3. Designated use

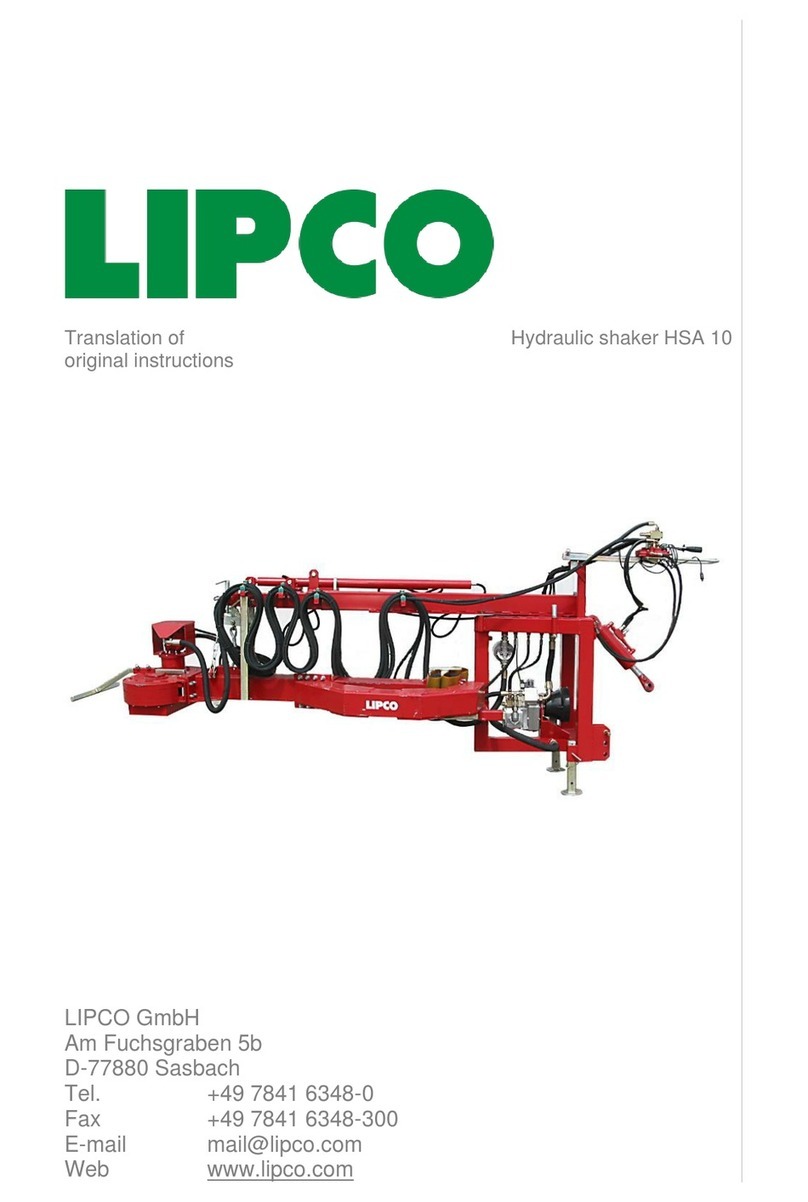

The LIPCO hydraulic shaker HSA 30, when connected to a tractor, is

designed for hydraulic shaking of fruit and other crop trees.

Because of his modularly design, the LIPCO hydraulic shaker can be

used for front and rear attachment.

Any other use for purposes other than those described here is not

according the designated use. Do not held the manufacturer liable

for damage resulting from such use; the risk for such use lies entirely

with the user.

Operating the unit within the limits of its designated use also means

following the instructions for operation, transport and maintenance

described by the manufacturer.

Persons who are familiar with the unit and informed about possible

risks must carry out any work, maintenance and repair on the LIPCO

hydraulic shaker HSA 30.

Please observe the relevant accident prevention regulations as well

as the other generally recognized maintenance, safety, industrial

medicine and road traffic rules and instructions.

The manufacturer cannot held liable for damage resulting from unau-

thorized modifications of the LIPCO hydraulic shaker HSA 30.

•Note for use on public roads

Before driving on public roads and paths, make sure that the

combination of tractor and LIPCO hydraulic shaker HSA 30 or

other combined equipment complies with the applicable traffic

regulations (maximum gross weight, maximum axle loads, lights,

warning signs, etc.). It may be necessary to transport the LIPCO

hydraulic shaker HSA 30 on a flatbed truck.

•Note

The LIPCO hydraulic shaker HSA 30 is also referred to in this

operating manual only as LIPCO-HSA.