Link-Belt PULSE Use and care manual

Link‐Belt Pulse

Calibration Manual

(Level 2)

Access on Cranes with Outrigger Sensors

®

Link‐Belt is a registered trademark.

Link‐Belt Pulse Calibration Manual

Table Of Contents

General Information . . . .. . . .. . . . . .. . . . .. .. . . .. .. . . . .. .. .. . . .. .. . . . . . .. . . .. .. . . .. . .. . . .. .. .. . 1

Display ButtonIdentification . . .. . . .. . . . . . .. . . .. .. . . . .. .. . . .. .. .. . . . .. .. . . . . .. . . . .. .. . . .. .. . . 1

Calibration And Programming Procedures . . . .. .. . . .. .. .. . . .. .. . . . . . .. . . .. .. . . .. . .. . . .. .. .. . . 2

Boom Length Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Zero Telescope Cylinder Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Calibrate Boom Length –PAT Reel Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Calibrate Boom Length

-

Pin And Latching Booms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Calibrate Boom Length –Full Power Booms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Boom Angle Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Swing Angle Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pressure Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Program Pressure Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Reset Pressure Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Outrigger Programming And Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hydraulic Fly Angle Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Main Winch Friction Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Auxiliary Winch Friction Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Bias And Slope Sliders Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fly Weight Calibration (Fly Erected) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Fly Weight Calibration (Fly Stowed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Diagnostics . .. .. .. . . .. .. .. . . . .. .. . . .. .. .. . . . .. .. . . . . .. . . .. .. . . .. . .. . . .. .. .. . . .. . .. . . . . .. . . . 29

CAN Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Active System Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

System Fault Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Boom Telescope Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Outrigger Position Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Sensor Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Setup . . .. . . . .. . . . . .. . . .. . .. . . .. .. . . .. .. .. . . . .. .. . . . . . .. . . .. .. . . . .. .. . . .. .. .. . . . .. .. . . . . .. . 34

Enable Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Counterweight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Auxiliary Lifting Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Winch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Misc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Front Winch Rope Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Rear Winch Rope Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

About . . . .. . . .. . . . . . .. . . .. .. . . . .. .. . . .. .. .. . . .. .. . . . . . .. . . .. .. . . . .. .. . . .. .. .. . . . .. .. . . . . .. . 39

Appendix A ................................................................................ 40

Friction And Dynamic Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Appendix B ................................................................................ 45

HED Programming Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Appendix C .. . . .. . .. . . .. .. .. . . .. .. . . . .. .. .. . . .. .. . .. . . .. .. . . .. .. . .. . . .. .. . . . . .. . . . .. .. . . .. . 54

ECM Programming Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

General Information

1.

Required Tools

a.

Testweights

-

[1approximately2,000lb

(907kg)

and 1 approximately 10,000 lb

(4 536kg)

]

b.

Measuring Tape

-

200 –300 ft graduated in

tenth’s of a foot

c.

Digital level

2.

For calibration purposes, boom mode must be se-

lected to allow full extension of all boom sections.

REFERTOTHECRANERATINGMANUALFOR

SAFE OPERATION.

3.

If software is to be updated, record

ALL

Friction

Slider Bar Values

BEFORE

programming any of

the Electronic Control Modules (ECM's).

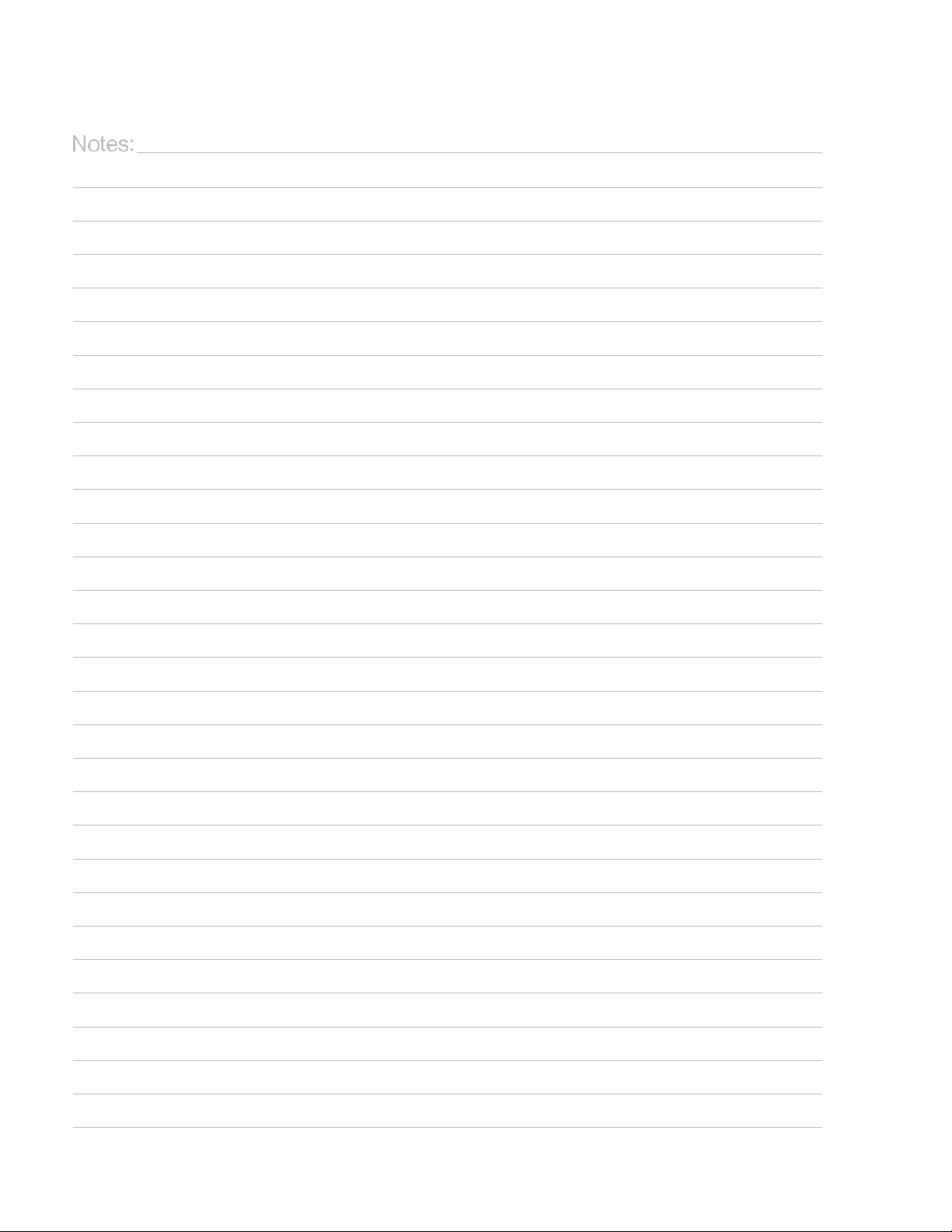

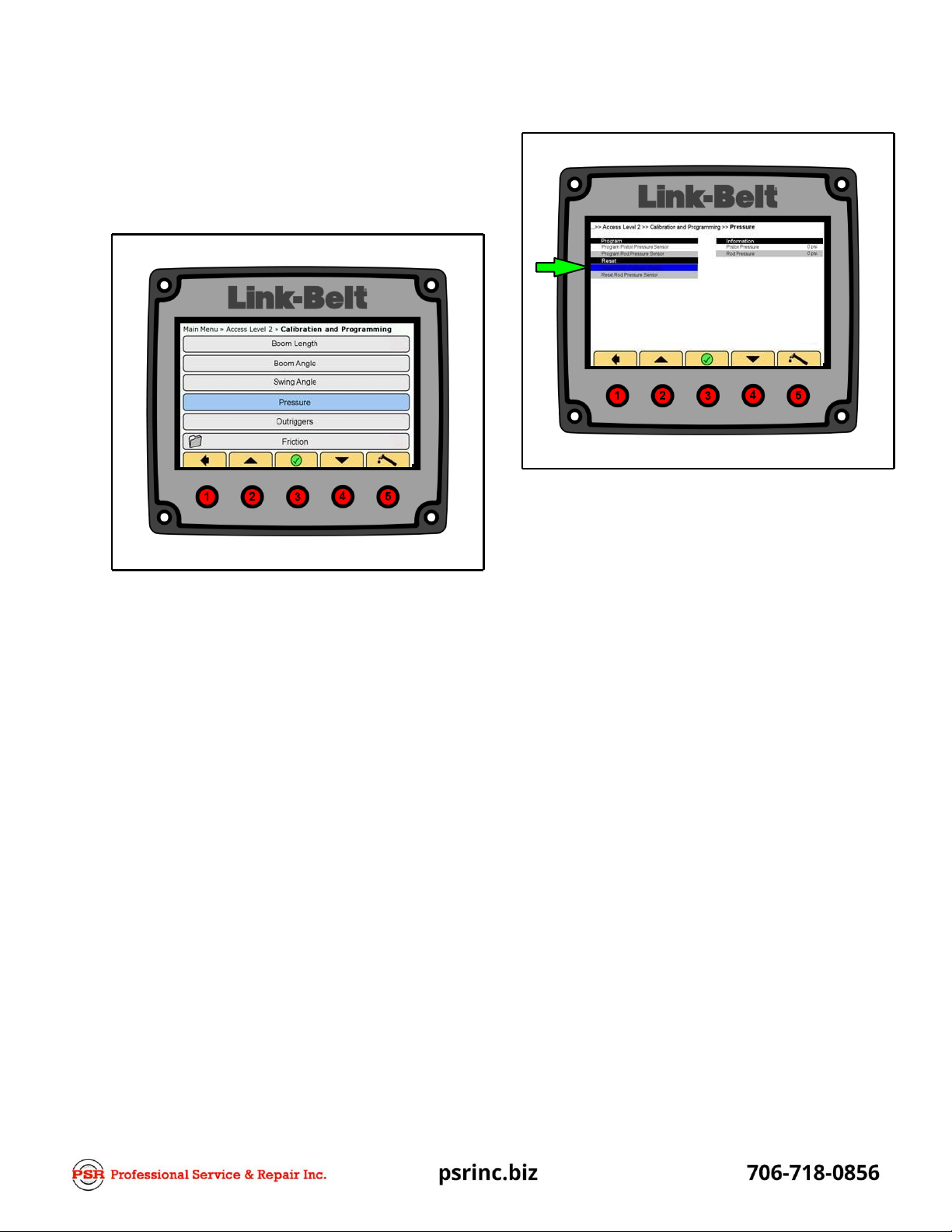

Display Button Identification

1. The Buttons on the actual Pulse Display are not

numbered, but for the purpose of this document,

Buttons 1 through 5,starting on the left,will beref-

erenced as Button numbers as shown below.

1

2

3

4

5

Calibration And Programming

Procedures

1.

Calibration Mode Entry

a.

Press Button 1 to enter the Main Menu.

c.

Use Buttons 2 and/or 4 to navigate to the first

number of the Password and press Button 3 to

enter the number. Follow this procedure for

each number of the Password. Press Button 3

one more time when checkmark is highlighted.

1.

Level 2 Password is 22222.

2.

When Password is entered correctly,Main

Menu, Access Level 2 screen should ap-

pear.

b.

Press Buttons 1, 3, and 5 simultaneously, then

release, to enter Access Level 2.

Boom Length Calibration

Zero Telescope Cylinder Calibration

1.

Fully retract the boom.

2.

In Access Level 2, use Buttons 2 and/or 4 tonavig-

ate to Calibration and Programming.

3.

Press Button 3 to enter Calibration and Program-

ming.

4.

Use Buttons 2 and/or 4 to navigate to Boom

Length.

5.

Press Button 3 to enter Boom Length.

6.

Use Buttons 2 and/or 4 to navigate to Calibrate

Telescope Cylinder.

7.

Connect the Manual Control Box to the Manual

Mode Plug on the crane. Refer to the Crane Oper-

ator's Manual for the location of the connection.

8.

Push the Activate Switch up and hold. Push the

Pin/Unpin Switch up to PIN and the Latch/Unlatch

Switch down to UNLATCH.

9.

Confirm that the PINNED and NOT LATCHED lights

are illuminated. The telescope cylinder may have

to be extended or retracted slightly to obtain NOT

LATCHED.

10.

Fully retract the telescope cylinder until it bottoms

out.

11.

Press Button 3 to set the telescope cylinder zero

point.

12.

The Display should show question, “Are you sure?”

13.

Press Button 3 to confirm “Yes” or press Button 4 to

confirm “No”.

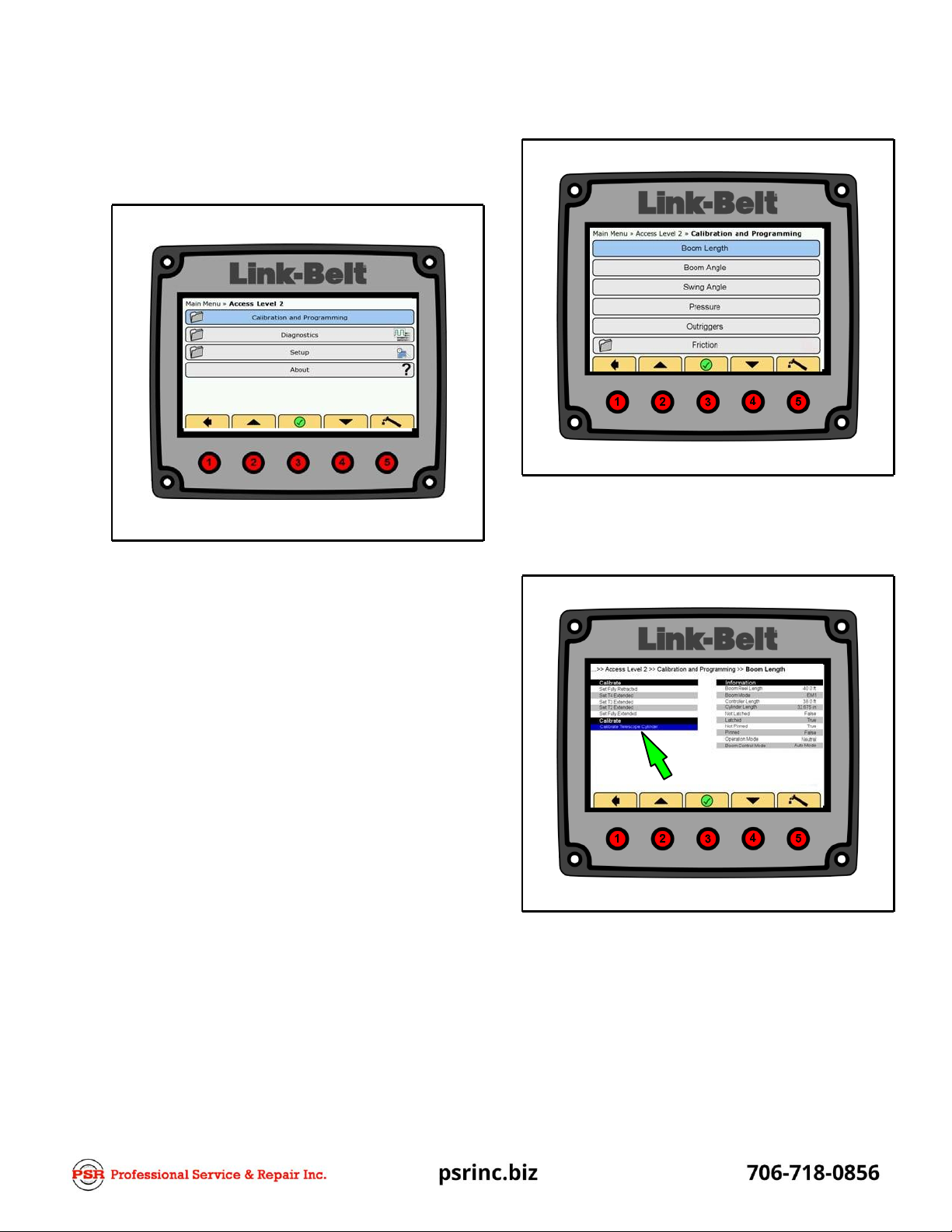

CAUTION

Manual mode is intended

only for emergency

operation.

Improper operation of the

boomin manual mode can

cause major damage tothe

boom.

7

8

9

10

1

2

6

5

4

3

1.

2.

3.

4.

Extend/Retract Switch

Pin/Unpin Switch

Latch/Unlatch Switch

Not Latched IndicatorLight

5.

6.

7.

Not Pinned Indicator Light

Latch Forward Indicator Light

Latch Rearward IndicatorLight

8.

Pinned IndicatorLight

9.

Latched Indicator Light

10. Activate Switch

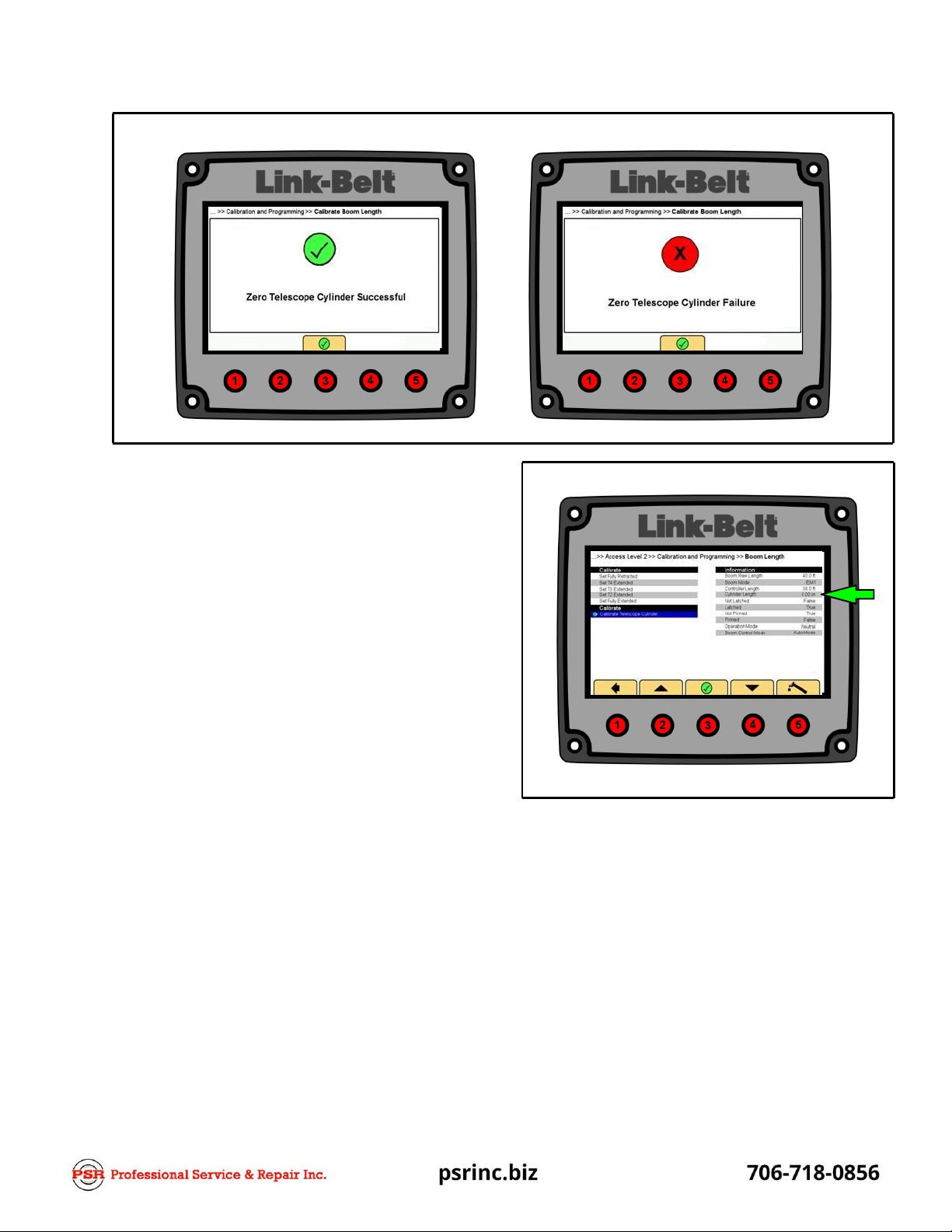

14.

Depending on the previous inputs, “Zero Tele-

scope Cylinder Successful” or “Zero Telescope

Cylinder Failure” should be shown.

Note: If a “Zero Telescope Cylinder Failure” is

shown when trying to zero the telescope cylin-

der, confirm that the Manual Control Box is

plugged in and the “PINNED and NOT

LATCHED” sensors are active.

15.

Extend the telescope cylinder slightly and retract it

again to verify the telescope cylinder returns to

0.00” ±.009”

(0.00cm

±

.023cm)

.

16.

With “Zero Telescope Cylinder Successful” discon‐

nect and properly store the Manual Control Box.

17.

Press and hold the telescope pedal to return the

telescope cylinder to its starting point and let the

system Latch and Unpin the section.

18.

Zero Telescope Cylinder is complete.

2-Gear Reeling Drum

3-Gear Reeling Drum

Calibrate Boom Length –PAT Reel Initial Setup

1.

Remove cover from PAT reel.

2.

Adjust soft stop on length potentiometer.

a.

Soft stop adjustment for 2-gear reel, use small

screwdriver and rotate potentiometer counter-

clockwise until potentiometer stops.

b.

Soft stop adjustment for 3-gear reel, use small

screwdriver and rotate potentiometer clock-

wise until potentiometer stops.

3.

Replace cover on PAT reel.

4.

Setup complete.

Calibrate Boom Length

-

Pin And Latching Booms

Note: Adjustsoft stop on PATreel first. Refer to

“

Ca

li

bra

t

e

Boom

Length

-

P

A

T

Ree

l

Ini

ti

a

l

Se

tu

p

”

.

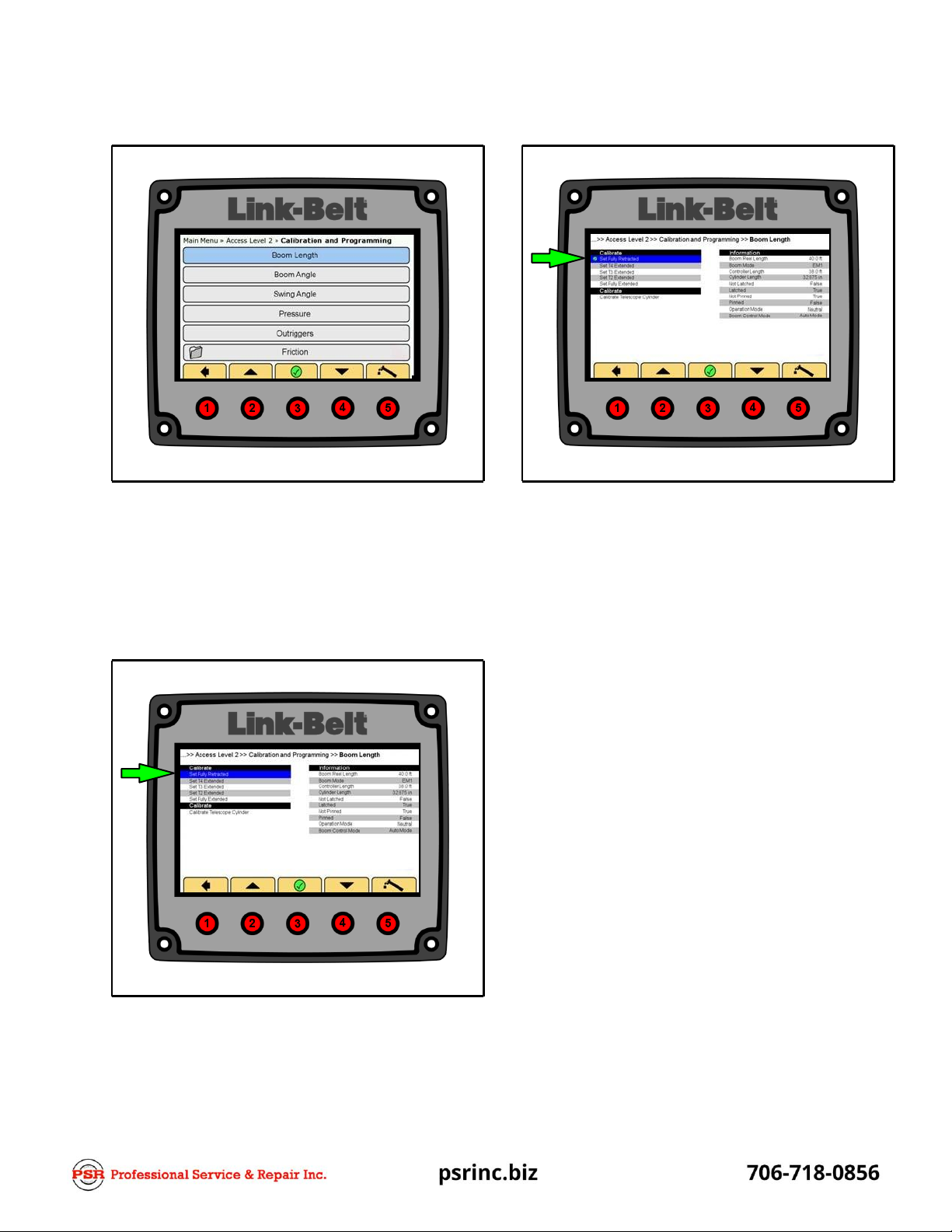

1.

In Access Level 2, Calibration and Programming,

use Buttons 2 and/or 4 to navigate to Boom

Length.

2.

Press Button 3 to enter Boom Length.

4.

Fully retract the boom for the first calibration point.

With the boom fully retracted and in the “PINNED

and LATCHED” condition, press Button 3 which

will place a green checkmark by the

Set Fully Re-

tracted

position as in the example above.

Note: Pressing Button 2 and/or 4 will navigate

through the extended sections to be calibrated

highlighting them in BOLD type.

5.

Extend the boom until the next section is extended

and is PINNED and NOT LATCHED and the tele-

scope cylinder is returning to the home position.

Note: Section must be PINNED and NOT

LATCHED before calibration will be accepted.

6.

Press Button 3 to set the next extended section

boom length and a green checkmark will appear

indicating the calibration point. Repeat this pro-

cedure until all sections have been extended.

Note: The last section will not PIN and UNLATCH.

7.

When completed all sections will have green

checkmarks indicating all sections have been cal-

ibrated.

8.

Boom Length Calibration is now complete.

3. Use Buttons 2 and/or 4 to navigate to Set Fully Re-

tracted.

Calibrate Boom Length –Full Power Booms

Note: Adjustsoft stop on PATreel first. Refer to

“

Ca

li

bra

t

e

Boom

Length

-

P

A

T

Ree

l

Ini

ti

a

l

Se

tu

p

”

.

1.

In Access Level 2, Calibration and Programming,

Use Buttons 2 and/or 4 to highlight BoomLength.

2.

Press Button 3 to enter Boom Length.

4.

Fully retract the boom for the first calibration point -

with the boom fully retracted, press Button 3 which

will place a green checkmark at the

Set Fully Re-

tracted

position as in the example above.

Note: Pressing Button 2 and/or 4 will scroll

through the extended sections to be calibrated

highlighting them in BOLD type.

5.

Using the Boom Telescope Override Switches ex-

tend the Tip and Outer boom sections.

6.

Press Button 3 to set the extended section boom

length and a green checkmark will appear indicat-

ing the calibration point. Do not retract Tip and

Outer boom sections, proceed to Step 7.

7.

Using the Boom Telescope Override Switches ex-

tend the Center boom section (if equipped, if not

equipped proceed to Step 9).

8.

Press Button 3 to set the extended section boom

length and a green checkmark will appear indicat-

ing the calibration point.

9.

Fully extend the boom.

10.

When completed all sections will have green

checkmarks indicating all sections have been cal-

ibrated.

11.

Boom Length Calibration is now complete.

3.

Use Buttons 2 and/or 4 to highlight Set Fully Re-

tracted.

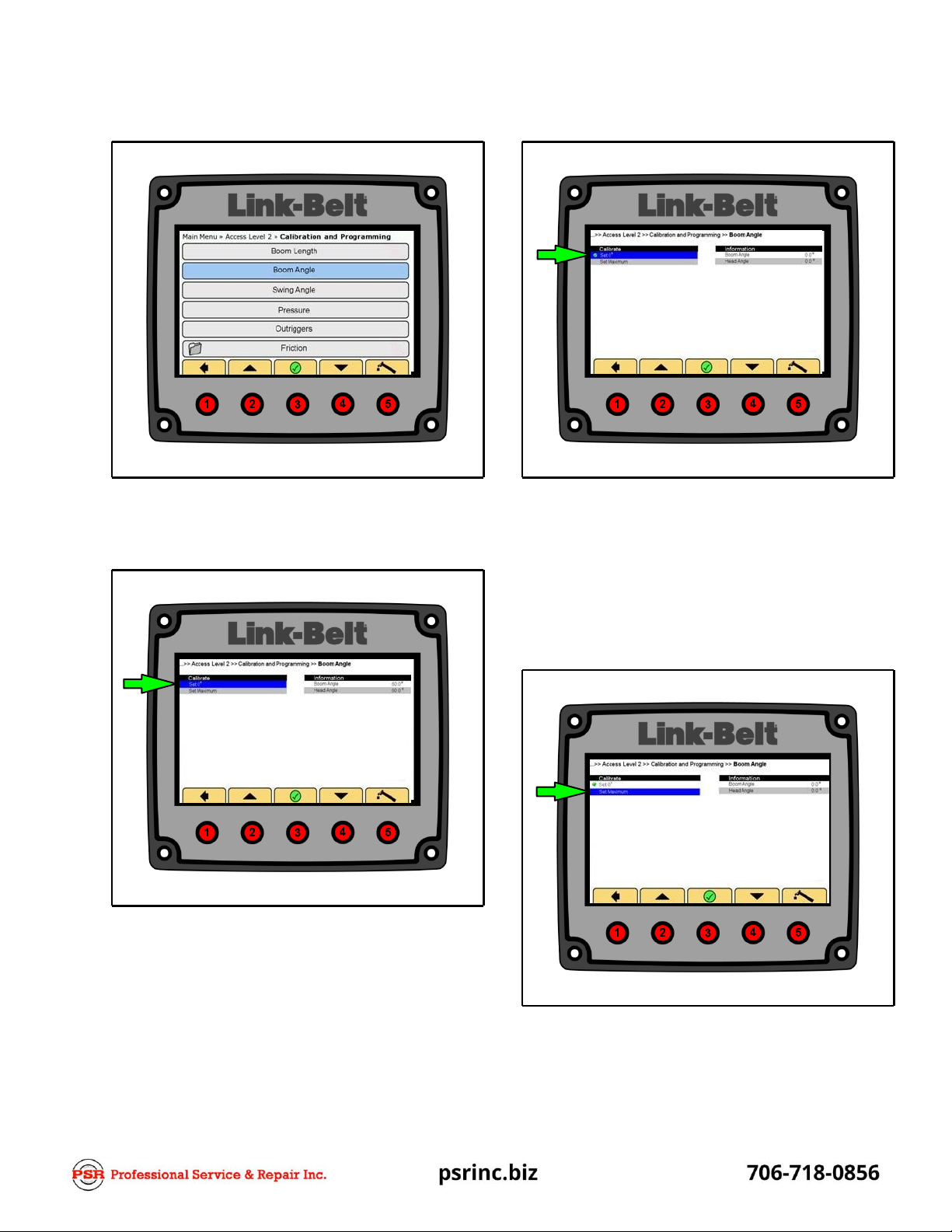

Boom Angle Calibration

1.

In Access Level 2, Calibration and Programming,

use Buttons 2 and/or 4 to navigate to Boom Angle.

2.

Press Button 3 to enter Boom Angle.

6.

A green checkmark will appear indicating position

has been calibrated.

7.

Raise the boom to 80 degrees, verifying with a di-

gital level. (If 80 degrees cannot be obtained use

the next lower whole reading. I.E.

=

79 degrees.)

Note: The Software does not contain a decimal

point so a whole number must be used.

3.

Use Buttons 2 and/or 4 to navigate to Set 0°.

4.

Ensure the boom is at zero degrees, verifying with

a digital level.

5.

Press Button 3 to enter Set 0°.

8.

Use Buttons 2 and/or 4 to navigate to Set Maxim-

um.

9.

Press Button 3 to enter Set Maximum.

10.

Enter actual angle value. I.E. 80 degrees. Use But-

tons 2 and/or 4 to navigate to the first number and

press Button 3 to enter the number. Repeat for the

second number.

11.

Use Buttons 2 and/or 4 to navigate to the green

checkmark.

12.

Press Button 3 to enter the span value.

13.

A green checkmark will appear indicating the posi-

tion has been calibrated.

14.

Boom Angle Calibration is now complete.

Swing Angle Calibration

1.

In Access Level 2, Calibration and Programming,

use Buttons 2 and/or 4 to navigate to Swing Angle.

2.

Press Button 3 to enter Swing Angle.

6.

A green checkmark will appear indicating the 0°

position has been calibrated.

7.

Release the travel swing lock.

8.

Swing to the right.

9.

Ensure degree reading is increasing.

Note: If swing angle decreases, the signal wires

on the swing potentiometer will need to be re-

versed.

10.

Swing the upper directly over the rear of the carrier

and set the travel swing lock.

11.

Use Buttons 2 and/or 4 to navigate to Set 180°.

12.

Press Button 3 to set the 180° position.

13.

A green checkmark will appear indicating the 180°

position has been calibrated.

14.

Swing Angle Calibration is now complete.

3.

Swing the upper directly over the front of the carrier

and set the travel swing lock.

4.

Use Buttons 2 and/or 4 to navigate to Set 0°.

5.

Press Button 3 to set the 0° position.

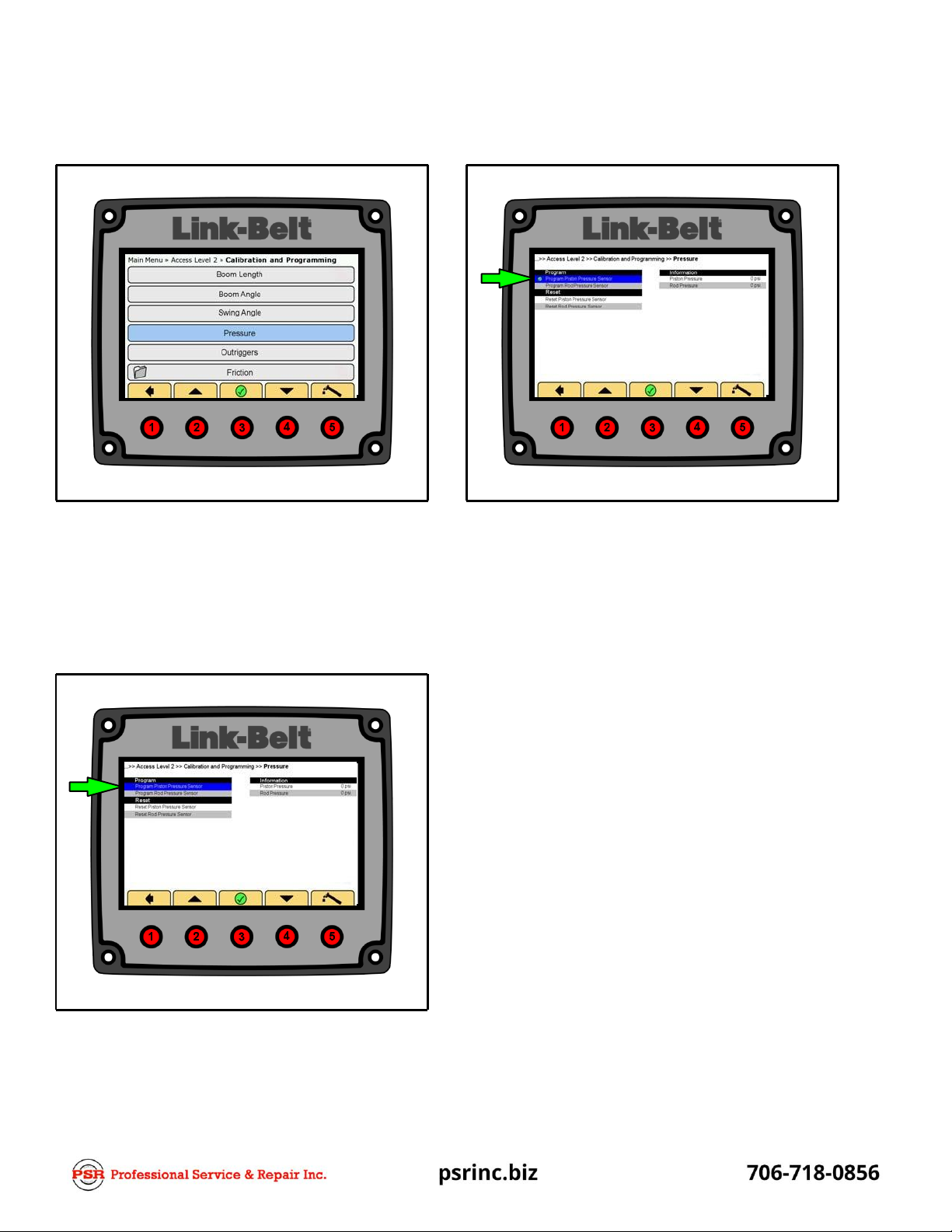

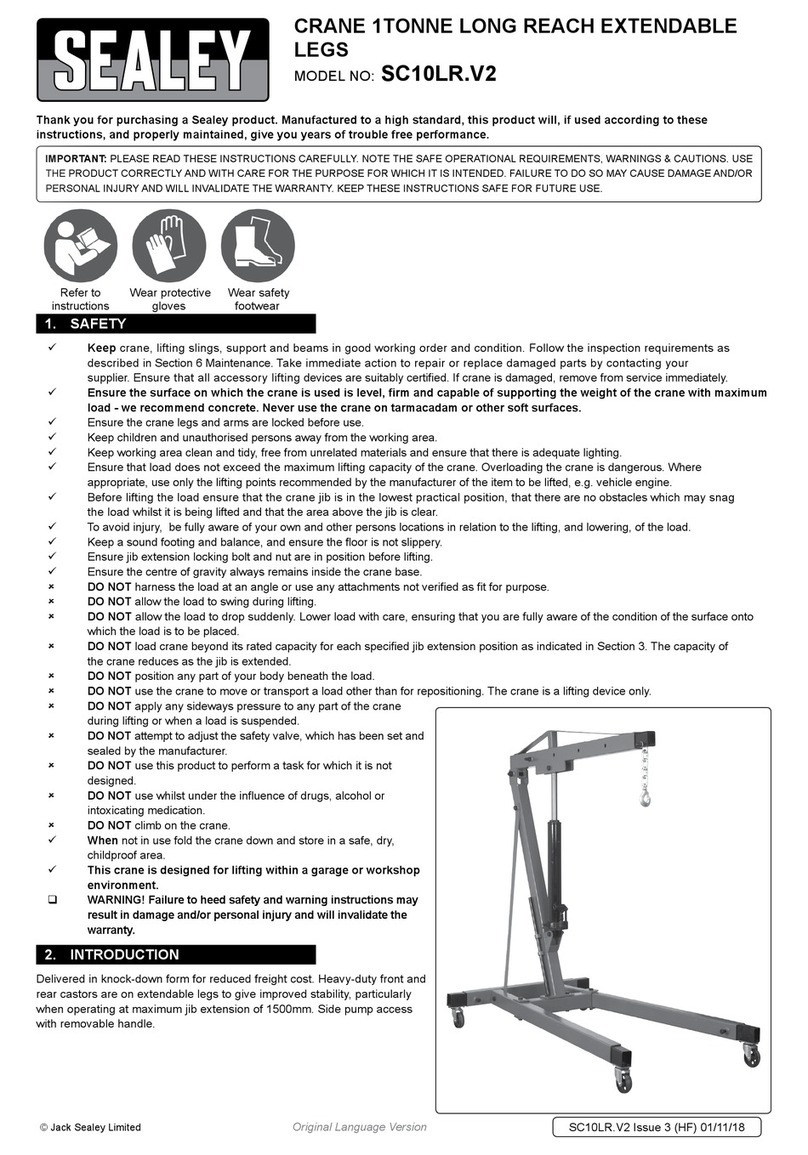

Pressure Programming

Program Pressure Transducers

1.

In Access Level 2, Calibration and Programming,

use Buttons 2 and/or 4 to navigate to Pressure.

2.

Electrically disconnect both pressure transducers

from the system.

3.

Press Button 3 to enter Pressure.

4.

Electrically connect the Piston pressure trans-

ducer.

7.

A green checkmark will appear indicating piston

pressure transducer has been programmed. The

piston pressure transducer readout should now re-

flect hydraulic pressure.

Note: The piston pressure transducer can re-

main connected after it has been programmed.

8.

Electrically connect the Rod pressure transducer.

9.

Use Buttons 2 and/or 4 to navigate to ProgramRod

Pressure Sensor.

10.

Press Button 3 to program the rod pressure trans-

ducer.

11.

A green checkmark will appear indicating the rod

pressure transducer has been programmed. The

rod pressure transducer readout should now re-

flect hydraulic pressure.

12.

Pressure Transducers Programming is now com-

plete.

5.

Use Buttons 2 and/or 4 to navigate to ProgramPis-

ton Pressure Sensor.

6.

Press Button 3 to program the piston pressure

transducer.

Reset Pressure Transducers

This is used to reset the CAN ID to factory default. If

this procedure is used, the CAN ID’s must be repro‐

grammed by repeating the previous procedures,

“Program Pressure Transducers”.

1.

In Access Level 2, Calibration and Programming,

use Buttons 2 and/or 4 to navigate to Pressure.

2.

Press Button 3 to enter Pressure.

3.

Use Buttons 2 and/or 4 to navigate to Reset Piston

Pressure Sensor.

4.

Press Button 3 to reset the piston pressure trans-

ducer to factory default.

5.

A green checkmark will appear indicating the pis-

ton pressure transducer has been reset.

6.

Use Buttons 2 and/or 4 to navigate to Reset Rod

Pressure Sensor.

7.

Press Button 3 to reset the rod pressure transducer

to factory default.

8.

A green checkmark will appear indicating the rod

pressure transducer has been reset.

9.

Pressure Transducers are now reset to factory

default.

Outrigger ProgrammingAnd

Calibration

This is used to program and calibrate the outrigger

sensors.

1.

In Access Level 2, Calibration and Programming,

use Buttons 2 and/or 4 to navigate to Outriggers.

2.

Press Button 3 to enter Outriggers.

3.

Use the following procedures to Program the out-

rigger sensors.

a.

Disconnect CAN Bus cables from all four out-

rigger beams.

b.

Connect CAN Bus cable to front left outrigger

beam.

Note: This is the sensor connection on the

outrigger cylinder that functions the left out-

rigger beam on the right side of the crane.

c.

Use Buttons 2 and/or 4 to navigate to “Pro‐

gram Front Left”.

d.

Press Button 3 to enter Program Front Left.

Verify the green checkmark appears.

e.

Disconnect CAN Bus cable from front left out-

rigger beam. Connect CAN Bus cable to front

right outrigger beam.

Note: This is the sensor connection on the

outrigger cylinder that functions the right

outrigger beam on the left side of thecrane.

f.

Use Buttons 2 and/or 4 to navigate to “Pro‐

gram Front Right”.

g.

Press Button 3 to enter Program Front Right.

Verify the green checkmark appears.

h.

Disconnect CAN Bus cable from front right

beam. Connect CAN Bus cable to rear left out-

rigger beam.

Note: This is the sensor connection on the

outrigger cylinder that functions the left out-

rigger beam on the right side of the crane.

i.

Use Buttons 2 and/or 4 to navigate to “Pro‐

gram Rear Left“.

j.

Press Button 3 to enter Program Rear Left.

Verify the green checkmark appears.

k.

Disconnect CAN Bus cable from rear left

beam. Connect CAN Bus cable to rear right

outrigger beam.

Note: This is the sensor connection on the

outrigger cylinder that functions the right

outrigger beam on the left side of thecrane.

l.

Use Buttons 2 and/or 4 to navigate to “Pro‐

gram Rear Right”.

m.

Press Button 3 to enter Program Rear Right.

Verify the green checkmark appears.

n.

Connect CAN Bus cables to all outrigger

Table of contents

Other Link-Belt Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Sealey

Sealey SC10LR Quick start gudie

Fassi

Fassi F 240.24 Use and maintenance

Hercules

Hercules FMR 800 operating instructions

Manitowoc

Manitowoc National Crane 800D Operator's and service manual

MULTIQUIP

MULTIQUIP EM120P series Operation and parts manual

Broderson

Broderson IC-200-2J Operation and maintenance manual