Page Number - 5

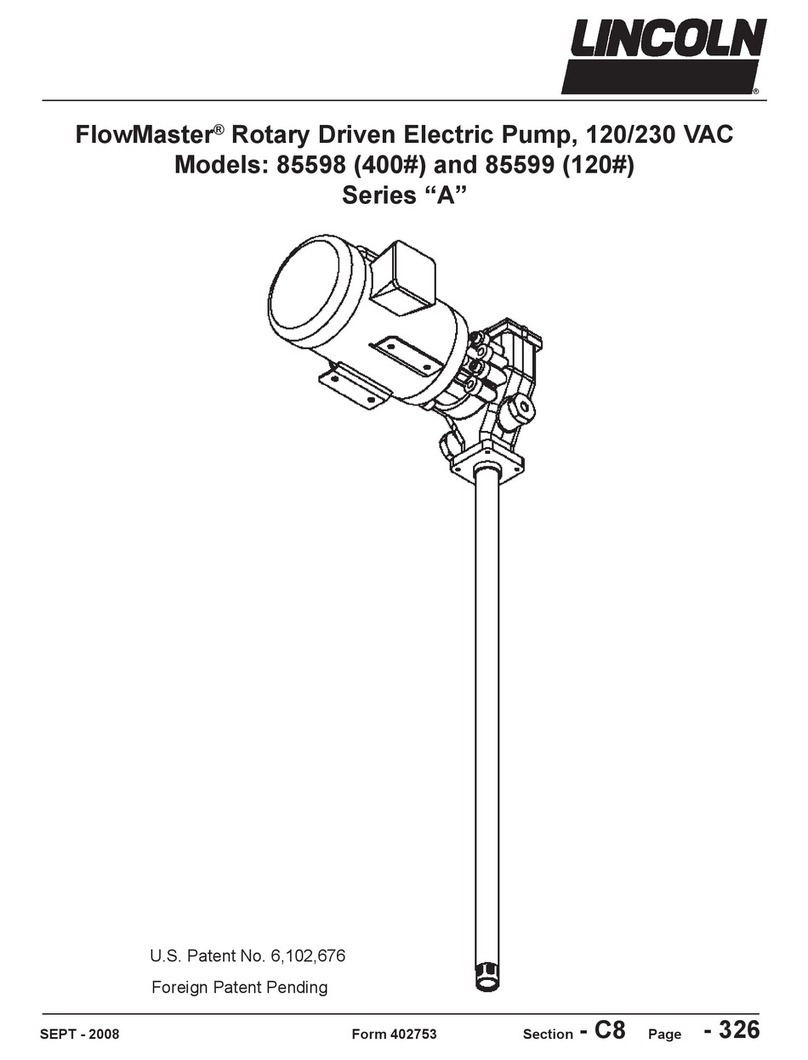

FlowMaster™ Rotary Driven Electric Pump

Form 422823

9.Remove the two outlet pin nuts (32) from the housing (68).

10.Remove the pump subassembly (1 through 27) from the

pump housing (68). Pushing the subassembly up with a

wooden or plastic rod 3/4 O.D. against the check seat

housing (27) is helpful.

11.Remove the housing tube (56) from the pump housing

(68) by inserting a 3/4” rod through the inlet holes at the

bottom of the housing tube (56) and unscrewing it.

12.Remove the bronze bearing (52), the O-Ring (53) and the

backup washer (54) from the housing tube (56).

13.Remove the crankrod assembly (1 through 7) from the

pump by unscrewing the button head screws (11) and

then pulling out the wrist pin bushings (12).

14.Remove the check seat housing (27) from the

reciprocating tube (20). There is a 3/8 Allen head

socket in the throat of the check seat housing (27) to

facilitate removal.

15.Unscrew the wrist pin anchor (13) from the

reciprocating tube (20) and pull the plunger assembly

(8 through 19) from the tube.

16.Using a 1/2” wooden or plastic rod, push the cup seal

(21) and the pump cylinder (23) from the reciprocating

tube (20).

17.Remove the pump plunger (19) from the plunger link

rod (16). A spanner wrench, which uses the holes in

the pump plunger, is required.

18.Unscrew the plunger link rod (16) from the plunger

tube (10) and slide off the cup seal (15), the backup

washer (14) and the wrist pin anchor (13).

19.Unscrew the plunger tube (10) from the outlet pin (8).

20.To dismantle the crankrod assembly (1 through 7),

remove flat head screws (1) and the counter weights

(2).

21.Remove the retaining rings (5) and press the crank

eccentric (6) out of the ball bearing (7). Be sure to

support the ball bearing (7) on the inner race.

PumpAssembly Procedure

1. When the pump is dissembled, it is recommended to

replace all seals and gaskets, which are included in the

270663 repair kit. In addition, replace o-rings (44), (36)

and (63).

2. In the process of disassembly, examine the following

components and replace if excessive wear is indicated:

ball bearing (7), crank eccentric (6), crankrod (4), wrist

pin bushings (12), plunger tube (10), pump plunger and

upper check parts (19, 18 and 17), pump cylinder (23),

check seat housing and lower check ball (27 and 25),

upper bronze bushing (52), housing tube (27), shovel

plug (59), and reciprocating tube (20). Also check shaft

seal (40).

3. Assembly Procedure is the reverse of the Disassembly

Procedure except for the following:

4. Install parts (21) through (27) into the reciprocating tube

(20) after the plunger assembly (8 through 19) is

installed.

5. Install the pump subassembly (1 through 27) into the

pump housing (68) before tightening the housing tube

(56) to the pump housing (68). Be sure the

reciprocating tube (20) is inserted through both

bushings before tightening the housing tube (56).

6. When pressing the pump shaft in (37), support the inner

race of the rear ball bearing (60) and the crank assembly

(1 through 7) to insure proper assembly.

7. If replacing the pump shaft ball bearings (38 & 60),

support the housing (68) inner wall behind the snap rings

(39 & 61) when re-installing the bearing.

8. Use loctite 242 (or similar product) medium strength

thread lock on all torqued threaded connections. Extreme

care must be exercised to prevent excess compound

from flowing into critical areas such as clearance fits and

ball check. Allow a minimum of 30 minutes cure time

before operating the pump.

9. Torque Specifications:

A. Plunger tube (11) to outlet pin (9) - 100 to 110 In.-Lbs.

B. Button head screws (11) to wrist pin anchor (13) 100

to 110 In.-Lbs.

C. Plunger tube (10) to plunger link rod (16) - 100 to 110

In.-Lbs.

D. Plunger link rod (16) to pump plunger (19) - 100 to

110 In.-Lbs.

E. Flat head screws (1) to counter weight (2) - 100 - 110

In.-Lbs.

F. Wrist pin anchor (13) to reciprocating tube (20) - 20 to

25 Ft.-Lbs.

G. Check seat housing (27) to reciprocating tube (20) -

20 to 25 Ft.-Lbs.

H. Outlet pin nut (32) to pump housing (73) - 30 to 35 Ft.-

Lbs.

I. Housing tube (56) to pump housing (73) - 20 to 25 Ft.-

Lbs.

J. Gearbox mounting screws (46) - 20-25 Ft.-Lbs.

K. Gearset mounting screws (48) - 60-70 In.-Lbs.

L. Motor mounting screws and jam nuts (51 & 42) - 100-

110 In.-Lbs.

M. Bearing cover screws (66) - 32 -38 In. Lbs.

10.Fill crankcase with SAE 10W 30 motor oil up to the center

of the pump shaft (37) before fastening housing cover

(30) and housing gasket (31). If pump will be used in

very cold environments, use Mobil Assow HFA Low

Temperature Oil. This oil stays fluid even at -70° F.