1. SAFETY INFORMATION

8

LPW / LPWS / LPWX ENGINE OPERATORS' HANDBOOK

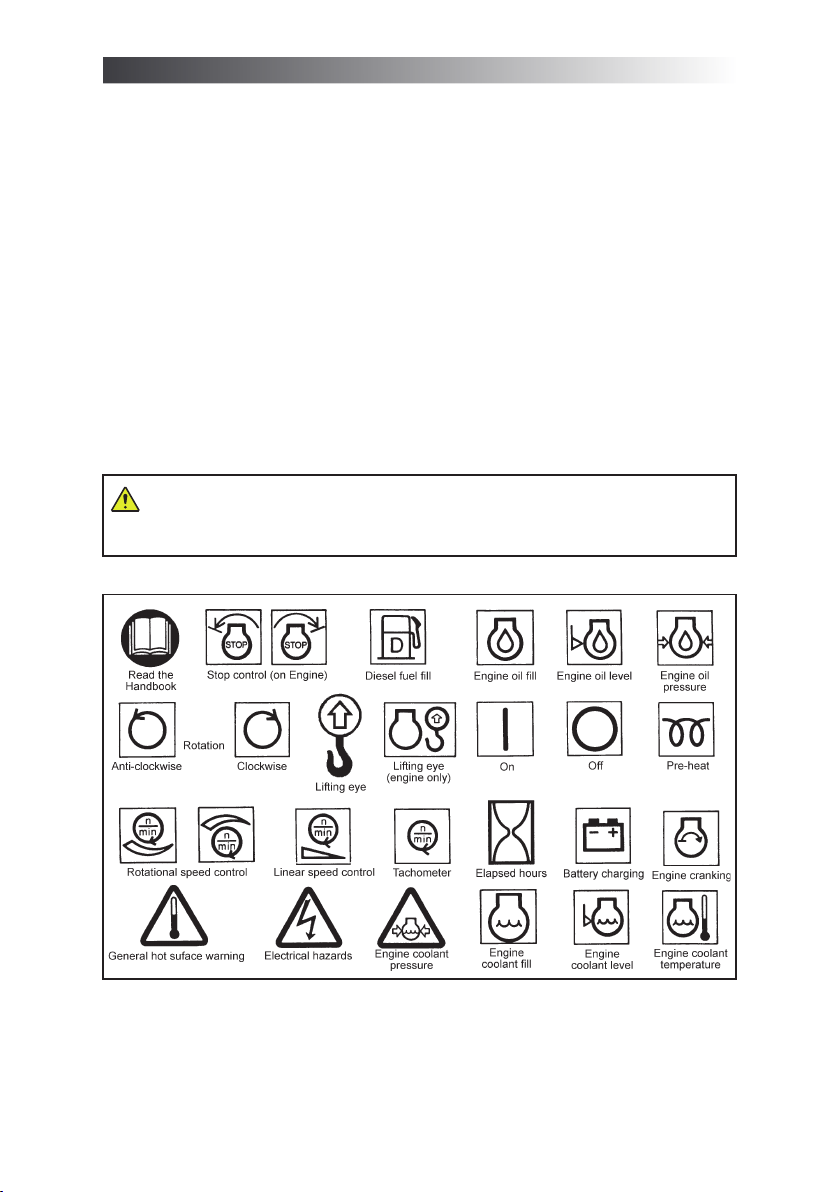

1. Safety Symbols This fi gure identifi es the ISO 8999 symbols currently used by Lister Petter

WARNING

KEEP THE BODY AND CLOTHING

CLEAR OF MOVING OR HOT PARTS

ATALL TIMES. CONTACT OF MOVING

PARTS WITH UNPROTECTED SKIN

CAN CAUSE SEVERE BURNS.

ENTANGLEMENT WITH ROTATING

EQUIPMENT CAN CAUSE SERIOUS

INJURY OR DEATH.

• Tie long hair back securely.

• Wear close-fi tting clothing.

• Do not wear a necktie, scarf, loose

clothing or necklace when working

close to a running engine.

• Where possible, remove rings and

other jewellery to prevent entanglement

in moving parts. These items could also

cause a short circuit if any part of the

electrical system is being worked on.

WARNING

Prolonged exposure to loud noise

can cause impairment, or loss, of

hearing.

• Wear suitable ear protection against

objectionable or uncomfortable loud

noise.

• To avoid loss of concentration, do

not use music or radio headphones

while operating an engine.

• When undertaking maintenance, do

not work under any plant that is only

held by overhead lifting equipment.

• Where appropriate, make sure that

guards are properly fi tted.

1.3 PRECAUTIONS WITH

CHEMICALS

Protect yourself from exposure to

hazardous chemicals at all times, as

this can cause serious injury. Potentially

hazardous chemicals include lubricants,

fuel, coolant concentrate, battery acid,

paint and adhesives.

Manufacturers' safety data sheets

will provide specific details of the

physical and health hazards, safety

and emergency procedures and

1. This gure identies the ISO 8999 symbols