5

WARNING: Never place tools or other ob-

ject into the fan.

WARNING: Never touch electrical compo-

nents with wet or damp hands.

WARNING: To ensure the cooling unit

works properly and at full capacity, make sure

air supply to the unit is not obstructed.

WARNING: Water temperature during sani-

tation must not be higher than 25 °C!

WARNING: Always make sure the power

socket you intend to plug the cooler into is ac-

cessible, so that the appliance can be immedi-

ately unplugged in case of emergency.

WARNING: When unplugging the device

from the socket, grab the plug and pull it out.

Do not under any circumstances pull at the ca-

ble; risk of damage.

WARNING: To turn the device ocomplete-

ly, unplug the appliance from the power sock-

et.

WARNING: In the event the electrical wiring

of the product becomes damaged, summon a

trained service technician. Do not under any

circumstances repair the device yourself.

WARNING: The cooling system contains

ammable coolant R290 (propane)!

WARNING: Emergency maintenance and

repair of the cooling system must be done by

trained, authorised technicians familiar with

cooling and electrical systems. The technicians

should have special training and qualication

for handling ammable substances in order to

perform service on coolers containingR290.

Follow basic regulations and safety measures

regarding service and repair!

WARNING: Do not use open ame or po-

tential sources of sparks in the vicinity of a

cooler using R290 coolant!

WARNING: After unpacking, place the cool-

er so that heat created by the cooling unit can

be vented suciently.

WARNING: Do not place objects that could

prevent air circulation on top of the cooler.

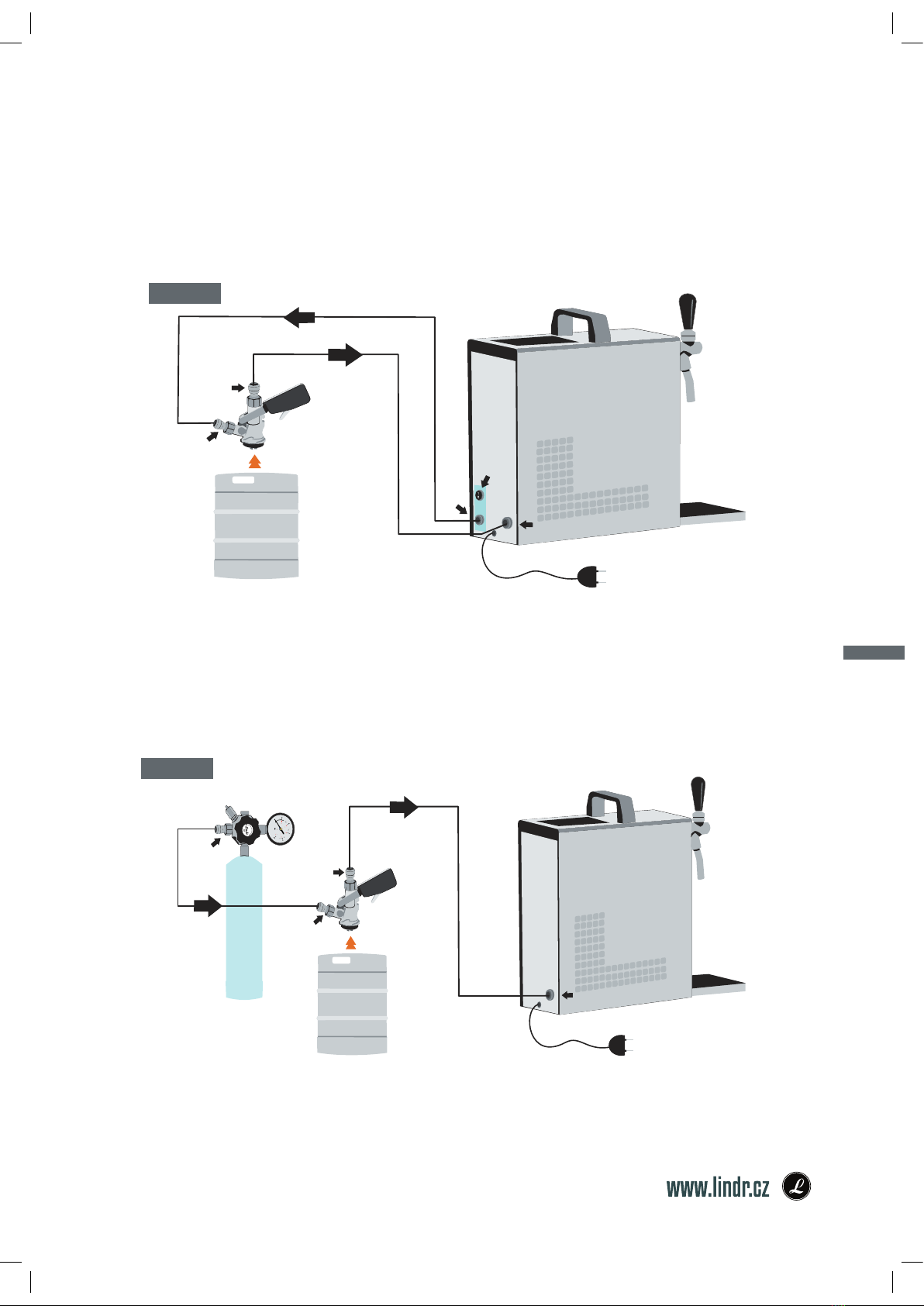

5. INSTALLATION AND PLACEMENT

Place the cooler onto a stable, level surface

(maximum permitted inclination: 2 degrees).

The appliance requires unobstructed air circu-

lation.

• Ensure sucient free space for air circulation

and heat dissipation.

• Ensure sucient supply of fresh air.

• The device must not be placed in an enclosed

space.

• The device must not be placed in the vicinity

of heat sources or exposed to direct sunlight.

Minimum distance of vents from an obstacle

that would limit air circulation must be 30 cm.

Minimum distance for sections with no air

vents is 7 cm. Ideally, use the device in a cool

and well-ventilated room. The device is de-

signed for use at ambient temperature of at

least 16 °C and at most 32°C.

WARNING: The device MUST NOT be used

or stored at ambient temperature lower than

0 °C. The device is designed for use in a normal

environment, always under a roof, protected

from rain or sunlight. Climate class N.

DANGER: Protect the cooler and electrical

connection from rain and spraying water!

WARNING: Do not under any circumstanc-

es lay the cooler on its side, not even during

transport.

NOTE: In order for the device to work

correctly and at maximum output, it is im-

portant to not cover up any of the device's

vents and ensure sucient air circulation.