Gocator Line Profile Sensors: User Manual 3

Table of Contents

Copyright 2

Table of Contents 3

Introduction 11

Safety and Maintenance 12

Laser Safety 12

Laser Classes 13

Precautions and Responsibilities 14

Class 3B Responsibilities 14

Nominal Ocular Hazard Distance (NOHD) 15

Systems Sold or Used in the USA 16

Electrical Safety 16

Handling, Cleaning, and Maintenance 17

Environment and Lighting 17

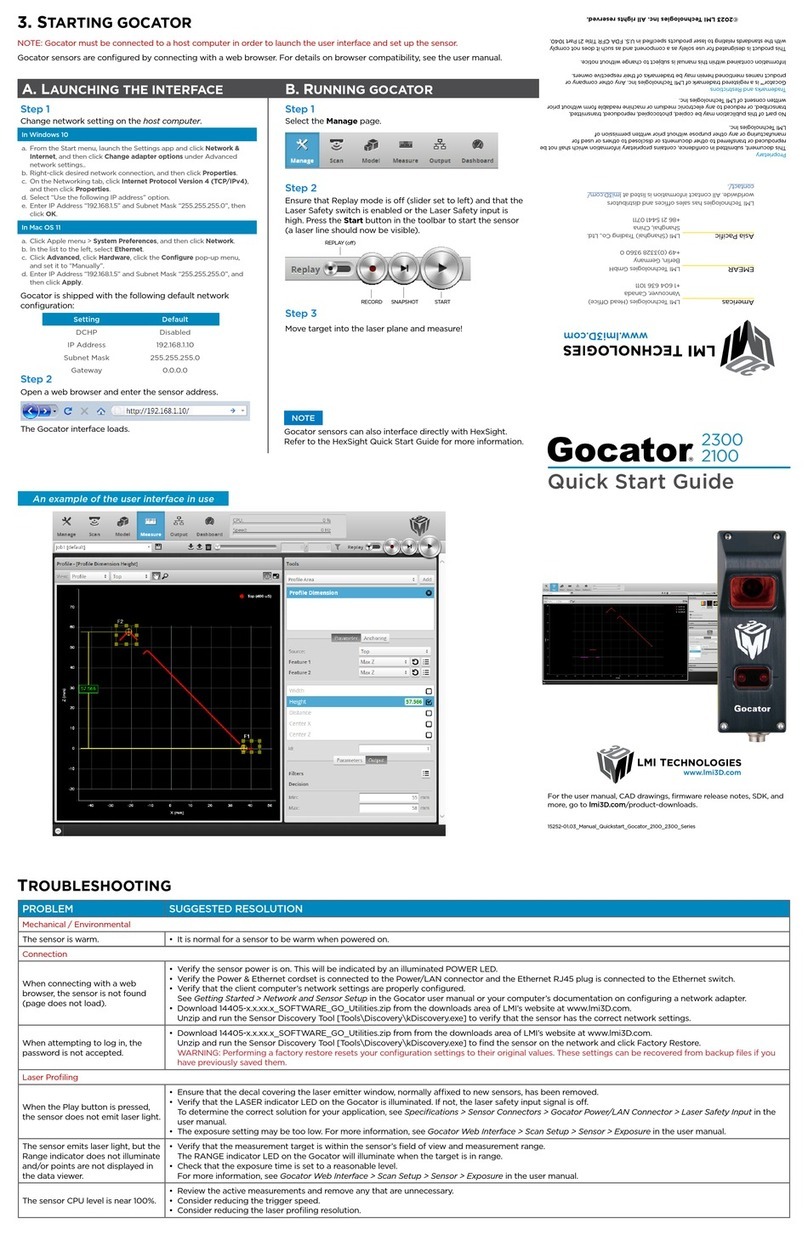

Getting Started 19

System Overview 19

Standalone System 19

Dual-Sensor System 20

Multi-Sensor System 21

Hardware Overview 22

Gocator Sensor 22

Gocator Cordsets 22

Master 100 23

Master 400 / 800 / 1200 / 2400 24

Master 810 / 2410 25

Calibration Targets 26

Installation 28

Mounting 28

Orientations 29

Grounding: Gocator 31

Grounding: Recommended Practices for

Cordsets 31

Installing DIN Rail Clips: Master 810 or 2410 32

Grounding: Master Network Controllers 33

Grounding When Using a DIN Rail (Master

810/2410) 33

Rut-Scanning System Setup 34

Layout 34

System Setup 35

Software Configuration 36

System Operation 36

Network Setup 37

Client Setup 37

Gocator Setup 39

Running a Standalone Sensor System 39

Running a Dual-Sensor System 40

Next Steps 43

How Gocator Works 44

3D Acquisition 44

Clearance Distance, Field of Viewand

Measurement Range 45

Resolution and Accuracy 46

X Resolution 46

Z Resolution 47

Z Linearity 47

Profile Output 49

Coordinate Systems 49

Sensor Coordinates 49

System Coordinates 50

Part and Section Coordinates 52

Switching between Coordinate Systems 53

Uniform Spacing (Data Resampling) 53

Data Generation and Processing 54

Surface Generation 54

Part Detection 55

Sectioning 55

Part Matching 56

Measurement and Anchoring 56

Output and Digital Tracking 57

Gocator Web Interface 58

User Interface Overview 58

Toolbar 59

Creating, Saving and Loading Jobs (Settings) 59

Recording, Playback, and Measurement

Simulation 61

Recording Filtering 63

Downloading, Uploading, and Exporting

Replay Data 64

Metrics Area 66

Data Viewer 67

Status Bar 67

Log 67

Frame Information 68

Interface Language 68