Form 403049 Page 5

The adjustment screw allows 15 turns

of adjustment over the timing range.

The adjustment screw should be

turned 20 turns counter-clockwise to

insure you are starting at a minimum.

Note: You can not adjust below

minimum - additional turns counter-

clockwise have no effect.

Each clockwise turn will equal approx-

imately .3 seconds. Add the number of

turns clockwise to reach the approx-

imate desired timing. Some additional

adjustment may be necessary depend-

ing on the accuracy needed.

Use the light on the cycle timer to help

in setting the time. The light will turn on

when there is power going to SV2.

TROUBLESHOOTING

If the following procedures do not

correct the problem, contact a factory

authorized service center. When

submitting equipment to be repaired,

be sure to state the nature of the

problem and indicate if a repair cost

estimate is required.

PROBLEMS

CYLINDERPRESSUREGAUGE

DOESNOTREGISTERPRESSURE.

A. No system pressure to the pump.

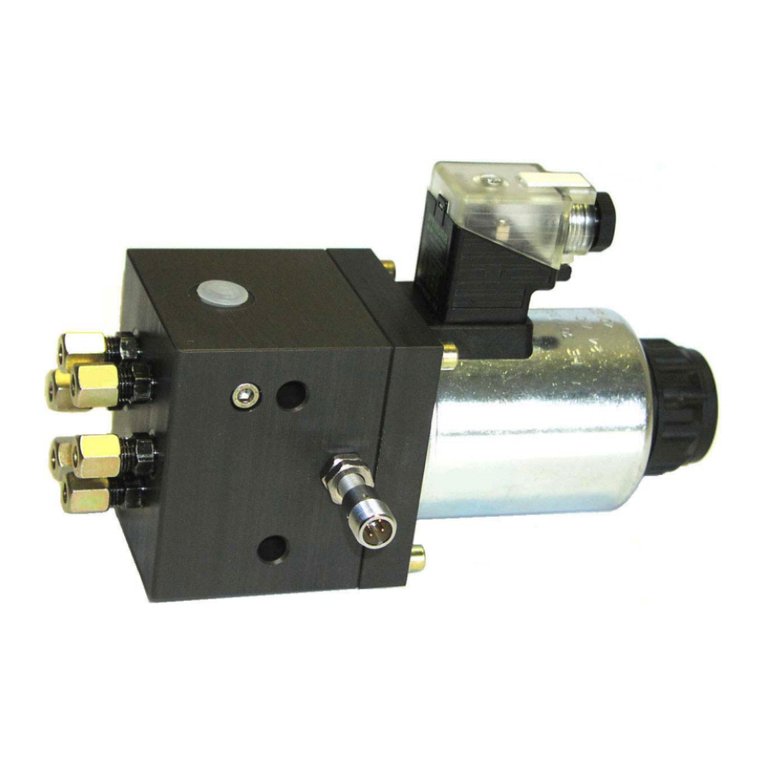

B. No 24 VDC signal at solenoids SV1

and SV2.

C. Pressure reducing valve set too low.

Increase setting by 1/2 turn to check

operation.

D. Primary solenoid valve SV1 may be

inoperative.

PUMPPRESSUREBUILDSVERY

SLOWLYOR NOT ATALL.

A. No pulsing signal at SV2.

B. Pressure reducing valve may be set

too low.

C. Grease viscosity may be too high for

temperature at which pump is

operating.

D. If pressure is not building at all,

secondary solenoid valve SV2 may

be inoperative.

E. Pump piston ball checks and inlet

checks may have foreign matter

trapped causing leakage. Remove,

inspect and clean if necessary.

F. Inspect sealing surfaces between

upper and lower inlet checks.

Replace if rough or pitted.

G. Replace shovel rod if rough or pitted.

Replace shovel rod packing.

H. Inspect lubricant supply line for

leaks or breaks.

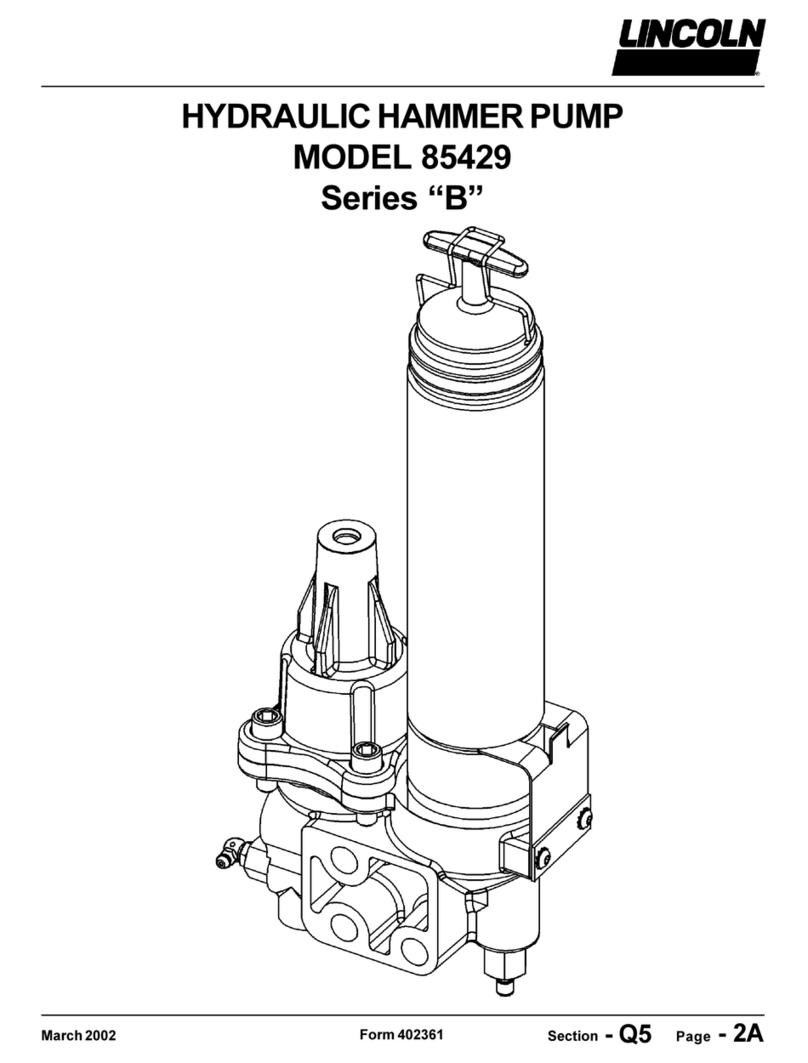

DISASSEMBLY

Refer to SERVICE PARTS for part

numbers and location. Bleed all

pressure from hydraulic and grease

lines before disassembling pumps.

A. Disconnect hose assemblies

(241806 and 271598©) from upper

portion of the pump.

B. Remove cylinder adapters and

gaskets (241961 and 241810).

C. Remove bolts and washers

securing cover to pump (50058 and

48083).

D. Remove cover and valve assembly

(241799 and 84970).

E. Using two wrenches, unscrew

coupling nut (241805) from pump

shaft end (11329).

F. Remove four upper bolts (50771)

and lock washers (68186) securing

mounting plate (241803) to the tie

rods (241804).

G. Remove hydraulic cylinder (241814)

and mounting plate (241803).

H. The hydraulic cylinder can be

disassembled from mounting plate

by removing four bolts (242048) and

lock washers (68186).

I. Tie rods (241804) can now be

removed from pump outlet body

(40537) by removing four lower bolts

and lock washers (50771 and

68186).

J. Unscrew pump tube from outlet body

(40537).

K. Extend pump piston rod (11340) out

of the bottom of outlet body (40537).

Place wrenches on piston end

(11329) and flats of piston rod

(11340) and unscrew piston rod.

Thread the piston rod through the

gland packing to allow removal of the

pump tube.

L. Unscrew gland packing nut (12333)

from outlet body and remove all

gland parts.

M. Remove the priming tube (239719)

from the bushing extension (61273).

N. Extend plunger rod (11723) out of

bushing extension and unscrew

priming plunger (11724) to allow

removal of priming check parts and

plunger rod (11723).

O. Remove bushing extension (61273)

and unscrew plunger and bushing

assembly (90554) from pump tube.

Unscrew coupling nut (12211) from

coupling adapter (12210) to allow

removal of plunger and bushing

assembly intact, reducing the chance

of loosing ball stop (57027) and

check ball (66010).

ASSEMBLY

To reassemble, perform DISASSEM-

BLY procedures in reverse.

IMPORTANT

To prevent damage to pump gland

packing and to help increase packing

life, lube pump piston rod before

assembly. Thread piston rod through

gland packing when assembling pump

REPAIR

Repair is limited to replacememt of

listed service parts. Special procedures

and tools are required. Contact Lincoln

Technical Service, One Lincoln Way,

St. Louis, MO 63120-1578, (314)

679-4200 Ext. 782 for your nearest

authorized service center.

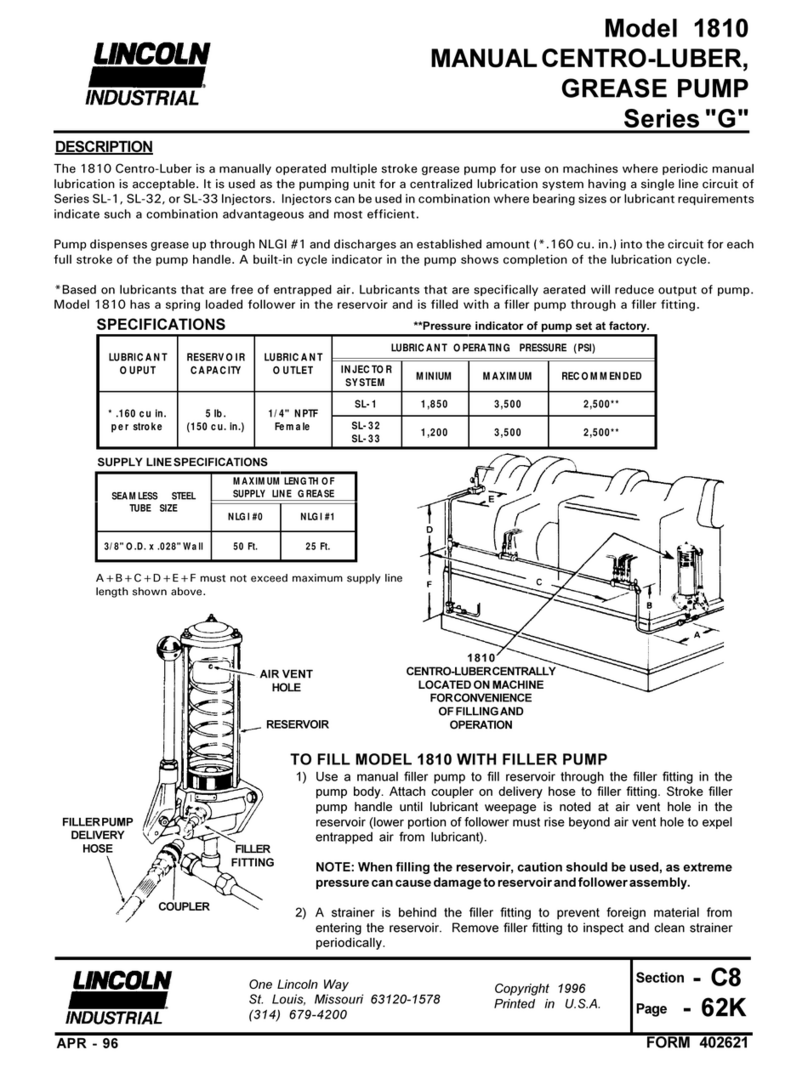

When ordering replacement parts, list:

part number, description, model

number and series letter.

ACCESSORIES

Model 84980 Hydraulic Operated

VentValve

Model 84990 Hydraulic Operated

Vent Valve Assembly

245530 Viton/Teflon

Packing Kit (For

Pumping Synthetic

Lubricants)

Model 85530 Controller

Model 249605 Cycle Timer/

Coil Assembly

Model 84015 24 VDC Timer

Model 69630 Pressure Switch

83001 Lower Pump Tube

Repair Kit

© Indicates change