Section 3 PROGRAMMER

INDEX

Function overview

B.1

Getting started

B.2

Program run mode

B.3

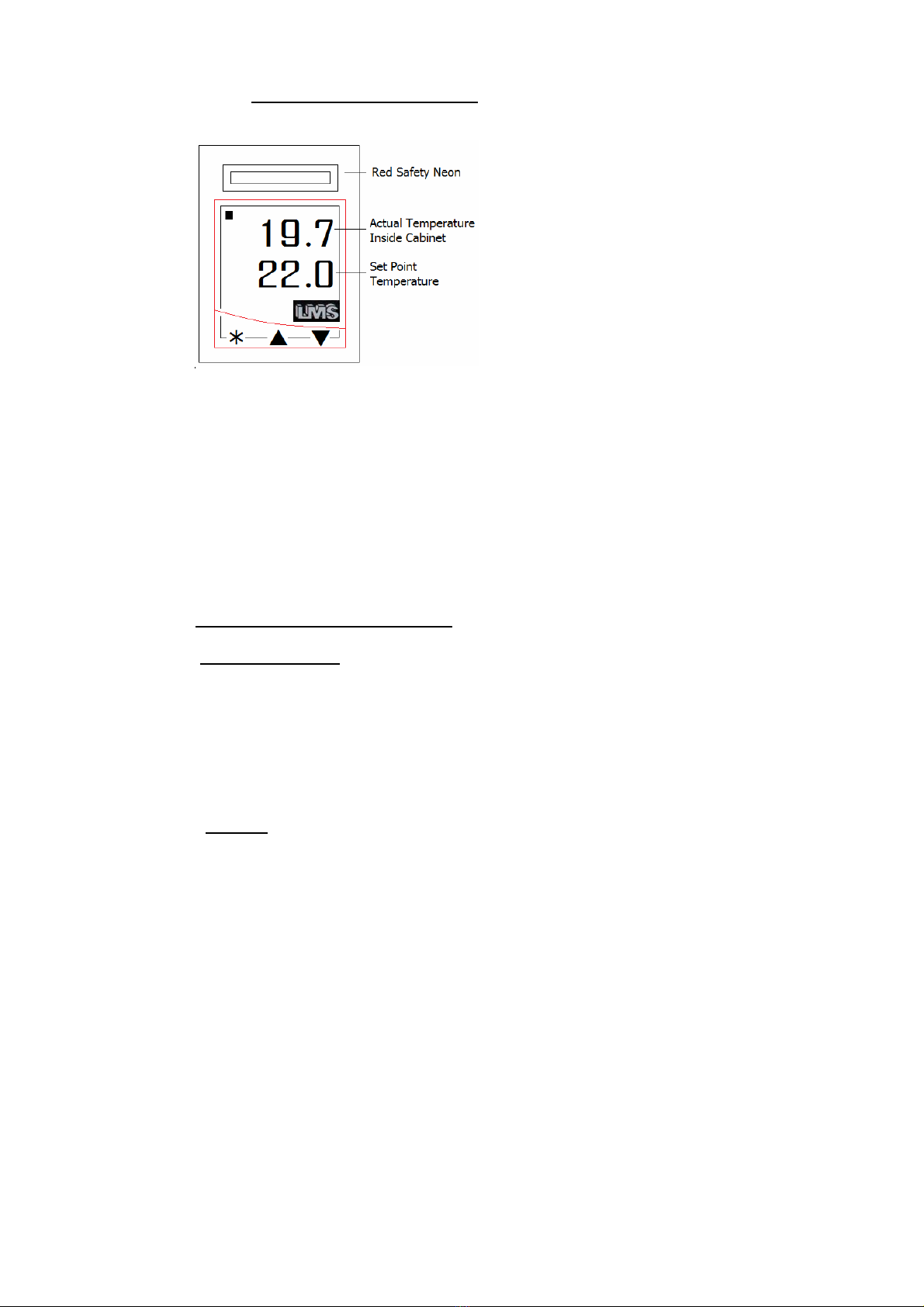

Display functions

B.4

Example program

B.5

Function map

B.6

Function list

B.7

Memory allocation table B.8

Memory full indicator

B.9

Programming example

B.10

Program edit example

B.11

3.0 FUNCTION OVERVIEW

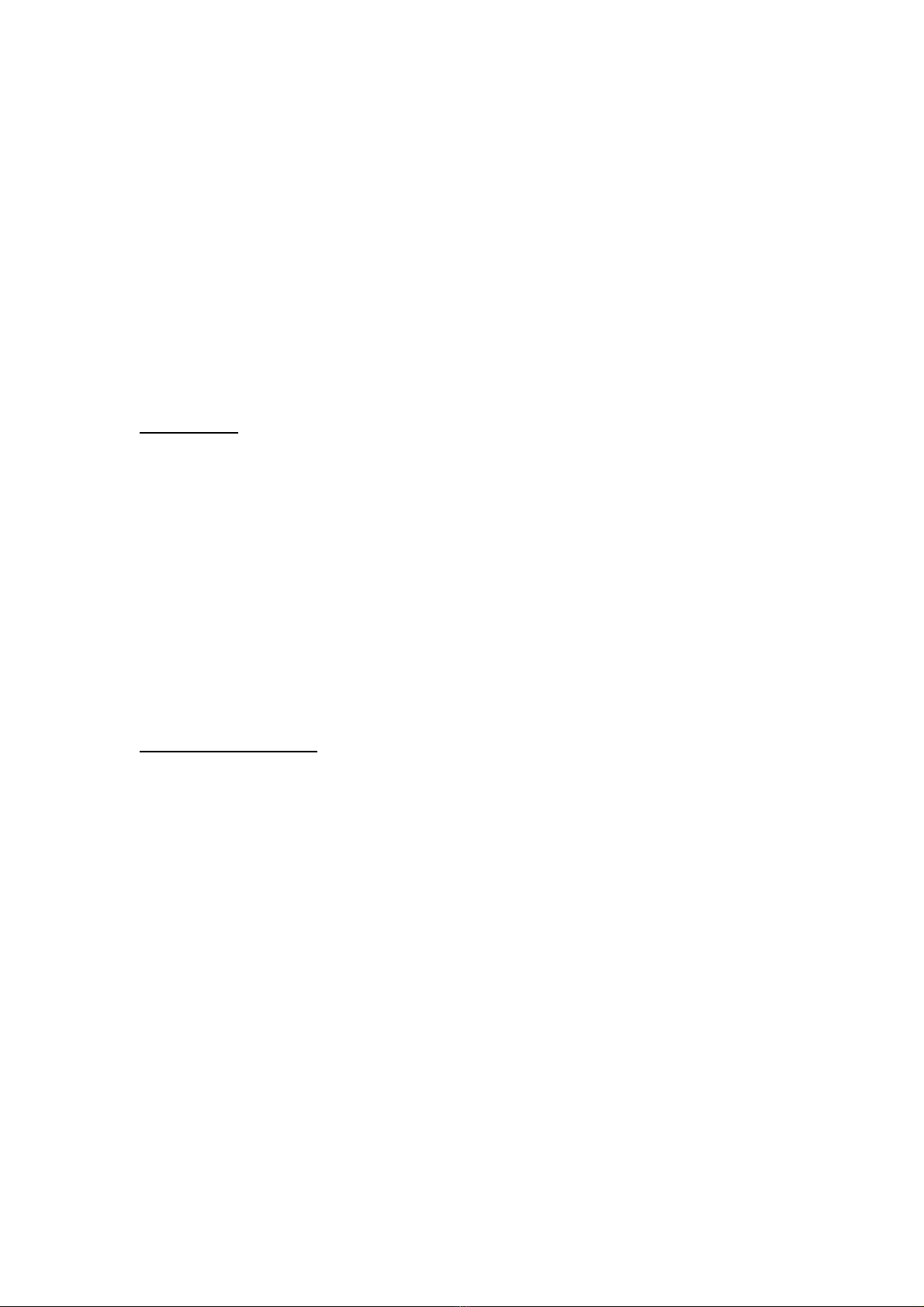

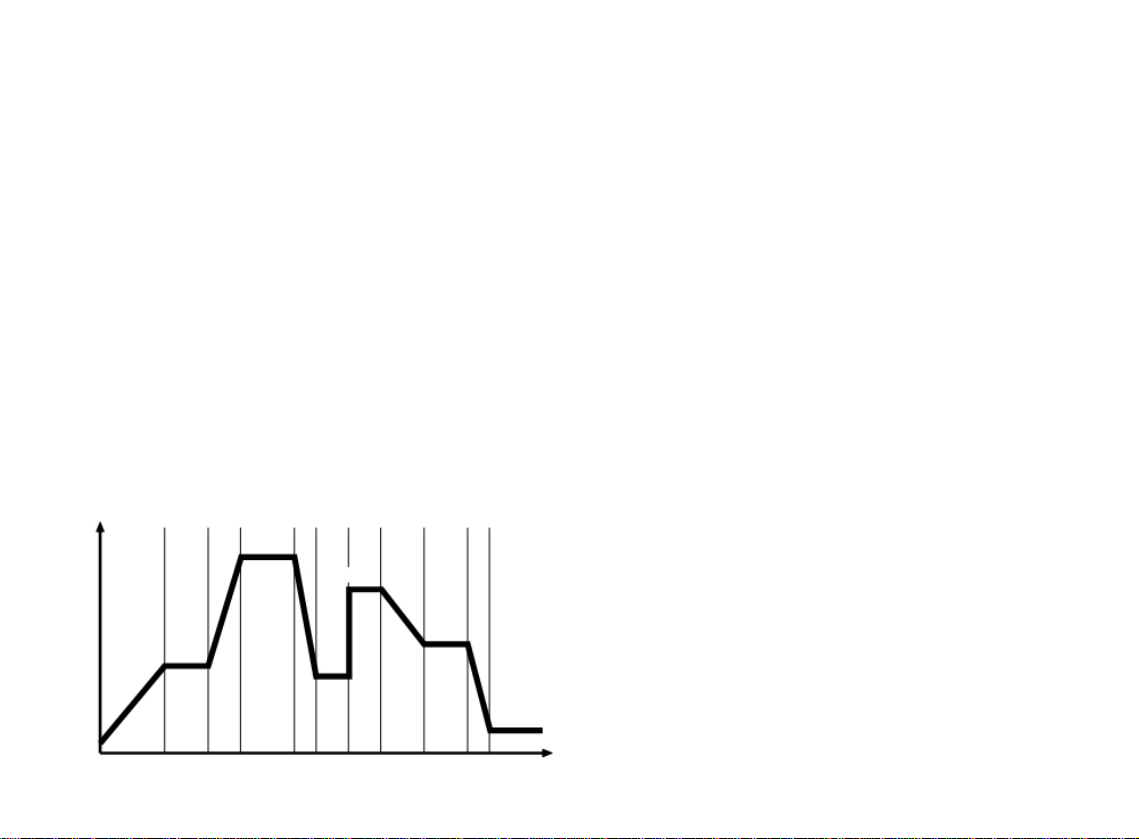

The Programmer function in Level P enables the instrument to control applications

needing Setpoint changes over time. Examples of this are Ramp changes where a gradual

Rate of change can be set, or Step changes which are instantaneous. These can be

separated by Soak periods during which the process is held at a constant value. Each

individual time interval of the program or Segment, together with it’s associated moving

setpoint value can be stored as a unique Program and for example be represented by the

diagram below.

Setpoint

Soak Step

Ramp

Time (Segments)

In addition to those settings that determine the segment profile, it is also necessary to set

program start values, together with the preferred ramp rate time units for each individual

program.

At the end of a sequence, a Program can be arranged to repeat (Loop), either a specified

number of Cycles, or continuously. Only one Loop can be included in a Program. When the

program is running, the Display indicates progress through the sequence of segments, and

can additionally be interrogated for further segment information.

It is also possible to CALL an already existing program as a sub program that can be

inserted as a segment of another program.

To speed up Program configuration, several Edit functions have been provided so that

individual Segments and Programs may be Deleted or Inserted, and an entire Program

may be Copied and then Pasted into another that it will replace.

For safety reasons, three modes of recovery from a power failure are available. These either

automatically Re-start the Program from the beginning, Continue it from where it stopped, or

Hold it waiting for a user re-start.

Either one or both of the two auxiliary outputs can be configured as Event outputs.

Engaging the Holdback feature will temporarily halt Setpoint ramping to allow the process

temperature to catch up should it deviate by more than a pre-set amount during a Ramp

segment.

To afford maximum programming flexibility, memory is allocated dynamically, and not pre-

allocated. This allows the user the freedom to configure a small number of long programs

or a larger number of shorter ones, up to the permitted maximum of 126 Segments per

program, and a limit of 31 Programs. Should these limits be exceeded, or the Programmer

memory become fully used, the display will read ProG FULL. Programs can be planned

using the Memory Allocation Table which details the memory requirements of individual

segment types. During configuration a check can be kept on memory usage by

interrogating the USEd feature of the display to give an instant reading of ‘percentage

memory used’.

Finally, once a program has been configured, it can be run from the run off/on/hold

controls in Level P, and in addition a quick access run/hold toggle is directly available from

the front panel.

The Programmer Functions List describes the full range of available Settings for each

Programmer Function together with their display mnemonic. The instrument is supplied

with a suite of Factory Settings for each Function. These are shown in bold type.

The Functions Map illustrates the relationship between the Functions and their Settings

and provides a guide to the Keying Operations required to navigate around the menu

when configuring or running a Program.