Lintec MC-700 Series User manual

LN0427E2103E0

Mass Flow Controller

Instruction Manual

MC-700 Series

Safety Precautions

Incorrect handling may cause death or injury

(1) Before connecting the fittings, check that no damage or defects are found on

the fittings. Make connections properly and make sure that a leak test is

conducted before actual operation to prevent fluid from leaking into the

atmosphere (Hereafter, the measured fluid is called “gas” or “fluid”).

(2) DO NOT apply any fluids corrosive to materials exposed to gas. Corrosion may

cause fluid to leak into the atmosphere. Check the gas type to be used in advance.

(3) This device is not designed as an explosion proof structure. DO NOT use this

device in a place where explosion-proof structures are required. Doing so may

cause fire or explosion.

Incorrecthandlingmayleadtomedium orslightinjuryor may

causedamage to,orlossof,facilitiesorequipment

(1) Observe the precautions listed in the WARNING (above)

(2) Strictly observe the electrical specifications. Not doing so may cause fire,

damage to sensors or malfunction.

(3) This device is not designed to be waterproof. DO NOT locate this device

outdoors orin a place where it may be splashedwith water. Doing so may cause

fire, trouble, or malfunction of the device.

(4) DO NOT modify this device. It may cause fire or other problems.

(5) This device is not designed to handle hot swap. Please avoid attaching and

removing the power supply connector and interface connector with the power

switched on. Attachment and/or removal with the power on may result in failure

of the device.

(6) While a power supply is applied to MFC, ±15VDC must be applied

simultaneously. If only +15VDC or -15VDC is applied, electronic circuits will

become unstable and it may cause a malfunction of MFC.

(7) This device is a precious device, please handle it carefully. Dropping down or

handling it carelessly will cause damage. Please use assist instrument while

moving or setting the device.

(8) Regular maintenance is recommended for steady use of this device

(Recommended proofreading frequency is once a year).

1. Introduction

This manual explains basic operation of the MC-700 series (Hereafter, it is called

"MFC"). Please read through this manual and other separate volumes (Digital

Interface Manual, Special Function Manual, Command Chart) carefully to

familiarize yourself with the features of this device.

2. Summary

This device is the mass flow controller with the function of switching different

kinds of gas and flow rate (Hereafter called "variable function" or "VR"). By using

the 3 rotary switches on the MFC, the gas type and flow rate can be changed. The

rotary switches are placed conveniently on top of the MFC unit so that

adjustments can be made accordingly even after the unit is set in position. For old

models, stocking MFC for each of gas and flowrate was necessary because only

one spec is available to one MFC, and MC-700 can reduce your stocking because

it can be used for more than one spec with one MFC.

3. Features

The MFC has the following features.

(1) LINTEC’s proprietary ambient temperature compensation type flow sensor.

·The influence of ambient temperature is small due to the sensor temperature

control following the ambient temperature.

·Since the temperature distribution of the sensor is constant, high-speed response

is possible.

(2) Gas type and flow rate setting can be changed by using the 3 switches on the

mass flow controller unit.

(3) Digital interface (RS-485) is standard equipment and the maximum of 32 MFCs

could be connected together with daisy chain.

(Option: Digital interface RS-232C is possible)

(4) Small structure of dead volume using diaphragm valve.

(5) Stainless steel 316L is used because of good corrosion resistance and seal ability.

(6) Particule-free structure

(7) RoHS compliant, CE conformity

4. Structure

The MFC consists of sensors, bypass, valves, and a microcomputer for signal

processing. A digital PID feedback control system controls the valve action so that

flow rate output from the sensor agrees with flow rate setting value.

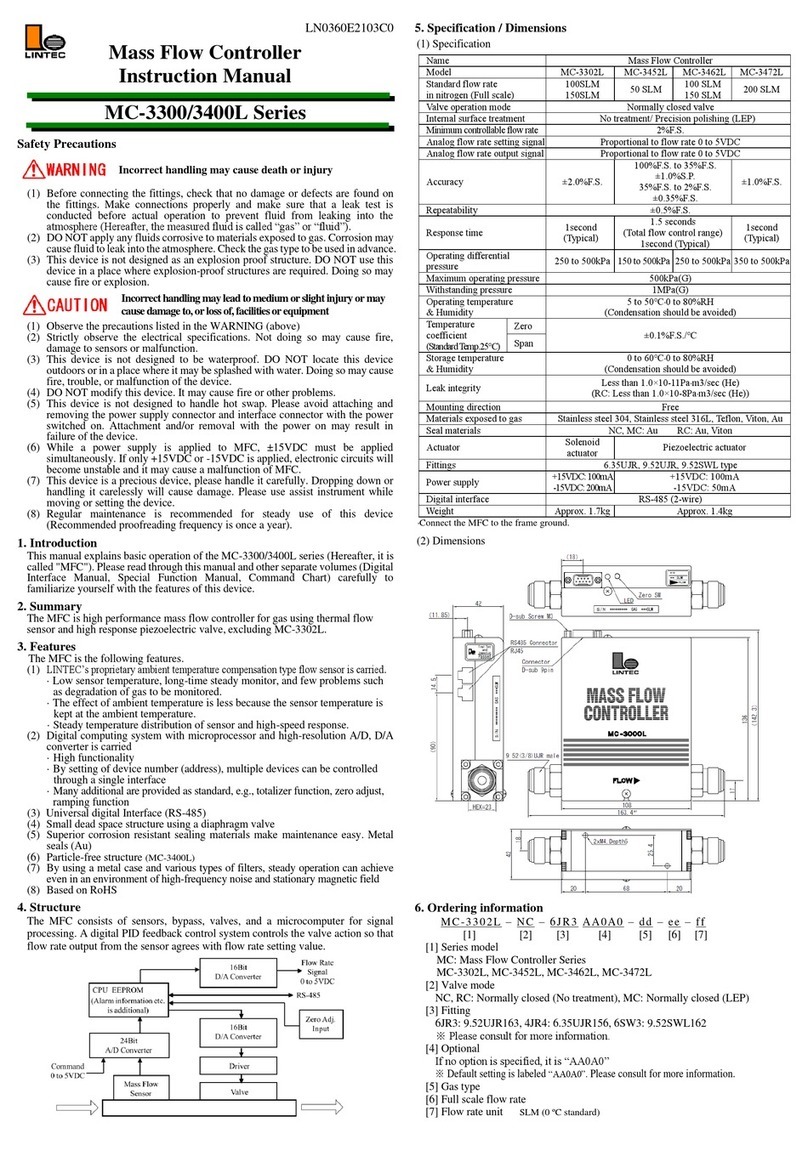

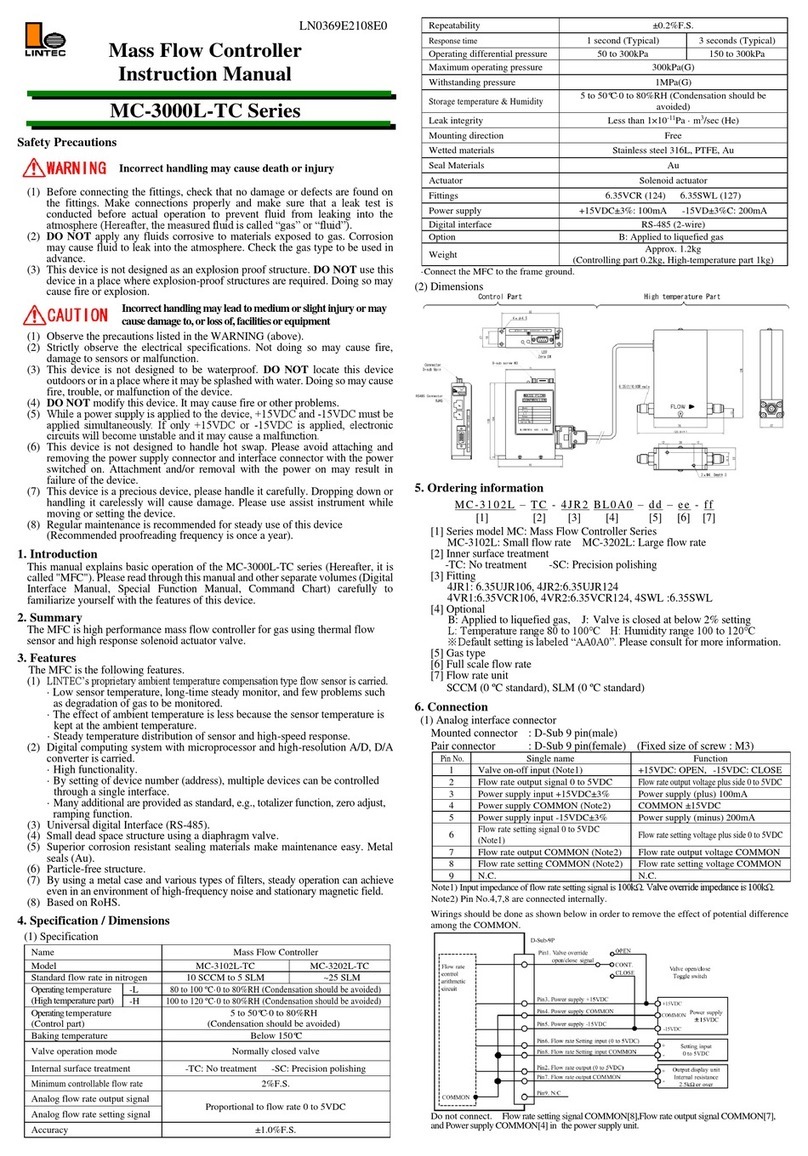

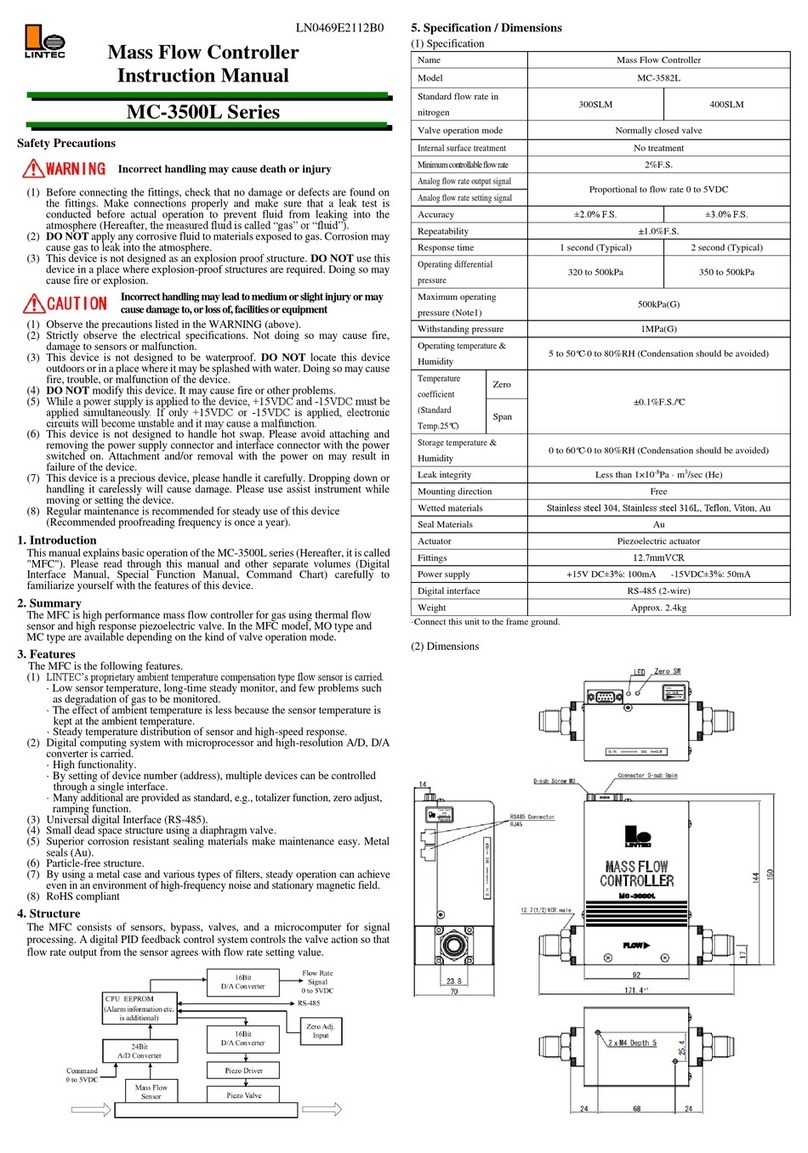

5. Specification / Dimensions

(1) Specification

Name

Mass Flow Controller

Model

MC-710

MC-720

MC-730

Standard flow rate in

nitrogen VR number

10SCCM to 3SLM

(VRnumber02to06)

3.1 to 10SLM

(VR number 07)

11 to 50SLM

(VRnumber08and09)

Valve operation mode

Normally closed / Normally open

Internal surface treatment

No treatment / Precision polishing

Flow rate control range

2% of full scale

Analog flow rate setting

signal

Proportional to flow rate: 0 to 5VDC

Analog flow rate output

signal

Proportional to flow rate: 0 to 5VDC

Variable function (VR)

Changeable by using rotary switches (0.50 to 2.00)

Range is limited by original flow rate range of unit

Accuracy (Note1)

±1.0%F.S.

Repeatability (Note1)

±0.2%F.S.

Response time

1sec (Typical)

Operating differential

pressure (Note2)

50 to 300kPa

100 to 300kPa

150 to 300kPa

Maximum operating

pressure

300kPa(G)

Withstanding pressure

1MPa(G)

Operational temp/

Humidity range

5 to 50°C / 0 to 80%RH (with no condensation)

(Accuracy insurance 15 to 35°C)

Storage temp /

Humidity range

0 to 60°C/ 0 to 80%RH (with no condensation)

Leak integrity

Less than 1×10-11Pa·m3/sec (He)

Mounting direction

Free

Materials exposed to gas

Stainless steel 316L, PCTFE, PTFE

Seal materials

Stainless steel 316L

Actuator

Piezo electric actuator

Fitting

6.35VCR Type: 124mm

6.35VCR Type: 106mm (option)

6.35SWL Type: 127mm (option)

Power supply

+15VDC±3%: 120mA -15VDC±3%: 50mA

Analog interface

D-sub 9pin (male), Fixed size of screw:M3

Digital interface

RS-485 (RJ45 Jack) 2-wire Maximum connection 32 units

RS-232C(RJ45Jack)Maximumconnection100units(R0/R1Option)

Weight

Approx. 1 kg

Note 1) The value at the time of shipping. This may change with usage of VR function.

Note 2) The value at the time of shipping. This may change with gas type and flow rate setting.

·Connect the MFC to the ground.

(2) Dimensions

6. Ordering information

MC-710 MC - 4VR2 A0A0A0 - 06 - N2 - 1.5SLM

[1] [2] [3] [4] [5] [6] [7]

[1] Model: MC: Mass Flow Controller Series MC-710 MC-720 MC-730

[2] Valve operation mode · Internal surface treatment

NO: Normally opened valve / No treatment

NC: Normally closed valve / No treatment

MO: Normally opened valve / Precision polishing

MC: Normally closed valve / Precision polishing

[3] Fitting

4VR2: 6.35VCRType 124mm

4VR1: 6.35VCRType 106mm (option)

4SWL: 6.35SWLType 127mm (option)

※Please consult us for other fitting types.

[4] Other options

Default settings is labeled “A0A0A0”, please consult for more information.

[5] VR Number

[6] Gas type

[7] Full scale flow rate and unit: SCCM(0°C standard), SLM(0°C standard)

7. Connection

(1) Analog interface connector

Mounted connector : D-Sub 9 pin(male)

Pair connector : D-Sub 9 pin(female) (Fixed size of screw : M3)

Pin

No.

Signal name

Function

1

Valve override open/close signal(Note3)

+15VDC:OPEN, -15VDC:CLOSE

2

Flow rate output signal 0 to 5VDC

Flowrateoutputvoltageplusside0to5VDC

3

Power supply input +15VDC±3%

Power supply (plus) 120mA

4

Power supply COMMON (Note4)

COMMON ±15VDC±3%

5

Power supply input -15VDC±3%

Power supply (minus) 50mA

6

Flowratesettingsignal 0to5VDC

Flow ratesettingvoltage0 to 5VDC (plus)

7

Flow rate output COMMON (Note4)

Flow rate output signal COMMON

8

Flow rate settingCOMMON (Note4)

Flow rate setting signal COMMON

Note3) Impedance for flow rate setting signal is 10MΩ, valve override signal resistance is 100kΩ.

Note4)Pin No.[4],[7]and No.[8] are connected internally in MFC.

Wirings should be done as shown below in order to remove the effect of potential difference

among the COMMON.

Do not connect. Flow rate setting signal COMMON[8], Flow rate output signal[7], and

Power supply COMMON[4] in the power supply unit.

(2) Digital interface connector

Mounted connector : RJ-45 Modular jack

Pair connector : RJ-45 Modular plug

·Digital Interface (Port A)

Pin

No.

Signal Name

Function

RS-485

RS-232C(Note5)

1

Signal COMMON

RS-485/RS-232C Signal COMMON

2

Signal COMMON

RS-485/RS-232C Signal COMMON

3

N.C.

-

4

Signal

[-Txd/Rxd]

Signal [Rxd]

RS-485 2-wire system transmitter / receiver

minus signal

RS-232C receiver signal

5

Signal

[+Txd/Rxd]

Signal [Txd]

RS-4852-wiresystemtransmitter/receiverplussignal

RS-232C transmitter signal

6

N.C.

-

7

N.C.

-

8

N.C.

PowerOUT

(Note6)

RS-485 Unconnected

RS-232C Power Output 5VDC

·Digital Interface (Port B)

Pin

No.

Signal Name

Function

RS-485

RS-232C(Note5)

1

Signal COMMON

RS-485/RS-232C Signal COMMON

2

Signal COMMON

RS-485/RS-232C Signal COMMON

3

N.C.

-

4

Signal

[-Txd/Rxd]

Signal [Txd]

RS-485 2-wire system transmitter / receiver

minus signal

RS-232C transmitter signal

5

Signal

[+Txd/Rxd]

Signal [Rxd]

RS-4852-wiresystemtransmitter/receiverplussignal

RS-232C receiver signal

6

N.C.

-

7

N.C.

-

8

N.C.

-

Note5)Digital interface is RS-232C specification if the factory default option is specified as

R0 or R1. Refer to the attached sheet of digital interface instruction manual for connection.

Note6)[Power OUT] means the power output of RS-1 interface and it is not applicable for

connections to other machines without R1 option.

·RS-1 is a discontinued product. Therefore, MC-3000E series / MC-2000 series can be replaced

with MC-700 series including option.

8. Alarm functions

The MFC has two types of alarm functions built in. In addition, alarm status can be

confirmed using both digital communication (alarm output from the digital connector)

and anLEDlocatedontopofthebodyoftheMFC.Asalarmsettingscanonlybechanged

using digital communication, please carry out necessary changes using this method. For

details, please refer to the Interface Instruction Manual.

Alarm

Set off

LED indicator

A

Setting value ≠flow rate output

Continuous Red

Flow totalizer Alarm level 2

Rotary switch setting error (Note 7)

Continuous Red (only analog mode)

Power supply voltage (+15VDC) drop

Off

B

Voltage of valve control change

Red (every 0.5sec flashing)

Abnormal zero offset (Note 7)

Flow totalizer Alarm level 1

Other

Command error

Continuous Red (every 0.5sec flashing)

Normal

-

Green (every 1sec flashing)

9. Software switch (factory shipped value)

This MFC is provided with a software switch for operation mode setting. Before

operation, input the necessary data for various functions by using the digital interface.

Details of the functions are described in the special function manual.

Software switch

Available values

Function

Default

Device number

00 to 99

Device No. Registration

00

Alarm A range

0 to 99 [%]

Setting Alarm A range

5%

Alarm B range

0 to 99 [%]

Setting of Alarm B range

20%

Alarm timer

0 to 99 [seconds]

Setting of Alarm timer

5 seconds

Alarm cancel

timer

0 to 99 [seconds]

Setting of time of alarm sound after

error is cleared

2 seconds

Alarm A output

Enable / Disable

Setting of Alarm A output

Enable

Alarm B output

Enable / Disable

Setting of Alarm B output

Disable

(Note 7)

Operation mode

Analog / Digital

Switching of Analog/digital

Analog

Power on mode

Analog / Digital

Switching of Operation mode in

power turning on

Analog

Valve control

C / O / H / S

Close / Open / Hold / Servo

Servo

Control mode

2%Close/2%Hold/Nor

mal

Control mode setting at flow rate

setting <2%

2%Close: Valve Close

2%Hold: 2% Control

Normal: Normal Control

2%Close

Variable range

0.50 to 2.00(Analog)

5000 to 20000(Digital)

Both Analog and

Digital have limits

according to the

specification

<Variable range setting>

Analog mode

(Priority to rotary switch)

Digital mode

(Priority to digital setting)

However, in the case that rotary

switch is 0.00, priority will be

given to the digital setting even in

Analog mode.

Depende

nt on full

scale

flow rate

Communication

protocol

(RS-485/RS-232C)

(Note7)

9600 to 38400bps

8bit / 7bit

Odd / Even / None

1bit / 2bit

Baud rate

Character length

Parity

Stop bit

9600bps

7bit

None

2bit

Note7) Zero adjustment error alarms regardless of the “Enable”/ “Disable”of the alarm.

·If the zero adjust button on the top of the MFC is pressed and held for over 5 seconds, the

communication protocol is reset to default.

10. Operation

(1) Procedure

1) This product is packed in a clean room before shipment. Please break the

seals in a clean room after taking it out of its box.

2) Check the gas type and flow rate and check the direction of the gas flow and

the MFC before installation.

3) Check for gas leaks from the tubing with a helium (He) leak detector.

4) Connect the interface connectors according to the Connector table.

5) Power requirements are +15VDC:120mA and -15VDC: 50mA. Check the

voltage, polarity, and capacitance of the power supply voltage.

6) Turn on power supply and let the equipment warm up for at least 5 minutes

(Recommended time: 30min).

7) Adjust the zero point by pressing the zero adjustment, switch located on the

top of the MFC. Before zero-point adjustment, check that gas is not being

supplied and the device was warmed up for 30 minutes or more in order to

ensure sensor stability.

8) Input the flow rate setting signal and supply gas with required differential

pressure to the MFC. The MFC will begin to control the gas flow in

proportion to the preset voltage. Full-scale voltage is 5VDC. Maximum

input voltage is ±15.5VDC.

9) When the output flow rate signal is used, the tolerance voltage of the

external device should be more than ±15.5VDC. When it’s connected the

output valve may be within the range of the maximum voltage ±15.5VDC.

10) Complete shut-off cannot be achieved with the mass flow controller.

If complete shut-off is desired, a shut-off valve should be installed.

11) When ahighly reactivegas is used, thoroughly purge all foreign matter from

the tubing and the MFC before operation.

12) When contaminated gas is used, install a filter at the equipment inlet.

13) Use the MFC within the range of the operating temperature (15 to 35°C),

and keep it at the same temperature with the gas. If used in any environment

that does not meet the above-mentioned requirements, the flow rate cannot

be measured accurately and the device may fail.

14) Do not switch the power supply on and off within one second. It may cause

failure.

(2) Valve control signal

The MFC features a forced valve open/close input function.

The connector pin No.1 is used to input the internal valve open/close signal.

By inputting this signal, a forced opening/closing of the internal valve can be

performed without depending on the value of the flow rate preset signal.

When +15VDC is input: fully open

When –15VDC is input: fully closed

(3) Variable Range function

By using one device of MFC, it is possible to modify multiple flow rate ranges

and gas types. To modify the flow rate or the gas type, refer to the following VR

corresponding chart or the calculation formula, and modify the variable range by

the rotary switches (for analog control) or digital communications (for digital

control).

Flow range and gas type

Model

VR number

Flow rate range

in Nitrogen

VR value

applicable

Standard

flow rate

MC-710

02

10 to 30 SCCM

0.50 to 1.50

15 SCCM

03

25 to 100 SCCM

0.50 to 2.00

50 SCCM

04

75 to 300 SCCM

0.50 to 2.00

150 SCCM

05

0.25 to 1 SLM

0.50 to 2.00

500 SCCM

06

0.75 to 3 SLM

0.50 to 2.00

1.5SLM

MC-720

07

2.5 to 10 SLM

0.50 to 2.00

5 SLM

MC-730

08

10 to 30 SLM

0.50 to 1.50

15 SLM

09

30 to 50 SLM

0.60 to 1.00

30 SLM

[Formula]

(standard flow rate) ÷ (desired flow rate) × (conversion factor)

By using this function, the flow rate and gas type may be changed, however if a

different gas is to be used, please consider the properties of the gas and confirm

the responsiveness before usage. Also, in the case that the gas may cause debris

or particle, please refrain from using it. If you have any questions of conversion

factor, please contact us.

(4) Digital interface

The MFC features the RS-485 or RS-232C (Note 5) digital interfaces. Many

special functions can be employed using the digital interfaces.

Please refer to other manuals (Digital Interface Manual, Special Function

Manual Command Chart).

11. Product warranty

(1) Period

This product is guaranteed for a period of 1 year from date of shipment. Defects

are repaired according to the following regulations.

(2) Scope

Warranty coverage is restricted to this product only. Any other damage caused by

an is not covered.

(3) Disclaimer facts

The following repairs are not covered by the warranty:

1) Failure caused by by-product of fluid used

2) Failurecaused by misuse (including careless operation)orincorrect repair or

modification

3) Failure caused by dropping after purchasing

4) Failure caused by a natural disasters

Even if the warranty period is still in effect, the following items may not be

repaired.

1) In case of the product is returned with fluid remaining inside

2) In case of what kind of fluid was not informed used on the product

The MFC is a precision instrument. Control may become unstable if electric noise,

temperature change of fluid, pulsation of fluid pressure etc. occurs. Please be

forewarned.

This instruction manual is subject to revision without notice

http://www.lintec-mfc.co.jp

CorporateHeadquarters

4-1-23Sekinotsu, OtsuCity, ShigaPref.520-2277, Japan

TEL. +81-(0)77-536-2210FAX.+81-(0)77-536-2215

TokyoBranchOffice

3FHattoriBuild.,4-30-14YotsuyaShinjyuku-kuTokyo160-0004,Japan

TEL. +81-(0)3-5366-2801FAX.+81-(0)3-3341-3513

This manual suits for next models

3

Other Lintec Controllers manuals

Popular Controllers manuals by other brands

Phocos

Phocos CIS-MPPT-LED 85/15 user manual

IOtech

IOtech Personal488 user manual

HighPoint

HighPoint RocketRAID 37 Series installation guide

Hanna Instruments

Hanna Instruments HI 504 instruction manual

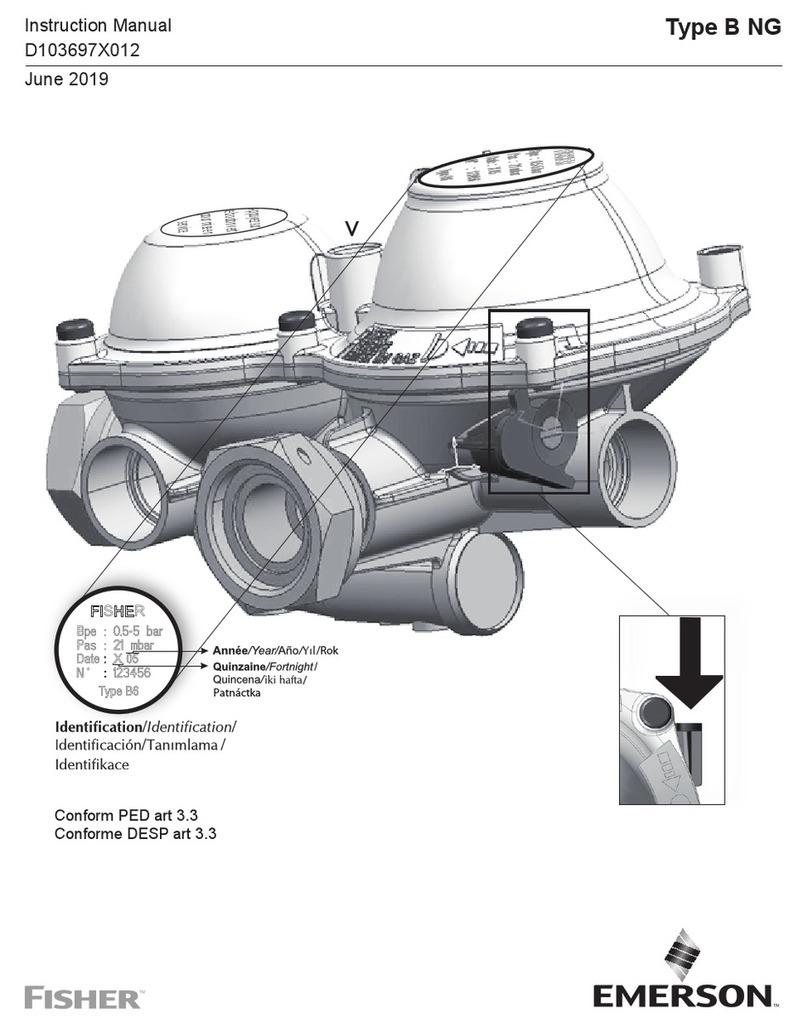

Emerson

Emerson Fisher Type B NG instruction manual

Agilent Technologies

Agilent Technologies XGS-600 instruction manual

KSB

KSB EA-C Series Installation & operating manual

RainFlo

RainFlo PC115A user manual

AMX

AMX NetLinx Integrated Controller NI-2100 Hardware reference guide

Synergy 21

Synergy 21 SR-1006 Series quick start guide

4qd

4qd PRO-160 Series instruction manual

Westlock

Westlock 2600 Installation and operating instructions