Operating manual chair STG 10/15 Version: 12.0 (02/2010)

4.1

4.2

4.3

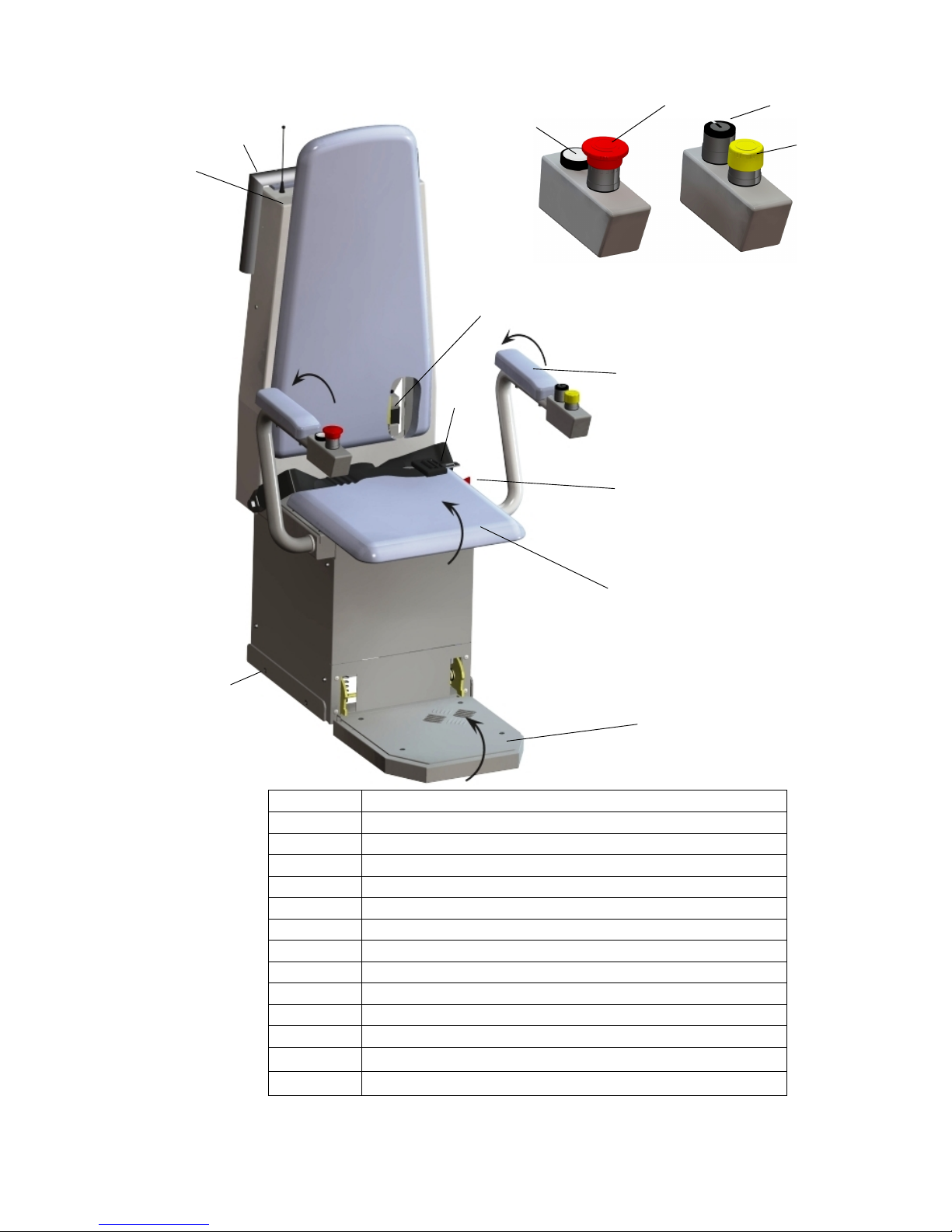

Main switch

The main switch (red key) is located on the chair frame, beside the seat (see page 7/item

5). The key can be removed by turning it anti-clockwise, thus disconnecting the power

supply.

Deep discharge protector

All T80 chair lifts are equipped with an acoustic deep discharge protector. This acoustic

signal generator is intended to protect the batteries against deep discharge. If the battery

voltage drops below 22 V, a beep sounds at intervals of approx. 5 seconds. In this case

you should drive immediately to the next charging station – if possible the lower

charging station – and allow the lift to charge up there for several hours (this takes place

automatically in the charging station). The beep stops after proper charging. The sound

can be turned off by pressing the emergency stop button; this has no influence on the

charging process.

Note: A signal likewise sounds if the chair lift is not charged 30 seconds after the last

motor movement.

Battery charger (indicator lamps)

The indicator lamps on the battery charger indicate the respective condition of the battery

charger. A distinction must thereby be made between three different versions of battery

charger. The main distinguishing feature is the number of LEDs.

3 LEDs: Green Yellow Red

No electricity supply to the

charger

Off Off Off

No battery connected On Flashes (briefly) Off

Charging On Flashes slowly Off

Battery fully charged On On, goes off briefly every

2 seconds.

Off

2 LEDs: Green Yellow

No electricity supply to the

charger

Off Off

No battery connected On Off

Charging On Flickers

Battery fully charged On On

If charging does not take place, although the battery charger is ready for use and the lift

is located correctly in a loading station:

Please check the charging circuit breaker (see page 7, item 11); this is located at the rear

of the chair lift. To do this, the cover (exterior installations only) must be lifted up (fold

the lower part toward the running rail; after that it can be pulled away in a downward

direction). The switch (small rocker arm) on the charging circuit breaker must be in the

up position. Afterwards the cover is to be attached again.

1 LED: LED

No electricity supply to

the charger

Off

No battery connected Red

Charging Yellow

Battery fully charged Green