Link Controls CDO Series User manual

CDO

Door Operator / CDO/ LC-3158 Rev.B

Stuart Road, Manor Park, Runcorn, Cheshire, WA7 1TS

Warning : Please read these instructions fully before installation

Link Controls

Instructions for Rolling Door Operator type :

2 – Door Operator / CDO / LC- 3158 Rev.B

1. Contents 3. General safety instructions

2. Key to symbols

Guarantee

The function and safety of the equipment is only guaranteed

if the warning and safety instructions included in these

operating instructions are adhered to.

Link Controls is not liable for any personal injury or damage

to property that occurs as a result of the warning and safety

instructions being disregarded.

Link Controls does not accept any liability or warranty for

damage due to the use of non-approved spare parts and

accessories.

Using the equipment for its intended purpose

Operators of the CDO range are designed exclusively for

opening and closing roller shutter doors (complete with

installation of a safety brake as required)

Target group

Only qualied and trained specialists are permitted to install

and service the operator. Qualied and trained professionals

full the following requirements:

- knowledge of the general and specic safety and accident

prevention regulations,

- Knowledge of the relevant regulations,

- trained in the use and care of appropriate safety equipment,

- Capable of recognising the dangers associated with

installation.

Only qualied and trained electricians may connect the

operator and carry out electrical maintenance.

Qualied and trained electricians full the following

requirements:

- knowledge of the general and specic safety and accident

prevention regulations,

- knowledge of the relevant electrical regulations,

- trained in the use and care of appropriate safety

equipment,

- capable of recognising the dangers associated with

electricity.

Instructions for installation and connection

- The controls must be disconnected from the electricity

supply before carrying out electrical works. It must be

ensured that the electricity supply remains disconnected

during the works.

- Local protective regulations must be complied with.

- Mains cables and control cables must be laid separately.

1. Contents 2

2. Key to symbols 2

3. General safety instructions 2

4. Overview of products 3

5. Installation 4

6. Initial Operation 6

7. Emergency operation 10

8. Maintenance 11

9. EU Declaration of Conformity 12

Danger of personal injury!

The safety instructions must be

observed!

Warning! Danger to property!

The safety instructions must be

observed!

Information

Special information

OR

Reference to other sources of

information

Door Operator / CDO / LC- 3158 Rev.B – 3

Regulations and bases for testing

For connecting, programming and servicing, the following

regulations must be observed (the list is not exhaustive).

Construction product standards

- EN 13241-1 (Products without re resistance or smoke

control characteristics)

- EN 12445 (Safety in use of power operated doors -

Test methods)

- EN 12453 (Safety in use of power operated doors -

Requirements)

- EN 12635 (Industrial, commercial and garage doors and

gates - Installation and use.)

- EN 12978 (Safety devices for power operated doors and

gates - Requirements and test methods)

Electromagnetic compatibility

- EN 55014-1 (Radio disturbance, household appliances)

- EN 61000-3-2 (Disturbances in supply systems -

harmonic currents)

- EN 61000-3-3 (Disturbances in supply systems -

voltage uctuations)

- EN 61000-6-2 (Electromagnetic compatibility (EMC) -

Part 6-2: Generic standards - Immunity for industrial

environments)

- EN 61000-6-3 (Electromagnetic compatibility (EMC) -

Part 6-3: Generic standards - Emission standard for

residential, commercial and light-industrial environments)

Machinery guidelines

- EN 60204-1 (Safety of machinery, electrical equipment of

machines, part 1: general requirements)

- EN 12100-1 (Safety of machinery. Basic concepts,

general principles for design. Basic terminology,

methodology)

Low voltage

- EN 60335-1 (Household and similar electrical

appliances - Safety)

- EN 60335-2-103 (Particular requirements for drives for

gates, doors and windows)

Various options

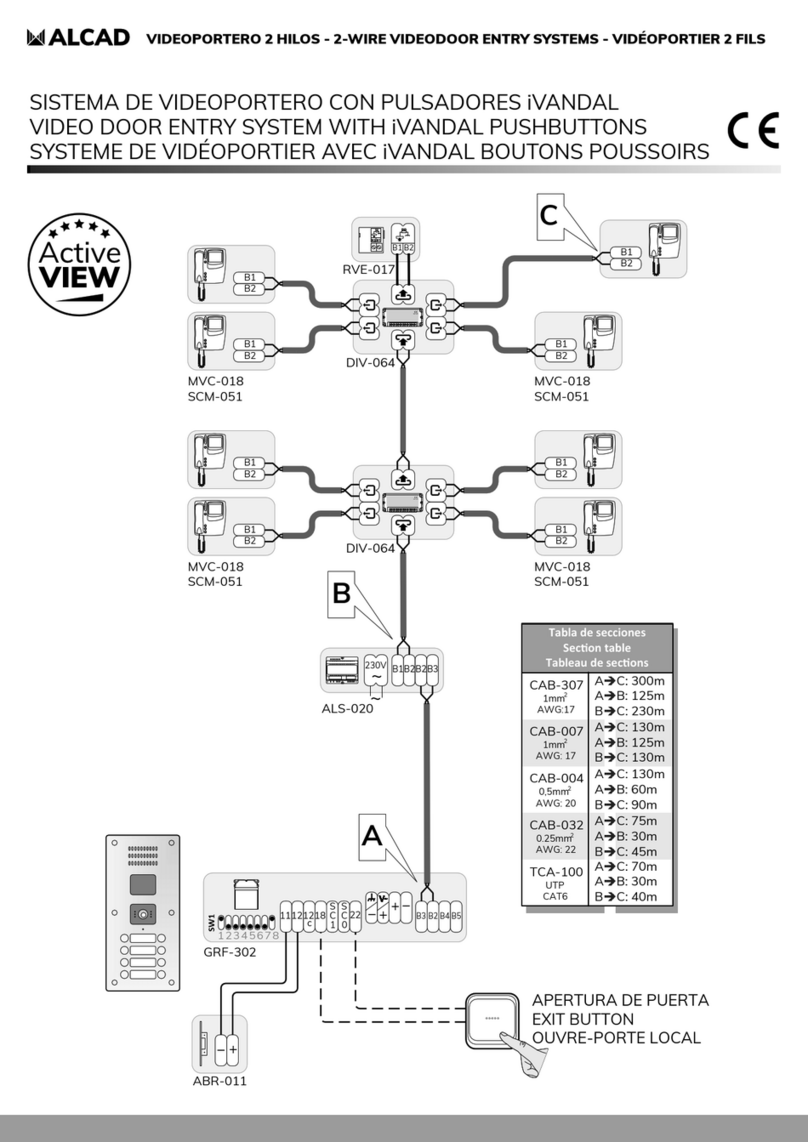

The following package options are available for the

ange mounted CDO Rolling Door operator:

The operators listed below can be supplied with

various manual overrides.

CDO-50 1ph

CDO-100 3ph / 1ph

CDO-150 3ph

CDO-175 3ph

CDO-200 3ph / 1ph

CDO-275 3ph

CDO-300 3ph

CDO-375 3ph

CDO-400 3ph

4. Overview of products

4 – Door Operator / CDO / LC- 3158 Rev.B

5.1 Preparation

Danger!

To avoid injury, the following points must

be observed:

- The operator must be installed free of

any tension.

- The operator must not move on the

mounting bracket.

- The design and subsurface of all

components must be suitable for the

forces encountered.

Warning!

To avoid damage to the operator and the

door, the operator must only be tted if:

- the operator is undamaged,

- the ambient temperature is -20 ºC to

+60 ºC,

- the altitude of the location does not

exceed 1,000 m,

- a suitably rated mains protection device

has been selected.

☞Before installation, ensure that:

- the operator is not blocked,

- the operator has been newly prepared after a lengthy

-storage period,

- all connections have been carried out correctly,

- the direction of rotation of the drive motor is correct,

- all motor protective devices are active,

- no other sources of danger exist,

- the installation site has been cordoned o over a

wide area.

Information

The relevant instruction for the door must

be observed when tting the drive to the

door.

- a suitably rated mains protection device

must be selected.

5.2 CDO Operator - Flange Mount Handing

Handing the operator

The CDO Range of operators can be supplied for

left or right hand installation. Please refer to the

diagram below when ordering.

Warning!

Damage due to improper installation the

drive! To avoid damage to the drive and to

the door, the drive must be mounted on a

torque support bracket that it is vibration

damped.

5. Installation

Handing ‘1A’

Handing ‘1B’

As viewed from above

As viewed from above

Door Operator / CDO / LC- 3158 Rev.B – 5

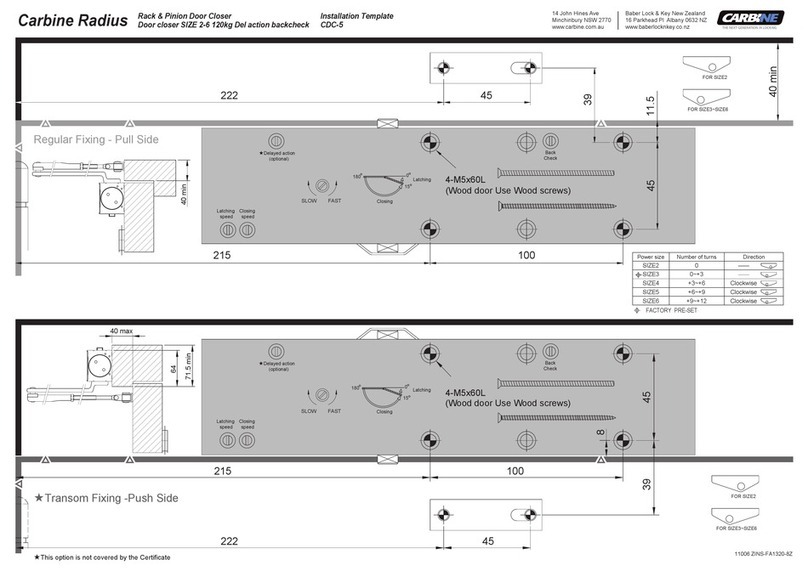

5.3 Mounting using sprocket

and chain - typical example

5.4 Dummy end / safety brake

- typical example

Danger!

A safety brake or equivalent device must

be tted to the dummy end of the shutter

barrel to protect the safety of the machine

against drive chain failure.

CDO Operator

Information:

Link Controls Ltd. constantly strives to

improve the quality of its goods and as

such reserves the right to replace/modify

products without prior notication. Any

examples given are intended for guidance

only.

Self-Aligning Flange Bearing

End Plate

Shutter Barrel

Drive End Shaft

Weld into Position

Plate Wheel

Drive Chain

Sprocket

End Plate

Self-Aligning Flange Bearing

Weld into Position

Dummy End Shaft

Shutter BarrelSafety Brake

Key

Brake Mounting

6 – Door Operator / CDO / LC- 3158 Rev.B

5.5 Installation of the emergency hand chain

(for operators with emergency hand chain)

Information:

To ensure that they work correctly, the

chain links must not be twisted.

☞Join the ends of the emergency hand chain together

with a chain connecting link.

Warning!

To avoid damage to the operator and

the door, the emergency hand chain

must be safely secured (for example in a

‘chain keep’ ) while the door is operated

electrically.

6.1 Preparation

Warning!

To avoid damage to the operator, the

following points must be observed:

- The types of cable and their diameters must be selected

according to current regulations.

- The nominal currents and the type of connection must

correspond to those on the motor type plate.

- The drive details must agree with the connected loads.

Information:

When operated with electronic control units,

the corresponding start-up instructions and

circuit diagrams must be complied with.

5. Installation 6. Initial Operation

6.2 Motor Connections

‘Standard’ 3ph Motor Connection

3 x 400V Star connection (standard)

The motor should be congured as shown above

for connection to a 3 x 400V control panel.

'400V / 690V' 3ph Motors Connection

3 x 400V Delta connection (CDO375 & CDO400)

The CDO375 & CDO400 should be congured as shown

above for connection to a 3 x 400V control panel.

Door Operator / CDO / LC- 3158 Rev.B – 7

‘Inverter Drive’ 3ph Motor Connection

3 x 230V Delta connection (inverter)

The motor should be congured as shown above

for connection to a 3 x 230V control panel.

Warning!

Ensure the correct motor connection

conguration is used to avoid damage

to the motor. Do not use ‘230 VAC Delta’

connection for 3ph/400VAC control panels.

Safety Circuit

The safety circuit combines the Thermal Trip and,

for operators with Manual Override, the Interlock

Switch.

The Thermal Trip is a heat sensitive switch

embedded in the motor windings that will operate

should the motor be overloaded.

The Hand Chain Interlock provides a means

of control circuit isolation to prevent electrical

operation whilst the door is being operated

manually.

Warning!

To ensure compliance with BS 7671 wiring

regulations (IET) the Thermal Trip must

be connected into the relevant controller

safety circuit (Stop circuit).

Note:- For operators with a disengage clutch, the

disengage switch output must be connected in

series with the motor safety circuit (N/C).

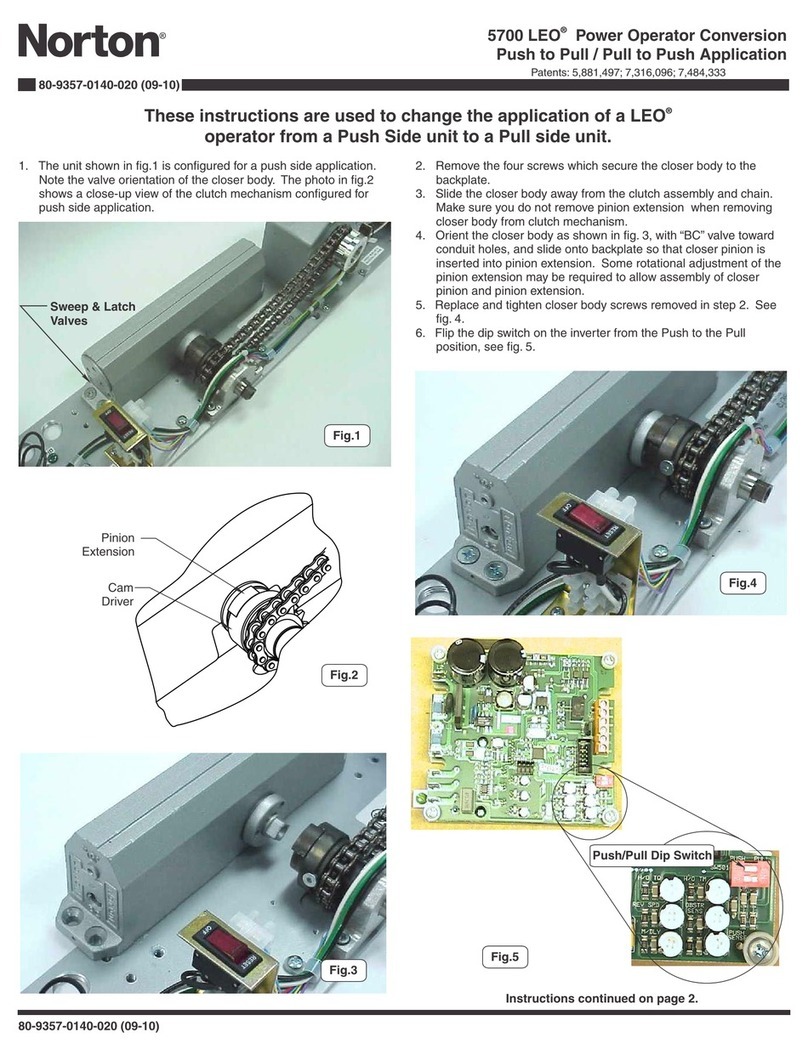

6.3 Mechanical Limit Switches

'O' Control cam for limit switch, CLOSED (green)

'K' Control cam for limit switch, OPEN (white)

'T' Control cam for limit switch, AUX (yellow)

'I' Control cam for limit switch, AUX (red)

Limit Switch Connections (microswitches)

'O'

'K'

'T'

'I'

Worm Gear

Control / Limit

Cams

Terminals

8 – Door Operator / CDO / LC- 3158 Rev.B

6.4 Setting Mechanical Limits

Control / Limit Cam Adjustment

Each control cam has a locking screw and a ne

adjustment screw.

The locking screw is used to lock the

corresponding control cam in the desired position.

Finer adjustment can be made with the ne

adjustment screw.

Set the CLOSED end position

☞Drive the door to the CLOSED end position.

☞Set the control cam ('O' - GREEN) so that the

CLOSED limit switch is actuated.

☞Tighten the locking screw.

Set the OPEN end position

☞Drive the door to the OPEN end position.

☞Set the control cam ('K' - WHITE) so that the

OPEN limit switch is actuated.

☞Tighten the locking screw.

Warning!

To avoid damage to the operator it is

important that all unused cams MUST be

locked in position

Fine Adjustment Screw

Locking Screw

6.5 Check the system

Check the direction of travel

☞Drive the door in the CLOSED direction.

The operator must close the door.

☞Drive the door in the OPEN direction.

The operator must open the door.

Information:

If the door’s direction of travel does not

correspond to the commands keyed

in, then the direction of rotation must

be changed. Instructions for changing

the direction of rotation are given in the

control unit operating manual.

After this the direction of travel must be

checked again.

Check the limit switch settings

☞Drive the door to the CLOSED end position.

The operator must stop in the desired position.

☞Drive the door to the OPEN end position.

The operator must stop in the desired position.

Check the mechanical functions

After assembling and installing all components the

functions of the system must be checked.

☞Check that all mountings have been securely

tightened.

☞Check all the functions of the system.

☞Check that the operator runs smoothly.

☞Check whether the operator is leaking oil.

If the operator makes unusual noises or leaks oil:

- The operator must be taken out of service immediately,

- Contact technical support.

Door Operator / CDO / LC- 3158 Rev.B – 9

6.6 Digital Limits

Electronic interface

A: AVE plug (absolute value encoder plug)

B: AVE plug terminal (absolute value encoder

plug terminals.

Information:

Please refer to the control unit operating

manual for instructions on setting the limit

end positions.

A

B

Wiring allocation,

AVE (absolute value encoder) plug

The numbers on the plug are also the wire

numbers.

4: Safety circuit input (N/C)

5: RS 485 B

6: GND

7: RS485 A

8: Safety circuit output (N/C)

9: 7...18V

DC

AVE (absolute value encoder) plug terminal (7-12)

C: Thermal element in the drive

D: Manual emergency control

(emergency crank or emergency chain)

10 – Door Operator / CDO / LC- 3158 Rev.B

7. Emergency Operation

Danger!

To avoid injury, the following points must

be observed:

- Emergency operation may only be

carried out from a safe standing position.

- Emergency operation may only be

carried out when the motor is stationary.

- The system must be disconnected from

the power supply during emergency

operation.

- Operators with a spring brake must be

actuated against the closed brake when

opening or closing the door.

- For safety reasons, brakes in doors

without a weight counterbalance must

only be released in the closed door

position for testing purposes.

- Accidental releasing of the brake must

be rendered impossible by preventive

measures at the installation site.

During maintenance works or in the case of an electrical

failure, the door can be moved towards the OPEN or

CLOSED positions with the help of the emergency

manual override equipment.

Information:

If the door is moved beyond the CLOSED

or OPEN end positions, the operator

may no longer be activated electrically

- place the door back into a normal

position before attempting powered

operation.

Operation with emergency wheel

guide & interlock

☞Lift the handchain o the safety switch and place

it on the chainwheel.

☞The Door can now be operated by hand chain.

Before power is restored, the above procedure

must be reversed

Operation with emergency hand crank

☞Push the emergency hand crank into the operator

as far as it will go.

☞Move the door in the OPEN or CLOSE direction

by turning the emergency hand crank.

☞Remove the emergency hand crank from the

operator after completing emergency manual

operation.

Door Operator / CDO / LC- 3158 Rev.B – 11

8. Maintenance

Warning!

To avoid damage to the operator and door,

the following points must be observed:

- Maintenance must only be carried out by

authorized persons.

- Directive BGR 232 must be complied with.

- Worn or faulty parts must be replaced.

- Only approved parts may be installed.

All maintenance work must be

documented.

Information:

The drive unit has lifetime lubrication and

is maintenance-free.

☞Check that all mountings have been securely

tightened.

☞Check the brake (if available).

☞Check the limit switches and safety switches.

☞Check for noises and oil leaks.

☞Check the mounting of the operator for corrosion.

☞Check the housing for damage.

Operation with emergency oor level

hand chain (KE)

Releasing

☞Gently pull the cable with the red handle downwards as

far as possible. The control voltage will be interrupted

and the door can no longer be operated electrically.

☞Release the emergency hand chain from its xing.

☞Move the door in the OPEN or CLOSE direction by

pulling on the emergency hand chain on the side

concerned.

Locking

☞Gently pull the cable with the green handle downwards

as far as possible. The control voltage will be switched

on again and the door can be operated electrically.

☞Attach the emergency hand chain to its xing.

The door can now be moved with the operator.

12 – Door Operator / CDO / LC- 3158 Rev.B

Link Controls Ltd. reserves the right to change / modify products without prior notication

02/01/2018

9. EU Declaration of Conformity

We hereby declare that the products described below:

CDO-50 / 100 / 150 / 175 / 200 / 275 / 300 / 375 / 400 Door Operator

are in conformity with the essential requirements of the Machinery Directive 2006/42/EC.

In addition, the partly completed machinery is in conformity with the Electromagnetic

Compatibility Directive 2014/30/EU and the Low Voltage Directive 2014/35/EU.

The following standards were applied:

EN 60204-1 Safety of machinery, electrical equipment of machines - Part 1:

General requirements

EN ISO 12100 Safety of machinery - Basic concepts, general principles for

design

EN 12453 Safety in use of power operated doors - Requirements

EN 12604 Industrial, commercial and garage doors and gates - Mechanical

aspects - Requirements

EN 61000-6-2 Electromagnetic compatibility (EMC) - Part 6-2: Generic

standards - Immunity standard for industrial environments

EN 61000-6-3 Electromagnetic compatibility (EMC) - Part 6-3: Generic

standards - Emission standard for residential, commercial and

light-industrial environments

EN 60335-2-103 Particular requirements for drives for gates, doors and windows

The relevant technical documentation is compiled in accordance with Annex VII(B) of

the Machinery Directive 2006/42/EC. We undertake to transmit, in response to a

reasoned request by the market surveillance authorities, this documentation in electronic

form within a reasonable period of time.

Person authorised to compile the relevant technical documentation:

Link Controls, Stuart Road, Manor Park, Runcorn, Cheshire, WA71TS

The machinery is incomplete and must not be put into service until the machinery into

which the partly completed machinery is to be incorporated has been declared in

conformity with the provisions of the Machinery Directive 2006/42/EC.

Place / Date:

Runcorn, 20/04/2016

Manufacturer’s signature:

Certicate Number 10668

ISO 9001

This manual suits for next models

9

Table of contents

Other Link Controls Door Opening System manuals

Popular Door Opening System manuals by other brands

Relcross Door Controls

Relcross Door Controls 9130 installation instructions

Dorma

Dorma 8916 PH manual

Design Hardware

Design Hardware F2000V Series installation instructions

Alcad

Alcad IVANDAL instruction manual

Simons Voss Technologies

Simons Voss Technologies SmartHandle Series manual

Assa Abloy

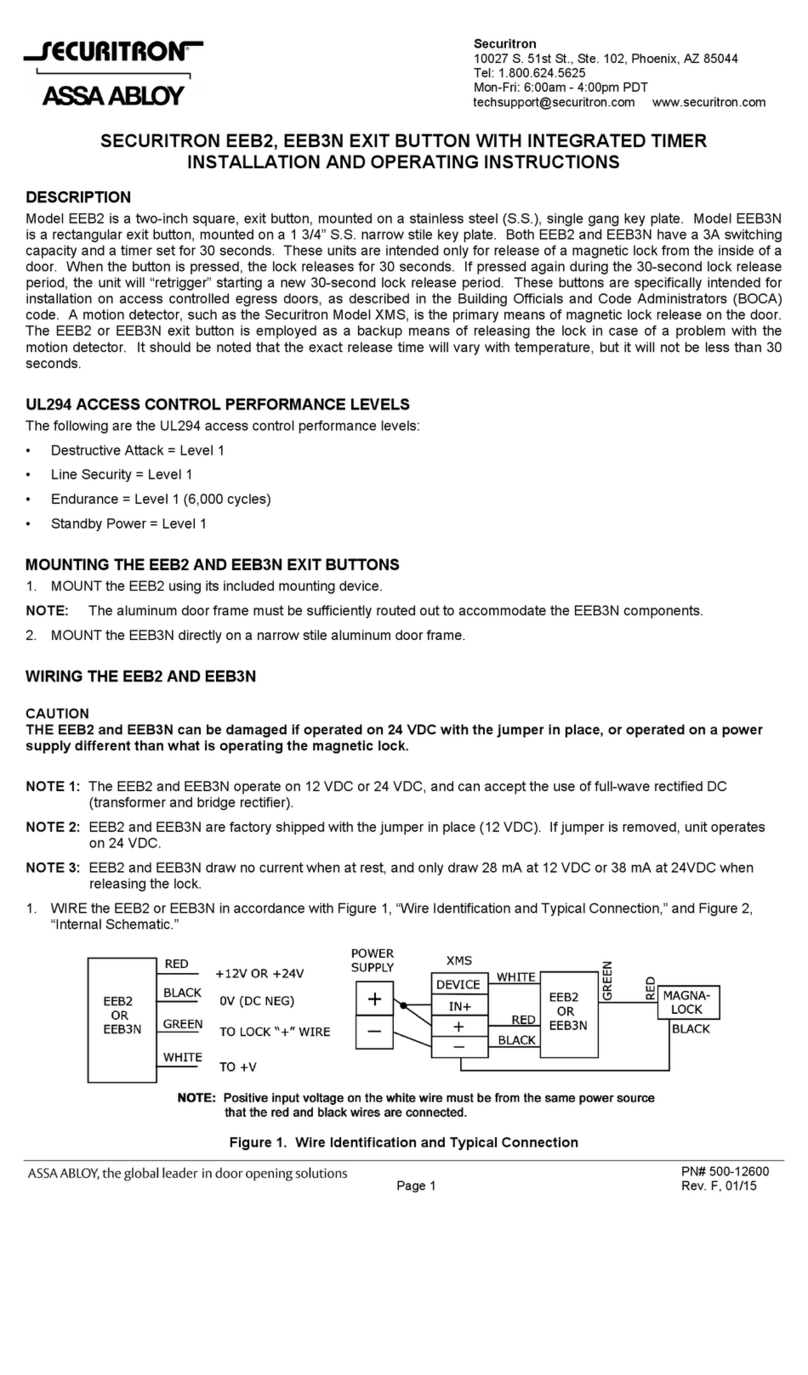

Assa Abloy Securitron EEB3N Installation and operating instructions