• Ensuretheliftingequipmenttobeused

has the correct capacity to lift the engine

and is designed to give a vertical lift from

directly above the lifting eyes.

• Checktoensuretheengineliftingeyes

are not damaged and they are secure.

• Ensurethereisclearancebetweenthe

lifting equipment hooks and the engine.

• Theliftingeyesttedtotheengineare

suitable for lifting the engine and acces-

sory assemblies originally tted by Lister

Petter.

Waste Disposal Precautions

WARNING

Extreme care must be taken to ensure

that waste oil, fuel, lter elements, cool-

ant concentrate, battery electrolyte, sol-

vents or other toxic wastes are disposed

of in accordance with local regulations to

prevent contamination.

Fuel System Precautions

a. When priming or checking the fuel injec-

tion pump timing, care must be taken to

wipe spilled fuel from the outside of the

engine.

b.Alwaystanewjointwhenaunionhas

been disturbed.

c. Special care must be taken to see that

there is no leakage from the joints of the

fuel pipe connection to the pump.

d. When tightening or loosening the fuel

injection pump delivery connections, use

two spanners to prevent the unsealing of

the fuel pump delivery valve holders.

e. When refitting the fuel pipe from the

pump to injector, the connection to the

injector must be tightened before the

connection to the fuel pump.

This procedure will ensure that there is

no leakage from these joints.

f. It is most important that all fuel joints are

tight and leak proof.

g.Always ll the fuel tank through a ne

strainer, preferably at the end of the

engine work period.

Starter Battery Precautions

WARNING

Sulphuric acid in battery electrolyte is

poisonous, is strong enough to burn skin,

eat holes in clothing and cause blindness

if splashed into the eyes.

a. Do not smoke near the batteries and

keep sparks and flames away from

them.

b. Batteries contain sulphuric acid - if the

acid has been splashed on the skin,

eyes orclothesush it awaywithcopi-

ous amounts of fresh water and seek

immediate medical aid.

c. Keep the top of the battery well venti-

lated during charging. Switch off the

battery charger before connecting or

disconnecting the charger leads.

d. Disconnect the battery negative (earth)

leadrstandreconnectlast.

e.Never 'ash' connections to check cur-

rentow.

f. A damaged or unserviceable battery

must never be used.

g.Donotattempttochargeafrozenbat-

tery; it may explode; warm the battery to

16°C (60°F).

Oil Seals Containing Viton

Someenginesmaybettedwithseals

or 'O' rings manufactured from 'Viton' or a

similar material.

When exposed to abnormally high tem-

peratures, in excess of 400°C (752°F), an

extremely corrosive acid is produced which

cannot be removed from the skin.

If signs of decomposition are evident, or

if in doubt, always wear disposable heavy

duty gloves.

Lifting Precautions

The following points must be consid-

ered before attempting to lift the engine.

WARNING

Engine lifting eyes must not be used to lift

the complete plant.

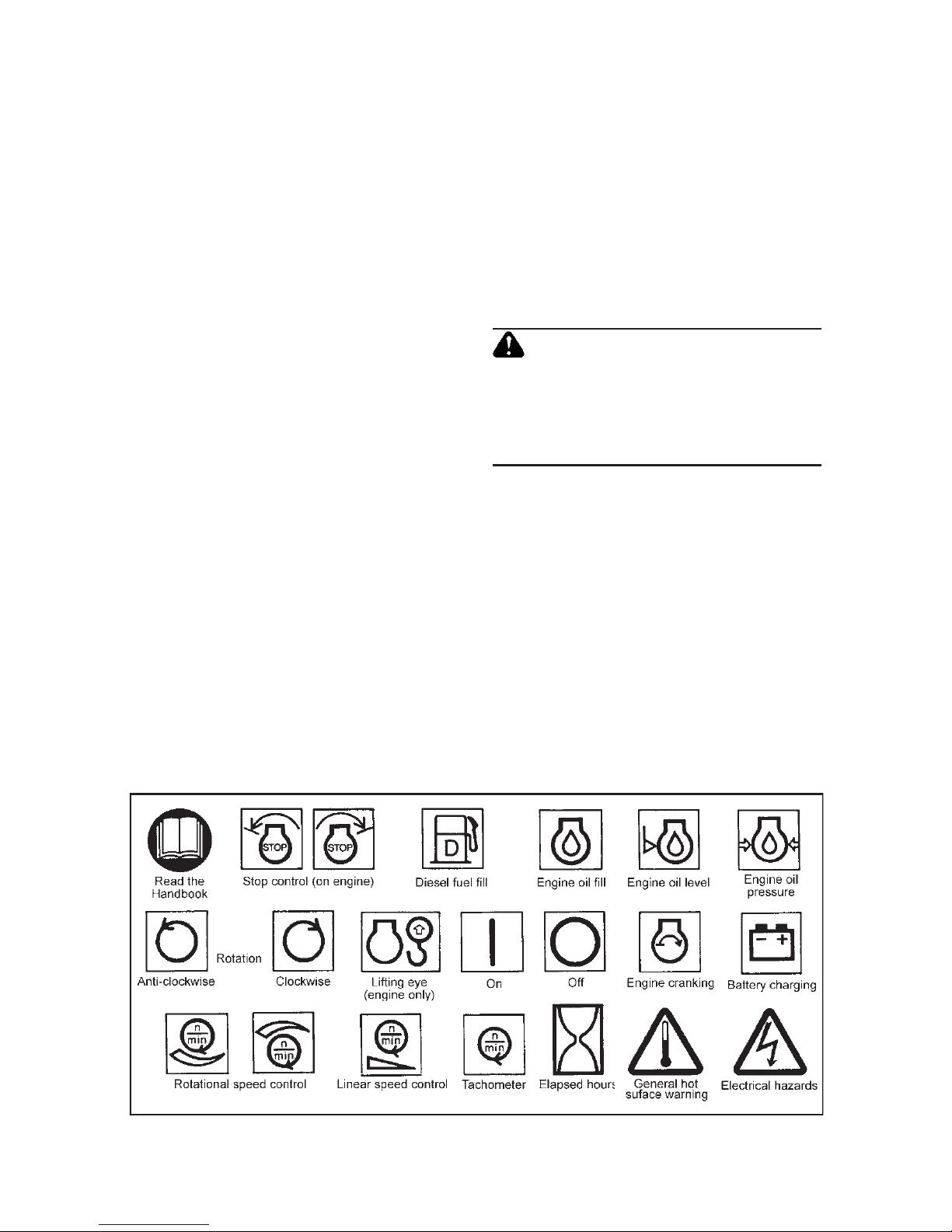

3. Safety Information and Precautions