Lion Precision SpindleCheck 1.1 User manual

INSTRUCTION

MANUAL SpindleCheck 1.1

M017-7450.003 SpindleCheck 1.1 Manual ii

This instruction manual details the operation of the

Lion Precision SpindleCheck Spindle Qualification

System. Please contact us if you have any

questions or suggestions on how we can be of

greater service to you.

Lion Precision

651-484-6544

www.spindlecheck.com

www.lionprecision.com

Software Version: 1.1

Manual Version: M017-7450.003

Table of Contents

APPROVALS AND SAFETY CONSIDERATIONS..................................................IV

INTRODUCTION.......................................................................................................... V

FUNDAMENTAL CONCEPTS.............................................................................................V

TESTS PERFORMED BY SPINDLECHECK...........................................................................V

ADDITIONAL CAPABILITIES OF SPINDLECHECK...............................................................V

STANDARDS AND REFERENCES......................................................................................VI

ASSISTANCE..................................................................................................................VI

SOFTWARE INSTALLATION.................................................................................VII

SPINDLECHECK SOFTWARE..........................................................................................VII

SOFTWARE BASICS................................................................................................VIII

SELECT MODE OF OPERATION .....................................................................................VIII

BASIC NAVIGATION ......................................................................................................IX

QUADRANT DISPLAYS...................................................................................................XI

SPINDLECHECK CONFIGURATION.................................................................... XII

GENERAL CONFIGURATION .........................................................................................XIII

CALIBRATION CONFIGURATION...................................................................................XIV

DIAGNOSTICS...............................................................................................................XV

SPINDLECHECK SENSOR COMMUNICATION...................................................................XV

SPINDLECHECK HARDWARE.............................................................................XVI

SENSOR SYSTEM ELECTRONICS ..................................................................................XVII

PROBE CONNECTIONS ................................................................................................XVII

SENSOR SYSTEM PROBES ............................................................................................XIX

INDEX SPACER .............................................................................................................XX

PROBE NEST ................................................................................................................XX

PRECISION TARGET PIN...............................................................................................XXI

MAKING MEASUREMENTS AND READING PLOTS..................................... XXII

UNDERSTANDING AND INTERACTING WITH PLOTS ......................................................XXII

SETUP FOR MAKING MEASUREMENTS .......................................................................XXIII

RUNNING TESTS........................................................................................................XXVI

RESPONSE TIME AND SCREEN UPDATES ....................................................................XXVI

SPECIFICATIONS................................................................................................XXXII

APPENDICES.......................................................................................................XXXIII

GLOSSARY..................................................................................................................XL

Lion Precision •St. Paul, Minnesota 55128-7082 USA

Telephone: 651-484-6544 •Fax: 651-484-6824 •www.lionprecision.com

Copyright © 2016 All Rights Reserved •Document # M017-7450

Approvals and Safety Considerations

The SpindleCheck sensors and electronics are compliant with the following standards:

Safety: 61010-1

EMC: 61326-1, 61326-2-3

To maintain compliance with these standards, the following operating conditions must be

maintained:

●All I/O connecting cables must be shielded and less than three meters in length

●Use the included CE approved power supply. If an alternative power supply is

used, it must have equivalent CE certification and provide safety isolation from

the mains according to IEC60950 or 61010.

●Sensors must not be attached to parts operating at hazardous voltages in excess

of 33VRMS or 70VDC

Use of the equipment in any other manner may impair the safety and EMI protections of

the equipment.

M017-7450.003 SpindleCheck 1.1 Manual v

Introduction

The SpindleCheck is a hardware and software package for measuring the dynamic

performance of machine tool spindles.

Fundamental Concepts

SpindleCheck uses noncontact, capacitive sensors to measure error motions as changes in

position of a precision target pin installed and rotating in the machine spindle.

The pin includes a copper strip used to trigger a once-around index pulse. This index sets

a reference for angular location of the spindle to align measurements from multiple

rotations.

The measurements are collected and analyzed by the SpindleCheck software. The results

of the live measurement or archived measurement file are presented on polar and linear

plots with calculated values of standard error motion measurements.

Tests Performed by SpindleCheck

SpindleCheck performs the following tests as described in ISO, ANSI/ASME, and JIS

standards:

●Radial rotating sensitive direction

●Radial fixed sensitive direction

●Axial error motion

●Thermal stability

●Temperature variation error

●FFT Analysis

Additional Capabilities of SpindleCheck

●Oscilloscope display

●Analog meter display

M017-7450.003 SpindleCheck 1.1 Manual vi

Standards and References

●ANSI/ASME Standard B5.54-2005, Methods for Performance Evaluation of CNC

Machining Centers

●ANSI/ASME B5.57-2012, Methods for Performance Evaluation of CNC Turning

Centers

●ANSI/ASME B89.3.4-2010, Axes of Rotation, Methods for specifying and testing

●ISO230 Part 3 (2001), Test Conditions for Metal Cutting Machine Tools, Evaluation

of Thermal Effects

●ISO230 Part 7 (2005), Geometric Accuracy of Axes of Rotation

●JIS B 6190-7, Test Code for Machine Tools Part 7, Geometric Accuracy of Axes of

Rotation

Assistance

For assistance with the installation and operation of the SpindleCheck system, please

visit our web site at: www.spindlecheck.com or contact us at:

Lion Precision

563 Shoreview Park Road

St. Paul, MN 55126

651-484-6544

www.lionprecision.com

www.spindlecheck.com

M017-7450.003 SpindleCheck 1.1 Manual vii

Software Installation

SpindleCheck Software

Minimum Requirements

Windows 7 (32 or 64 bit), Windows 8

2 GB Ram; 1 GB Free Disk Space (minimum)

1 GHz Processor

1 Available USB port (2.0 or higher); 1024 x 768 Minimum Screen Resolution

Installation Procedure

The SpindleCheck program is installed in the \PROGRAM FILES (X86)\LION

PRECISION\SPINDLECHECK directory on your hard disk. If you install the SpindleCheck

software a second time using the same subdirectory, the previous installation will

automatically be uninstalled first.

To use the SpindleCheck flash drive:

1. Insert the Lion Precision SpindleCheck flash drive in an available USB port.

2. View the contents of the flash drive.

3. Run SpindleCheckInstall.exe

4. Follow the directions of the installation programs.

5. Once the installation has copied all files, restart the computer.

6. After restarting, run the program by selecting the icon on the desktop, or by

selecting Start > All Programs > SpindleCheck > SpindleCheck.exe.

The flash drive also contains demo data files and other valuable documents related to

spindle measurement and improving machined part quality. These files are stored in the

My Documents > Lion Precision > SpindleCheck > Docs.

M017-7450.003 SpindleCheck 1.1 Manual viii

Software Basics

Select Mode of Operation

When the program is launched (Start > SpindleCheck ), the initial splash screen requires

you to choose an operating mode:

●Measure

●Load Data File

“Measure”

Select this option only if the SpindleCheck electronics are connected to the computer.

“Load Data File”

This mode only produces static displays of files loaded for viewing. It can be used for

viewing and analysis of saved test data without the SpindleCheck electronics connected

to the computer.

SpindleCheck can also view files from the Spindle Error Analyzer (SEA), but will only

display the data available in SpindleCheck; it will not display data from channels 4 (X2)

or 5 (Y2) or any of the tests not included in SpindleCheck.

The SpindleCheck electronics do not need to be connected to view saved data files.

M017-7450.003 SpindleCheck 1.1 Manual ix

Basic Navigation

The SpindleCheck software uses several simple conventions that make the software easy

to use.

●Menus display lists of selectable options.

●Buttons execute functions or gain access to features.

●Panels display fields of information.

●In configuration windows, white background fields are inputs, while gray

background fields are only indicators

Top Menu and Status Bar

Top Menu

File

Live Display: Connects to the SpindleCheck electronics and begins to collect

measurements according to configuration parameters.

Load Data File: Loads saved rotational test data for display. Data files have .lda

extensions.

Load Thermal File: Loads saved thermal test data for display in the thermal window.

Thermal files have .lts extensions.

Save Data File: Saves the current rotational test data to a file. Thermal data is

automatically saved while the thermal test is in progress.

Print Screen: Prints the current screen to a printer, PDF, or print preview. When printing,

window backgrounds are changed to light gray for better printing results.

Exit: Exits the program

Configuration

Show Configuration: Displays configuration windows in all four quadrants. This will

always display configuration windows in all four quadrants, even if a test window was

previously selected for one of the quadrants.

Save Configuration: Saves the current configuration settings to the current file name.

Save Configuration As: Saves the current configuration settings to a new file name.

Load Configuration: Loads an existing configuration file.

Probe Meter: When connected to the electronics, the full screen Probe Meter is

displayed. This is useful for probe placement during setup and for seeing low frequency

machine structural movements when the spindle is not rotating.

Return to Test Displays: Returns test displays to all four quadrants. This selection will

always display test windows in all four quadrants, even if a configuration window had

been previously displayed in one of the test quadrants.

M017-7450.003 SpindleCheck 1.1 Manual x

Help

Manual: Opens a PDF view of this manual.

Typical Mounting: Displays an image of a typical setup.

Lion Support: Contact information and online resources for support in operating

SpindleCheck.

About: Revision level and other information about the software.

Status Bar

The Status Bar is to the right of the Top Menu. It contains information about the data

currently being viewed. That data will be different for viewing data from a file compared

to viewing live data streaming from the SpindleCheck sensor electronics.

Run/Pause: This button is only visible when the electronics are connected, AND the

index probe is detecting rotation. SpindleCheck defaults to Run mode when a rotation is

detected and the button will display “Pause.”

Clicking Pause will immediately freeze the screen with the last 32 revolutions of data and

change the Status Bar color to yellow. This mode can be used for closer examination of

the data and for saving a data file. When Paused, the button will change to “Run.”

Clicking Run resumes the process of collecting measurement data from the device and

displaying it.

Version (v.): The current version of the SpindleCheck software. When viewing a file, the

Version field displays the version of software in use when the data was collected.

Date/Time: Displays the current date and time while displaying live data. Displays the

date and time the data was collected when viewing a file.

Machine ID: Displays the current text in the Machine ID field of the General

Configuration panel.

Operator Name: Displays the current text in the Operator Name field of the General

Configuration panel.

Status Bar Color

The Status Bar background color indicates the overall system status.

Green: Computer is connected and communicating with the sensor electronics.

Yellow: Computer is connected and communicating but it is “Paused.”

Orange: Probe Meter is displayed full screen and no other measurement data is being

collected.

Red: Error mode. Either communication with the sensor electronics has been interrupted

(check connections and power) or there has been a program error.

White: Viewing files or otherwise idle.

M017-7450.003 SpindleCheck 1.1 Manual xi

Quadrant Displays

SpindleCheck displays four quadrants on your screen. Each quadrant displays a selected

view of the current data or configuration information. The current data may be live data

from the sensors or saved data from a previous measurement.

Each quadrant has a menu bar (Quadrant Menu) which begins with Display. Use the

Display menu to select which panel to display in that quadrant. If a selected panel is

already being displayed in a different quadrant, that panel will move to the selected

quadrant and the display’s previous quadrant will be replaced with a Notes screen.

Active Quadrant

Some functions like keyboard shortcuts execute functions in the “active” quadrant which

has a darker title bar. Quadrants are activated by clicking anywhere in the quadrant.

Notes Screen

Screen-prints are often used to document spindle tests. It is helpful to have machine

information displayed on the screen when the screen is printed.

To display a Notes quadrant, select Display > Notes in a quadrant.

Click in the text box to enter text. To change the displayed image, select View > Select

Graphic from the Notes screen’s tool bar.

Maximizing Displays to Full Screen

Initially, each display uses one quarter of the screen (quadrant). Select View > Maximum

Size to fill the entire screen, or double click the right mouse button over the display to be

maximized.

M017-7450.003 SpindleCheck 1.1 Manual xii

Minimizing Displays to a Quadrant

Select View > Normal Size to return a maximized display to its quadrant, or double click

the right mouse button over the display.

SpindleCheck Configuration

SpindleCheck software must be properly configured for proper operation.

Most of the required configuration information is correct as the default values when

SpindleCheck is installed. The only exception may be the Target data. The default values

are for the 20 mm precision target pin. If you are using a different target, you will need to

change the values for target configuration. Also, the target’s serial number will have to be

added to the configuration if you want that number tracked in the data files.

The complete configuration consists of data from four different configuration windows.

Access the configuration windows through Main Menu > Configuration > Show

Configuration to display all configuration windows, or in any individual quadrant select

Quadrant Menu > Display > Configuration > [Selected Configuration Window].

When connected a SpindleCheck electronics, these windows display the current

measurement configurations and can be edited.

When viewing a file, these windows display the configuration information contained in

the file being viewed and cannot be edited.

There are different types of configuration information:

Indicators: These read-only fields display information acquired from the system or

calculated from other fields. They have a lightly shaded background.

Inputs: These may be required or optional input settings that must be manually entered

by the user. Inputs have a white background.

Configuration settings can be saved with Configuration > Save Configuration in the

main menu bar.

M017-7450.003 SpindleCheck 1.1 Manual xiii

General Configuration

Field

Type

Notes

Operator Name

Input

Machine

Input

Configuration

Indicator

In Live View, displays path and file name of

current configuration. Use Configuration >

Save Configuration As to change file

name/location.

When viewing a file, this indicates the path

to the file being viewed; Save is disabled.

Date Format

Input

Dimensional Units

Input

Select Inches or Micrometers

Target S/N

Input

Record the serial number of the precision

target pin or masterball being used for the

test. This number is recorded in the data file

for later reference.

Auto-Calculate

Input

Nonflat targets require correction factors for

accurate measurements. When auto-

calculate is checked (recommended), the

target correction factors are automatically

determined by the target shape and

dimension and probe model.

Target Shape

(X, Y, Z)

Input

Select target shape for each probe channel.

Target Dimension

(X, Y, Z)

Input

Select the diameter of the target for each

probe channel

Target Multiplier

(X, Y, Z)

Input

A multiplier used with capacitive sensor

channels to correct for measurement

changes due to a nonflat target.

Roundness Error

(X, Y, Z)

Input

Optional listing of target roundness errors

(in nanometers) for record keeping. Must be

entered manually.

M017-7450.003 SpindleCheck 1.1 Manual xiv

Calibration Configuration

During live measurements, the calibration configuration window displays calibration

details of the SpindleCheck device currently connected. When viewing a file, it displays

the calibration details of the system used when the file was created.

Calibration information is given for three capacitive channels (X, Y, Z). For SEA files

with more than three channels, only X, Y, Z will be shown.

Field

Type

Notes

Probe Model

Indicator

Probe model calibrated for the channel

Probe S/N

Indicator

Probe serial number

Driver Model

Indicator

Model of the probe driver electronics

Driver S/N

Indicator

Individual driver channel serial number

Near Gap

Indicator

The smallest gap at which the channel is

calibrated

Far Gap

Indicator

The largest gap at which the channel is

calibrated

Last Cal

Indicator

Last time the system was calibrated

Next Cal

Indicator

When the system is due for calibration

M017-7450.003 SpindleCheck 1.1 Manual xv

Diagnostics

The Diagnostics window shows current measurement and diagnostic information coming

from the SpindleCheck device. The Diagnostics window will display some values when

files are being viewed, but is only useful during live measurements.

Field

Type

Notes

Disp. (µm)

(X, Y, Z)

Indicator

The current output in dimensional units

Counts

(X, Y, Z)

Indicator

The current output of each channel in counts

between 6,000-60,000 for live

SpindleCheck

Will show “Volts” when viewing SEA files

Sensitivity

(X, Y, Z)

Indicator

The sensitivity of each channel in

Counts/µm (Volts/µm for SEA files)

Target Multiplier

(X, Y, Z)

Indicator

The Target Correction as selected/entered in

the General Configuration window

Temperature

Indicator

Internal temperature of the SpindleCheck

device in °C

Main 5.5

Voltage

Indicator

DC voltage output of the 5.5 V power

supply

Input Voltage

Indicator

DC supply voltage into the SpindleCheck

device

Main PS5.5

Current

Indicator

Output current of the 5.5 V power supply

RPM

Indicator

Current RPM of the spindle based on Index

probe. If maximum RPM is exceeded,

indicator will be red.

SpindleCheck Sensor Communication

This window offers information regarding the communication between the PC and device

electronics. Lion Precision support may require some of this information during

troubleshooting should there be a communication problem. This information is not

generally useful for normal operation.

M017-7450.003 SpindleCheck 1.1 Manual xvi

SpindleCheck Hardware

M017-7450.003 SpindleCheck 1.1 Manual xvii

Sensor System Electronics

The sensor system electronics include driver electronics for the capacitive and index

probes, USB port for communicating with the PC, power and ground connections, and

indicators useful during setup.

The electronics enclosure has a magnetic base.

Probe Connections

The Index sensor channel and X, Y, and Z capacitive displacement sensor channels are

color coded. The colored blocks of each channel must match the color-coded rings on

each probe.

Calibration stickers for each capacitive sensor channel (X, Y, Z) are located on the back

of the device. These indicate probe serial numbers and their association with particular

channels.

M017-7450.003 SpindleCheck 1.1 Manual xviii

Index Sensor (Purple)

An index pulse is used to detect rotation. This signal is also used to

align readings from multiple revolutions. The Index sensor uses an eddy

current probe to detect the copper plating on the target pins.

Alternatively, a piece of copper tape can be used if using a target

without the copper plating.

The indicator lights provide feedback regarding the index function.

Signal Strength

The Index probe senses a difference between the copper and steel on the

target. When the spindle is rotating, the resulting AC signal is used to

time the measurements of the rotating spindle. The AC signal must be

sufficiently large to ensure reliable triggers to the system. The closer the

probe is to the target, the greater the signal strength, but the probe must maintain a safe

distance from the rotating target to avoid contact. The INDEX SPACER is provided to

set the ideal gap in most circumstances.

Signal Strength Indicator Conditions

●Green: Good signal strength

●Red: Poor signal strength or no rotation

INDEX

This indicator lights Green when the Index probe is reading the copper strip and is Off

when the Index probe is over the steel.

< 60 RPM

This indicator is Green when the system detects less than 60 RPM and enters “slow”

mode. This requires no action on the operator’s part, but can be informative for

troubleshooting. This indicator can take as long as a few minutes to update when speed

slows from above 60 RPM to below 60 RPM.

NOT READY

The top and bottom indicators light Blue during the 60-90 second initialization period

when power is applied to the SpindleCheck electronics. No communication between the

computer and device is possible during this time.

M017-7450.003 SpindleCheck 1.1 Manual xix

Capacitive Displacement Sensors (X, Y, Z)

The X, Y, and Z Axes each have a separate color-coded capacitive

displacement sensor channel.

X: Blue (Channel 1 on calibration sheet)

Y: Green (Channel 2 on calibration sheet)

Z: Red (Channel 3 on calibration sheet)

Indicator lights are Green when the probe is within its calibrated

range.

The Near or Far light will be Red when the probe is outside of its

calibrated range.

The Near and Far lights will be Blue when the capacitive probe is not

connected.

Sensor System Probes

The system includes four probes: one eddy-current Index probe, and three capacitive

displacement probes for X-, Y-, and Z-Axes.

Capacitive Probes (X, Y, Z)

Noncontact capacitive probes measure the precision target pin as it turns. The probes are

8 mm in diameter, have a total measurment range of 250 µm, and a minimum gap (Near

Gap) of 125 µm.

Calibration sheets and calibration stickers on the back of the electronics housing will list

the specifics of the calibrations. If capacitive probes are damaged, the electronics and

probes must be returned to the factory for probe replacement and recalibration.

Eddy Current Probe (Index)

The eddy-current Index probe provides a once-around

signal to align data for multiple rotations. Its nominal

distance from the target is 0.5 mm (0.02 inch). The tip is

ceramic. Use caution to prevent damage. Replacement probes are available: Part

Number P015-4657.

M017-7450.003 SpindleCheck 1.1 Manual xx

Index Spacer

The Index Spacer is 0.5 mm (0.02 inch) thick and is used to set

the gap between the Index probe and copper plated portion of the

precision target pin.

Replacement Part Number A017-7560.

Probe Nest

The probe nest includes mounting for X, Y, Z probes and an Index probe. An optional

grounding brush (P017-6152) is available. Instructions for grounding brush installation

are in Appendix B.

Adapting Existing Probe Nests

If you have an existing probe nest and want to adapt it to SpindleCheck, you will need to

add an Index Probe Bracket (P017-6157). See Appendix C. You can also add a magnetic

base (P017-6117), see Appendix D.

Table of contents

Popular Measuring Instrument manuals by other brands

SMC Networks

SMC Networks PPA100 Series instruction manual

Avery Weigh-Tronix

Avery Weigh-Tronix M3060 User instructions

Berner

Berner 43345 operating instructions

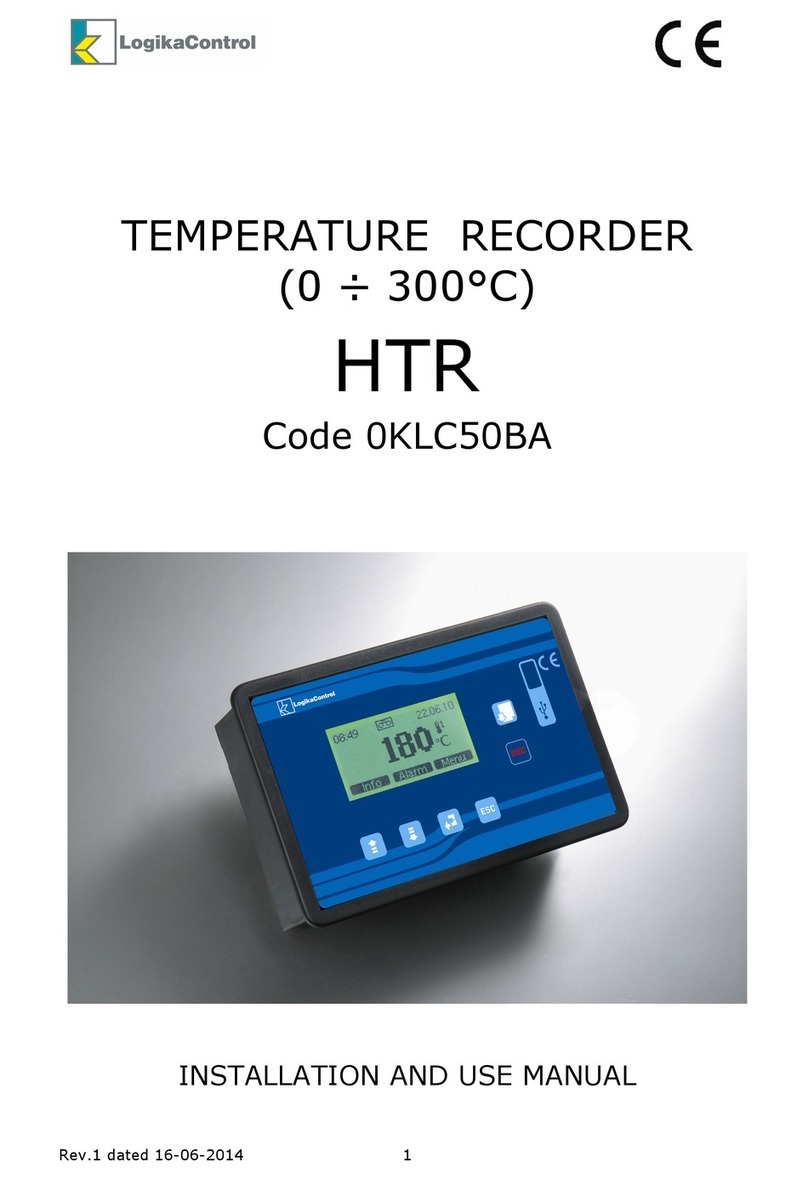

LogikaControl

LogikaControl HTR Installation and use manual

Elcometer

Elcometer 121/2 operating instructions

Klein Tools

Klein Tools CL900 instruction manual