Lintec MC-7000D Series User manual

LN0575E2202A1

High Response

Mass Flow Controller for DeviceNet™

Instruction Manual

MC-7000D Series

Safety Precautions

Incorrect handling may cause death or injury

(1) Before connecting the fittings, check that no damage or defects are found on

the fittings. Make connections properly and make sure that a leak test is

conducted before actual operation to prevent fluid from leaking into the

atmosphere (Hereinafter, the fluid used is referred as “gas” or “fluid”).

(2) DO NOT apply any corrosive fluid tomaterials exposed to gas. Corrosion may

cause gas to leakinto the atmosphere. Checkthegas type to be used in advance.

(3) Thisdeviceisnotdesignedasan explosionproofstructure.DONOTusethisdeviceina

placewhereexplosion-proofstructuresarerequired.Doingsomaycausefireorexplosion.

Incorrecthandlingmay leadtomediumorslightinjury or may

causedamageto,orlossof,facilitiesorequipment

(1) Observe the precautions listed in the WARNING (above).

(2) Strictly observe the electrical specifications. Not doing so may cause fire,

damage to sensors or malfunction.

(3) This device is not designed to be waterproof. DO NOT locate this device

outdoors or in a place where it may besplashed with water. Doing so may cause

fire, trouble, or malfunction of the device.

(4) DO NOT modify this device. It may cause fire or other problems.

(5) This device is notdesigned to handle hot swap. Please avoid attaching and removingthe

powersupplyconnectorandinterfaceconnectorwiththe powerswitchedon. Attachment

and/orremovalwiththepoweronmayresultinfailureofthedevice.

(6) This device is a precious device, please handle it carefully. Dropping down or

handling it carelessly will cause damage. Please use assist instrument while moving

or setting the device.

(7) Regular maintenance is recommended for steady use of this device

(Recommended proofreading frequency is once a year).

1. Introduction

This manual explains basic operation of the MC-7000D series (Hereinafter referred

as "MFC"). MFC is equipped with a network interface, and can be operated by

connecting to a network environment of DeviceNet ™.

Since MFC is a slave device, please prepare a master device of DeviceNet ™

network interface.

The device profile follows the MFC profile in ODVA specification.

Please go through the ODVA specification and MC-7000D device profile manual

for proper use.

2. Summary

The MFC is high performance mass flow controller for gas using high response

thermal flow sensor and high response piezoelectric valve. Valve operation mode

is normally closed type. Also, MFC interface employs Device Net™ network, so

MFC is compatible with other makers.

3. Features

The MFC is the following features.

(1)

LINTEC’s proprietary ambient temperature compensation type flow sensor is carried.

· Low sensor temperature, long-time steady monitor, and few problems such

as degradation of gas to be monitored.

·The effect of ambient temperature is less because the sensor temperature is

kept at the ambient temperature.

·Steady temperature distribution of sensor and high-speed response.

(2) Digital computing system with microprocessor and high-resolution A/D, D/A

converter is carried.

· High functionality.

·By setting of device number (address), multiple devices can be controlled

through a single interface.

· Many additional are provided as standard, e.g., totalizer function, zero adjust,

ramping function.

(3) MFC employs DeviceNet™ network protocol.

(4) Small dead space structure using a diaphragm valve.

(5) Single power supply 24VDC (Recommended).

(6) Superiorcorrosion resistant sealing materials make maintenance easy. Metal seals (Au).

(7) Particle-free structure.

(8) By using a metal case and various types of filters, steady operation can achieve

even in an environment of high-frequency noise and stationary magnetic field.

(9) Based on RoHS.

4. Structure

The MFC consists of sensors, valves, and a microcomputer for signal processing.

A digital PID feedback control system controls the valve action so that flow rate

output from the sensor agrees with flow rate setting value.

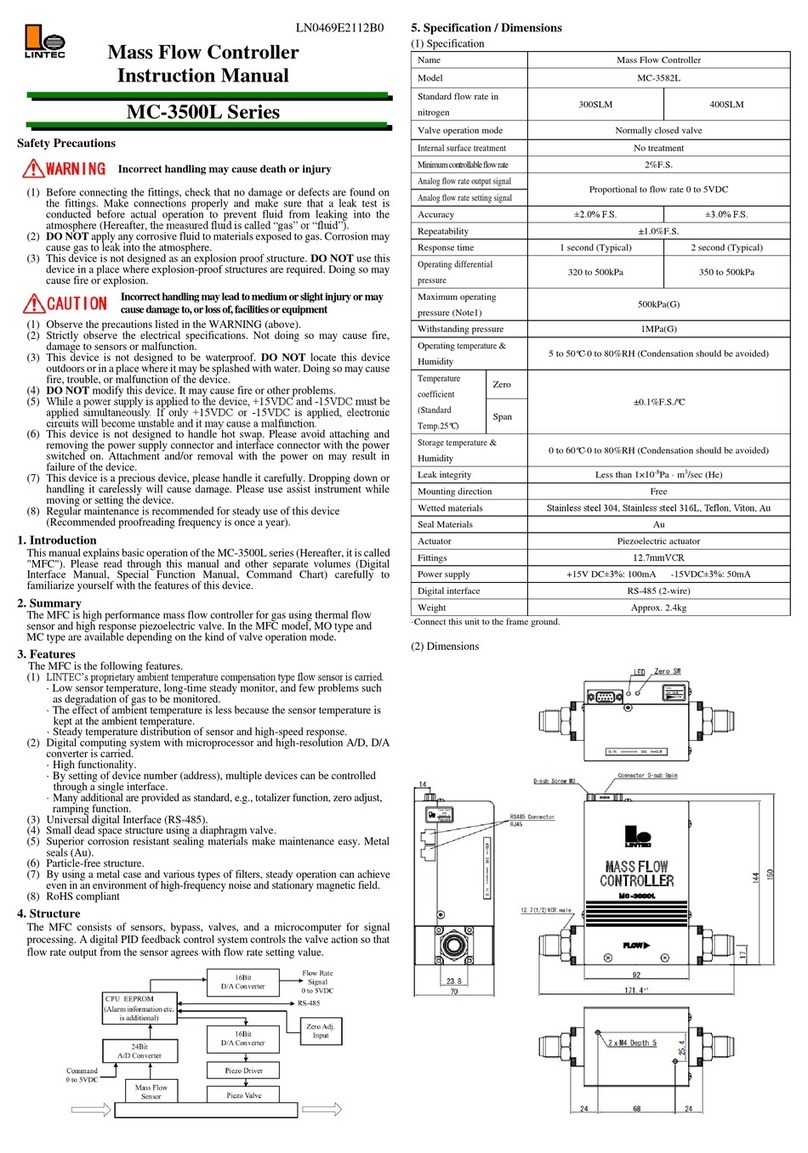

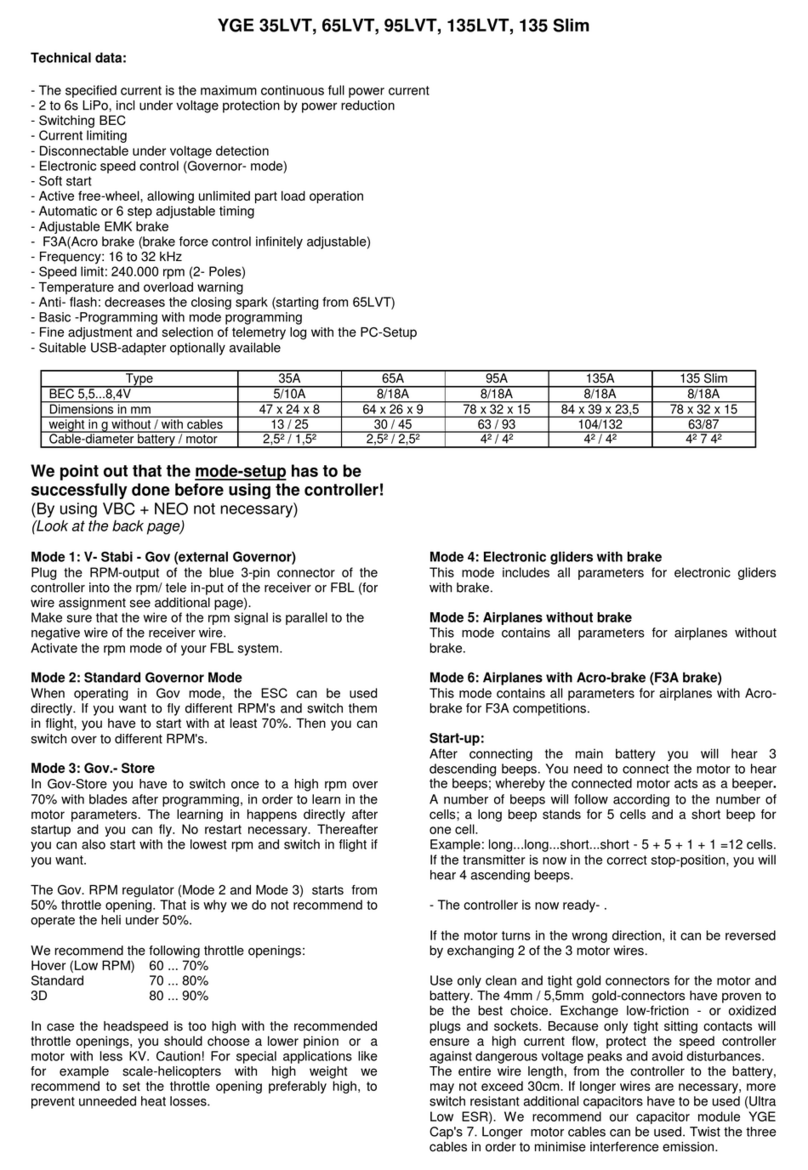

5. Specification / Dimensions

(1) Specification

Name

Mass Flow Controller

Model

MC-7100D

MC-7200D

Flow rate range

(N2 conversion)

10 SCCM ~5 SLM

~20SLM

Valve operation mode

Normally closed

Internal surface treatment

Precision polishing (LEP)

Minimum controllable flow rate

2%F.S.

Accuracy

100%F.S. to 25%F.S. ±1.0%S.P.

25%F.S. to 2%F.S. ±0.25%F.S.

Repeatability

±0.2%F.S.

Response time

0.2 second (Typical)

Operating differential

pressure

50 to 300kPa

100 to 300kPa (~10SLM)

200 to 300kPa (~20SLM)

Maximumoperating pressure

300kPa(G)

Withstanding pressure

1MPa(G)

Operating

temperature

&

Humidity

5 to 50ºC·0 to 80%RH (Condensation should be avoided)

Storage temperature &

Humidity

0 to 60ºC·0 to 80%RH (Condensation should be avoided)

Leak integrity

Less than 1×10-11Pa · m3/sec (He)

Mounting direction

Free

Wetted materials

Stainless steel 316L, PCTFE, PTFE, Au

Seal Materials

Au

Actuator

Piezoelectric actuator

Fittings

6.35VCR (106mm, 124mm)

1.125 W-Seal (79.8mm), 1.125 W-Seal (92mm)

Power supply

24VDC (Recommended) (Note1)

Digital interface

DeviceNet™

Weight

Approx. 1kg

Note1) Using 24VDC power supply for high response.

· Connect the MFC to the frame ground.

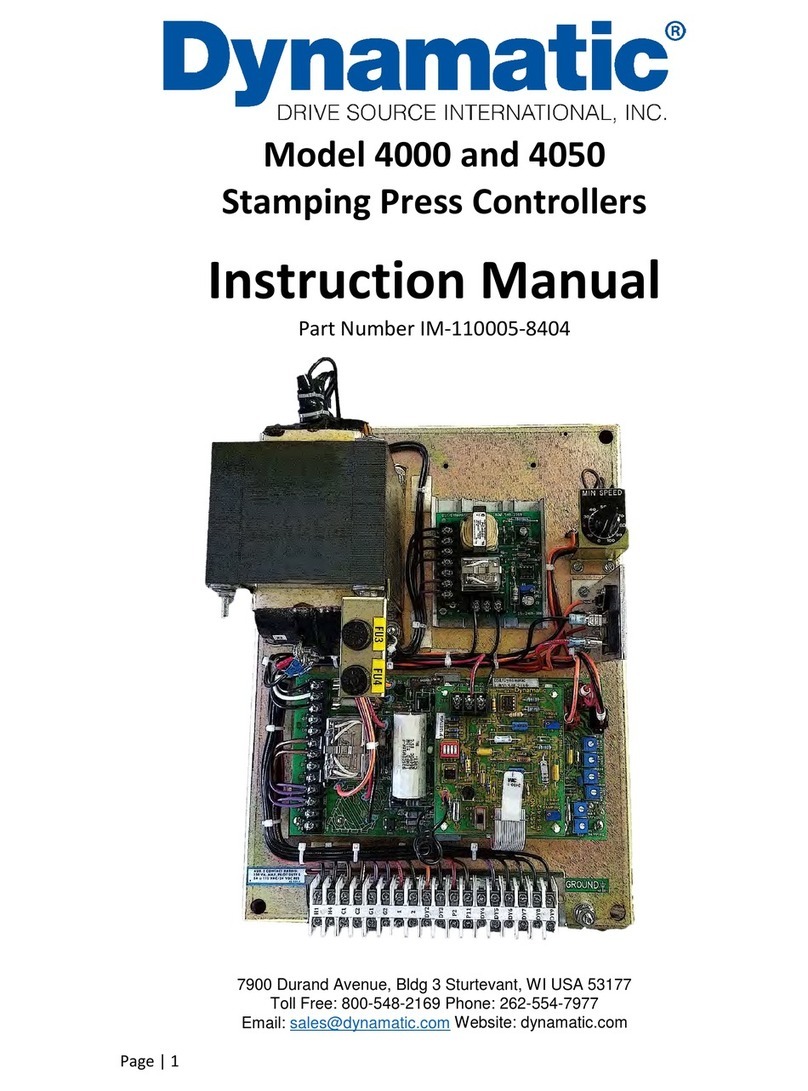

(2) Dimensions

MC-7100D, MC-7200D (6.35VCR, 106mm)

MC-7100D, MC-7200D (1.125W-Seal, 79.8mm)

28.6

2×M4 Depth 5mm

1

71

14.8

17.9

14.3

DeviceNet

Connector

101.6

113

79.8±0.3

18.5

38

25.4

STATUS

ZERO ADJ. NET MOD

RATEMSD LSD

28.6

6.9

4xφ4.4

21.8±0.2

INLET

OUTLET

24.4

S/N ********* GAS ***SLM

126

112

18.5

38

S/N ********* GAS ***SLM

28.6

2×M4 Depth 5mm

71

14.8

17.9

14.3

DeviceNet

Connector

28.6

6.9

12.7

STATUS

ZERO ADJ. NET MOD

RATEMSD LSD

77.4

106±0.5

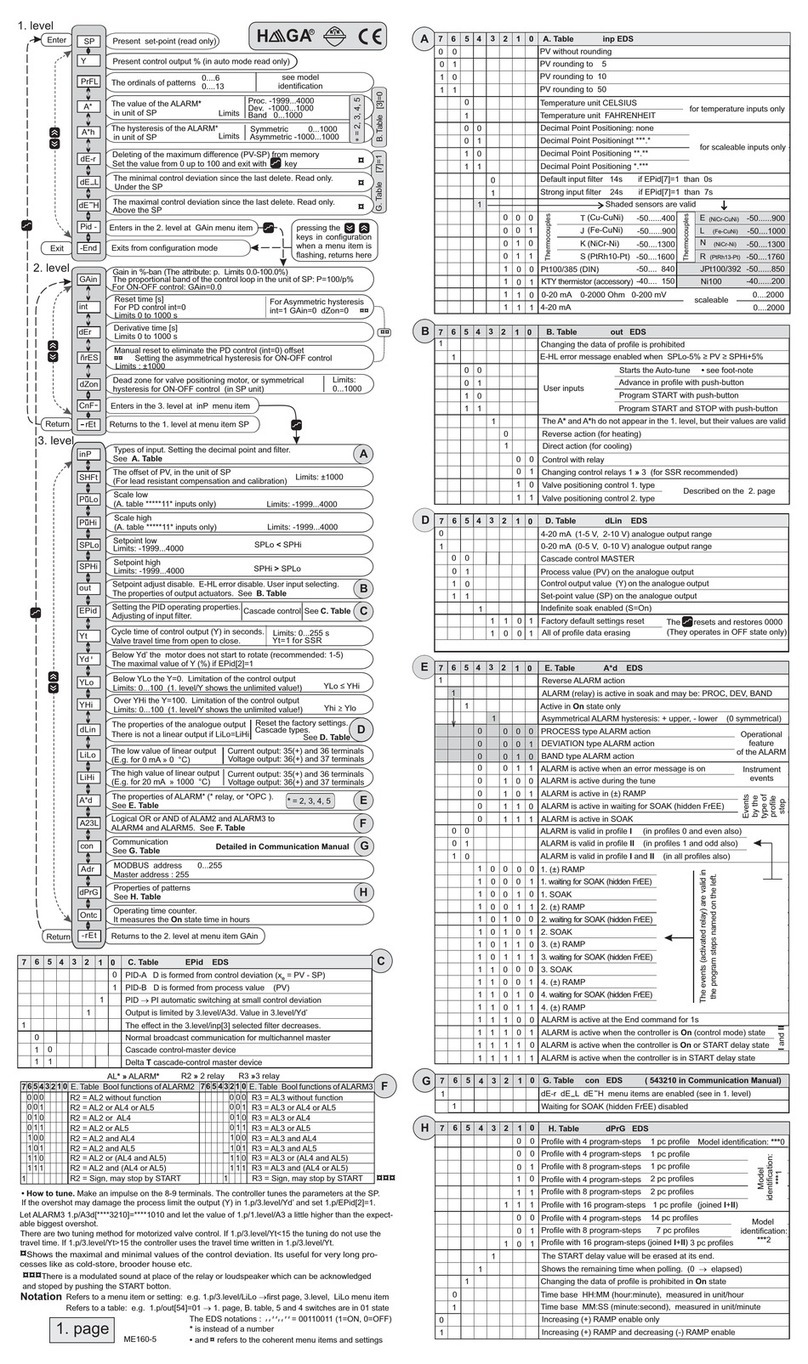

6. Ordering information

MC-710*D –MC –4VR1 JA0A0 –dd –ee –ff

[1] [2] [3] [4] [5] [6] [7]

[1] Series model MC: Mass Flow Controller Series

MC-7100D, MC-7200D

*Power connector orientation 0: Side direction, 1: Upper direction

[2] Valve mode

MC: Normally close (Precision polishing)

[3] Fitting size

4VR1:6.35VCR106, 4VR2:6.35VCR124, 4SWL:6.35SWL

SPW3: Surface mount 1.1.25W-Seal 92mm,

SPW4: Surface mount 1.125W-Seal 79.8mm

※ Please consult for more information.

[4] Optional

J:

Valve is closed at below 2% setting (Required option)

※ Default setting is labeled

“JA0A0”.

Please consult for more information.

[5] Gas type

[6] Full scale flow rate

[7] Flow rate unit

SCCM (0 ºC standard), SLM (0 ºC standard)

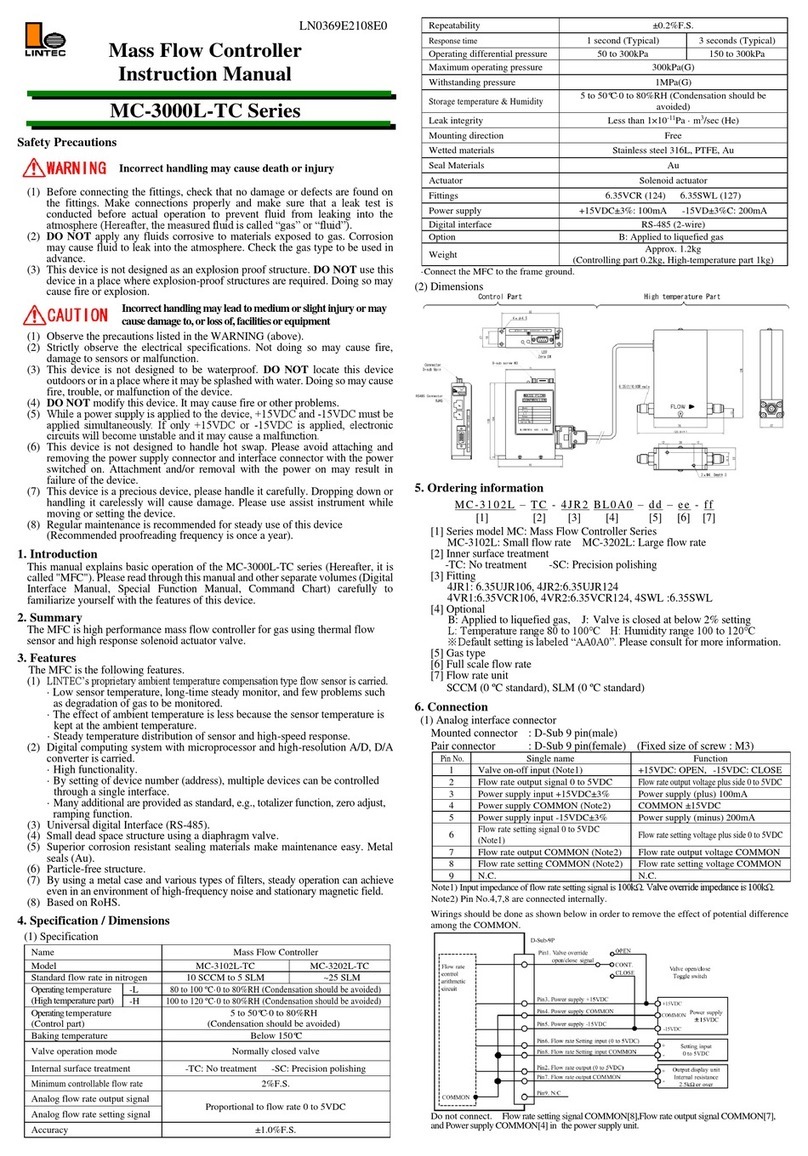

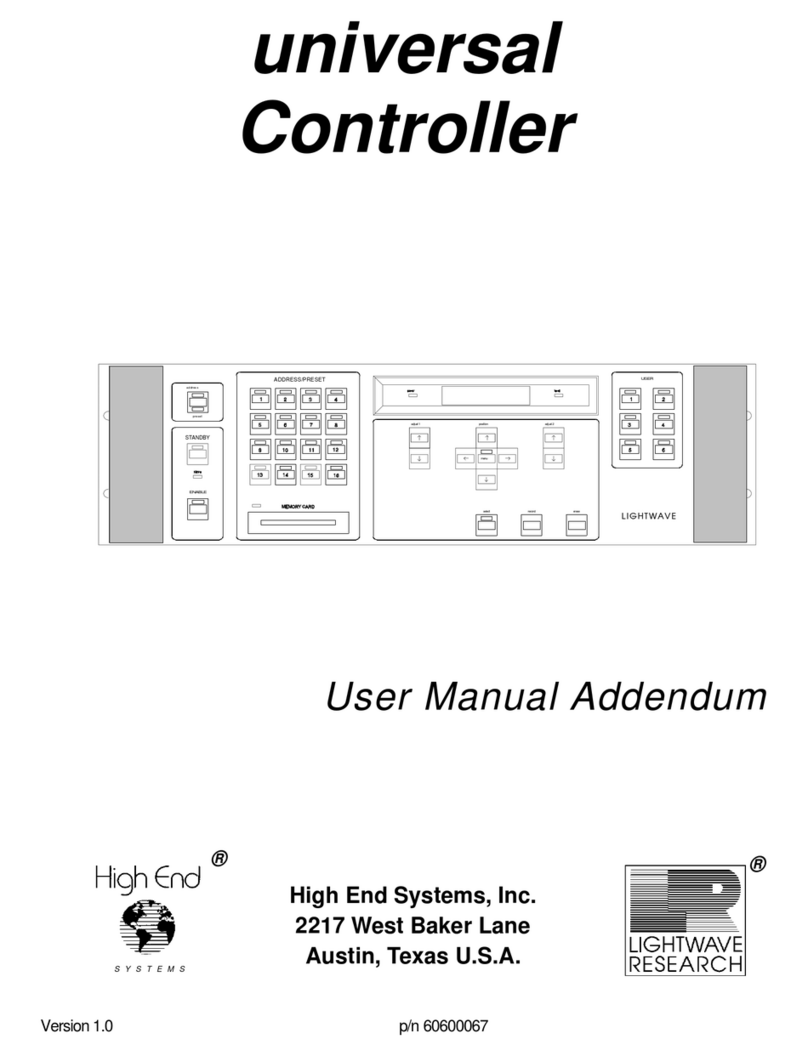

7. Connection

(1) DeviceNet™ connector: 5 Pin type micro connector (IEC60947-5-2)

Pin No.

Signal name

Function

1

Drain

Shield

2

V+

Power supply 11 to 25VDC (+)

3

V-

Power supply (-)

4

CAN_H

CAN interface HI

5

CAN_L

CAN interface LO

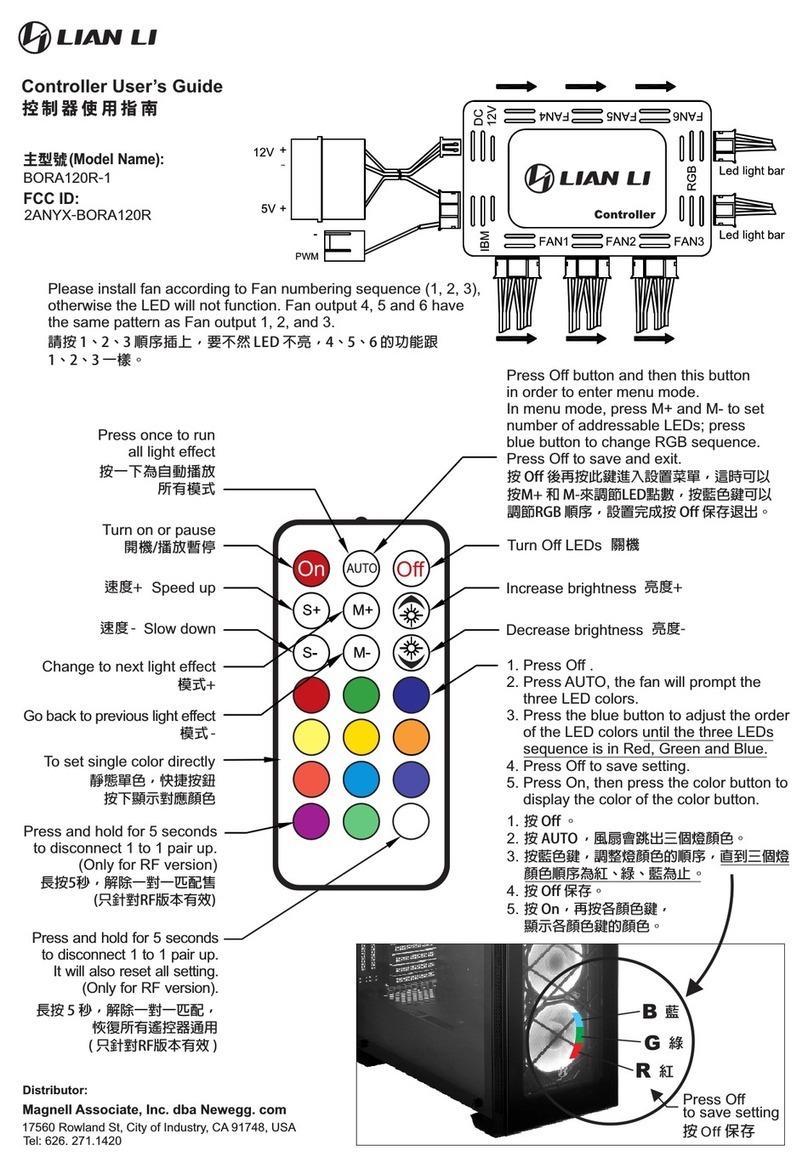

(2) Rotary switch, LED (on top of the MFC)

8. Operation

Procedure

(1) This product is packed in a clean room before shipment. Please break the

seals in a clean room after taking it out of its box.

(2) Check the gas type and flow rate, and check the direction of the gas flow and

the MFC before installation.

(3) Check for gas leaks from the tubing with a helium (He) leak detector.

(4) Prepare a master for DeviceNet™ and connect with specified power, cable

and connector.

(5) Connect with the network.

(6) Turn on power supply and let the equipment warm up for at least 5 minutes

(Recommended time: 30min).

(7) Please power on the MFC for 30 mins, then conduct zero-point adjustment

without gas flowing by pressing the button on the top of device or software.

(8) Within the specific pressure range, MFC will start to control the flow rate

after input the setting.

(9) Complete shut off cannot be achieved with the mass flow controller. If

complete shut off is desired, a shut-off valve should be installed.

(10)When a highly reactive gas is used, thoroughly purge all foreign matter from

the tubing and the MFC before operation.

(11)When contaminated gas is used, install a filter at the equipment inlet.

9. Product warranty

(1) Period

This product is guaranteed for a period of 1 year from date of shipment. Defects

are repaired according to the following regulations.

(2) Scope

Warranty coverage is restricted to this product only. Any other damage caused

by this product is not covered.

(3) Disclaimer facts

The following repairs are not covered by the warranty:

1) Failure caused by by-product of fluid used.

2) Failure caused by misuse (including careless operation) or incorrect repair or

modification.

3) Failure caused by dropping after purchasing.

4) Failure caused by a natural disaster.

Even if the warranty period is still in effect, thefollowing itemsmay not be repaired.

1) When the kind of fluid used in the product is unclear.

2) The product is returned with fluid remaining inside and safety cannot be

confirmed.

The MFC is a precision instrument. Control may become unstable if electric

noise, temperature change of fluid, pulsation of fluid pressure etc. occurs.

Please be forewarned.

This instruction manual is subject to revision without notice.

http://www.lintec-mfc.co.jp

CorporateHeadquarters

4-1-23Sekinotsu, OtsuCity,ShigaPref.520-2277,Japan

TEL. +81-(0)77-536-2210FAX.+81-(0)77-536-2215

TokyoBranchOffice

3FHattoriBuild.,4-30-14YotsuyaShinjyuku-kuTokyo160-0004,Japan

TEL. +81-(0)3-5366-2801FAX.+81-(0)3-3341-3513

NET

Network Status

Network Status LED

MOD

Module Status

Module Status LED

ZERO ADJ.

Zero Adjustment

Zero Adjustment button

Display

Name

Description

Default

MSD

LSD

Node Address

Decimal setting:

MSD: a digit in tens place

LSD: a digit in ones place

The setting number above 64 will be Software

Set Mode.

63

RATE

Data Rate

Baud rate switch

1: 125 kbps

2: 250 kbps

5: 500 kbps

Otherwise: Software set mode

5

This manual suits for next models

2

Other Lintec Controllers manuals