Lipco GSG-AN-VM Setup guide

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

2 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

3 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

Introduction

Dear Customer:

Thank you for choosing a LIPCO Saddle-mount fan unit with tank

trailer GSG-AN-VM. We are confident that you will be satisfied with

our product.

In order to achieve maximum performance from your new LIPCO

Saddle-mount fan unit with tank trailer GSG-AN-VM over an extend-

ed period, please follow the instructions in this operating manual

closely. This will help you to prevent any damage and to prevent

accidents that could result from failure to comply with the manual

and for which LIPCO can assume no liability.

This operating instruction is an essential component of the machine

and therefore must always be included when the machine is sold,

also if it is sold to third parties.

By carefully storing the operating manual in a safe place, both you

and the operator will have a comprehensive reference work at hand.

Note:

The illustrations, descriptions and data contained in this operating

manual are not binding. LIPCO reserves the right to make changes

at any time, without prior notice.

This manual applies only to the LIPCO Saddle-mount fan unit with

tank trailer GSG-AN-VM and does not replace the operating instruc-

tions for components, built-in by the customer.

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

4 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

Table of contents Page

1. Authorized use..........................................................................6

2. Warnings on the machine.........................................................7

3. General safety regulations........................................................8

4. Safety information for handling plant protection agents ...........9

5. Accident prevention ................................................................10

6. Design details of the GSG-AN-VM - standard equipment......11

7. Design details of the GSG-AN-VM - special equipment.........11

8. Advantages of LIPCO tunnel spray technology......................12

9. Technical data GSG-AN-VM...................................................13

10. Design details of the LIPCO tank trailer / standard version....14

11. Technical data tank trailer.......................................................15

12. Components of GSG-AN-VM..................................................16

12.1. Filters ......................................................................................16

12.2. Adjustment of fan row width:...................................................17

12.3. Adjustment of fan distance......................................................18

12.4. Tanks of GSG-AN-VM ............................................................19

12.5. Various valves of GSG-AN-VM:..............................................20

13. Preparation .............................................................................22

14. Attachment to towing vehicle..................................................23

14.1. Information for hydraulic connection.......................................25

15. Attachment of the universal joint shaft....................................27

16. Attaching the LIPCO tank trailer .............................................29

17. Driving on roads with the GSG-AN-VM ..................................30

18. Operating the LIPCO GSG-AN-VM ........................................31

18.1. Determining the amount of spray liquid needed.....................31

18.2. Checking the driving speed.....................................................31

18.3. Calculation of the driving speed..............................................32

18.4. Nozzle selection and output volume.......................................33

18.5. Nozzle chart............................................................................34

18.6. Checking liquid output at the GSG-AN-VM.............................35

18.7. Nozzle adjustment during operation .......................................37

18.8. Spray nozzle adjustment.........................................................38

18.9. Worth knowing about proper nozzle adjustment ....................39

18.10. Adjustment of outer fan .......................................................40

18.11. RPM fan setting...................................................................41

18.12. Recycling unit ......................................................................42

19. Setting the GSG-AN-VM.........................................................45

19.1. Calculation of the spray liquid discharge ................................45

19.2. Calculation of the required plant protection agent/spray ........46

19.3. Sequence for checking the dosing and distribution accuracy of

the GSG-AN-VM.....................................................................47

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

5 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

19.4. Which plant protection agents can be used in the GSG-AN-

VM?.........................................................................................47

20. Procedure of spray test...........................................................48

21. Preparation of spraying liquid .................................................49

22. Emptying the GSG-AN-VM after use......................................52

23. Residual volume .....................................................................53

24. Interruption of spraying process .............................................53

25. Cleaning of GSG-AN-VM after use.........................................55

26. Maintenance ...........................................................................57

27. Machine inspection .................................................................61

27.1. Pressure check .......................................................................61

27.2. Flow rate check.......................................................................61

28. Trouble shooting .....................................................................62

29. Storage of the machine...........................................................64

30. Guarantee...............................................................................66

31. Functional diagram GSG-AN-VM ...........................................67

32. Wiring diagram GSG-AN-VM (hydraulic / electrical)...............68

33. Notes.......................................................................................69

34. EC-Declaration of conformity..................................................71

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

6 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

1. Authorized use

The LIPCO Saddle-mount fan unit with tank trailer GSG-AN-VM with

recycling technology is designed for double-sided spraying of plant

protection agents for vineyards, rose and berry plantations and simi-

lar cultures.

LIPCO-GSGfan units are Julius-Kühn Institute Braunschweig /

Germany (JKI) approved and registered in the list of loss-reducing

devices. For classification and authorized use please refer to actual

folder „Verlustmindernde Geräte“ (www.jki.bund.de/geraete“)

Technical modifications without any written agreement, either by

LIPCO or by JKI, are not allowed. Otherwise LIPCO Saddle-mount

fan unit with tank trailer GSG-AN-VM will lose its classification as

loss-reducing device.

Any other use will be considered as not authorized. The manufactur-

er will not be liable for damages resulting from unauthorized use; the

user will be solely responsible for all risks in this case.

Authorized use also includes compliance with the manufacturer’s

operating, maintenance and repair instructions.

The operator is responsible for compliance with applicable accident

prevention regulations, in addition to the generally recognized safety,

occupational health and traffic safety regulations.

Unauthorized modifications to the LIPCO Saddle-mount fan unit with

tank trailer GSG-AN-VM will release the manufacturer from liability

for resulting damages.

Note for use on public roads

Before driving on public roads and paths, make sure that the combi-

nation of tractor and LIPCO Saddle-mount fan unit with tank trailer

GSG-AN-VM or other combined equipment complies with the appli-

cable traffic regulations (maximum gross weight, maximum axle

loads, lights, warning signs, etc.). It may be necessary to transport

the LIPCO Saddle-mount fan unit with tank trailer GSG-AN-VM on a

flatbed truck.

Note

Following this operating instruction will use the abbreviation

GSG-AN-VM instead of LIPCO Saddle-mount fan unit with tank

trailer GSG-AN-VM.

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

7 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

2. Warnings on the machine

Before operating the machine, always read the oper-

ating manual and comply with all safety instructions!

Always shut off the motor and remove the ignition

key when performing maintenance or repairs!

Danger of parts being catapulted while drive unit is in

operation –maintain safety clearance!

Operate machine only at the specified speed

(max. 540 rpm)!

Danger of poisoning –never climb into container!

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

8 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

3. General safety regulations

The operation of mobile plant protection units is associated with cer-

tain risks. Therefore, you must comply with the following safety regu-

lations:

•Before operating the machine, always read the operating manual

and comply with all safety instructions!

•Never remove or modify safety devices!

•Secure the area beneath the machine for repairs or inspections!

•Switch off the machine prior to performing maintenance or care!

•Always maintain safety clearances!

•Caution! Do not enter the work area while the universal joint shat

is rotating! There is an increased risk of accident in case of con-

tact. For your safety, do not wear loose clothing or accessories

(e.g. scarves)!

•Operate, maintain or repair the GSG-AN-VM only by especially

trained personnel who are aware of the risks involved!

•The operator is responsible for compliance with applicable acci-

dent prevention regulations, in addition to the generally recog-

nized safety, occupational health and traffic safety regulations!

•The warning and information signs on the machine provide im-

portant information for safe operation; compliance with these

warnings will increase your safety!

•Persons not involved must keep out of the work area of the ma-

chine.

•Keep children away from the GSG-AN-VM and spray.

•Operate machine only at the specified speed

(max. 540 rpm)!

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

9 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

4. Safety information for handling plant protection agents

•Do not use plant protection agents that tend to gum up or con-

geal –they have a negative effect on spraying.

•Before applying heat (welding, soldering, etc.) in order to repair

the tunnel spray unit or attachments,

•Clean tunnel spray unit or attachments, which were in contact

with plant protection agent, thoroughly with water, before apply-

ing heat (welding, soldering…)

•Do not remove or modify standard safety devices!

•Replace damaged safety devices by new ones.

•Replace damaged seals and shut-off devices!

•People in contact or working with plant protection agent have to

wear suitable protective clothing against contamination! (e.g.

safety gloves…)

•Always comply with the regulations of the phytosanitary manu-

facturer and of the trade association. AID brochure 1042 (2) pro-

vides information on the safe handling of plant protection agents.

Relevant literature is available by:

Evaluation and information service for nutrition, agriculture and

forestry (AID), P.O. Box 20 02 53, 53173 Bonn.

AID brochure 2079 (1):

Filling of phytosanitary: caution in taking water from the drinking

water supply and public waters.

AID brochure 1042 (2):

Caution in handling herbicides and plant protection agents.

•Do not eat, drink or smoke when working with herbicides and

plant protection agents.

•Wash hands and face thoroughly with soap and water after every

contact with spraying equipment or spray liquid and after com-

pletion of work.

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

10 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

5. Accident prevention

Failure to comply with the simplest basic rules are causing

most accidents occurring during use, maintenance or transport.

Therefore, it is important that all persons involved with use of the

machine are aware of and comply with the following rules:

•In order to achieve maximum performance from the GSG-AN-VM

it must be in proper working condition.

Perform maintenance and repair only by trained people.

•Replacement parts must fulfill the minimum technical specifica-

tions required by the manufacturer! Only use of LIPCO original

replacement parts will fulfill these requirements.

•Before each use, check the trailer hitch bolts on the three-point

mount and all studs and nuts!

•Exercise special caution when using roads or paths, e.g. for turn-

ing the entire tunnel spray unit.

•Always shut off the motor and remove the ignition key when per-

forming maintenance or repairs!

•During work and transport on public road, do not transport ob-

jects or persons on the machine!

•Operate machine only with drive unit fully protected, i.e. univer-

sal joint shaft completely covered and additional protection on

tractor and GSG-AN-VM. Make sure that the universal joint shaft

connections lock securely into place!

•The machine should be on a level surface or a stable support

during all work on the machine!

When working on the machine in raised position, always secure

by mechanical means using suitable supports!

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

11 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

6. Design details of the GSG-AN-VM - standard equipment

•Frame with double-coat paint RAL 6011

•Hydraulic tangential fan unit width adjustment (infinitely variable /

common or single action) with hydraulic cylinder. Operation via

electro-hydraulic control block.

•4 hydraulic driven tangential fans, equipped with collecting tray

and hydro injector for the leading back of the unused liquid - min-

imum operating pressure 5 bar required for suction

•one V4A nozzle tube each integrated in the tangential fans,

with 6 drip-stop rotary nozzle bodies with flat fan venturi nozzles

(IDK 90° green –or other output quantities on request) –individ-

ually adjustable

•pressure (80 mesh), suction (50 mesh) and recycling filter (50

mesh)

•full electrical control: Nozzles, pressure and recycling can be

controlled via control box on tractor, manometer built into control

box

•electro-hydraulic control block for adjustment of fan width and

fan control

•160 l pump, 20 bar

•universal joint shaft

7. Design details of the GSG-AN-VM - special equipment

•Width adjustment 1.30 m instead of 1.10 m

•Odometer system for row width adjustment via control box with

digital display and +/- action

•Working lights between fans (left and right)

•3-way tap with quick-release coupler and 2.50 m hose for exter-

nal suction

•Electrical monitoring unit with digital display (spray output l/min.

and effective spray output in liters)

•Other tires

•Other nozzles

•2 agent-sprayer type BS 2

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

12 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

8. Advantages of LIPCO tunnel spray technology

•The fan design causes a higher spray concentration and there-

fore a more intensive deposition of spray on the plants.

•Natural wind outside the fan have nearly no negative influence

on spraying result.

•Non-deposited spray will be collected in a pan and filtered for re-

use.

•The spray nozzles can be switched on and off depending on the

height of the foliage wall for optimum use of spray.

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

13 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

9. Technical data GSG-AN-VM

GSG-AN-VM

Weight (without trailer)

kg

500

Required drive power

kW

45

Pump type

AR 160 bp

Fan units

no.

4

Row distance - min.

m

1,60

Row width standard:

m

1,70 –2,40

Row width special edition:

m

1,70 –3,20

Row height

m

2,20

Width adjustment

m

0,20 –1,10

Required pump capacity from tractor side

l / min

30

L

m

3,02

B

m

2,04

M

m

2,45

External main dimensions including tank trailer:

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

14 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

10. Design details of the LIPCO tank trailer / standard version

The LIPCO tank trailer is available with following standard equip-

ment:

•frame with double-coat paint RAL 6011

•adjustable drawbar

•600 / 1000 / 1500 liter tank with tank cleaning nozzle and injector

agitator, water jet mechanism integrated in filling screen

•Fresh water container with 3-way tap to change to machine

cleaning integrated

•Hand-washing container

•Hose connection to saddle-mount unit with quick coupling

•12V lighting in accordance with motor vehicle regulations

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

15 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

11. Technical data tank trailer

1000 l Tank

1500 l Tank

Weight (empty)

kg

320

348

Tank width

m

1,14

1,24

Fresh water container

l

Hand washing container

l

Standard tyres

10.0/75-15.3 tt 8 PR

11.5/80-15.3 8 PR

B –Outer dimensions incl. wheels

m

1,24

1,35

L

m

2,30

1,60

H

m

2,30

1,60

Outer dimensions:

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

16 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

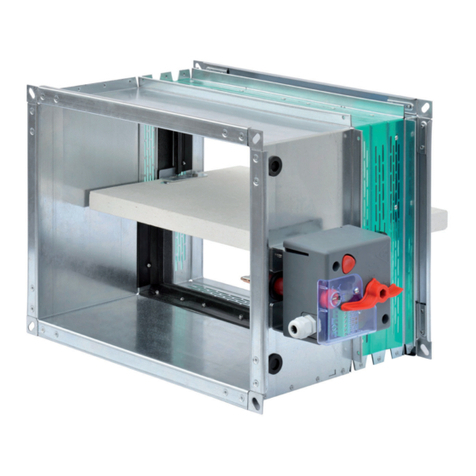

12. Components of GSG-AN-VM

12.1. Filters

Suction filter –50 mesh:

•Suction filter is located bet-

ween spray liquid tank and

pump.

Suction filter

•The filter insert should be

checked several times daily for

dirt and cleaned, if necessary.

Fig. 1

Pressure filter –mesh width 80 mesh:

•The pressure filter is located

between the shutoff motors.

•The quick cleaning unit in low-

er end of the pressure filter is

connected to hydro injector in

tank and permanently pressur-

ized.

Drain valve has to be perma-

nently open.

Fig. 2

•This circuit guarantees an extended cleaning cycle.

•More pressure filters are integrated in the spaying nozzles.

•These nozzles filters should be checked by the end of the spay-

ing procedure and cleaned if necessary.

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

17 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

Pressure filter 2 –mesh width 80 mesh:

•Additional pressure filters in

circuit close to spray nozzles

•The filter inserts must be

checked several times daily

and cleaned, if necessary.

Fig. 3

Recyclingfilter –80 mesh:

•Recycling basket strainer is

integrated in the return circuit

of the recovered spray liquid.

Recycling-/ pressure and suc-

tion filters have to be cleaned

every 20 ha of treated surface.

•Recycling filter designed as

basket strainer, located in the

upper area of the spray liquid

tank.

Fig. 4

12.2. Adjustment of fan row width:

•The row width, with built-in

hydraulics, is adjusted from the

tractor via the control box.

Fig. 5

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

18 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

12.3. Adjustment of fan distance

Hook to adjust chain length

•Fan distance can be adjusted

by reallocating adequate chain.

Fig. 6

•Set the chain to a length, that distance between nozzles and

foliage is about 16 –26 cm. See below.

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

19 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

12.4. Tanks of GSG-AN-VM

Spray liquid tank:

Spray liquid tank

Hand washing tank

Fresh water tank

Fig. 7

•Fill the hand-washing tank only with fresh water. The hand wash-

ing tank is designed only for washing the operator’s hands after

spraying process.

Note:

Do not fill the fresh water tank with spray liquid!

Do not drink from the tank!

Fresh water tank designed for Inside / outside cleaning of GSG-

AN-VM after end of spraying process.

Operating instruction

Saddle-mount fan unit with tank trailer GSG-AN-VM

20 - 72

011170-05-EN BA GSG-AN-VM / 2019-01-16

12.5. Various valves of GSG-AN-VM:

2-way valve “2”

3-way valve “1”

Fig. 8

Function of the 3-way valve (Fig. 8)

•Position: “Suction tank”

Liquid is pumped from the spray liquid tank / fresh water tank to

the nozzles in the tunnel walls.

•Position: “Clean suction filter”

Spray liquid circuit is blocked, suction filter can be removed and

cleaned.

•Position: “Empty tank”

Spray liquid tank can be emptied.

Place the collector beneath the valve and dispose of the collect-

ed spray agent in accordance with JKI BRAUNSCHWEIG (JKI)

regulations.

Function of the 2-way valve (Fig. 8)

•Position: “Machine cleaning”

Pump conveys fresh water from the fresh water tank

through the spray nozzles to the injectors and via the

recycling filter back into the spray liquid tank.

•Position: “Suction tank”

Pump conveys spray liquid from the spray liquid tank

to the spray nozzles.

Table of contents

Popular Fan manuals by other brands

Makita

Makita CF002GZ instruction manual

P.LEMMENS

P.LEMMENS HRup 800 Installation and maintenance manual

Black & Decker

Black & Decker BFSR16B instruction manual

twin city

twin city ES-52 Installation, operation & maintenance manual

Teral

Teral CTFII instruction manual

KDK

KDK 17CQM Operating and installation instructions