Torchmate 5100 viii

Unpacking: FlexCut 200/FlexCool 35

The FlexCut 200 is liquid cooled and is supplied with the FlexCool 35. For complete instructions on the FlexCut

200 and the FlexCool 35, see their corresponding user guides - FlexCut 200 - IM10422, FlexCool 35 - IM10423

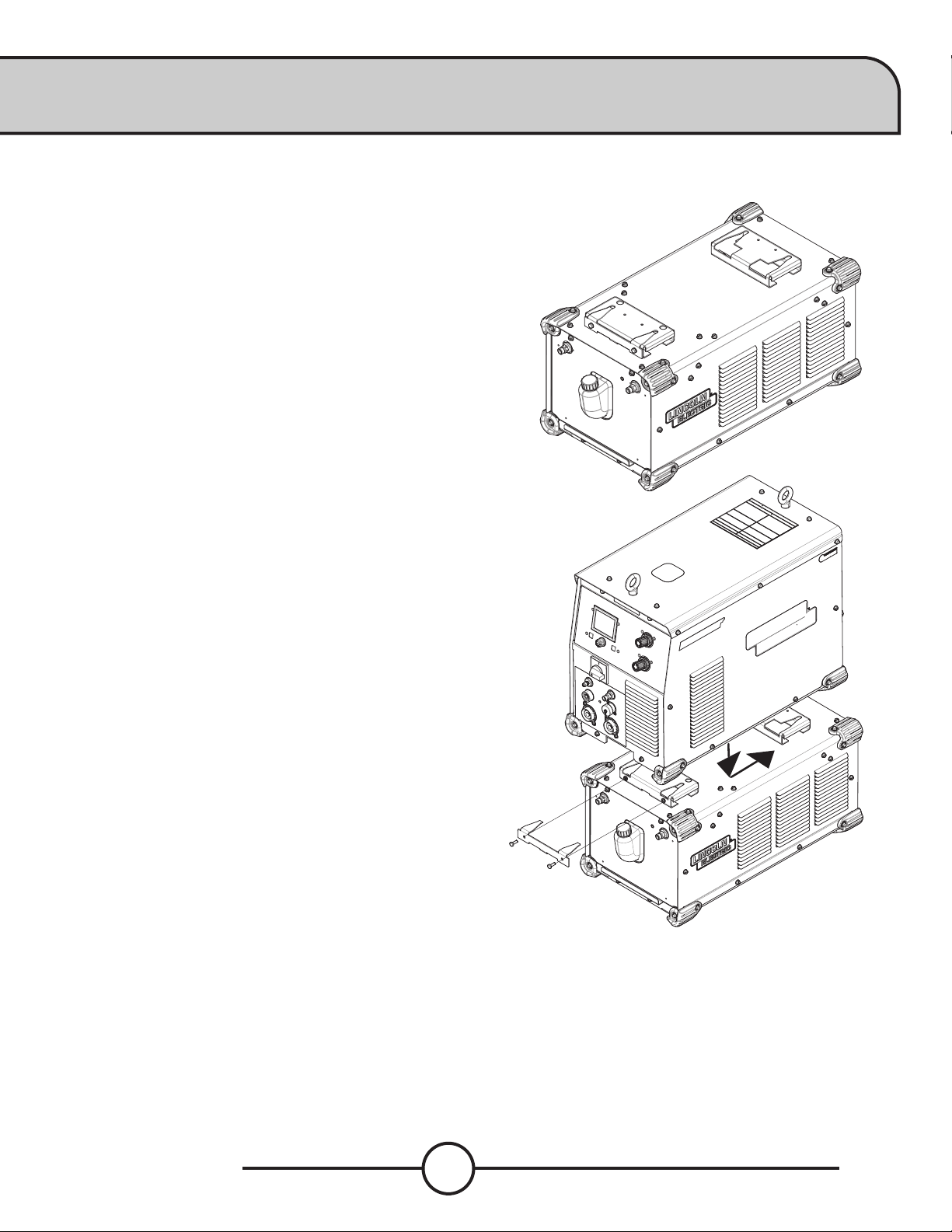

Unpacking the FlexCool 35:

The packaging of the cooler is designed to withstand

shipping abuse. If any shipping damage has occurred, contact

your certied Lincoln distributor or service center. When

unpacking the unit, avoid thrusting sharp objects through

the carton, which may damage the machine. Below is the

recommended procedure for unpacking the cooler:

1. Cut and remove banding straps around skid and carton

2. Remove carton

3. Cut and remove banding straps around skid and cooler

4. Remove cooler, literature, and other items

Save the instruction manual and service directory supplied with

the FlexCool 35 for parts orders and future maintenance service.

Mounting the FlexCool 35 underneath the FlexCut 200:

The FlexCool 35 can be mounted underneath the FlexCut 200

machine or by itself on a at surface. No power source should

ever be installed underneath the FlexCool 35.

Securing the FlexCut 200 to the FlexCool 35:

1. Begin by setting the FlexCool 35 on a hard at surface.

2. Remove the two 7/16" bolts and the locking bracket from the

front mounting bracket.

3. Lift the FlexCut 200 and place it on top and slightly

forward of the FlexCool 35.

4. Carefully guide the FlexCut 200 so that the quick lock feet on

the bottom of the power source slide into the channels of

the mounting brackets on top of the FlexCool 35. Be sure all 4

feet are within the channels.

5. Slide the FlexCut 200 all the way back so that it is sitting

exactly overtop of the FlexCool 35. The feet should be all the

way at the back of the channels.

6. Replace the locking bracket into the front mounting bracket

of the FlexCool 35. Torque both 7/16" bolts to 50 in-lbs.

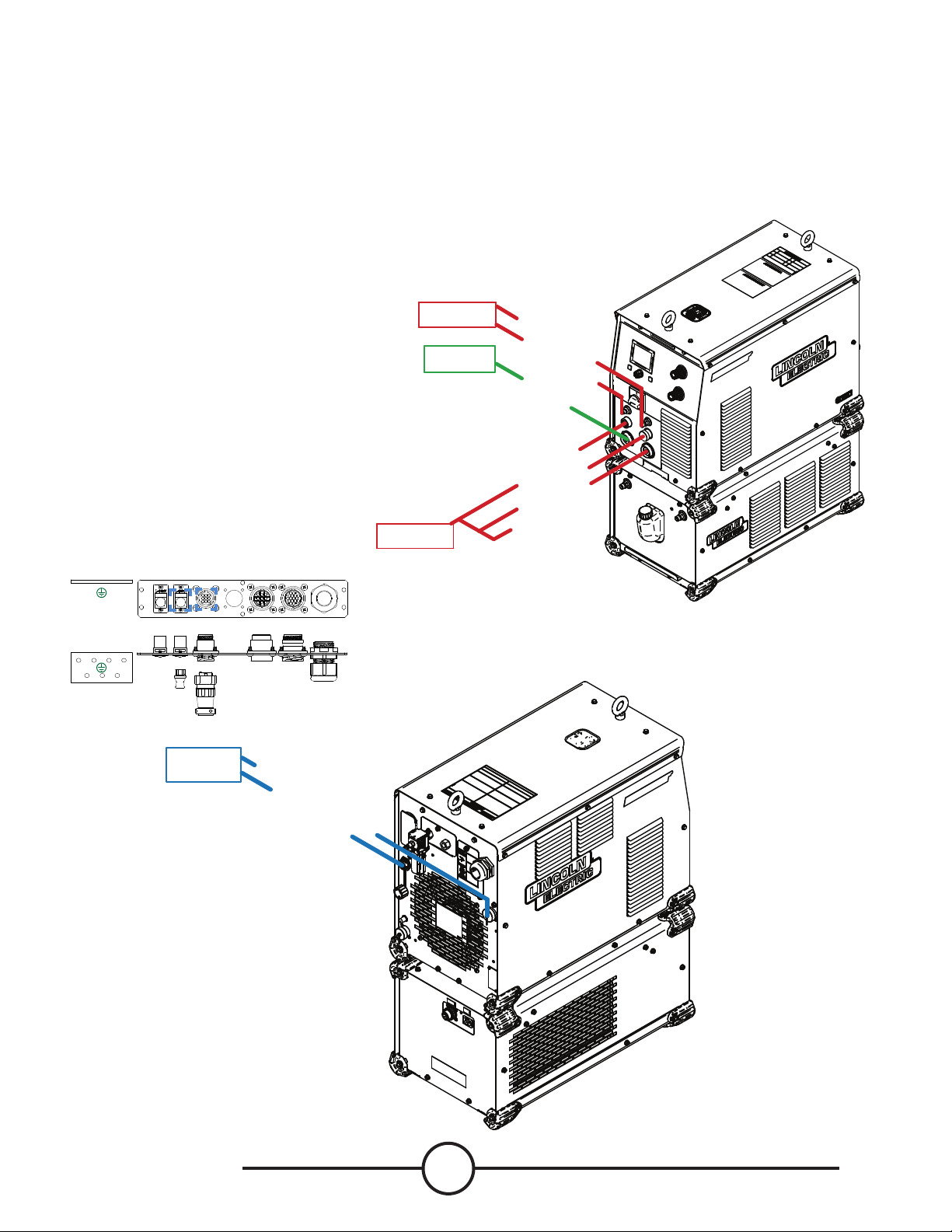

1.5 gallons of coolant are preloaded into the machine at the facility for live re testing.

Pour 0.75 gallons (2.84 liters) of coolant into the coolant reservoir ll hole through a funnel.

Use the coolant purge command in the machine UI menus to help prime the system.

While priming, add additional coolant to keep the reservoir full. The cooler is "FULL" when the coolant lies just

below the coolant reservoir opening.

Be certain to replace the reservoir ll cap when the reservoir is full. Operation of the FlexCool 35 without the

reservoir cap can cause unnecessary contamination and could be hazardous to others. See the FlexCool 35

manual for complete instructions and safety precautions.

Filling the Coolant Reservoir:

USE ONLY LINCOLN ELECTRIC TORCH COOLANT - BK500695