Lipco SMD 100 MA User manual

Instructions

Sowing Machine SMD 100/110/120/140..MA

2 - 20

100900-03-EN BA SMD 100_110_120_140 MA / 24.01.2020

1. Introduction

Dear Customer,

We thank you for having chosen a LIPCO Sowing Machine SMD. We

hope that you will be happy with your choice.

In order that your LIPCO Sowing Machine will serve you well for many

years, we ask you to pay close attention to the operating instructions

which you will find in this manual. This will help you to prevent

breakdowns and accidents resulting from non-observance of the

operating instructions, for which our company will not accept

responsibility.

This Instruction and Maintenance Manual is to be considered an

integral part of the machine itself and therefore it must always

accompany the machine when it is sold, even in the event of its sale

to third parties.

If you keep this manual in a safe place and in good condition, you -

and whoever must use the machine - will be able to have a complete

reference on hand at all times.

Note:

The illustrations, descriptions and specifications in this manual are not

binding. LIPCO reserves the right to make modifications without

notice.

Instructions

Sowing Machine SMD 100/110/120/140..MA

3 - 20

2. Contents page

1. Introduction 2

2. Contents 3

3. Designated use 4

4. Warning signs attached to the machine 5

5. Safety regulations 6

6. Accident prevention 7

7. Preparation 9

8. Technical data 10

9. Mounting the Sowing Machine on the Reversing Harrow UFD 11

10. Switching the Sowing Machine on and off 13

11. Seed dosing adjustment 13

12. Determining the seed quantity 14

13. Calculation of the seeding quantity for 1 m²: 14

14. Maintenance 15

15. After use 16

16. Warranty 17

17. Notices 18

18. Declaration of conformity 19

Instructions

Sowing Machine SMD 100/110/120/140..MA

4 - 20

100900-03-EN BA SMD 100_110_120_140 MA / 24.01.2020

3. Designated use

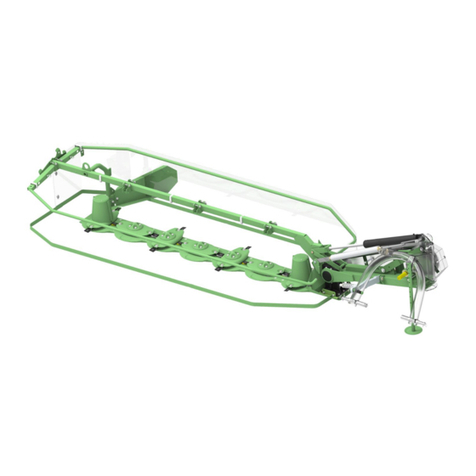

The LIPCO Sowing Machine SMD, when mounted on the LIPCO

Reversing Harrow UFD and connected to (small) tractors, is designed

to be used for sowing seed over the entire area of grassland.

The LIPCO Sowing Machine SMD is not designed to apply plant

protection products or bait.

Any other use for purposes other than those described here is

considered contrary to the designated use. The manufacturer cannot

be held liable for damage resulting from such use; the risk for such

use lies entirely with the user.

Operating the unit within the limits of its designated use also means

following the instructions for operation, transport and maintenance

described by the manufacturer.

Any work, maintenance and repair on the LIPCO Sowing Machine

SMD must be carried out by persons who are familiar with the unit and

have been informed about possible risks!

The relevant accident prevention regulations as well as the other

generally recognised maintenance, safety, industrial medicine and

road traffic rules and instructions must be observed.

The manufacturer cannot be held liable for damage resulting from

unauthorised modifications of the LIPCO Sowing Machine SMD.

•Using public roads and highways

Before using public roads and highways, make sure the

combination of tractor and LIPCO Sowing Machine SMD or the

combination of machines complies with the regulations of the

Road Traffic Act (allowed total weight, allowed axle loads, lighting,

warning signs, etc.). It may be necessary to transport the LIPCO

Sowing Machine SMD on a platform wagon.

Instructions

Sowing Machine SMD 100/110/120/140..MA

5 - 20

4. Warning signs attached to the machine

Before starting operation, the personnel must have

read the operating and safety instructions and must

observe them.

Instructions

Sowing Machine SMD 100/110/120/140..MA

6 - 20

100900-03-EN BA SMD 100_110_120_140 MA / 24.01.2020

5. Safety regulations

The operation of machines with rotating or moving parts always bears

risks. Please always follow the safety regulations:

•Apart from the indications in the operating instructions, the

generally applicable safety and accident prevention regulations

have to be observed.

•Never remove or alter the safety devices.

•Do not touch rotating or moving parts.

•Never lie down under the unit for repair or control purposes when

not carefully secured before.

•Use the Sowing Machine only in perfect condition.

•For maintenance work switch off the unit.

•Attention! Do not enter the working area when the universal joint

shaft is rotating! In case of contact there is an increased risk of

accidents. For your own safety, do not wear wide or loose clothes

(e.g. scarves)!

•Any work, maintenance and repair on the LIPCO Sowing Machine

must be carried out by persons who are familiar with the unit and

have been informed about possible risks!

•The warnings and signs attached to the unit give important

information on safe operation; observing these instructions

ensures your safety!

Instructions

Sowing Machine SMD 100/110/120/140..MA

7 - 20

6. Accident prevention

Most accidents that occur during work, maintenance or transport of a

machine are due to non-observance of the most elementary rules of

accident prevention.

It is, therefore, necessary that all licensed users (relatives, employees,

colleagues) read and observe the rules given below and written on the

adhesive labels of the machine itself:

•Before starting the machine and the tractor, check road and

operating safety!

•Before starting any work on the machine, it should be placed on

level ground! When working with the unit lifted, always ensure

mechanical protection by means of adequate supporting

elements! Turn off the engine and pull the ignition key.

•In order to achieve the highest possible performance of the LIPCO

Sowing Machine SMD, it must always be in perfect condition.

Maintenance or repairs must be carried out by trained persons

only. Spare parts must at least comply with the technical

requirements specified by the manufacturer! This is only

guaranteed for LIPCO original spare parts!

•Switch off the tractor and pull the ignition key before making any

adjustments, carrying out maintenance or cleaning!

•Before each use, fixtures, nuts and screws must be checked to

ensure they are firmly tightened!

•Before attaching the unit to and removing it from the three-point

suspension, place the operating device of the tractor in the

position in which unintentional lifting or lowering is excluded!

•Before starting up, please make sure that no people or animals

are in the vicinity!

•Do not leave the machine running without supervision!

•During service or repair work, make sure that no one can start up

the machine accidentally!

Instructions

Sowing Machine SMD 100/110/120/140..MA

8 - 20

100900-03-EN BA SMD 100_110_120_140 MA / 24.01.2020

•Do not wear wide or loose clothes (e.g. scarves)!

•Do not, for any reason, climb onto the machine during operation!

•In the transport position of the unit, sufficient lateral arresting of

the tractor three-point suspension has to be ensured!

•Do not transport any persons or objects on the attachment unit

during work or transport on the road!

•Do not act with any objects on the machine during operation!

•Never use the machine without the chain protection roller and the

seeding box lid, since these parts provides protection against

rotating machine components!

•When adjusting the Sowing Machine, always turn off the engine-

driven machine observing all safety measures!

Instructions

Sowing Machine SMD 100/110/120/140..MA

9 - 20

7. Preparation

•Make sure that all safety devices are in place and the unit is in

perfect working order!

•Check all screws for tight seat and opening slide for smooth

running!

•Caution! When fastening the Bowden cable, make sure no

squeezing is produced! (Danger of kinking)

Instructions

Sowing Machine SMD 100/110/120/140..MA

10 - 20

100900-03-EN BA SMD 100_110_120_140 MA / 24.01.2020

8. Technical data

Type

Weight

(kg)

Volume

(L)

SMD 100 MA

60

51

SMD 110 MA

66

51

SMD 120 MA

78

60

SMD 140 MA

90

63

Main dimensions

B

L

H

SMD 100 MA

1180

660

540

SMD 110 MA

1280

660

540

SMD 120 MA

1380

660

540

SMD 140 MA

1580

660

540

The dimensions only apply to the sowing machine SMD … MA,

without UFD!

Attention:

As for the trailer loads and semi-trailer loads, the regulations and

instructions by the traction vehicle manufacturer must be adhered to.

Remarks about noise and vibration:

It is not expected, that the values for noise and vibration of these

attachment unit will exceed the values of the engine-driven machine.

Instructions

Sowing Machine SMD 100/110/120/140..MA

11 - 20

9. Mounting the Sowing Machine on the Reversing Harrow UFD

The Sowing Machine is mounted on the LIPCO Reversing Harrow

UFD, i.e. it can be mounted or dismounted easily. The feed brush is

chain-driven.

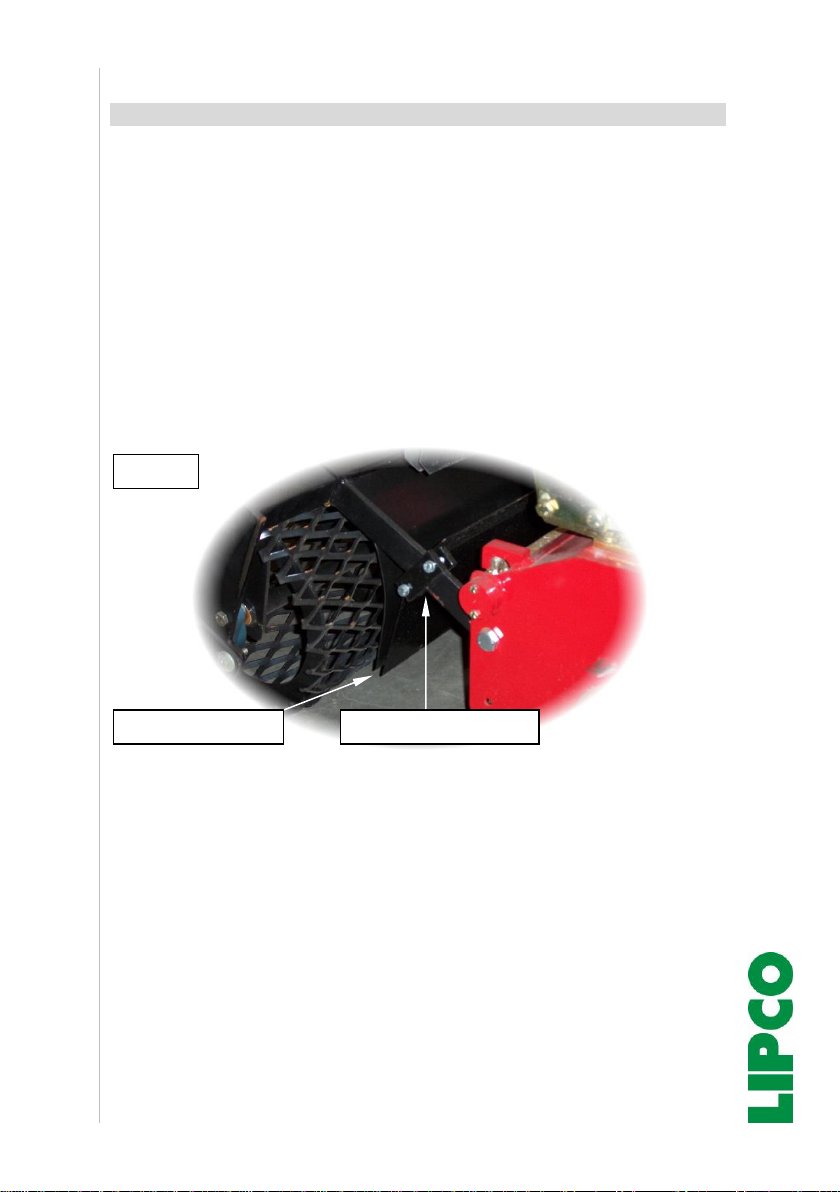

First, the mounting attachment and the protection funnel for the

Sowing Machine must be fixed on the carrier machine. Then place the

sowing machine on the harrow and fasten it with cotter pins.

The sheet metal funnel is mounted to the roller holder by means of the

clamping device. During mounting, make sure the distance between

the roller deflector sheet and the sheet metal funnel for the outlet is

about 5 mm to 10 mm.

Distance 5-10 mm

Fig. 1

Funnel fixture

Instructions

Sowing Machine SMD 100/110/120/140..MA

12 - 20

100900-03-EN BA SMD 100_110_120_140 MA / 24.01.2020

Screw holder onto machine

body of the Reversing

Harrow. Then mount the

Sowing Machine and insert

the safety cotter pins.

(Fig. 2)

Fasten support for the

Bowden cable to the three-

point frame, insert operating

unit and arrest it using the

wing screws.

(Fig. 3)

Fig. 2

Fig. 3

Holder

Holder

Holder

Instructions

Sowing Machine SMD 100/110/120/140..MA

13 - 20

10. Switching the Sowing Machine on and off

Opening and closing by

means of the slide take place

via the Bowden cable on the

Sowing Machine. (Fig. 4)

11. Seed dosing adjustment

The dosing is adjusted via

the dosing disc. (Fig. 5)

Fig. 4

Slide for opening and

closing

Fig. 5

Instructions

Sowing Machine SMD 100/110/120/140..MA

14 - 20

100900-03-EN BA SMD 100_110_120_140 MA / 24.01.2020

12. Determining the seed quantity

•When working on the lifted unit, always ensure mechanical

protection by means of adequate supporting elements!

Switch off the engine and pull the ignition key.

•Before starting the adjustment, the roller should be turned 1-

2 with closed slide, so that the seeds are distributed evenly

on the inner side of the slide.

•Put a suitable container or a film under the unit.

•Open the slide.

•Rotate the roller by 1 turn.

•Weigh the seed and determine the seed quantity using the

conversion factor.

•Adjust the dosage using the dosage disc.

•If necessary, repeat the process and change the slide

position.

13. Calculation of the seeding quantity for 1 m²:

(* The conversion factor

results from the relation

between roller circumference

and hopper width)

Example:

Weighed amount of seed with one turn of the roller of the attachment

unit x conversion factor from the table = actual amount applied per

m².

Type:

Conversion factor

SMD 100 MA

1.06*

SMD 110 MA

0.97*

SMD 120 MA

0.88*

SMD 140 MA

0.76*

Instructions

Sowing Machine SMD 100/110/120/140..MA

15 - 20

14. Maintenance

Steps to be carried out in order to maintain the machine in good

working condition:

•Grease the roller bearings! (Fig. 6)

•The drive chain of the Sowing Machine has to be oiled 2-3 times

a year! (Fig. 7)

•Lubricate the dosage slide after every use!

•Check chain tension! To do so, dismount the chain case (Fig. 7).

•Check smooth running of the Bowden cable! The Bowden cable

has to be cleaned and oiled at least once a year!

Fig. 6

Dismounted chain

case

Fig. 7

Lubricating nipple

Instructions

Sowing Machine SMD 100/110/120/140..MA

16 - 20

100900-03-EN BA SMD 100_110_120_140 MA / 24.01.2020

15. After use

•If the LIPCO Sowing Machine is to remain unused for a longer

period, it is necessary to carry out the following steps:

•Thoroughly wash and dry the LIPCO Sowing Machine!

•Thoroughly check the function of the moving parts, replace any

damaged, worn or deteriorated parts!

•Check all screws for tight seat!

•Clean and oil the Bowden cable!

•Oil all unpainted metal parts to protect them against corrosion!

•Oil dosage slide and chain, lubricate roller support; and then cover

the LIPCO Sowing Machine and store it in a dry place so that it

will be ready for use any time.

•Attention!

Before using the unit again, follow the instructions in chapter "14.

Maintenance".

Instructions

Sowing Machine SMD 100/110/120/140..MA

18 - 20

100900-03-EN BA SMD 100_110_120_140 MA / 24.01.2020

17. Notices

Instructions

Sowing Machine SMD 100/110/120/140..MA

19 - 20

18. Declaration of conformity

Manufacturer: person authorized to compile the

technical files:

LIPCO GmbH

Ingenieurbuero Bauer

Am Fuchsgraben 5b

Scherzinger Weg 46

D-77880 Sasbach

D-79227 Schallstadt

Tel.

+49 7841 6348-0

Tel.

+49 172 7694 903

Fax

+49 7841 6348-300

E-Mail

E-Mail

Web

http://www.lipco.com

Denomination: LIPCO Sowing Machine

SMD 100 MA, 110 MA, 120 MA, 140 MA

Serial no:

Year of manufacture:

The manufacturer declares expressly, that the machinery fulfills all the

relevant provisions of the

•Directive 98/37/CE

To implement the safety and health requirements as stated in the CE

Directive, the following standard(s) and/or technical specification(s) has

(have) been applied:

•EN 1553 4/00, pr EN (144045) 9/97

This declaration of conformity loses its validity, if changes or modifications on

the machine were made, which are not approved in writing before by LIPCO.

Willi Lipp

- Technical director -

Sasbach, 2002.11.30

(Place and date of issue)

(Name, function and signature of responsible)

This manual suits for next models

3

Table of contents

Other Lipco Farm Equipment manuals

Popular Farm Equipment manuals by other brands

SaMASZ

SaMASZ SAMBA 160 Operator's manual

Dhollandia

Dhollandia DH-RPH 33 installation manual

MacDon

MacDon A40-D Unloading and assembly instructions

MacDon

MacDon M2170 Unloading and assembly instructions

Greenbroz

Greenbroz 215 CannaGin Destemmer user manual

MECHANICAL TRANSPLANTER

MECHANICAL TRANSPLANTER 5500WD Assembly and operators manual

BVL

BVL V-COMFORT Bedding operating manual

LELY

LELY Hibiscus 745 CD Vario Operator's manual

KW Cages

KW Cages Pro Pig 3952 Assembly instructions

GREAT PLAINS

GREAT PLAINS 2400TM Adjustment guide

breviglieri

breviglieri MekFarmer 170 Operating and maintenance manual

Gaspardo

Gaspardo ALITALIA Use and maintenance