English English

5

Digital communications for accurate and reliable

performance.

PC boards are potted in epoxy for the ultimate in

outdoor protec- tion.

Connectors are filled with environmental protective

grease.

Designed for the Power Wave®AC/DC 1000 SD

series of prod- ucts for the best arc in the industry.

Wire feed speed accuracy calibrated to within 2%.

Digital display of voltage and wire feed speed.

Tachometer controlled wire drive motor.

Flux Fill Switch.

Bright, high intensity digital read-outs.

Option to convert to hand-held pendant included.

Recommended Processes and

Equipment

The MAXsa™ 10 CONTROLLER is best suited for

submerged arc welding only with the Power Wave®

AC/DC 1000 SD, the MAXsa™ 22 or the MAXsa™

29 Feed Heads.

SAW

Welding Voltage

Wire feed parts are electrically live while welding and

while inching wire (with Touch Sense feature selection).

The electrically live parts are listed below:

Electrode Electrode Reel

Wire Drive Motor Drive Rolls

Gear Box Cross-seam Adjuster

Wire Straightener Welding Nozzle

Welding Cables Welding Cable Terminal

WARNING

Do not touch electrically live parts or electrodes with

your skin or wet clothing.

Insulate yourself from the work and ground.

Always wear dry insulating gloves.

MECHANICAL HAZARDS

Welding fixture or wire feeder will move during

welding or inching. Keep away from pinch points.

Electrode reel and drive rolls turn during welding or

inching. Keep gloved hands away from areas that

may catch the glove

Location and Mounting

The MAXsa™ 10 Controller will operate in harsh

environments and can be used outdoors with an IP 23

rating. Even so, it is important that simple preventative

measures are followed in order to assure long life and

reliable operation. The MAXsa™ 10 Controller must be

located where there is little risk of impacts to the

Controller.

This equipment is for industrial use only and it is not

intended for use in residential locations where the

electrical power is provided by the pub- lic low-voltage

supply system. There can be potential difficulties in resi-

dential locations due to conducted as well as radiated

radio-frequency disturbances. The EMC or RF

classification of this equipment is Class A.

High Frequency Protection

Locate the MAXsa™ 10 Controller away from radio

controlled machinery. The normal operation of the

MAXsa 10 Controller may adversely affect the operation

of RF controlled equipment, which may result in bodily

injury or damage to the equipment.

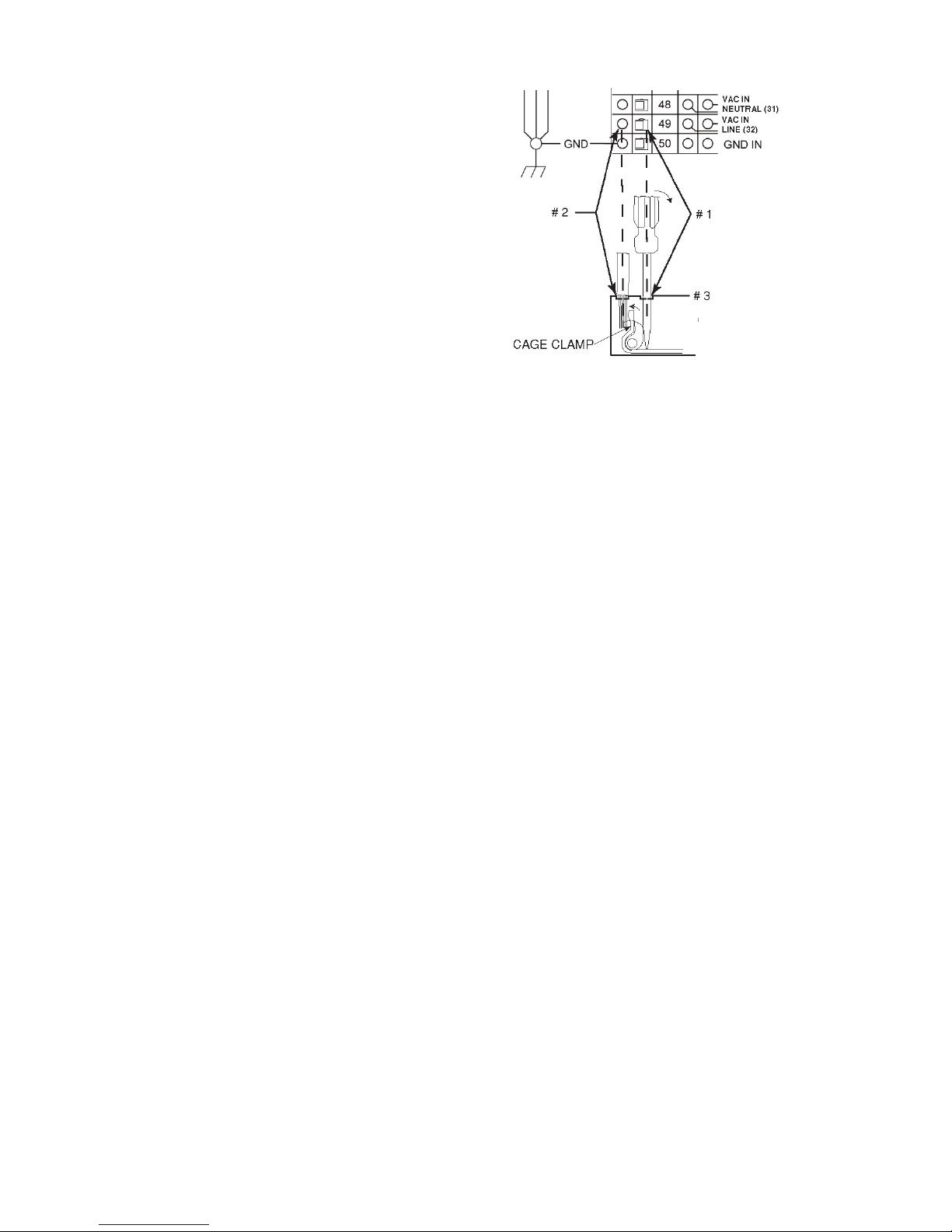

Auxiliary Equipment Input Power

Connection

The MAXsa 10 Controller has the ability to control

auxiliary equipment such as feeders, flux hoppers and

travel motors using solid state relays. There are three

relays (CR1,CR2 &CR3) in the MAXsa 10 Controller,

controlled by two independent coil drivers. The coils of

CR1 and CR2 are in parallel, therefore, they must turn

ON and OFF at the same time. The CR1 and CR2 relays

are designated for driving travel motors to control

motion. CR3 is driven separately, and is designated to

control flux hopper operation.

MAXsa 10 Controller Relay Ratings:

Coil: 12Vdc, resistance = 86 ohms at 25° C

Normally Closed (N.C.) Contacts: 3A @ 277VAC

Normally Open (N.O.) Contacts: 30A @ 277VAC

The MAXsa 10 Controller does not provide the input

power to feed any equipment, other than the MAXsa 22

or the MAXsa 29 feeders. Therefore a separate power

feed must be provided by the end user. The MAXsa 10

Controller has been shipped standard with all of the

wiring and connectivity to operate the Lincoln K325 TC-3

Travel Carriage (4-pin cable connector) and the Lincoln

K219 Automatic Flux Hopper (3-pin cable connector).

The CR2 Relay is wired to the 4-pin travel connector,

and the CR3 Relay is wired to the 3-pin flux connector,

both located on the bottom of the MAXsa 10 Controller.

If either of these is to be used with the MAXsa 10

Controller, the end-user must provide the 115VAC input

power to the terminal strip located inside the MAXsa 10

Controller. Access to the terminal strip may be obtained

via one of the two .875” dia. (22.2mm) access holes in

the bottom of the MAXsa 10 Controller. These access

holes are shipped with plug buttons installed. Remove

the plug button and install a suitable strain relief to

protect the wires. See Figure #1

WARNING

Although input power to MAXsa 10 Controller is turned

off, the customer installed auxiliary input may be

energized! Ensure that all input power to the MAXsa 10

Controller is turned off before opening the cover.

1. STATUS LIGHT

2. PENDANT CONNECTOR

3. MAXsa™ 22 or 29 WIRE DRIVE CONNECTOR

(14-PIN)

4. POWER WAVE®AC/DC 1000 ARCLINK

CONNECTOR

5. FLUX HOPPER CONNECTOR

6. TC-3 TRAVEL CARRIAGE CONNECTOR

7. ACCESS HOLE

Figure #1: MAXsa 10 Connections