4

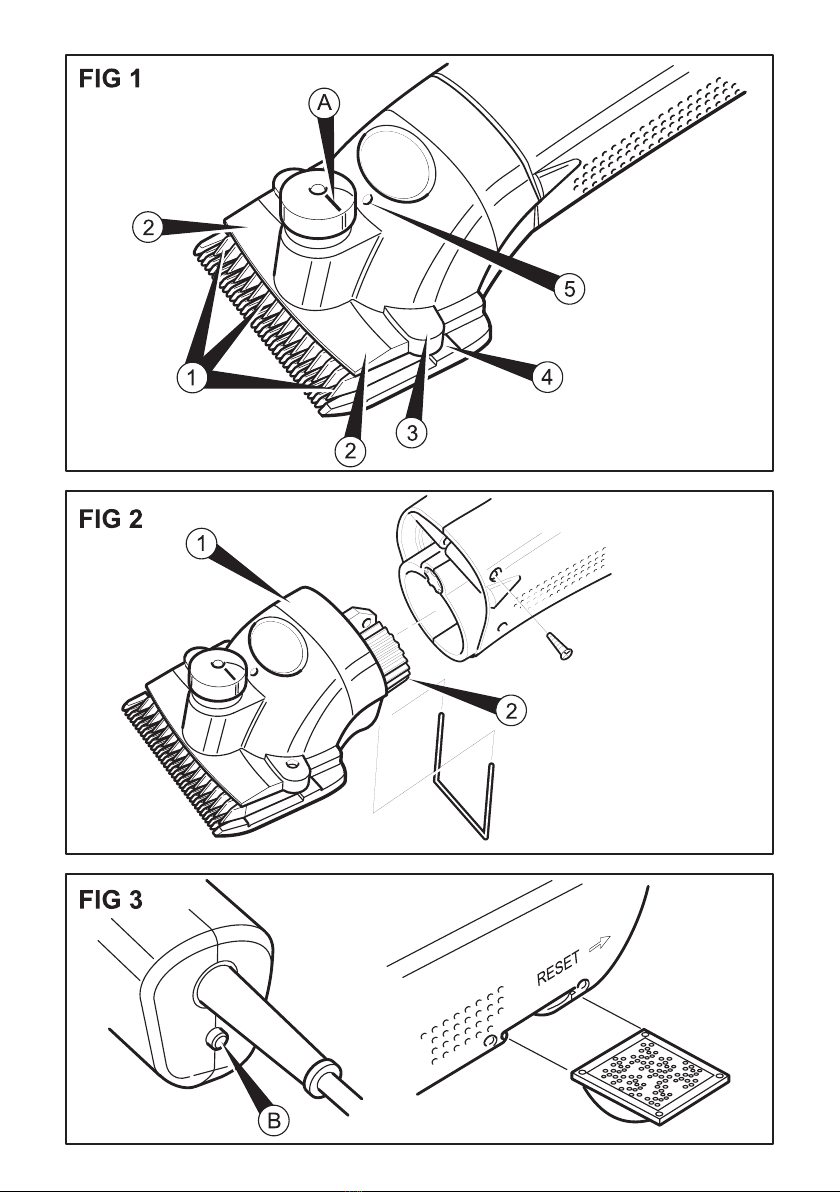

MAINTENANCE (Figs. 2 & 3)

It is particularly important to keep plug and cable clean and in good order at all times. The

motor and drive gears can be expected to give years of trouble free use if maintained and

serviced regularly. The following should be carried out at the end of each season, or more

regularly if used extensively.

GEARS (Fig. 2)

Every 200 hours running remove the clipper head (1). Wipe the clipper head and gear-

wheel (2) to remove hair and used grease. Coat the gearwheel with clean grease (Lister R2

or Shell Alvania R2 or equivalent). When the clipper head is removed, check the gear-

wheel for wear and broken teeth.

FILTERS (Fig. 3)

The motor air filter shown in Fig. 3 should be frequently removed and meticulously

cleaned (brush supplied) to ensure efficient running of the motor. To clear the gauzes, a

high-pressure air-line is ideal – otherwise wash in detergent solution and dry carefully. If

this maintenance is ignored, overheating of the motor could occur with possible irrevers-

ible damage to the motor, or inefficient clipping at the very least. DO NOT RUN MOTOR

WITH FILTER REMOVED.

WARNING: All maintenance should be carried out with the unit switched off and re-

moved from the mains supply.

RESET BUTTON (Fig. 3)

The clipper is fitted with an overload protection switch, which will trip if the clipper is

overloaded. Should this occur, the unit should be thoroughly checked before fully depress-

ing the button to reset. The button is situated at the backend of the motor body (B).

PARTS LIST (Fig. 4)

When ordering spare parts please specify:

Part number, description and quantity of spare part(s).

Whenever possible, quote the Model and Clipper Serial Number which will be found on

the specification plate.

U.K. USERS ONLY

WARRANTY, REPAIR & REGRIND

Items requiring attention under warranty, repair or regrind should be returned to your

dealer or the Lister factory.

A qualified repairer using genuine Lister parts must carry out repairs.

Do not dispose of this product in household waste. At the end of its useful life please

return this product for recycling to:

LISTER SHEARING EQUIPMENT LTD. DURSLEY, GLOS. GL11 4HR. ENGLAND