Page Number - 7

Form 402002

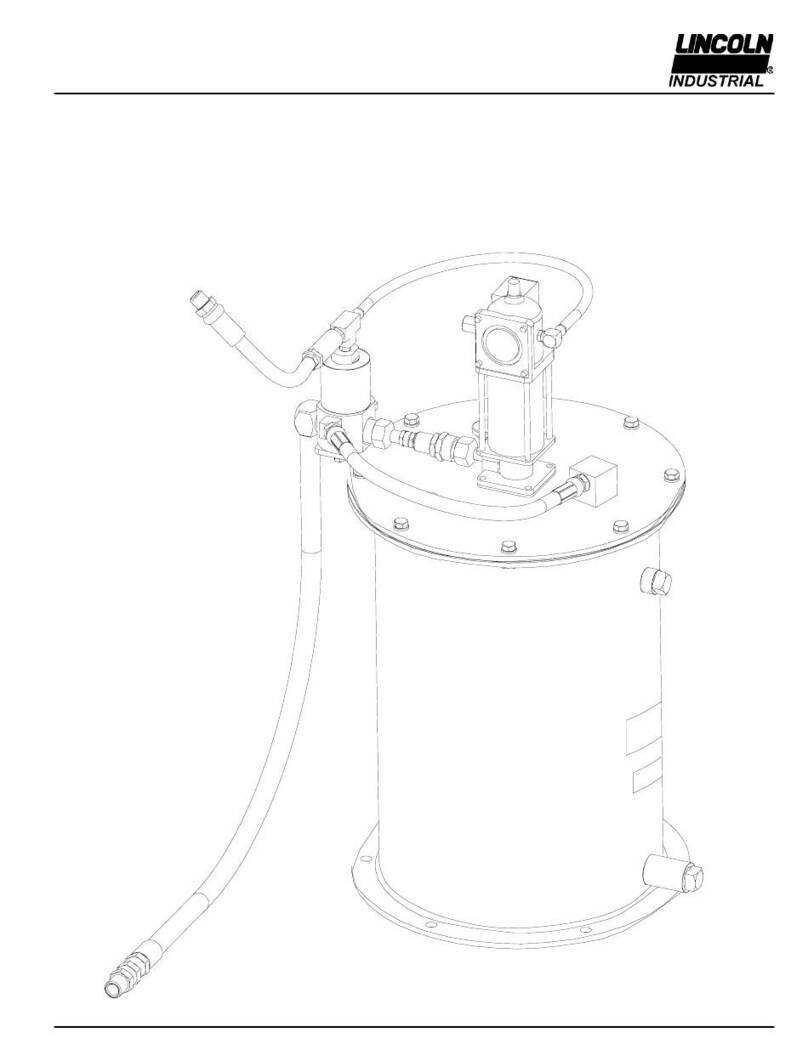

MODELS 4490, 4491, 4492

3.5:1 AIR OPERATED PUMP

SYSTEM START-UP

When operating the pump in a system for the first time, air

must be purged from the system. Expelling air from the pump

is very critical for the pump to prime and operate reliably.

Before connecting the pump to a system, make sure the pump

is placed into a container of the oil that is to be dispensed.

Connect a short length of hose to the pump outlet and direct

the open end of the hose into a container to catch the oil. Op-

erate the pump at low air pressure, 20-40 PSI, until the pump

primes, and oil flows smoothly from the end of the hose.

The system can now be connected to the pump outlet. Purge

the entire system in a similar manner, slowly pumping oil

through all reels and control valves until oil, free of air, flows

smoothly from each outlet.

PRESSURE RELIEF PROCEDURE

The following procedure should be followed when it becomes

necessary to shut the system down for service or container

changes.

• Disconnect the air supply from the air inlet of the pump.

• Bleed the lubricant pressure off the system by opening a

dispensing valve into a container. Hold the valve open until

all flow from the system stops.

• Close the shut-off valve between the pump and reservoir on

standpipe installations (if present).

• Close the shut-off valve between the pump outlet and sup-

ply lines (if present).

• Slowly loosen the lubricant supply line at the pump out-

let. A very small volume of oil will leak from the threads.

If pressure is present, stop the loosening procedure and

repeat the steps above.

REPAIR

Repair is limited to the service parts listed on following pages.

In most cases, service is going to be the replacement of soft

seals in the pump. See illus. 5 and 6 for internal components

of the pump. Illus. 5 indicates the disassembly/re-assembly

order of the pump. Illus. 6 indicates how all components fit

together and the correct placement of seals.

Contact your nearest authorized Lincoln Service Dealer or

Lincoln Technical Services for assistance.

Disassembly Procedure

• Follow Pressure Relief Procedure, above to remove all

pressure from the pump and related system.

• Disconnect air and supply lines from the pump and remove

from reservoir.

• On pumps with long pump tubes, remove the pump tubes

from the pump inlet.

• Carefully secure the pump in a vise holding at the pump

base. Take care not to damage the pump base or other

components.

• Loosen Allen head cap screws, (item #1), and remove.

Remove fluid cylinder (item #2) and set aside O-ring (item

#3).

• Make sure that fluid plunger components, (items #4

thru #9) are securely attached to piston rod ass’y, (item

#18).

• Loosen Allen head cap screws (item #14). Make sure

that the screws and air cylinder are not under spring

tension before removal of screws. Pull air cylinder (item

#21) away from pump body (item #15) before screws are

completely removed to make sure cylinder is not under ten-

sion.

• Remove air cylinder (item #21) and remove air piston as-

sembly (item #19) from air cylinder. Use a rod through air

inlet hole to gently push piston from cylinder. [Air plunger,

(item #19) is a sealed unit. Internal seals in the air plunger

are not replaceable. If problems are suspected with the air

plunger, the entire plunger must be replaced as a unit.]

• Spring (item #16) is now retained by the fluid plunger

components, (items #4 thru #9), only. With assistance

from another person, push the piston rod assembly (item

#18) slightly into pump body to relieve tension from fluid

piston components, (items #4 thru #9). Hold piston rod with

wrench on flats provided, and remove the fluid piston nut

(item #4). Gently remove the spring tension by allowing the

plunger rod to pull out of the pump body (item #15).

• Once spring tension is removed, remaining components

may now be removed from the pump body. (Piston Rod As-

sembly, (item #18) is permanently assembled in two pieces

at the factory, do not attempt to disassemble any further.)

• Remove retaining ring (item #10) and washer (item #11).

The U-cup seal (item #12) may now be removed from the

pump body, taking care not to damage surfaces of seal

bore.

• Once all components are disassembled, clean with mineral

spirits or other suitable solvent. Replace all replaceable

seals and worn parts.

• Reassembly will be the reverse of the above procedure.

• NOTE: When installing U-Cup seal (item #12) special care

is required to place the seal in the bore correctly. The seal

lips must face the outlet end of the pump, as seen in

Illus. 6. Make sure that retaining ring (item #10) is properly

seated when reinstalled.

Contact your nearest authorized Lincoln Service Dealer or

Lincoln Technical Services for assistance.

When ordering replacement parts, order by part number and

description. The model number and series letter may also be

required.