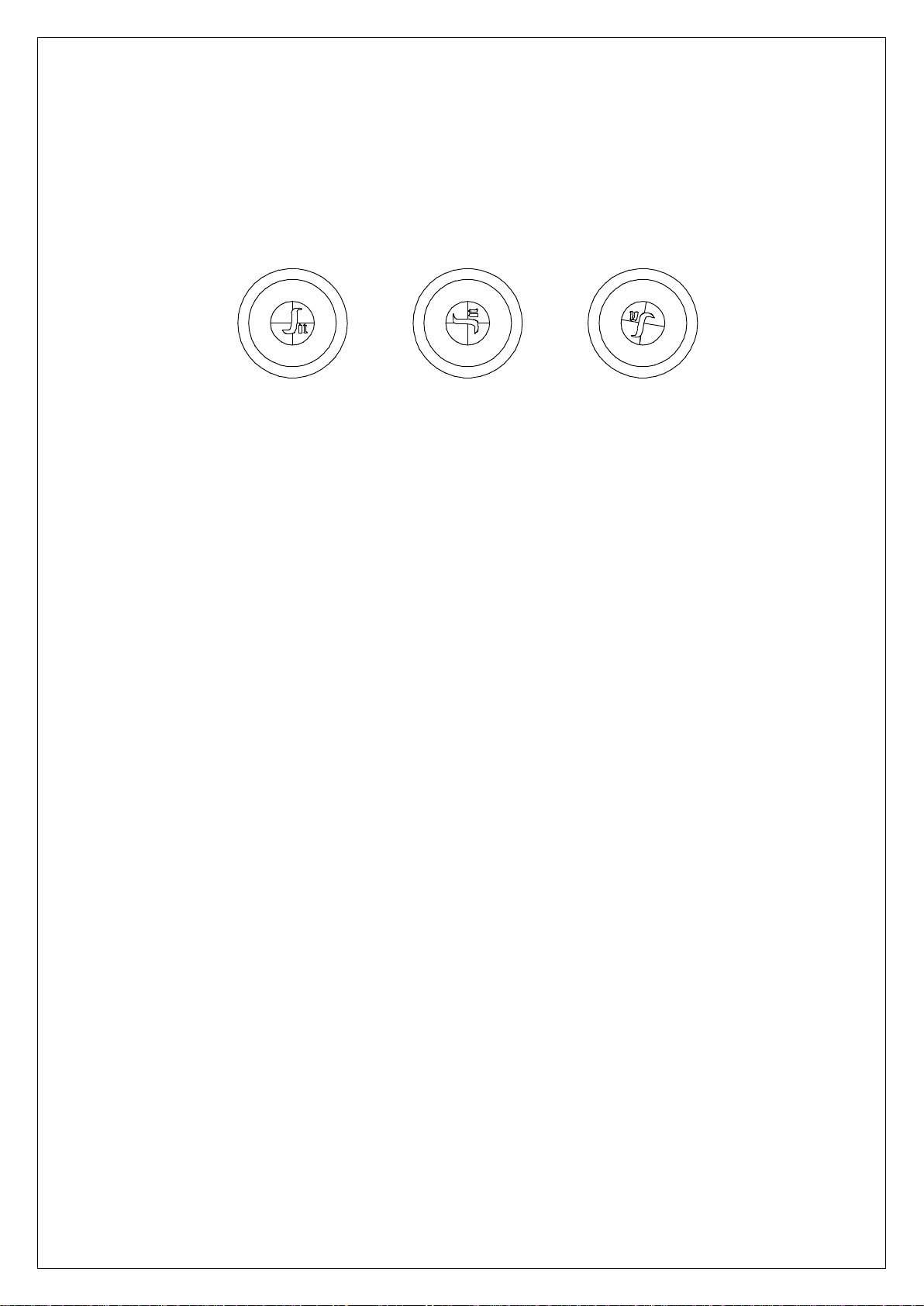

When the pilot is lit, release the pilot control knob and continue to turn fully anti-

clockwise to the ON position (Fig 4, C).

If the pilot flame fails to remain lit, return the pilot control knob to the off position and

repeat the process allowing a short period of time for the control to reset.

To operate the main burner, turn the thermostat control knob (Fig 3, 1) to the

required temperature setting.

OFF

PILOT

ON

OFF

PILOT

ON

OFF

PILOT

ON

AB C

Fig 4.

Standby

Once the pilot is lit, the appliance may be left on standby by leaving the pilot control

knob in the pilot ignition position. (Fig 4, B). When in this position the appliance

cannot be operated from the thermostat control knob. To re ignite the main burners

turn the pilot control knob anti-clockwise to the burner position, (Fig 4, C), and

operate the control thermostat as normal.

Safety cut-out

Should the safety thermostat operate during use, the appliance will shut down.

Allow the oil to cool before resetting the thermostat by depressing the red button

(Fig 3 8).

Shut down

When the appliance is not required, turn the thermostat fully anti-clockwise, which

will shut down the main burner but leave the pilot lit ready for when the appliance is

next required.

To turn the unit off completely, turn the thermostat fully anti-clockwise and the pilot

knob fully clockwise.

Drainage

Always allow the oil to cool to a maximum 55 oC before draining.

Remove the blanking nut from the front of the unit (Fig 3, 5). Fit the drain pipe,

which has a stowage clip under the lid, and place a suitable receptacle under the

pipe outlet. Lift the safety catch (Fig 3, 7) and operate the tap by moving the handle

(Fig 3, 6) to the right to drain. Remove the pipe and fit into its storage position in the

lid. Replace the blanking nut and close the tap before refilling the tank.

Take care when draining the oil that the drain bucket is not filled so full that it is

difficult to handle.