Lipco UKD-S Series User manual

Operating instructions Multipurpose Gyration Harrow Type UKD-L

90/110/125/140/155

Multipurpose Gyration Harrow Type UKD-S

130/150/190

LIPCO GmbH

Am Fuchsgraben 5b

D-77880 Sasbach

Tel. +49 (0) 7841 6068-0

Fax +49 (0) 7841 6068-10

email mail@lipco.com

Internet http://www.lipco.com/

UKD heavy

Version

UKD light

Version

Operating instructions Multipurpose Gyration Harrow UKD L/S

2 - 28 06.07.2004 / 00

Operating instructions Multipurpose Gyration Harrow UKD L/S

3 - 28 06.07.2004 / 00

Introduction

Dear Customer,

We thank you for having chosen a L

LI

IP

PC

CO

OM

Mu

ul

lt

ti

ip

pu

ur

rp

po

os

se

eG

Gy

yr

ra

at

ti

io

on

n

H

Ha

ar

rr

ro

ow

w.We hope that you will be happy with your choice.

In order that your L

LI

IP

PC

CO

OM

Mu

ul

lt

ti

ip

pu

ur

rp

po

os

se

eG

Gy

yr

ra

at

ti

io

on

nH

Ha

ar

rr

ro

ow

wT

Ty

yp

pe

eU

UK

KD

D

will serve you well for many years, we ask you to pay close attention

to the Operating instructions which you will find in this manual. This

will help you to prevent breakdowns and accidents resulting from

non-observance of the operating instructions, for which our company

will not accept responsibility.

This Instruction and Maintenance Manual is to be considered an

integral part of the machine itself and therefore it must always

accompany the machine when it is sold, even in the event of its sale

to third parties.

If you keep this manual in a safe place and in good condition, you -

and whoever must use the machine - will be able to have a complete

reference on hand at all time.

Note:

The illustrations, descriptions and specifications in this manual are

not binding. L

LI

IP

PC

CO

Oreserves the right to make modifications without

notice.

Operating instructions Multipurpose Gyration Harrow UKD L/S

4 - 28 06.07.2004 / 00

1. Designated Use 5

2. Warning signs attached to the machine 6

3. Safety regulations 8

4. Accident prevention 10

5. Construction features 12

6. Preparation 13

7. Technical Data 14

8. Connection of the machine to the tractor 17

9. Connecting the universal joint shaft 18

10. Adjustment of working depth 20

11. Maintenance of the machine 22

12. Replacement of tines 24

13. After use 24

14. Guarantee 26

15. EC Declaration of Conformity 27

Contents Page

Operating instructions Multipurpose Gyration Harrow UKD L/S

5 - 28 06.07.2004 / 00

The L

LI

IP

PC

CO

OM

Mu

ul

lt

ti

ip

pu

ur

rp

po

os

se

eG

Gy

yr

ra

at

ti

io

on

nH

Ha

ar

rr

ro

ow

wU

UK

KD

D, when connected to

any type of engine-driven machine from 10 to 35 kW, is designed to

till and level the ground in a single operation, thus preparing it for

seeding.

Any other use for purposes other than those described here is

considered contrary to the designated use. The manufacturer cannot

be held liable for damage resulting from such use; the risk for such

use lies entirely with the user.

Operating the unit within the limits of its designated use also means

following the instructions for operation, transport and maintenance

described by the manufacturer.

Any work, maintenance and repair on the L

LI

IP

PC

CO

OM

Mu

ul

lt

ti

ip

pu

ur

rp

po

os

se

e

G

Gy

yr

ra

at

ti

io

on

nH

Ha

ar

rr

ro

ow

wU

UK

KD

Dmust be carried out by persons who are

familiar with the unit and have been informed about possible risks!

The relevant accident prevention regulations as well as the other

generally recognised maintenance, safety, industrial medicine and

road traffic rules and instructions must be observed.

The manufacturer cannot be held liable for damage resulting from

unauthorised modifications of the L

LI

IP

PC

CO

OM

Mu

ul

lt

ti

ip

pu

ur

rp

po

os

se

eG

Gy

yr

ra

at

ti

io

on

n

H

Ha

ar

rr

ro

ow

wU

UK

KD

D.

•Using public roads and highways

Before using public roads and highways, make sure the

combination of tractor and L

LI

IP

PC

CO

OM

Mu

ul

lt

ti

ip

pu

ur

rp

po

os

se

eG

Gy

yr

ra

at

ti

io

on

nH

Ha

ar

rr

ro

ow

w

U

UK

KD

Dor the combination of machines complies with the

regulations of the Road Traffic Act (allowed total weight, allowed

axle loads, lighting, warning signs, etc.). It may be necessary to

transport the L

LI

IP

PC

CO

OM

Mu

ul

lt

ti

ip

pu

ur

rp

po

os

se

eG

Gy

yr

ra

at

ti

io

on

nH

Ha

ar

rr

ro

ow

wU

UK

KD

Don a

platform wagon.

1. Designated Use

Operating instructions Multipurpose Gyration Harrow UKD L/S

6 - 28 06.07.2004 / 00

2. Warning signs attached to the machine

Before starting operation, the personnel must have

read the operating and safety instructions and must

observe them.

When operating the hydraulic lift, stay outside the

lifting range of the three-point suspension.

Never reach between the rotating propeller shaft.

Before commencing maintenance and repair work,

switch off the engine and pull the key.

Do not exceed the prescribed speed (540 rpm) when

operating the unit!

Operating instructions Multipurpose Gyration Harrow UKD L/S

7 - 28 06.07.2004 / 00

Do not climb onto the machine while the engine is

running.

With the drive switched on and the tractor engine

running, maintain sufficient distance to rotating tools.

Operating instructions Multipurpose Gyration Harrow UKD L/S

8 - 28 06.07.2004 / 00

3. Safety regulations

The operation of machines containing rotating or moving tools

always bears risks. Please always follow the safety regulations:

•Before starting operation, the personnel must have read the

operating and safety instructions and observe them.

•Never remove or alter the safety devices!

•Do not touch rotating or moving parts!

•Never lie down beneath the unit for repair or control purposes

when the unit has not been carefully secured beforehand!

•Only use universal joint shafts in perfect condition and with

overload protection!

•For maintenance work switch off the device!

•Do not exceed the prescribed speed (540 rpm) when operating

the unit!

•Keep to the safety distance! (Attach danger sign on the side of

the machine)

•Attention!

Do not enter the working area when the universal joint shaft

is rotating! In case of contact there is an increased risk of

accidents. For your own safety, do not wear wide or loose

clothes (e.g. scarves)!

•Any work, maintenance and repair on the L

LI

IP

PC

CO

OM

Mu

ul

lt

ti

ip

pu

ur

rp

po

os

se

e

G

Gy

yr

ra

at

ti

io

on

nH

Ha

ar

rr

ro

ow

wmust be carried out by persons who are familiar

with the unit and have been informed about possible risks!

Operating instructions Multipurpose Gyration Harrow UKD L/S

9 - 28 06.07.2004 / 00

•The relevant accident prevention regulations as well as the other

generally recognised maintenance, safety, industrial medicine

and road traffic rules and instructions must be observed.

•The warnings and signs attached to the unit give important

information on safe operation; observing these instructions

ensures your safety!

•Persons that are not involved are not allowed to stay in the

working area of the machine.

•Machine clogging may only be eliminated with the machine in

the switched-off and secured state. This must be done by using

suitable means of worker protection.

•Never climb on to the running machine.

Operating instructions Multipurpose Gyration Harrow UKD L/S

10 - 28 06.07.2004 / 00

4. Accident prevention

Most accidents that occur during work, maintenance or transport of a

machine are due to non-observance of the most elementary rules of

accident prevention.

It is, therefore, necessary that all licensed users (relatives,

employees, colleagues) read and observe the rules that follow

below:

•Turn off the universal joint shaft and the motor of the tractor

before carrying out any adjustments, maintenance or cleaning!

•In order to achieve the highest possible performance of the

L

LI

IP

PC

CO

OM

Mu

ul

lt

ti

ip

pu

ur

rp

po

os

se

eG

Gy

yr

ra

at

ti

io

on

nH

Ha

ar

rr

ro

ow

w, it must always be in

perfect condition. Maintenance or repairs must be carried out by

trained persons only. Spare parts must at least comply with the

technical requirements specified by the manufacturer! This is

only guaranteed for L

LI

IP

PC

CO

Oo

or

ri

ig

gi

in

na

al

ls

sp

pa

ar

re

ep

pa

ar

rt

ts

s!

•Before each use, the suspension bolts of the three-point

suspension and the nuts and screws, especially those of the

tines, must be checked to ensure they are firmly tightened!

•Before starting up, please make sure that no people or animals

are in the vicinity!

•Take special caution when working alongside roads or pathways!

•Do not leave the machine running without supervision!

•Before commencing maintenance and repair work, switch off the

engine and pull the key!

Operating instructions Multipurpose Gyration Harrow UKD L/S

11 - 28 06.07.2004 / 00

•Do not wear wide or loose clothes (e.g. scarves)!

•Do not transport any persons or objects on the machine during

work or transport on the road!

•Only work with completely protected drive, i.e. joint shaft with

complete shaft protection and supplementary protection on

tractor and unit. Make sure the joint shaft connections engage

safely!

•Attach the holding chain of the joint shaft in order to avoid a

rotation of the joint shaft protection.

•Do not, for any reason, climb onto the machine during operation!

•Do not act with any objects on the machine during operation!

•Never use the machine without the roller, levelling plate and

side panes, since these provide protection to the machine

against rotating tools!

•When adjusting the levelling plate and the rollers, always turn

off the tractor engine and carry out such adjustments in

conditions of absolute safety!

•Prior to any work on the machine, it should be placed on level

and solid ground or on a stable support! When working with the

unit lifted, always secure the unit mechanically by means of

adequate supporting elements!

Operating instructions Multipurpose Gyration Harrow UKD L/S

12 - 28 06.07.2004 / 00

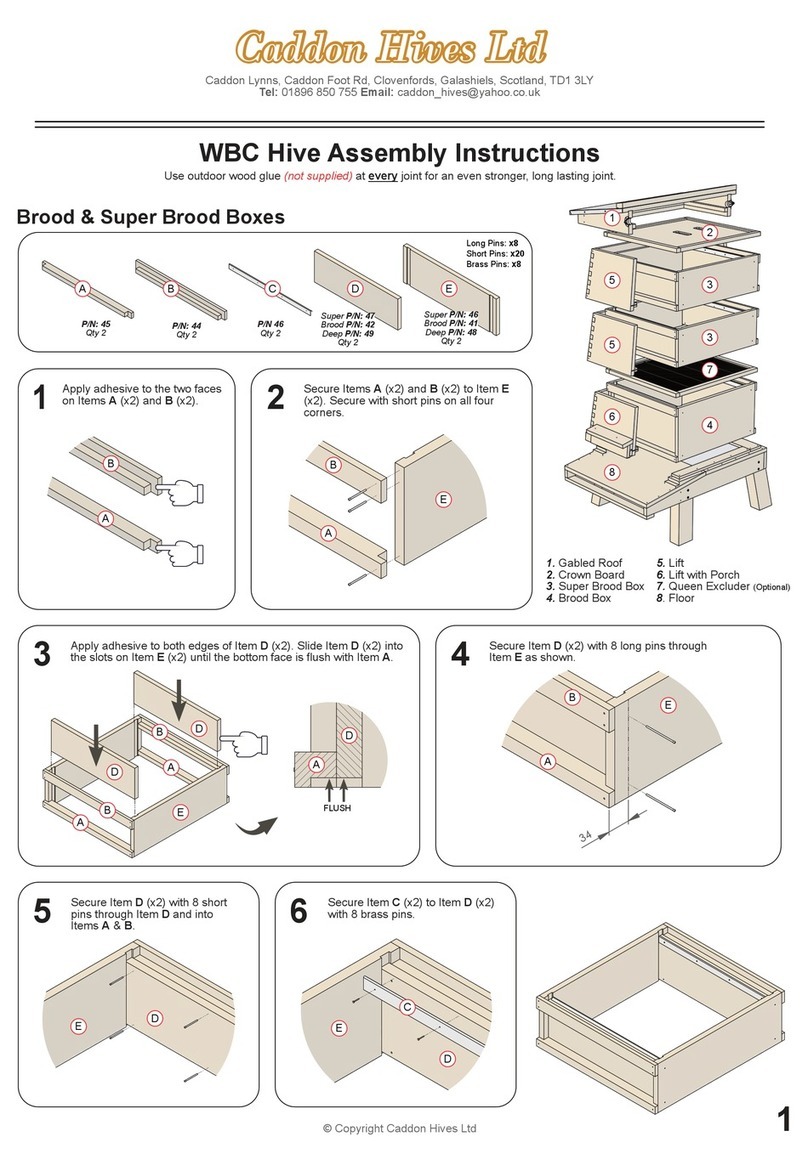

5. Construction features

The L

LI

IP

PC

CO

OM

Mu

ul

lt

ti

ip

pu

ur

rp

po

os

se

eG

Gy

yr

ra

at

ti

io

on

nH

Ha

ar

rr

ro

ow

wis the only machine that,

when connected to any type of engine-driven machine from 10 to 35

kW, is capable of tilling, levelling, and preparing the earth for

seeding in a single operation.

As shown in Fig. 1, the L

LI

IP

PC

CO

OM

Mu

ul

lt

ti

ip

pu

ur

rp

po

os

se

eG

Gy

yr

ra

at

ti

io

on

nH

Ha

ar

rr

ro

ow

wis

equipped with a height-adjustable levelling plate (A) for levelling the

earth. The rotating harrow (B) serves for crumbling the earth. Roller

(C) makes it possible to adjust the working depth of the rotating

harrow and to ram the earth.

Fig. 1

AB

C

Operating instructions Multipurpose Gyration Harrow UKD L/S

13 - 28 06.07.2004 / 00

6. Preparation

•Before using the unit, check whether all accident protection

devices on tractor, machine and joint shaft are attached

correctly and are in functioning order. Before operating the unit,

it is imperative to replace or install damaged or missing

components!

•Attention!

Use only universal joint shafts with overload protection

device! (Standard equipment includes a 1600 Nm shear pin

coupling)

•Check oil level (see chapter "11. Maintenance")

•Make sure that all screws are tightened and all elements are in

perfect working order.

Operating instructions Multipurpose Gyration Harrow UKD L/S

14 - 28 06.07.2004 / 00

7. Technical Data

Light Version incl. grid roller and levelling plate

Type: Weight

(kg) Rrequired

power (kW) Number

of tines

(pcs.)

UKD-L 90 140 10.5 10

UKD-L 110 155 13.5 12

UKD-L 125 185 15 14

UKD-L 140 210 18.5 16

UKD-L 155 220 22 18

Main dimensions

L B H

UKD-L 90 945 1050 880

UKD-L 110 945 1250 880

UKD-L 125 945 1400 880

UKD-L 140 945 1550 880

UKD-L 155 945 1700 880

Operating instructions Multipurpose Gyration Harrow UKD L/S

15 - 28 06.07.2004 / 00

Heavy Version incl. grid roller and levelling plate

Type: Weight

(kg) Required

power (kW) Number

of tines (pcs.)

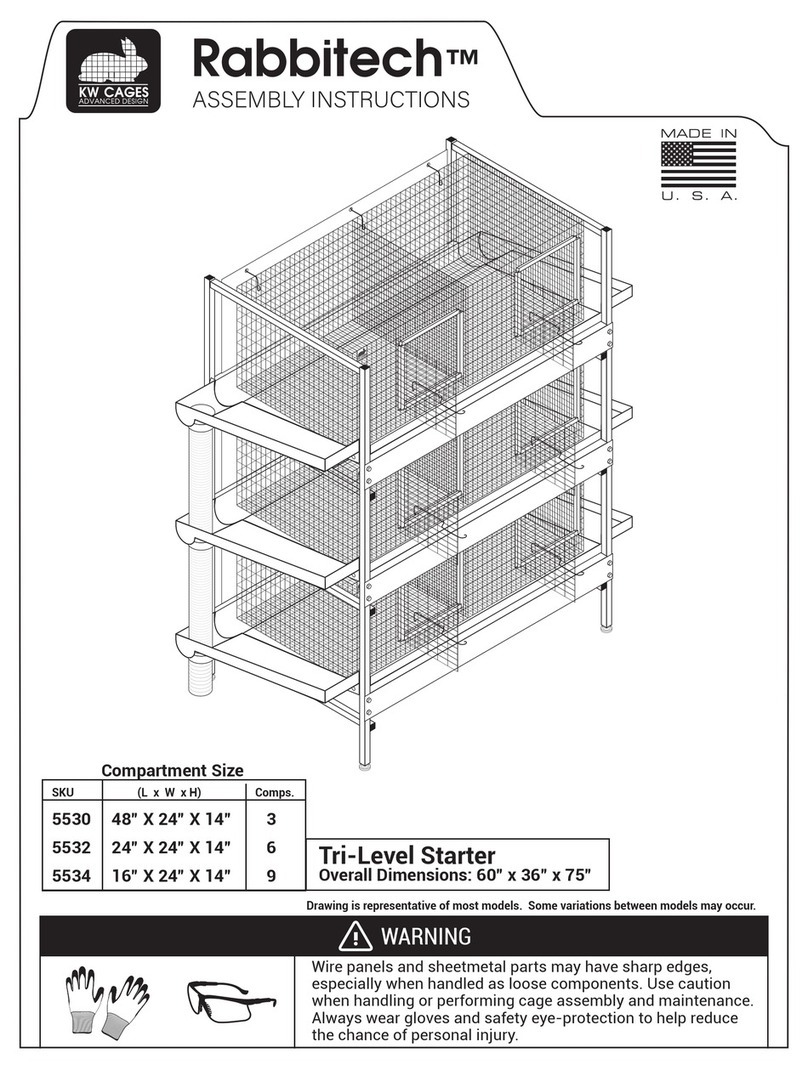

UKD-S 130 390 22 12

UKD-S 150 420 30 14

UKD-S 190 550 35 18

Heavy version incl. cage drum roller without levelling plate

Type: Weight

(kg) Required

power (kW) Number

of tines (pcs.)

UKD-S 130 340 22 12

UKD-S 150 355 30 14

UKD-S 190 470 35 18

Main dimensions

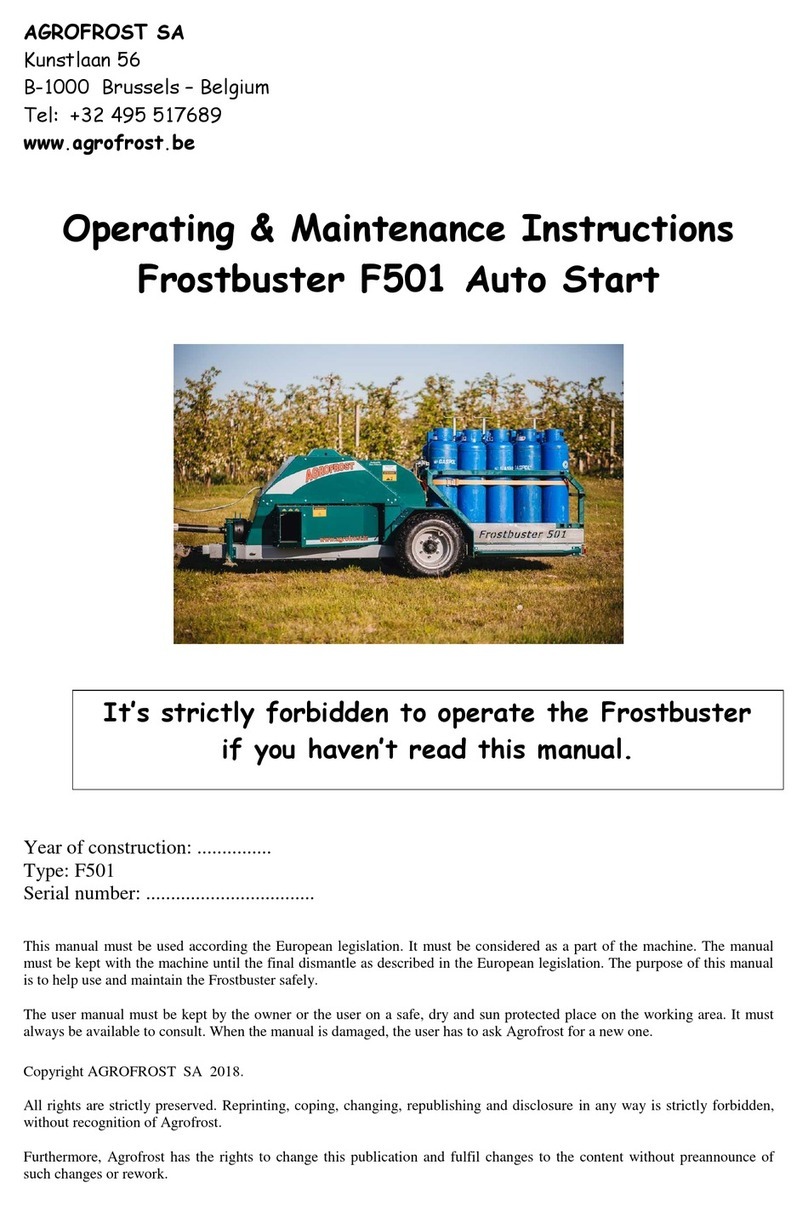

The above pictures show the machine with mounted sowing machine SMD-EA

Sowing machine is not included in the delivery!!

LB H

UKD-S 130 1220 1545 1050

UKD-S 150 1220 1745 1050

UKD-S 190 1220 2145 1050

Main dimensions apply to version incl. grid roller or cage drum roller.

Operating instructions Multipurpose Gyration Harrow UKD L/S

16 - 28 06.07.2004 / 00

Attention:

As for the trailer loads and semi-trailer loads, the regulations

and instructions by the traction vehicle manufacturer must be

adhered to.

Operating instructions Multipurpose Gyration Harrow UKD L/S

17 - 28 06.07.2004 / 00

8. Connection of the machine to the tractor

•Before starting the machine and the tractor, check road and

operating safety!

•Persons must never be allowed to stand between the tractor and

the attachment unit without having secured the vehicle against

rolling away by means of the locking brake and / or wheel cocks!

•Never stay in the rotating and pivoting area of the unit!

•Before attaching and removing the Gyration Harrow to the three-

point suspension, place the operating device in the position in

which unintentional lifting and lowering is excluded!

•In the transport position of the unit, sufficient lateral arresting of

the tractor three-point suspension has to be ensured, in order to

avoid lateral swing-out of the machine!

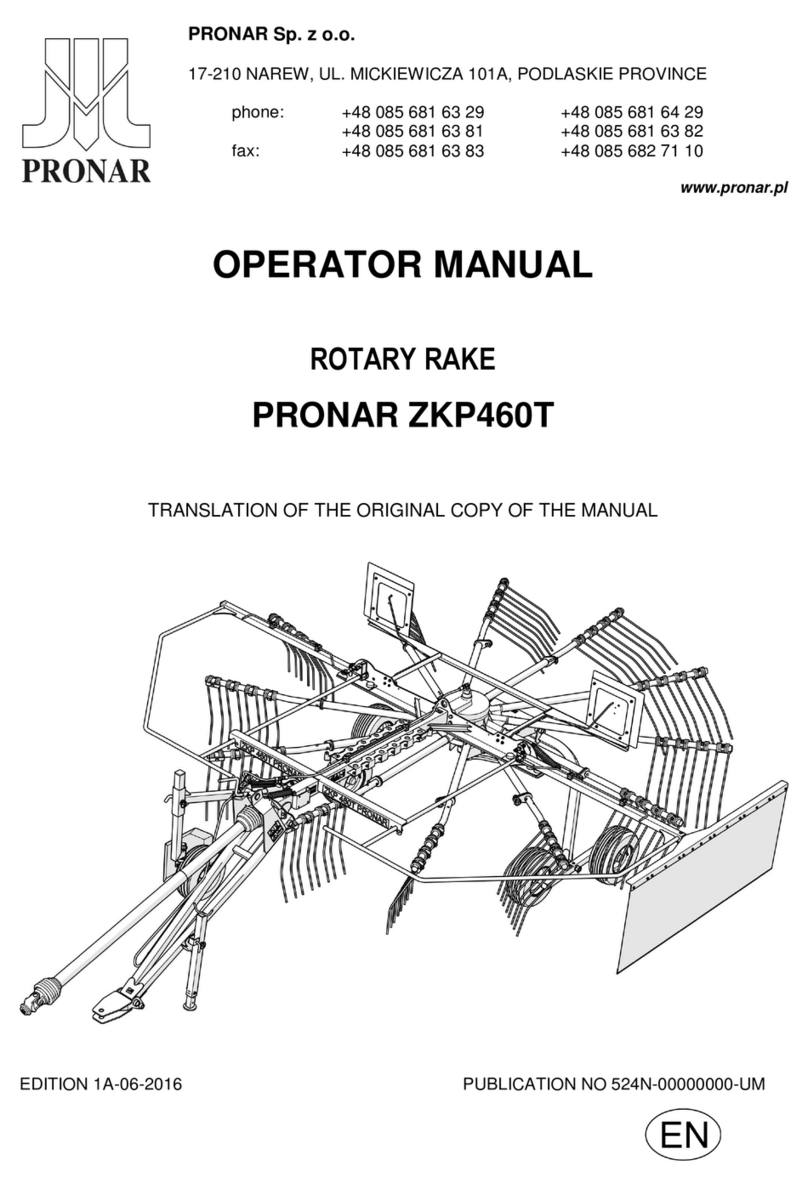

•Adjust the working position / inclination of the machine (Fig. 2,

Ref. B) by means of the compression link (Fig. 2, Ref. A).

Fig. 2

Operating instructions Multipurpose Gyration Harrow UKD L/S

18 - 28 06.07.2004 / 00

9. Connecting the universal joint shaft

•When the unit has been coupled to the tractor, check the exact

length of the universal joint shaft.

Very important:

Highest possible overlapping has to be aimed at. During

operation, the maximum extension of the joint shaft should

be half the overlapping distance of the sliding profile.

(Fig. 3)

When connecting to different tractors, the length has to be

checked again!

•Press sliding pin and push the joint shaft onto the power take-off

shaft until the sliding pin engages! (Fig. 4)

Fig. 4

Fig. 3

Operating instructions Multipurpose Gyration Harrow UKD L/S

19 - 28 06.07.2004 / 00

•This tractor symbol indicates the tractor side of the joint shaft.

Always attach the overload protection on machine side!

•Lubricate joint shaft prior to startup,

see lubrication plan! (Fig. 5)

•Attach the holding chain so that a sufficient pivoting area of the

universal joint shaft is guaranteed in all operating positions.

Never use the holding chain to suspend the universal joint shaft!

•For your own safety, replace the safety devices if they are

damaged or worn. When the machine is not in use, the universal

joint shaft can be hung in the bracket provided for protection!

•Make sure that when you mount the universal joint shaft on the

machine, the unit protective cover overlaps the joint shaft

protection in all operating positions!

•Attention!

Only use joint shaft types prescribed by the manufacturer!

(Standard delivery includes shear pin coupling Fig. 6)

Fig. 5

Fig. 6 Shear pin

Operating instructions Multipurpose Gyration Harrow UKD L/S

20 - 28 06.07.2004 / 00

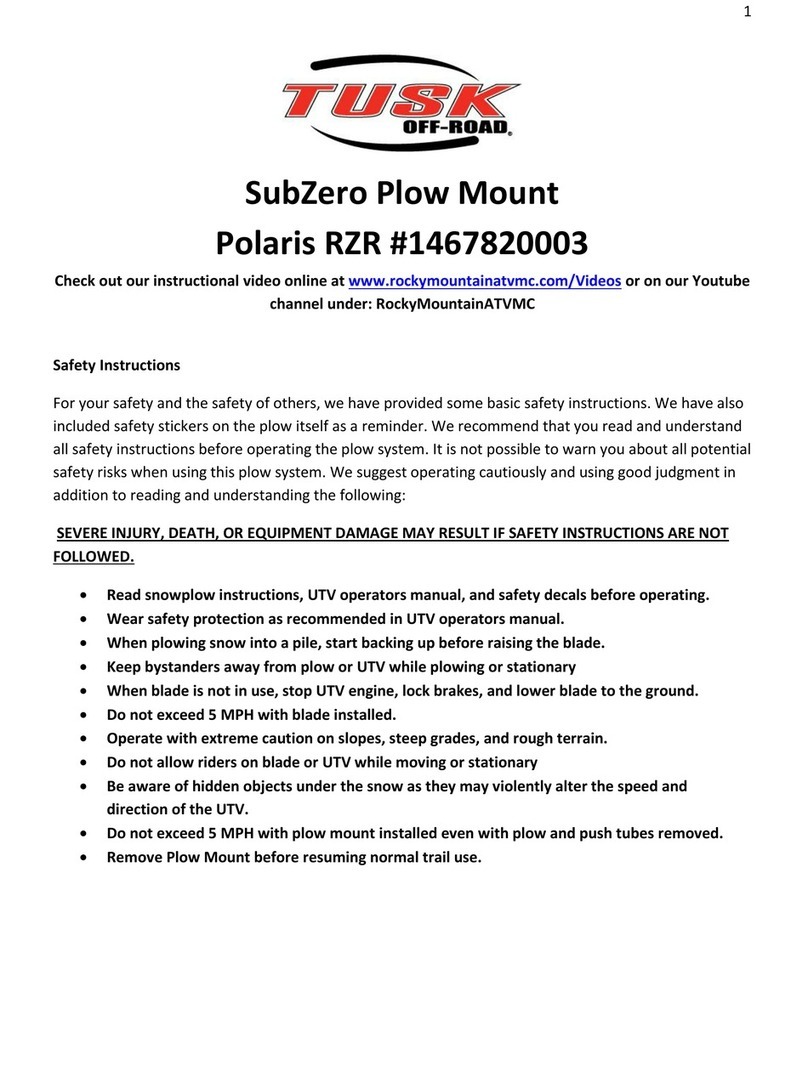

10. Adjustment of working depth

Rotate the adjustment spindle to set the desired working depth.. For

machines equipped with adjustment rod, the working depth is

adjusted by repositioning the linch pin on the adjustment rod (Figs. 7

+ 8). This pin is inserted into the desired hole on the adjustment rod.

It is possible to vary the working depth from 0 to 14 cm. It is

important for the machine to rest on its roller while working.

UKD-S adjustment spindle,

heavy version

Fig. 7

Fig. 8

adjustment spindle for

UKD-L 125/ -140/ -155

Adjustment rod for

UKD-L 90/ -100

This manual suits for next models

9

Table of contents

Other Lipco Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Checchi & Magli

Checchi & Magli WOLF Use and maintenance manual

John Shearer

John Shearer 3.0 Pasture Tyne Drill Operator's manual

PEUGEOT

PEUGEOT ELIS SENSE 27179 manual

Tusk

Tusk SubZero Polaris RZR quick start guide

American Eagle

American Eagle AE-T12S operating instructions

Case

Case AXIAL-FLOW 7230 Tier 4a Operator's manual