6

1.2 Basics of intended use

1.2.1 The machine is constructed according to the state of the art and

recognised technical safety rules. However, danger to life and limb of the

user or third parties, and/or damage to the machine or other property may

still arise from its use.

1.2.2 Only use the machine in technically faultless condition and for intended

use, aware of safety and danger complying with the operating manual!

You should particularly handle malfunctions which can compromise

safety immediately, or have them addressed by experts!

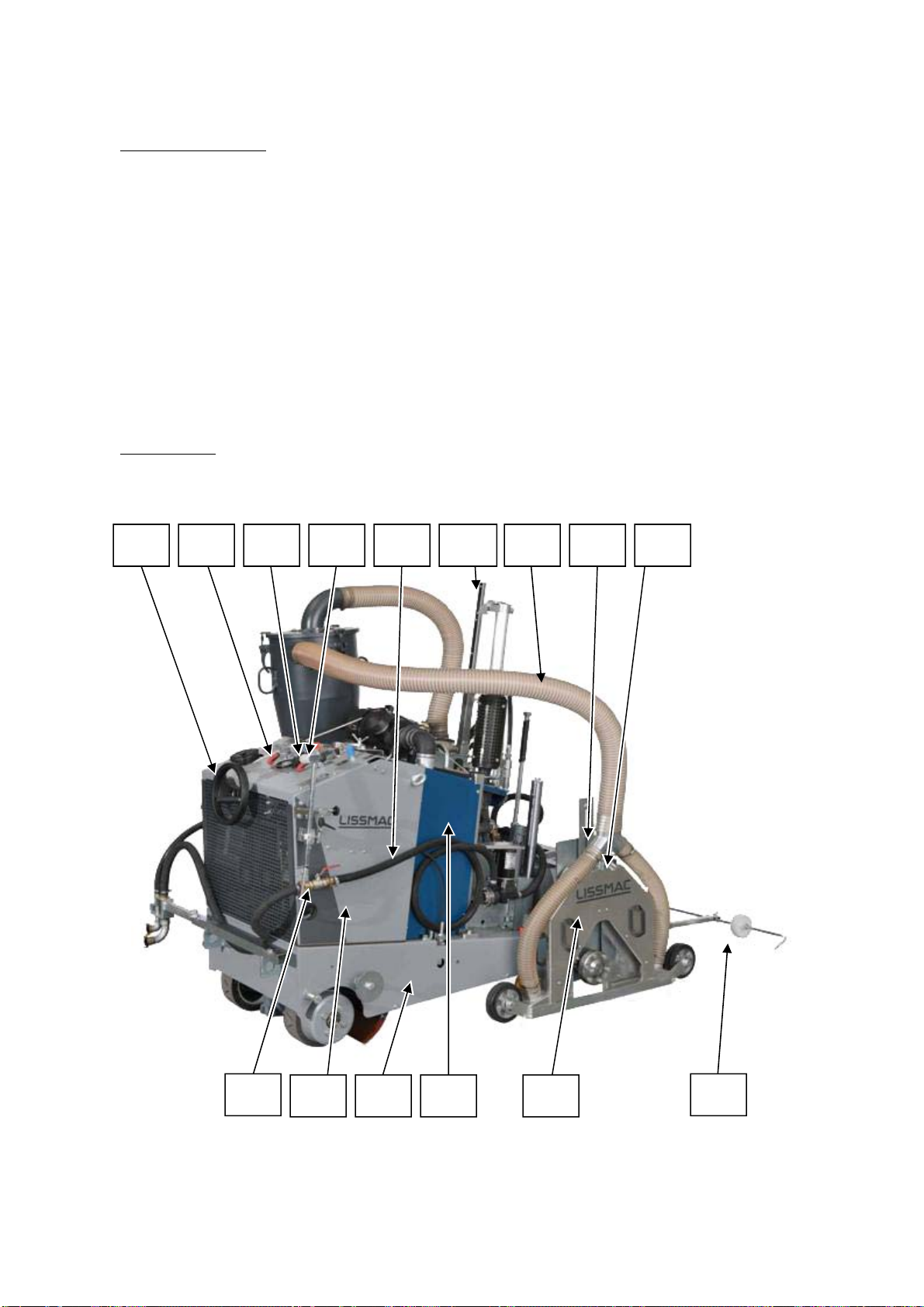

1.2.3 The floor cutter is exclusively intended for cutting joints in concrete or

asphalt. Cutting of wood, plastic or metal (except for reinforcement in

concrete) is not allowed!

Any other use or use above and beyond is not considered intended use.

The manufacturer/supplier assumes no liability for damages caused by

failure to comply with the intended use.

Intended use also includes compliance with the operating manual and

observance of inspection and maintenance requirements.

1.3 Organisational measures

1.3.1 The operating manual is to be kept permanently at the machine location

and easily accessible!

1.3.2 Follow and instruct others in all generally valid legal and otherwise

binding regulations for accident prevention and environmental protection

in addition to the operating manual!

1.3.3 Personnel assigned to activities on the machine must have read the

operating manual, particularly the Safety Instructions chapter, before

starting work. In the middle of work it is too late. This applies notably to

personnel who only work occasionally on the machine, e.g. for

changeovers and service.

1.3.4 At least occasionally, perform checks for safe and hazard awareness

work by operators while following the operating manual!

1.3.5 Use personal protection equipment if necessary or required by

regulations!

1.3.6 Observe all safety and danger instructions on the machine!

1.3.7 Keep all safety instructions and danger warnings on/in the machine

complete and in legible condition!

1.3.8 At the presence of safety-related changes to the machine or its running

behaviour, stop the machine immediately and report the problem to the

responsible post/person!

1.3.9 No changes, removal or addition of parts to the machine without the

approval of the supplier!

1.3.10 Only use original replacement parts from the manufacturer!

1.3.11 Observe required or prescribed deadlines given in the operating manual

for inspections!

1.3.12 Workshop equipment suitable for the work is absolutely necessary for

performing maintenance actions.