LNC LNC-T800 User manual

2008/4 Ver:V04.00.000 (4408110048)

LNC-T800

O

Op

pe

er

ra

at

to

or

r’

’s

s

M

Ma

an

nu

ua

al

l

Leading Numerical Controller

LNC Technology Co., Ltd.

LNC-T800

Table Of Contents

LNC Technology Co., Ltd. I

Table Of Contents

1CNC GROUP INSTRUCTION ................................................................. 1

1.1 Types of Operation Device ..............................................................................................................1

1.1.1 LCD Monitor.........................................................................................................................2

1.1.2 MDI Data Input Panel ..........................................................................................................2

1.2 Operation Device Introduction.........................................................................................................3

1.3 Screen and Fnction Instruction .......................................................................................................8

1.3.1 Alposition of the Display Screen..........................................................................................8

1.3.2 Functions of Each Function Group .................................................................................... 10

1.3.3 Absolute Coordinate screen ..............................................................................................17

1.3.4 Relative Coordiante Screen...............................................................................................18

1.3.5 Machine Coordinate Screen ..............................................................................................19

1.3.6 Handle Interrupt Screen.....................................................................................................20

1.3.7 Quit System .......................................................................................................................21

1.4 Program Function (PROG)............................................................................................................22

1.4.1 Current Program ................................................................................................................23

1.4.2 Background Program.........................................................................................................26

1.4.3 Program Checkup..............................................................................................................27

1.4.4 MDI ....................................................................................................................................28

1.4.5 DIRMNG ............................................................................................................................29

1.4.6 COMM. (RS232 Communiaction)......................................................................................44

1.5 Compensation Function (OFFSET)...............................................................................................49

1.5.1 WEAR:Tool Wear Compensation....................................................................................49

1.5.2 GEOM:Tool Shape Compensation..................................................................................52

1.5.3 SHIFT:Work Coordinate Offset .......................................................................................53

1.5.4 MACRO Variable ...............................................................................................................54

1.5.5 WORK:Workpiece Coordinate System ...........................................................................55

1.6 Graph Function (GRAPH) .............................................................................................................56

1.6.1 Function Introduction .........................................................................................................56

1.6.2 GRAPH ..............................................................................................................................56

1.6.3 SET ....................................................................................................................................57

1.7 Diagnosis Function (DGNOS) .......................................................................................................58

1.7.1 ALARM...............................................................................................................................58

1.7.2 SYSUPD :System Update..............................................................................................62

1.7.3 IOCSA................................................................................................................................75

LNC-T800

Table Of Contents

II LNC Technology Co., Ltd.

1.7.4 MLC2 .................................................................................................................................76

1.7.5 System Information............................................................................................................79

1.8 Software Panel function (SOFTPL)...............................................................................................80

1.9 PARAM ..........................................................................................................................................81

1.9.1 NC.SYS:System Parameter>..........................................................................................81

1.9.2 CHGUSR............................................................................................................................84

1.9.3 USROPT............................................................................................................................85

1.10 RESET ..........................................................................................................................................86

2LNC CONTROLLER OPERATION INSTRUCTION.............................. 87

2.1 Introduction of File Operation........................................................................................................87

2.1.1 Open File ...........................................................................................................................87

2.1.2 Copy File............................................................................................................................87

2.1.3 Delete File..........................................................................................................................88

2.1.4 Rename File ......................................................................................................................89

2.2 Program Edit .................................................................................................................................90

2.2.1 Program Edit......................................................................................................................90

2.2.2 Line Positioning .................................................................................................................90

2.2.3 Search for Word String ......................................................................................................90

2.2.4 Copy Data Segment ..........................................................................................................90

2.2.5 Delete Data Segment ........................................................................................................91

2.2.6 Teach Input ........................................................................................................................91

2.3 Manual Data Input (MDI) ...............................................................................................................92

2.4 Execution of Part Program ............................................................................................................92

2.5 Origin Return (HOME)...................................................................................................................92

2.6 Instruction on JOG Operation .......................................................................................................92

2.7 Instruction on MPG Operation.......................................................................................................92

2.8 Tool Wear Compensation Setting..................................................................................................93

2.9 Tool Length Compensation Setting ...............................................................................................93

2.10 Setting of Work Coordinate System (00, G54~G59).....................................................................94

2.11 Parameter Setting .........................................................................................................................95

2.12 Backup System Parameters..........................................................................................................95

2.13 Restore System Parameter...........................................................................................................96

LNC-T800

CNC Group Instruction

LNC Technology Co., Ltd. 1

1 CNC Group Instruction

1.1 Types of Operation Device

Ragarding the panel for the operators to proceed manipulation, it is divided into the MDI Data Input Panel and

the Operation Panel. MDI Data Input Panel’s major funtion is to let users edit or modify the program word by

word, and to set values. The Operation Panel is the control panel used to achieve kinds of manufacturing

needs, and it is composed of switches and buttons of many kinds of functions, and a Manual Pulse Generator

(handwheel, MPG), etc. The design of the Operation Panel may differ due to the differences between types of

machine tools, but this system provides a standard panel for machine tool manufacturers to utilize.

LNC-T800

CNC Group Instruction

2 LNC Technology Co., Ltd.

1.1.1 LCD Monitor

Figure 1.1-1 LCD Monitor

1.1.2 MDI Data Input Panel

A

F

K

P

U

X

B

G

L

Q

V

Y

C

H

M

R

W

Z

D

I

N

S

T

E

J

O

7

4

1

0

8

5

2

9

6

3

&

<

*

@

>

(

^

#

)

?+

!

_

Figure 1.1-2 MDI Data Input Panel

寶元科技

PS/2 Mouse port

PS/2 Keyboard port

LCD Switch

Sub function keys

Main function keys

LNC-T800

CNC Group Instruction

LNC Technology Co., Ltd. 3

1.2 Operation Device Introduction

Buttons shown on the LCD monitor and the MDI Data Input Panel can be divided into 4 types according to the

functions respectively:

(1). Major function button :

Right below the LCD are 6 horizontal buttons. They can be sued by users to input selections of functions

displayed at the lower side of the monitor.

Figure 1.2-1 6 major function buttons below the monitor

寶元科技

Major function buttons

LNC-T800

CNC Group Instruction

4 LNC Technology Co., Ltd.

(2). Minor function button:

After selecting the major function buttons, minor function contents will be displayed on the right side of

the monitor. Click the corresponding minor function button to make selection.

Figure 1.2-2 5 minor function buttons on the right side of the monitor

寶元科技

Minor function buttons

LNC-T800

CNC Group Instruction

LNC Technology Co., Ltd. 5

(3). Function group selection buttons:

Select from 8 types of function including POS, PROG, OFFSET, CAM, GRAPH, DGNOS, SOFTPL and

PARAM.

<POS> : Coordinate display screens

<PROG> : Program-related information screens

<OFFSET>: Tool compensation setting

<CAM> : Graphic-aided part program editing

<GRAPH> : Draw tool path

<DGNOS> : Display instant information of the diagnosis screen

<SOFTPL> : Software Panel switch

<PARAM> : Display parameter screen.

A

F

K

P

U

X

B

G

L

Q

V

Y

C

H

M

R

W

Z

D

I

N

S

T

E

J

O

7

4

1

0

8

5

2

9

6

3

;,.

&

<

*

@

>

(

^

#

)

?+

!

_

Function Group

selection buttons

LNC-T800

CNC Group Instruction

6 LNC Technology Co., Ltd.

(4). Letter and symbol buttons:

These letters, symbols and number buttons are mainly used to edit program and input data. Some of the

symbols are shrinked to the right lower corner of the buttons, and if need to use these shrinked symbols,

just hold the SHIFT button and click the symbol buttons.

(5). Edit buttons:

Use these buttons along with the cursor on the monitor to modify programs, set data and switch pages.

<SHIFT> : Accompany symbol and number buttons to input special symbols.

<INPUT> : Input button, confirm the input data.

<INS> : Switch between Insert Character and Replace Characer modes

<DEL> : Character cancellation button.

<HOME> : When editing program, move the cursor to the beginning of a line

<END> : When editing program, move the cursor to the end of a line

<SPACE> : Input a blank character

<CAN> : Cancel previous character

A

F

K

P

U

X

B

G

L

Q

V

Y

C

H

M

R

W

Z

D

I

N

S

T

E

J

O

7

4

1

0

8

5

2

9

6

3

;,.

&

<

*

@

>

(

^

#

)

?+

!

_

Symbol buttons

LNC-T800

CNC Group Instruction

LNC Technology Co., Ltd. 7

<PAGE↑> : Move to previous page

<PAGE↓> : Move to next page.

<→> : Cursor moves rightward

<←> : Cursor moves leftward

<↑> : Cursor moves upward

<↓> : Cursor moves downward

<RESET> : Reset system

A

F

K

P

U

X

B

G

L

Q

V

Y

C

H

M

R

W

Z

D

I

N

S

T

E

J

O

7

4

1

0

8

5

2

9

6

3

;,.

&

<

*

@

>

(

^

#

)

?+

!

_

Edit buttons

LNC-T800

CNC Group Instruction

8 LNC Technology Co., Ltd.

1.3 Screen and Fnction Instruction

There are 7 function groups in this controller. They are Coordinate (POS), Program (PROG), Compensation

(OFFSET), Graph (GRAPH), Diagnosis (DGNOS), Soft Panel (SOFTPL), and Parameter (PARAM). In this

manual,【 】is used to indicate the function buttons below and on the right side of the monitor, and < >

for buttons on the MDI Data Input Panel.

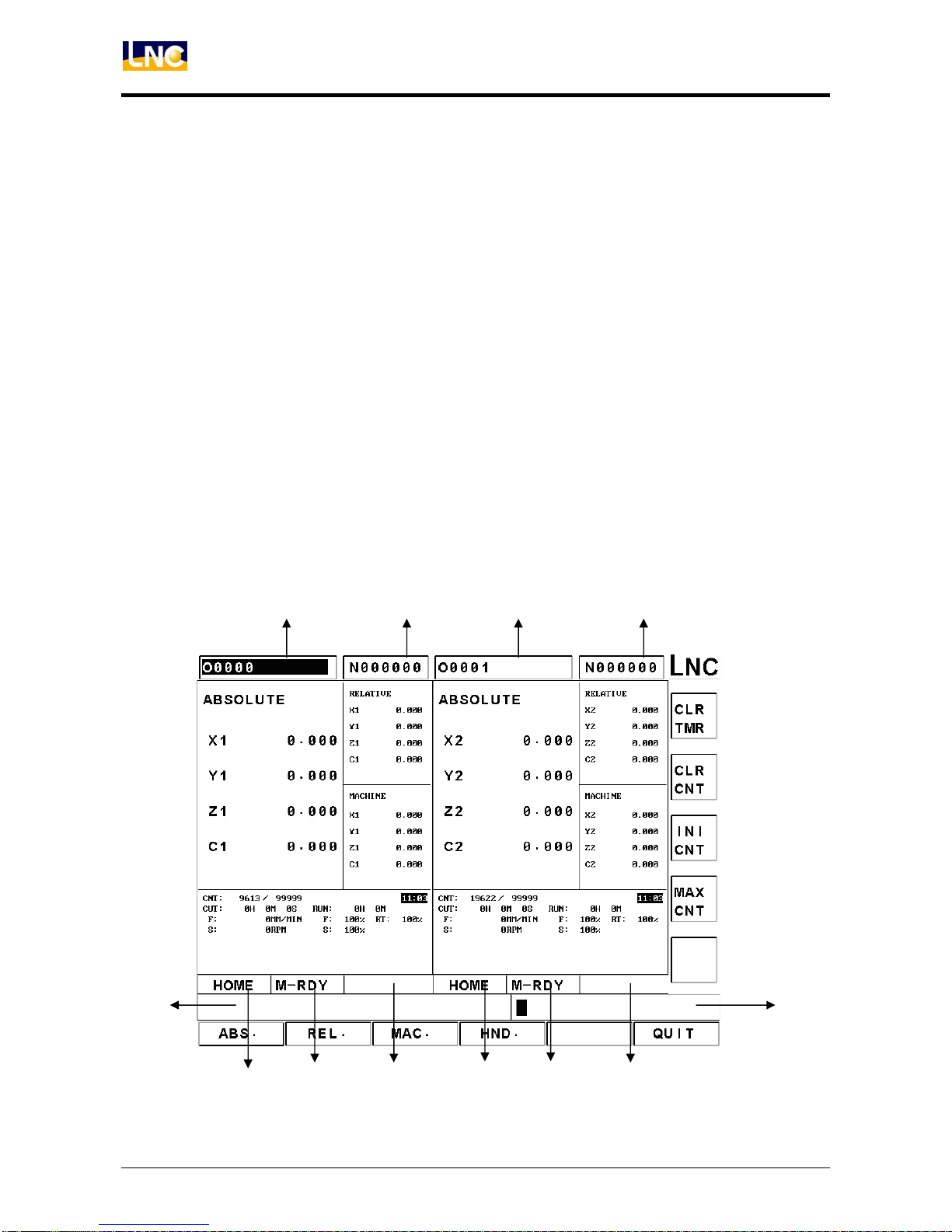

1.3.1 Alposition of the Display Screen

When switching groups in dual systems, both systems’ groups will be switched. The figure below is a screen

displaying simultaneous data of both systems, and on the left side of the screen (X1, Y1, Z1, C1) is System 1,

on the right side of the screen (X2, Y2, Z2, C2) is System 2. The position dedicated to System 1 and System 2

can be changed by Pr.4989.

The buttons only work on the currently working system. To know which the currently working system is,

distinguish from whether the cursor stays on position 1 or 3 in the figure below. When cursor stays on position

1, the currently working system is System 1; and when on position 3, the currently working system is System

2.

The screen introduction below is for the system data screens appear in the screen.

5

1 2 3 4

6 8 9 107

12

11

LNC-T800

CNC Group Instruction

LNC Technology Co., Ltd. 9

1: System 1 currently specified program name.

2: System 1 currently executed block.

3: System 2 currently specified program name.

4: System 2 currently executed block.

5: System 1 mode information.

6: System 1 machine status information.

7: System 1 alarm information (Alarm), warning information (Waring).

8: System 2 mode information.

9: System 2 machine status information.

10: System 2 alarm information (Alarm), warning information (Waring).

11: Simple information prompt area.

12: Input area.

Data of both systems can be displayed on the screen simultaneously or separately as shown in the following

figure:

LNC-T800

CNC Group Instruction

10 LNC Technology Co., Ltd.

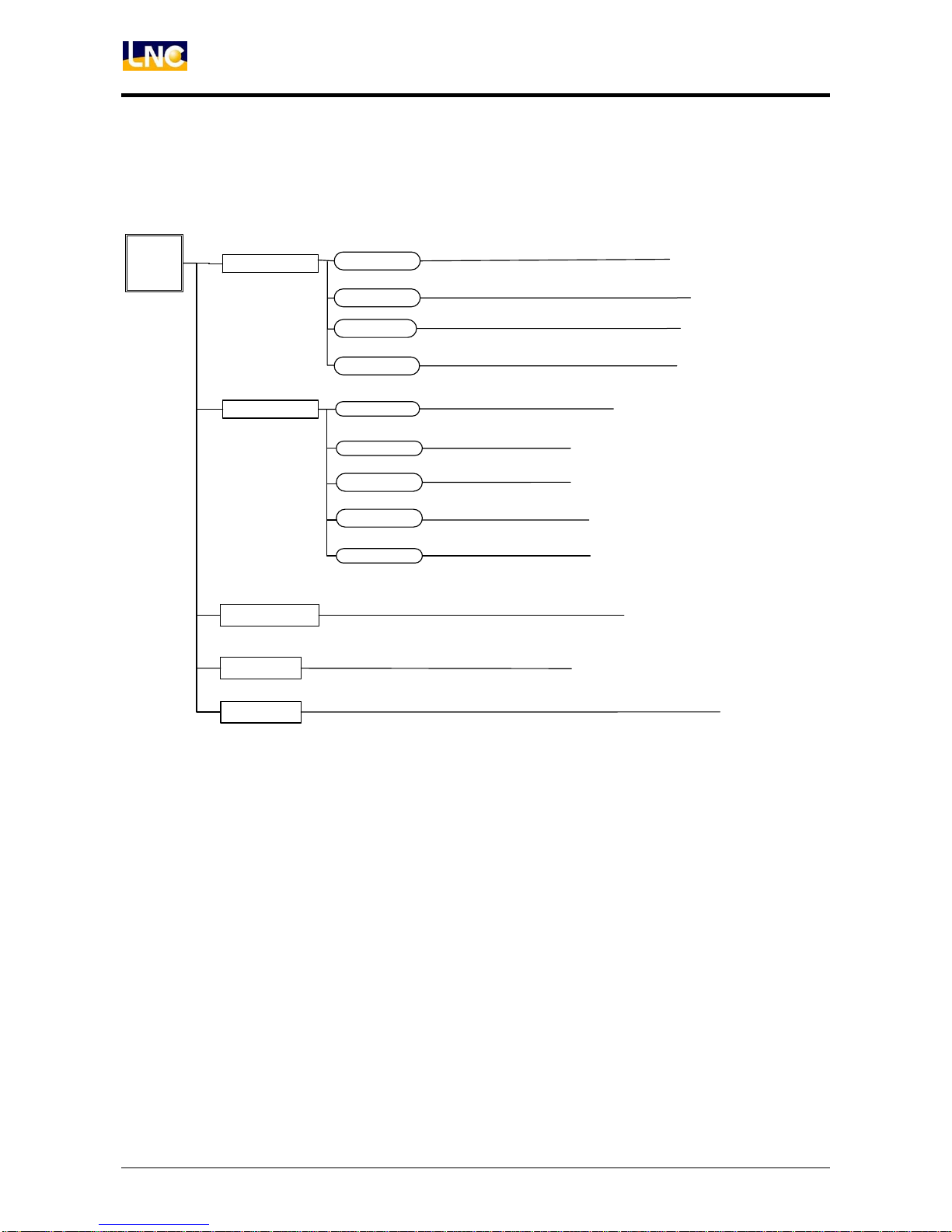

1.3.2 Functions of Each Function Group

Tree Diagram of POS Function Keys

ABSOLUTE

RELATIVE

MACHINE

POS

HND.

Show Mechanical coordinates

Set all relative coordinates to 0

Set relative coordinates of X axis to 0

Set relative coordinates of Y axis to 0

Set relative coordinates of Z axis to 0

Motion amount interpolated by handle

QUIT Quit the system

Set target parts count

Set operation time to 0

Set parts count to 0

Set initial parts count

CLR TMR

CLR CNT

INI CNT

MAX CNT

CLR.ALL

CLR.X

CLR.Y

CLR.Z

Set relative coordinates of Z axis to 0

CLR.C

Figure 1.3-1 Tree Diagram of POS Function Keys

LNC-T800

CNC Group Instruction

LNC Technology Co., Ltd. 11

Tree Diagram of PROG Function Keys

PROG

COMM.

MDI

PROCHK

DIRMNG

FGPROG

INS CYCL

EDITCYCL

LDEL

MARK

UN MARK

COPY

CUT

BIND

NEXT

NEXT

Copy the selected range

Move cursor to the designated line

Move cursor to the designated word

Insert MACRO

Edit MACRO

Delete the line pointed by cursor

Mark the selected range

Unmark the selected range

Paste the selected range

Cut the selected range

Open Teach In window

Open a file

Copy the selected file

Copy files from A to C

Copy files from C to A

Delete the selected file

Change the selected file name

Set default diretory

Show current program’s information

Download file via RS232

Upload file via RS232

Execute MDI command

COPY

COPYA>C

COPYC>A

DEL

REN

SETDIR

DOWNLOAD

UP LOAD

NEXT

COMM

SETT

File transmission main screen

Set RS232 protocol

NEXT

NET SET Set network connection

GOTO

WORDFIND

FILE

THINMODE

Figure 1.3-2 Tree Diagram of PROG Function Keys

LNC-T800

CNC Group Instruction

12 LNC Technology Co., Ltd.

Tree Diagram of OFFSET Function Keys

OFFSET ABS

SET ALL

INC

NORUNT

MINUNT

SET X

SET Y

SET Z

SET C

WEAR

WORK

SHIFT

Absolute input mode

Input unit: um

Input unit: mm

Incremental input mode

Local variable setup

Set mechanical coordinates of all axes

Set mechanical coordinates of X axis

Set mechanical coordinates of Z axis

Set mechanical coordinates of C axi

s

Set mechanical coordinates of Y axis

Coordinate system offset setup

ABS

INC

NORUNT

MINUNT

GEOM Absolute input mode

Input unit: um

Input unit: mm

Incremental input mode

#

@

MACRO

Global variable setup

Figure 1.3-3 Tree Diagram of OFFSET Function Keys

LNC-T800

CNC Group Instruction

LNC Technology Co., Ltd. 13

Tree Diagram of GRAPH Function Keys

GRAPH GRAPH

SET

Draw Tool Path

Set graphic drawing window

Figure 1.3-4 Tree Diagram of GRAPH Function Keys

LNC-T800

CNC Group Instruction

14 LNC Technology Co., Ltd.

Tree Diagram of DGNOS Function Keys

DGNOS

I/O

MLC2

SYSTEM

SYS UPD

ALARM Show system alarm

Show system version & debug message

Show system warning

Show system alarm/warning history

Show current I bit value

Show current O bit value

Show current C bit value

Show current S bit value

Show current A bit value

Show ladder diagram

Show current counter value

Show current R register value

Show current D register value

Show hardware diagnosis result

Enter System Upgrade page

Show system operation history

ALARM

WARN

HISMSG

LOGHST

OP LOG

I BIT

O BIT

C BIT

S BIT

A BIT

LAD

CNT

REG

DRG

Show current timer value

TMR

GBL

H.D

Show system data

Figure 1.3-5 Tree Diagram of DGNOS Function Keys

LNC-T800

CNC Group Instruction

LNC Technology Co., Ltd. 15

Tree Diagram of SOFTPL Function Keys

Figure 1.3-6 Tree Diagram of SOFTPL Function Keys

LNC-T800

CNC Group Instruction

16 LNC Technology Co., Ltd.

Tree Diagram of PARAM Function Keys

Figure 1.3-7 Tree Diagram of PARAM Function Keys

Table of contents