GENERAL

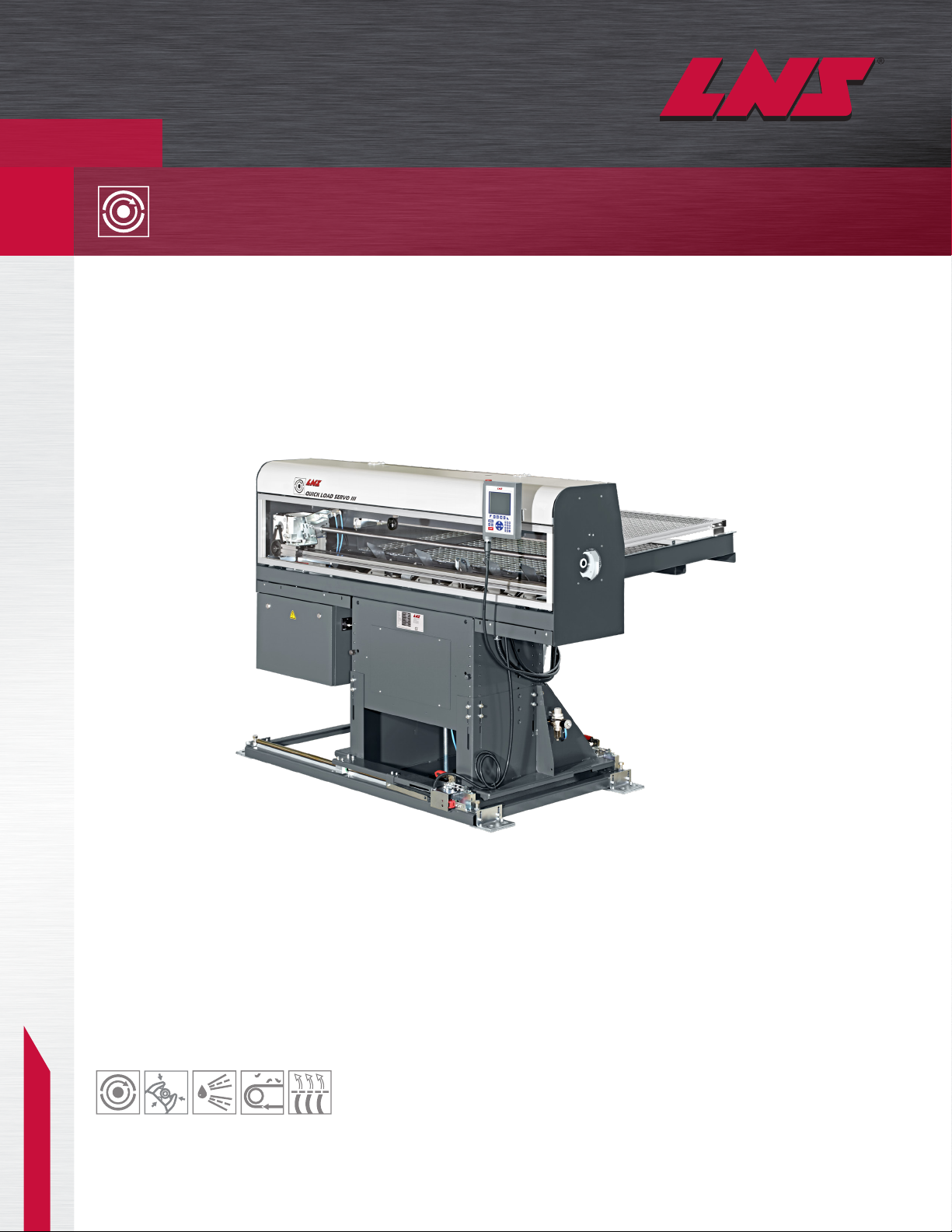

SERVICE MANUAL – QL Servo S3-T

TABLE OF CONTENTS

1. GENERAL .................................................................................................................................6

ABOUT THIS SERVICE MANUAL ............................................................................................6

WHO IS THIS MANUAL FOR?..................................................................................................6

OTHER APPLICABLE DOCUMENTS .......................................................................................6

IN THE CASE OF DAMAGE CAUSED DURING TRANSPORTATION....................................6

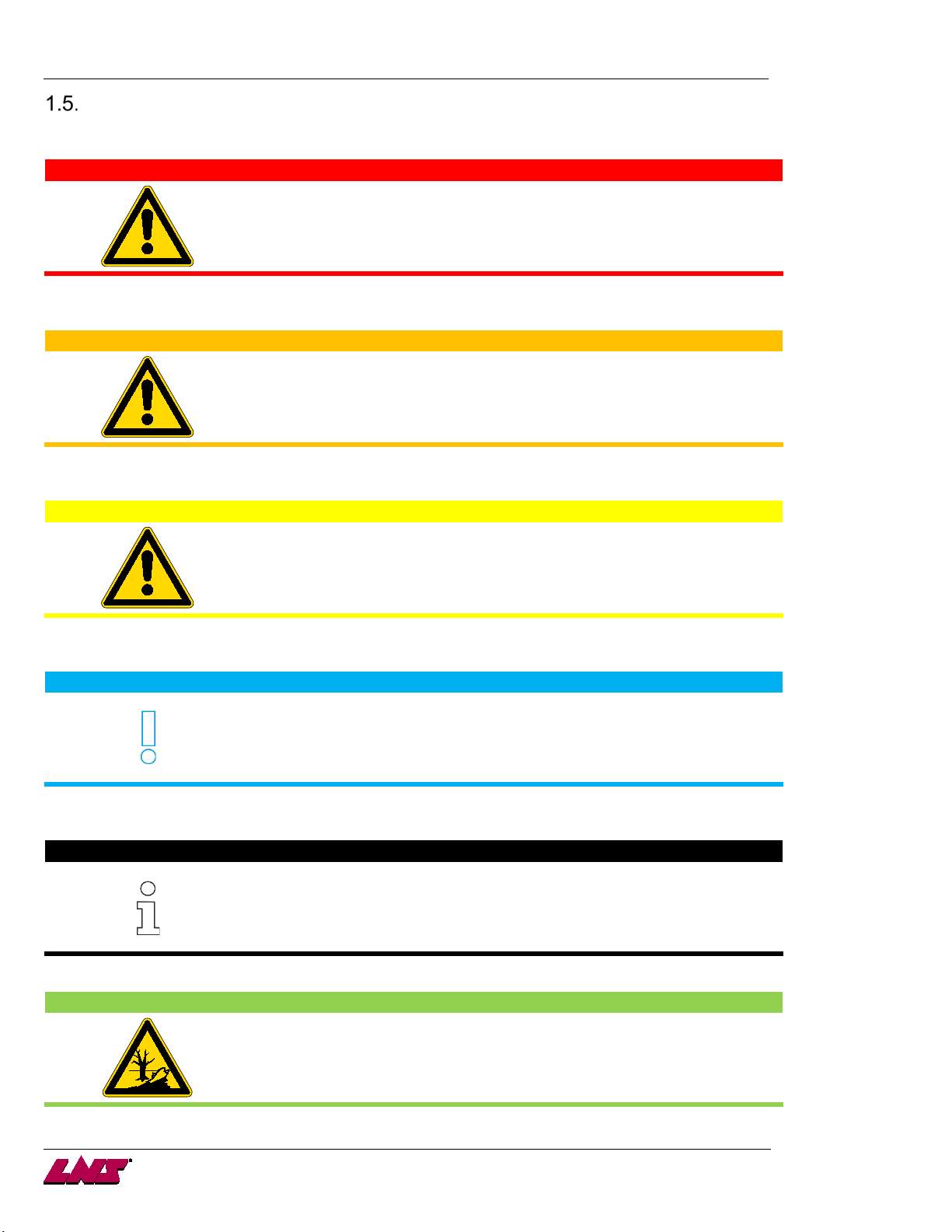

SYMBOLS AND WARNING LABELS........................................................................................7

CONVENTIONAL TERMS AND SYMBOLS..............................................................................8

COPYRIGHT..............................................................................................................................8

LIABILITY...................................................................................................................................8

SAFETY INSTRUCTIONS.........................................................................................................9

2. PROCEDURES........................................................................................................................10

SETUP, ALIGNMENT, AND ANCHOR PROCEDURE ...........................................................10

PUSHER CHANGEOVER .......................................................................................................15

SERVO MOTOR BELT TENSION ADJUSTMENT .................................................................17

CARRIAGE UNIT BELT TENSION ADJUSTMENT ................................................................18

DIAMETER ADJUSTMENT MOTOR REPLACEMENT ..........................................................19

HOME POSITION PROXIMITY SWITCH ADJUSTMENT – SQ5 ...........................................22

MEASURING CELL ADJUSTMENT – SQ3 ............................................................................23

PUSHER REVERSING DISTANCE ADJUSTMENT ...............................................................25

MAGAZINE AND LOADING FINGER ADJUSTMENT ............................................................26

CALIBRATION OF THE LOADING TABLE .............................................................................27

FINDING SOFTWARE/PLC VERSIONS.................................................................................28

SOFTWARE UPDATE .............................................................................................................28

PLC BATTERY REPLACEMENT ............................................................................................29

3. MECHANICAL EQUIPMENT ..................................................................................................30

BAR MAGAZINE......................................................................................................................30

LOADING TABLE ....................................................................................................................34

PUSHER CARRIER.................................................................................................................35

LOADING PUSHER.................................................................................................................36

FEEDING PUSHER .................................................................................................................36

RETRACTION..........................................................................................................................39

KIT FOR SQUARE BARS (OPTION) ......................................................................................39

KIT FOR QUICK PART LOADING (OPTION) .........................................................................40

4. PNEUMATIC EQUIPMENT .....................................................................................................42

LAYOUT OF THE ELEMENTS................................................................................................42

AIR TREATMENT UNIT ..........................................................................................................43

PNEUMATIC BATTERY ..........................................................................................................44

5. ELECTRICAL EQUIPMENT....................................................................................................46

SAFETY COMPONENTS ........................................................................................................46

ELECTRICAL COMPONENTS................................................................................................47

ELECTRICAL CABINET ..........................................................................................................48

REMOTE CONTROL ...............................................................................................................51

SERVO AMPLIFIER ................................................................................................................55

PROGRAMMABLE LOGIC CONTROLLER ............................................................................57

ACCESSORY COMPONENTS ...............................................................................................58

IDENTIFICATION MARKINGS – TYPE OF MATERIAL .........................................................59

CONNECTIONS ......................................................................................................................60