Installation manual Konstanz DC 1/25 Version 8.0 Last update: 2/15/10

Key word directory.......................................................................................................…. 1

Pre-conditions.............................................................................................................….. 2

Transport and interim storage...................................................................................…… 3

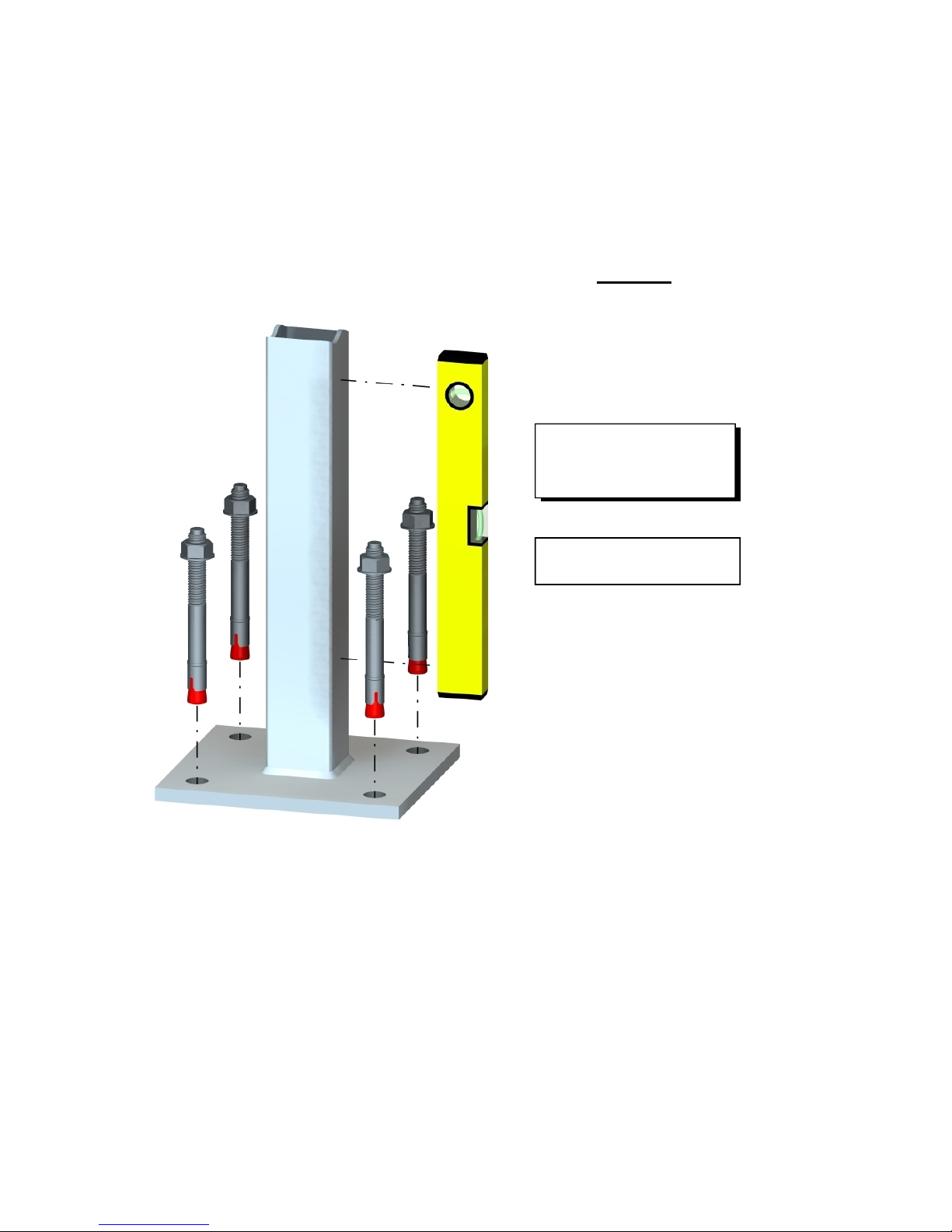

Setting supports ...........................................................................................................… 3

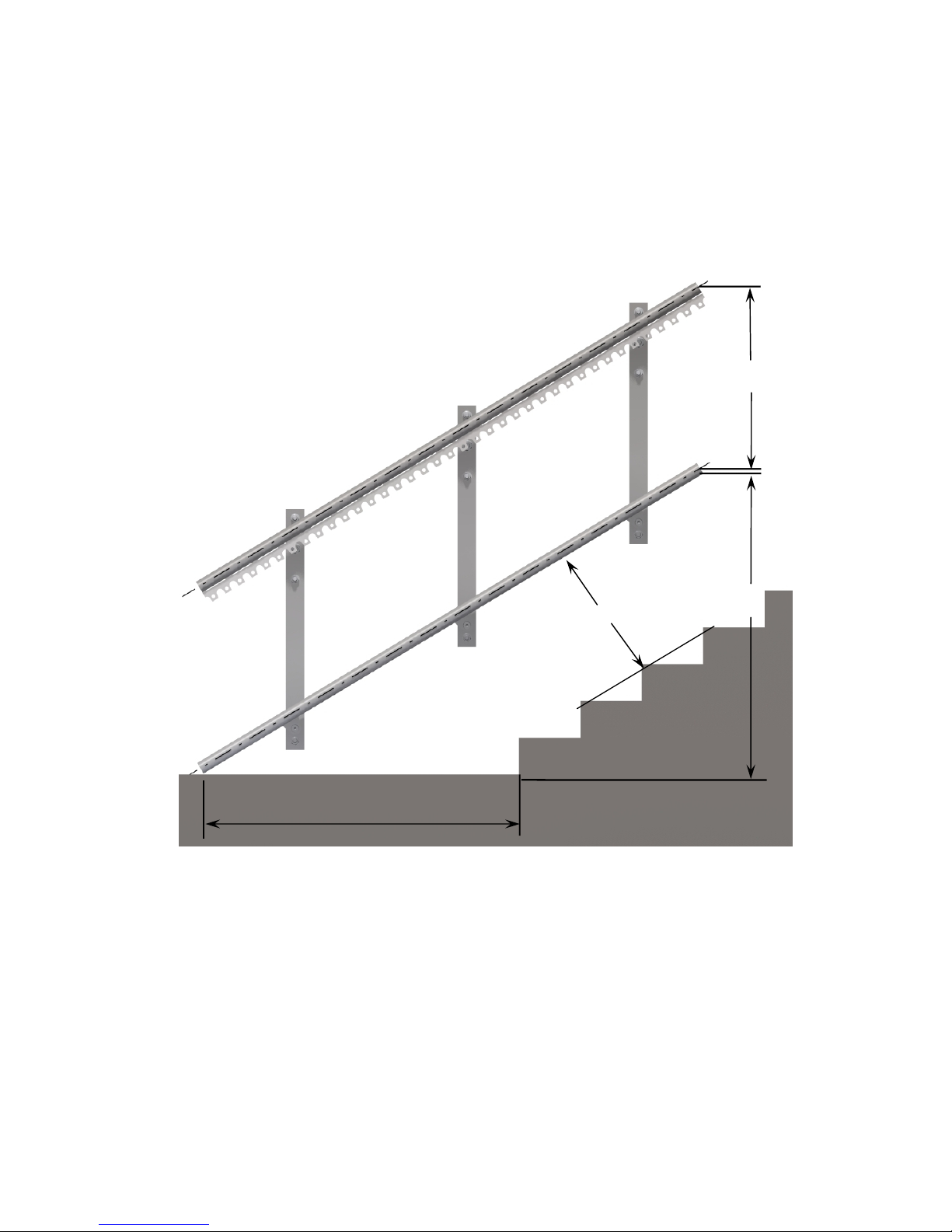

Setting up track....................................................................................................…….. 4

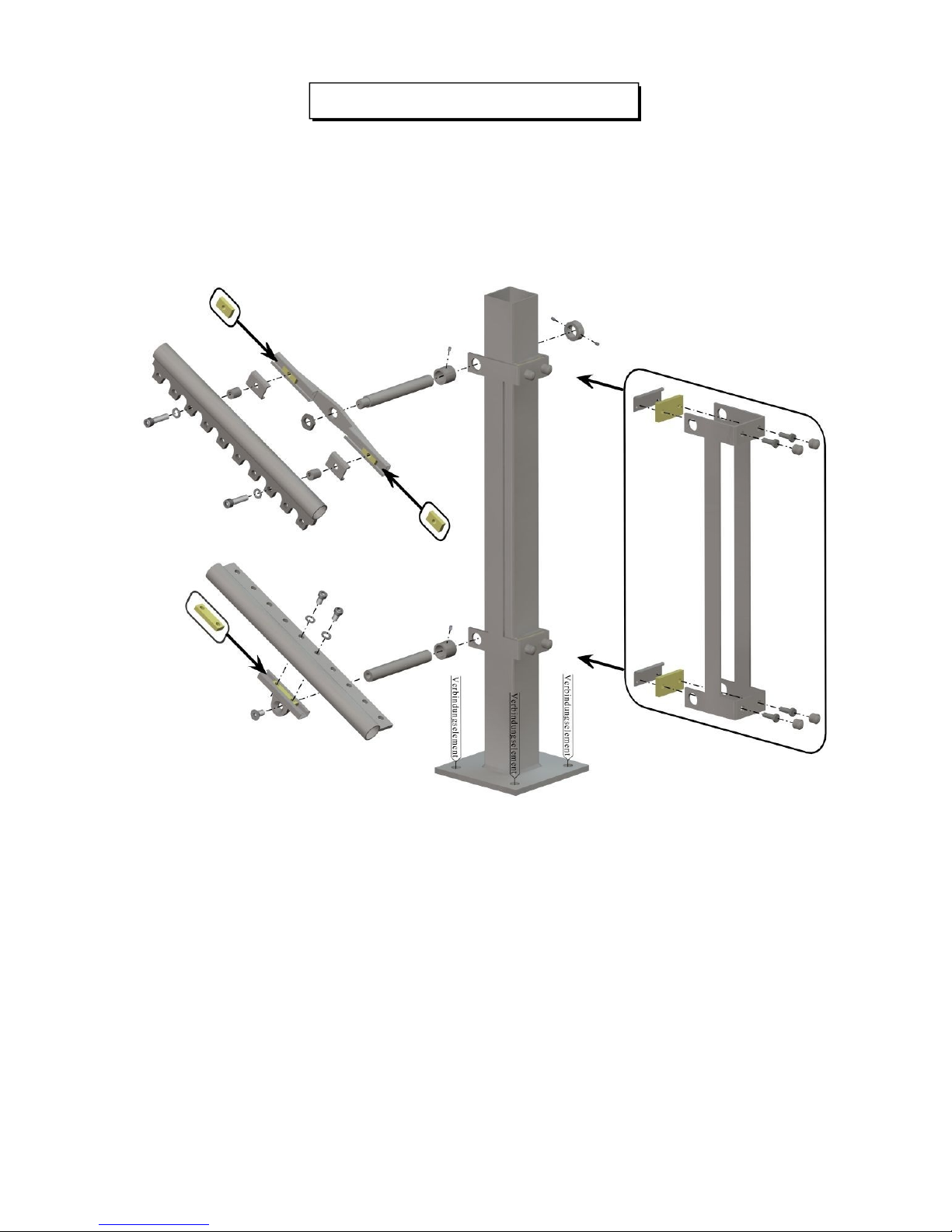

Fastening of track supports......................................................................................…. 5

Example of upper and lower stopping points .............................................................. 6

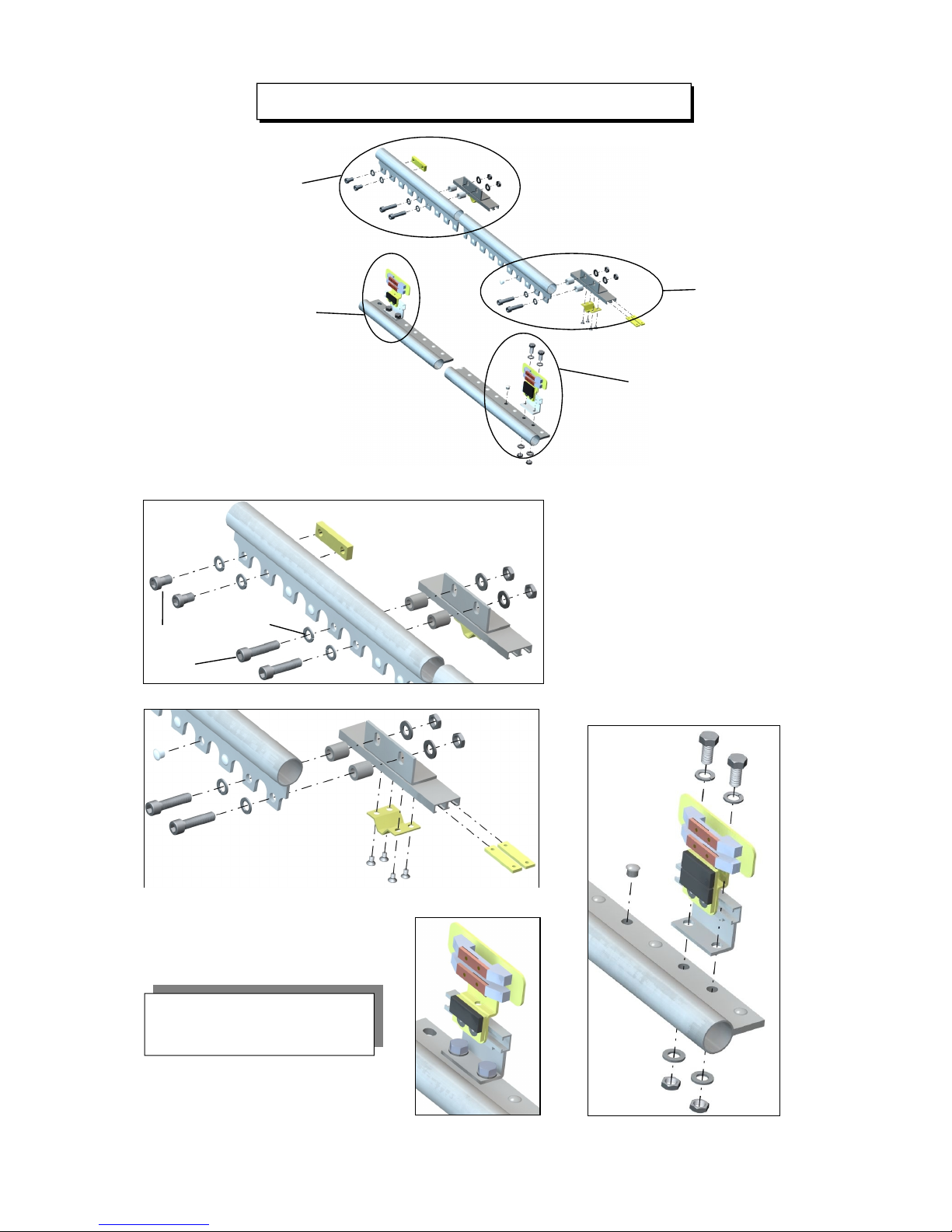

Fastening of track wall (concrete (B25), steel, other)..................................………… 7

Fastening of the Halfen track-wall...........................................................................…. 8

Rotate roller heads, drive the track to the platform...................................................…… 9

Connect track parts with one another....................................................................….. 10

Potential equalization....................................................................................................... 11

External command giver................................................................................................... 11

Loading devices................................................................................................................. 11

Set stopping points...................................................................................................…... 13

Overrun fuse........................................................................................................……… 14

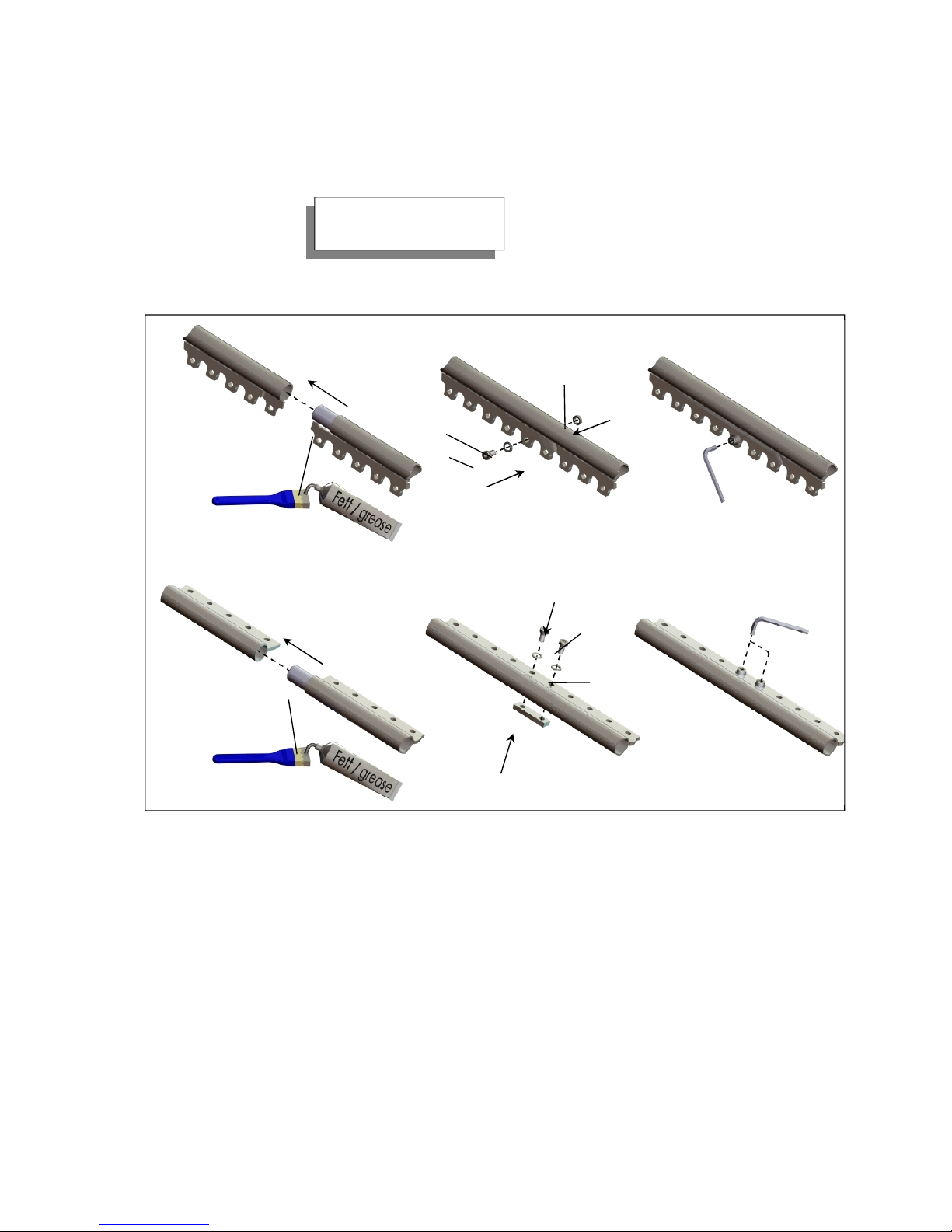

Screwing of the roller sets.....................................................................................……. 14

Sensitive surfaces under the platform frame.................................................................… 15

Track paneling and fall protection…..............................................................………….. 16

Shunt switch bar..............................................................................................………… 17

Concluding work and instruction of the operator ........................................……………. 17

Disassembly...................................................................................................................... 18

Notes about disposal........................................................................................................ 18

Appendix I: Maximal dimensions for assembly........................................................... 19

Appendix II: Free-standing supports (on the foundation).......................................... 20

Appendix II: Caught supports (on steps).............................................................…… 20

Recommendation for pin selection KONSTANZ........................................................ 21

Loading forces............................................................................................................…. 24

Key word Page