Lister Petter LT and LV Operators Handbookpage 2

Introduction

The purpose of this handbook is to lay

downoperatingguidelines forthe LT1 and

LV1 engine ranges.

The specification details given apply

to a range of engines and not to any one

particular engine, in cases of difficulty the

user should consult the local Lister Petter

DistributororDealer forfurtheradvice and

technical assistance.

The information, specifications,

illustrations, instructions and statements

contained within this publication are given

with our best intentions and are believed

to be correct at the time of going to press.

Our policy is one of continued

development and we reserve the right to

amend any technical information with or

without prior notice.

Whilst every effort is made to ensure

the accuracy of the particulars contained

within this publication neither the

Manufacturer, Distributor or Dealer shall

inanycircumstances beheld liableforany

inaccuracy or the consequences thereof.

The information given is subject to the

Company’s current Conditions of Tender

and Sale, and is for the assistance of

users and is based upon results obtained

from tests carried out at the place of

manufacture. This Company does not

guarantee that the same results will be

obtained elsewhere under different

conditions.

Using this Operators Handbook

It is recommended the individual

steps contained in the various

maintenance or repair operations are

followed in the sequence in which they

appear.

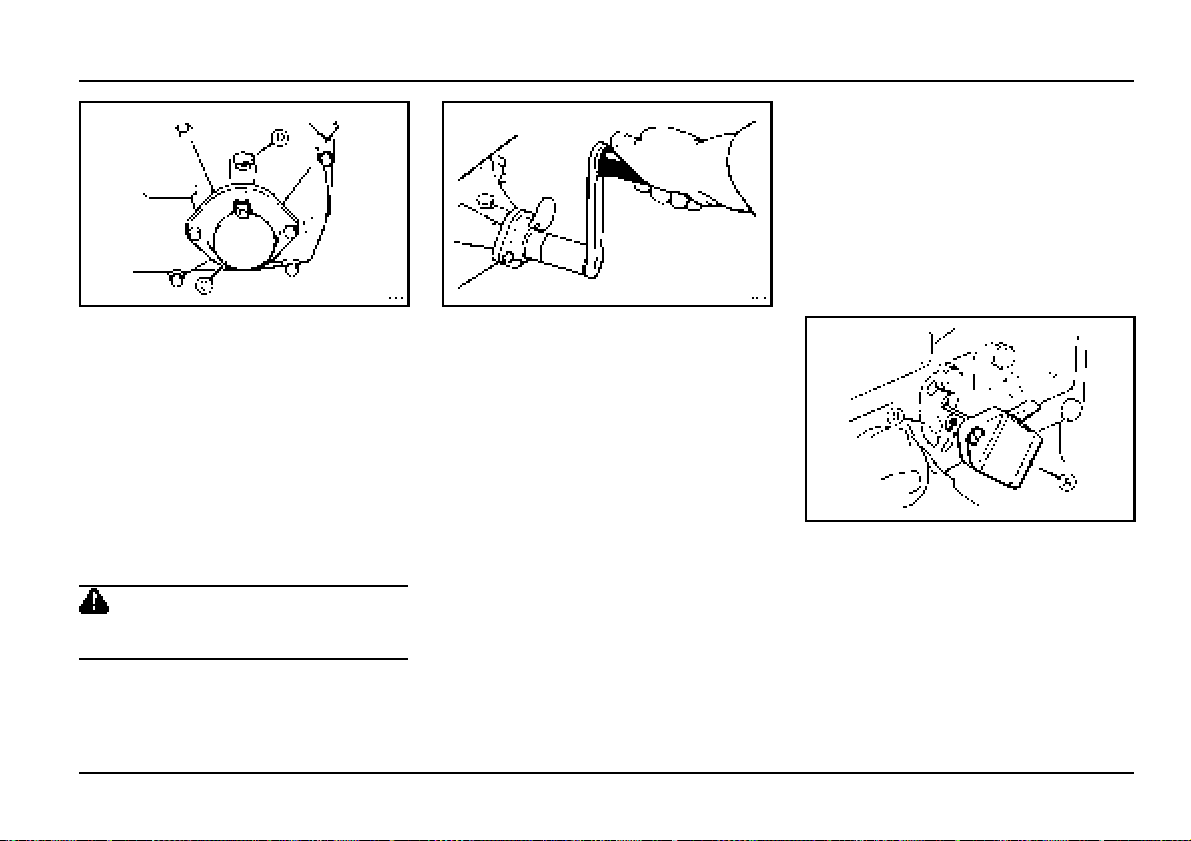

When a diesel engine is operating or

being overhauled there are a number of

associated practices which may lead to

personal injury or product damage.

Your attention is drawn to the symbols

shown and described below which are

applied throughout this publication.

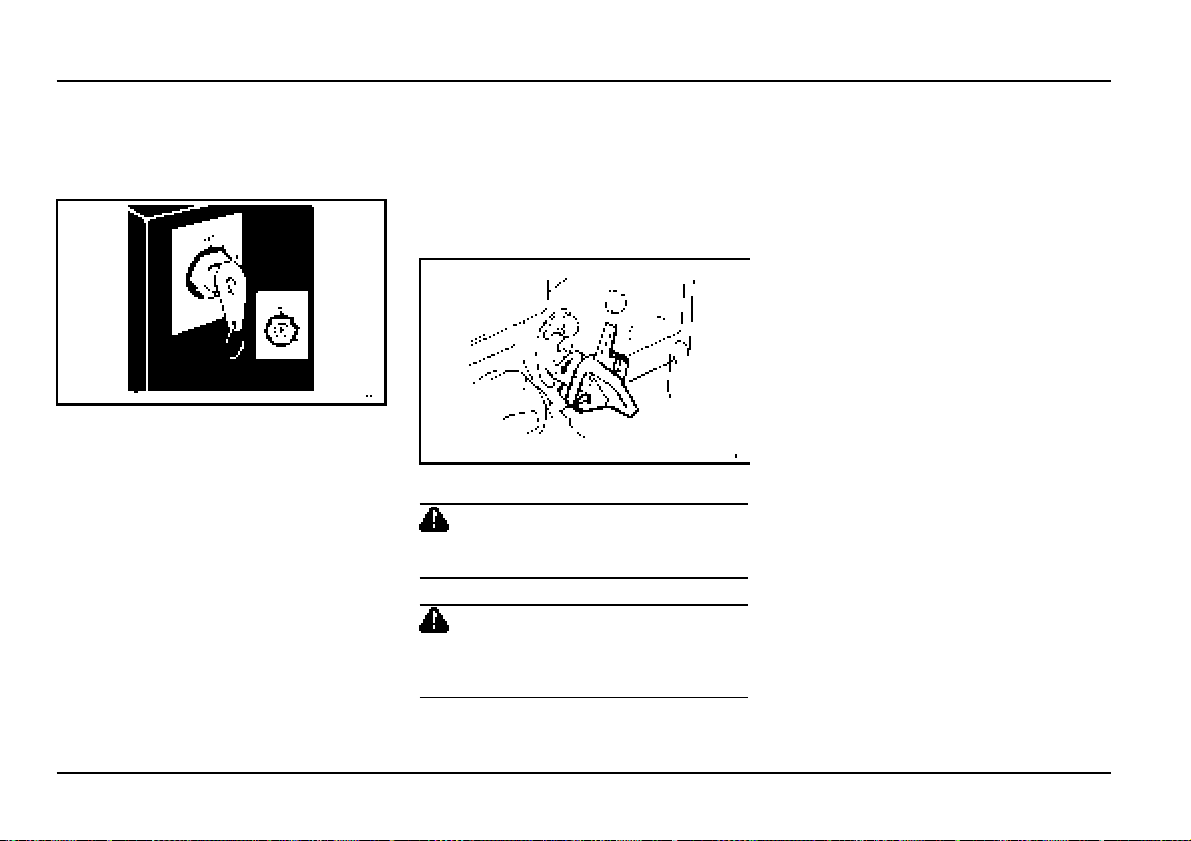

CAUTION

This caution symbol draws attention to

special instructions or procedures which,

if not correctly followed, may result in

damage to or destruction of equipment.

WARNING

This warning symbol draws attention to

special instructions or procedures which,

if not strictly observed, may result in

personal injury.

WARNING

A WARNING SYMBOL WITH THIS

TYPE OF TEXT DRAWS ATTENTION

TO SPECIAL INSTRUCTIONS OR

PROCEDURES WHICH, IF NOT

STRICTLY OBSERVED, MAY RESULT

IN SEVERE PERSONAL INJURY, OR

LOSS OF LIFE.

Running-in

A gradual running-in of a new engine

is not necessary. Extended light load

running early in the life of the engine may

cause detrimental damage to the cylinder

bore allowing lubricating oil to enter the

exhaust system.

To help assist engine running-in, all

engines are despatched with an initial fill

lubricating oil which must be changed

after 100 hours.

Associated Publications

Workshop Manual ............... P027-09207

Master Parts Manual ........... P027-08043

Technical Handbook ........... P027-09212

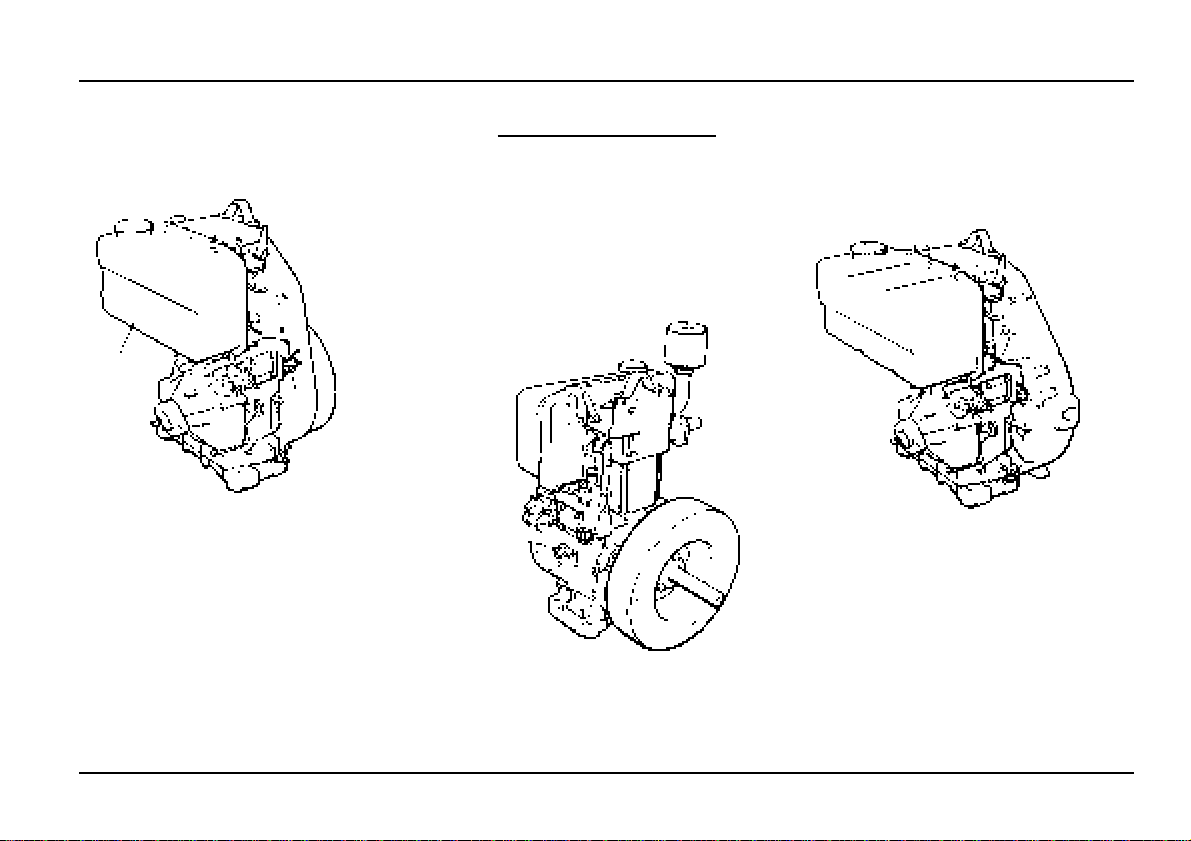

Introduction

Introduction