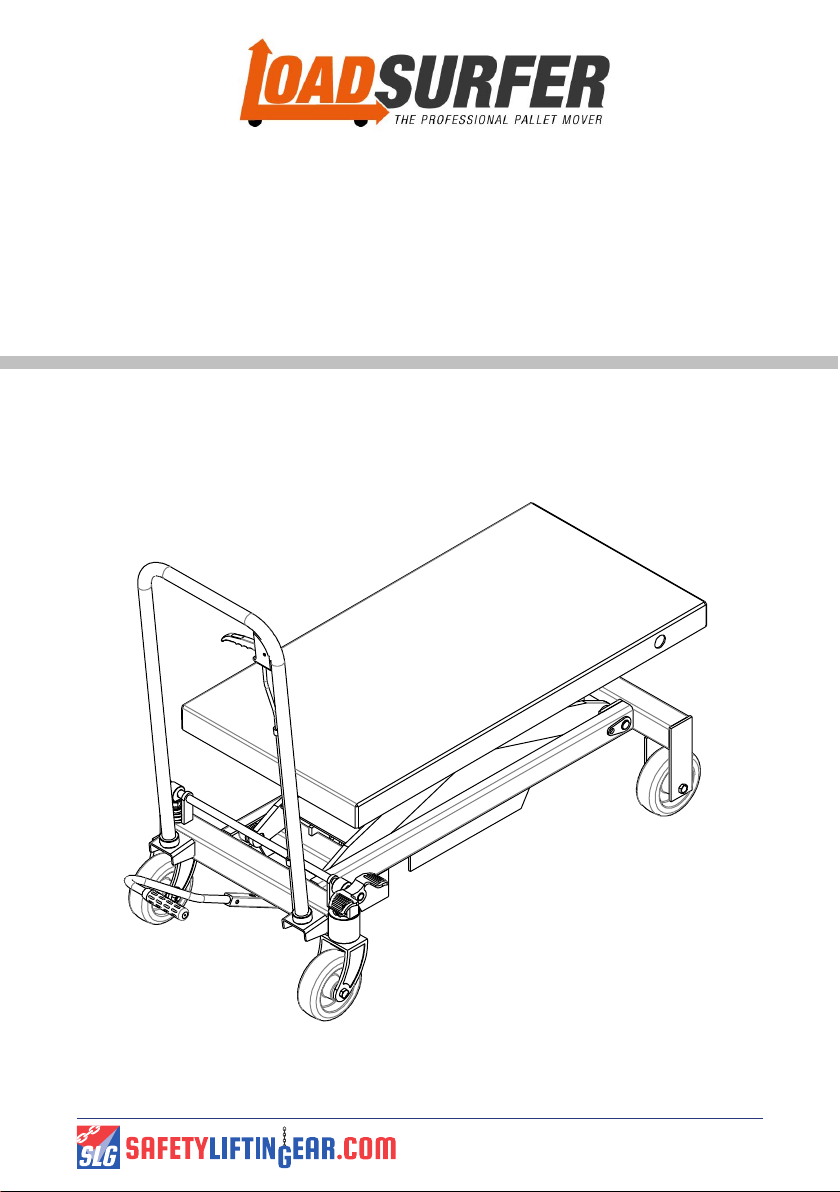

LoadSurfer PT800A User manual

PT800A/PT1000A Hydraulic Lift Table

⚫Operation manual

⚫Spare parts catalogue

Unit R1D Rockingham Gate

Poplar Way West

Cabot Park

Bristol

BS11 0YW

Contact Us

Tel: 0808 123 69 69

Fax: 0117 9381 602

Email: [email protected]

1

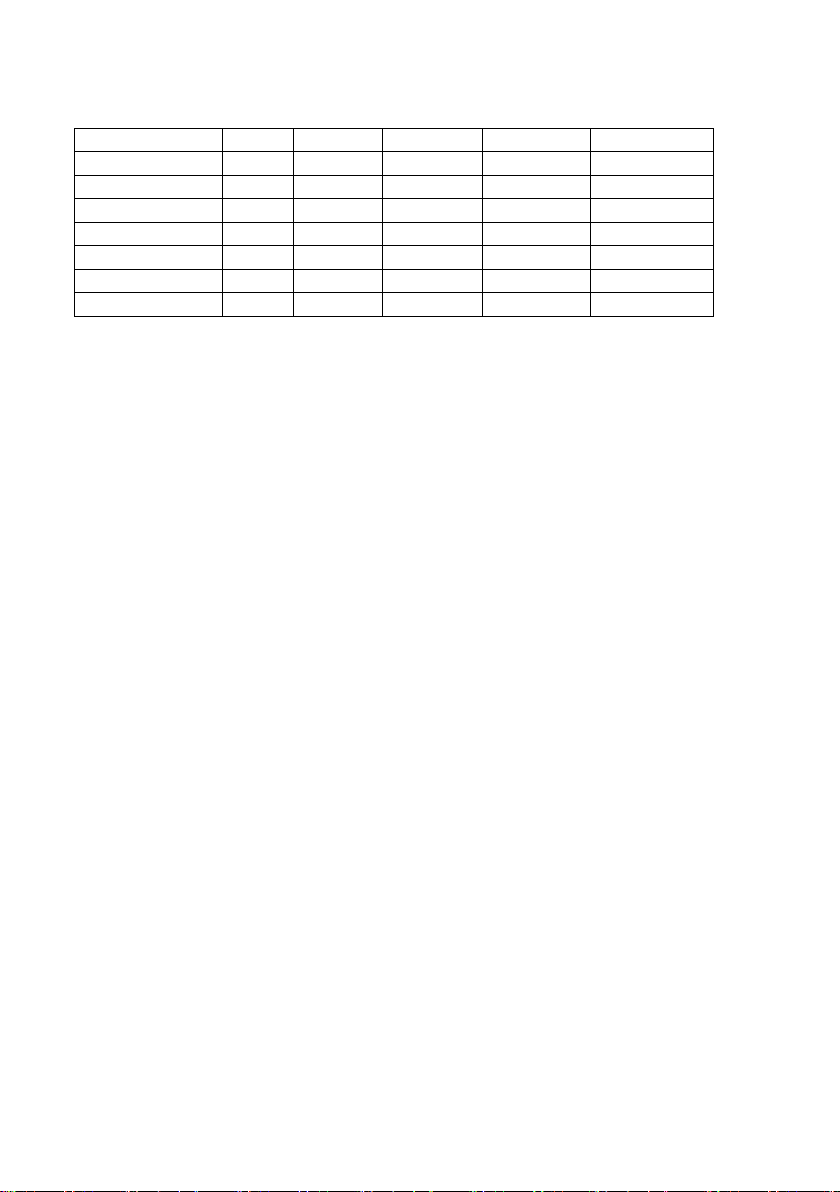

Ⅰ. Main technical parameters:

PT800A

PT1000A

Capacity

kg

800

1000

Max. lift height

mm

1000

1000

Min. height of table

mm

415

415

Table size

mm

1016X510

1016X510

Handle height

mm

990

990

Wheel diameter

mm

150

150

Service weight

kg

114

114

Ⅱ. Scope of application:

PT series table lift truck is a kind of high-lift transportation tool which is applicable for short-distance

transportation as well as goods lifting and lowering. Besides, it can also be used as station facilities

for workshop.

Ⅲ. Operation condition:

1. Lift table should be operated on solid and flat ground;

2. Operation temperature: -20-40C°.

Ⅳ. Notes(warning):

1. Read the instruction carefully before operation and get to know the performance and operation

requirements of the lift table. And the hydraulic lift table can’t be used unless it is authorized.

2. Do not overload the hydraulic lift table and operate it within the rated load. Overloading will

cause damage to the hydraulic lift table and human body.

3. It is forbidden for operators to stand or sit on the table to work.

4. Don’t put the hands or feet under the lowering table.

5. Please brake the truck when loading goods to prevent it from moving.

6. Off-set loading is forbidden when loading goods, and the goods should be distributed uniformly

on the whole table.

7. Loose or unstable goods are not permitted to be loaded.

8. Don’t put goods on working table for a long time.

9. The truck can’t be moved when goods are being lifted.

10. The truck can only be moved on flat and hard ground, it is forbidden to be used on sloping

ground or rugged ground;

11. When putting goods on table which has been hoisted, the weight of goods should be within

rated load, and the goods should be loaded lightly. (Safety valve only works in hoisting process,

if the truck has been hoisted, and then put overweight goods on it, the safety valve can’t work.

In this way, the truck may be damaged.)

12. When loading and unloading goods on hoisted table, don’t drag goods in cross direction, which

2

may cause serious off-set loading and make truck turn over.

13. When maintaining and repairing truck, stand bar should be used to support fork arm in order to

prevent table from falling (there should be no goods on table), and guarantee the safety in

maintenance and repairing.

14. Please operate strictly according to “notes (warning)”, otherwise it will bring damage to truck

and human body.

Ⅴ. Operation methods:

1. Please step on the foot lever for several times to raise the working table.

2. Please lift the handle knob upward slowly, and open the one-way valve to make the working

table descend slowly.

3. Please make the brake open before moving the truck.

Ⅵ. Maintenance and upkeep:

It is very important to conduct necessary maintenance and upkeep so as to prolong the service life

and safety of the lift table. Please check the lift table before operation according to the following

items:

1. Whether there is any distortion and bending of various positions of the lift table.

2. Please check the brake of the truck and the wearing condition of the wheels.

3. Check oil leakage in the hydraulic system.

4. Please add or fill lubricant to each friction surface before daily operation.

5. If there is any failure, the lift table should be repaired at once, then it can be put into use again.

6. Chang the hydraulic oil every twelve months, choose the following or close brand hydraulic oil

according to the climate conditions of different areas:

a) YBN32 is adaptive under the environment temperature of -10~+40°C;

b) YCN32 is adaptive under the environment temperature of -20~+40°C.

Ⅶ. Assembly method:

The handle and foot lever are dismantled when ex-factory, they might be fixed together by the

users when using. The assembly methods are as follows:

Handle installation method: as shown following drawing, fix the handle (B1) to mounting hole

of the truck body (A) with bolt (B7), spring washer (B6), flat

washer (B5), then screw down the bolt (B7) with wrench.

Foot lever mounting: insert the foot lever (B31) into the hole, put in the screw (B29) and the

plain washer (B27) , the spring washer (B28) ,then screw down the

screw (B29) with wrench.

3

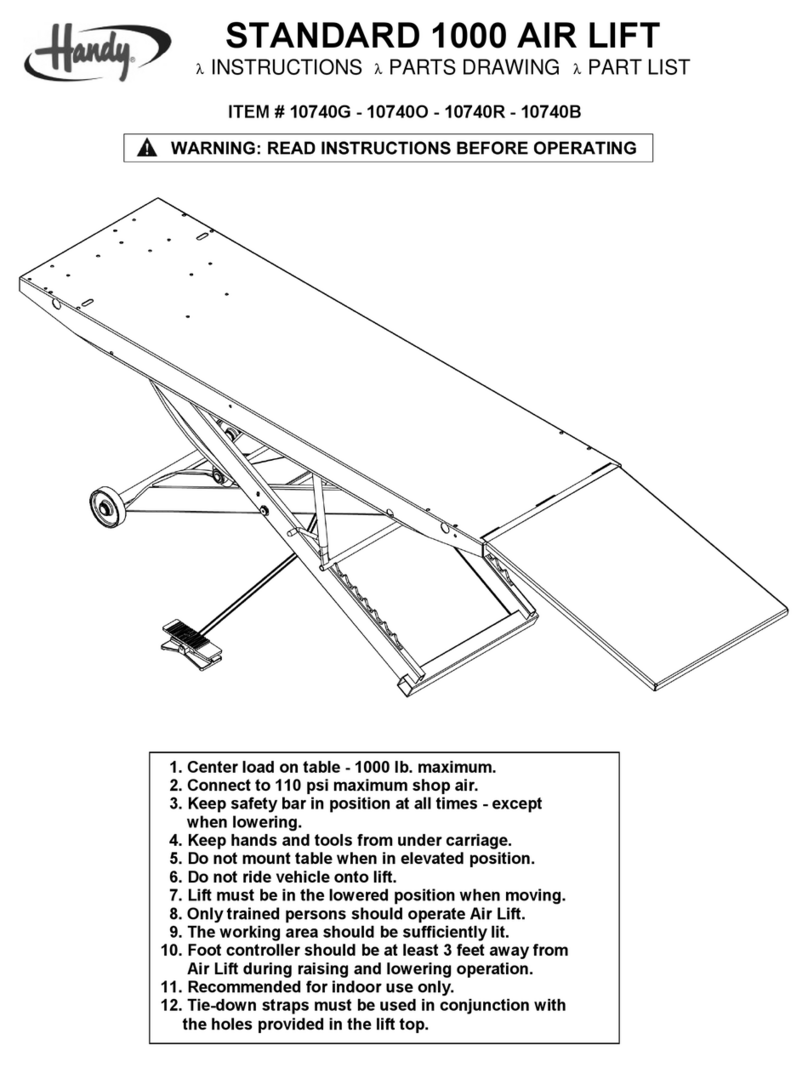

Ⅷ. Name of Parts

HANDLEHANDLEKNOBKNOB

HANDLEHANDLE

FOOTFOOTLEVERLEVER

TABLETABLE

SCISSORSCISSOR

FRAMEFRAME

PUMPPUMP

4

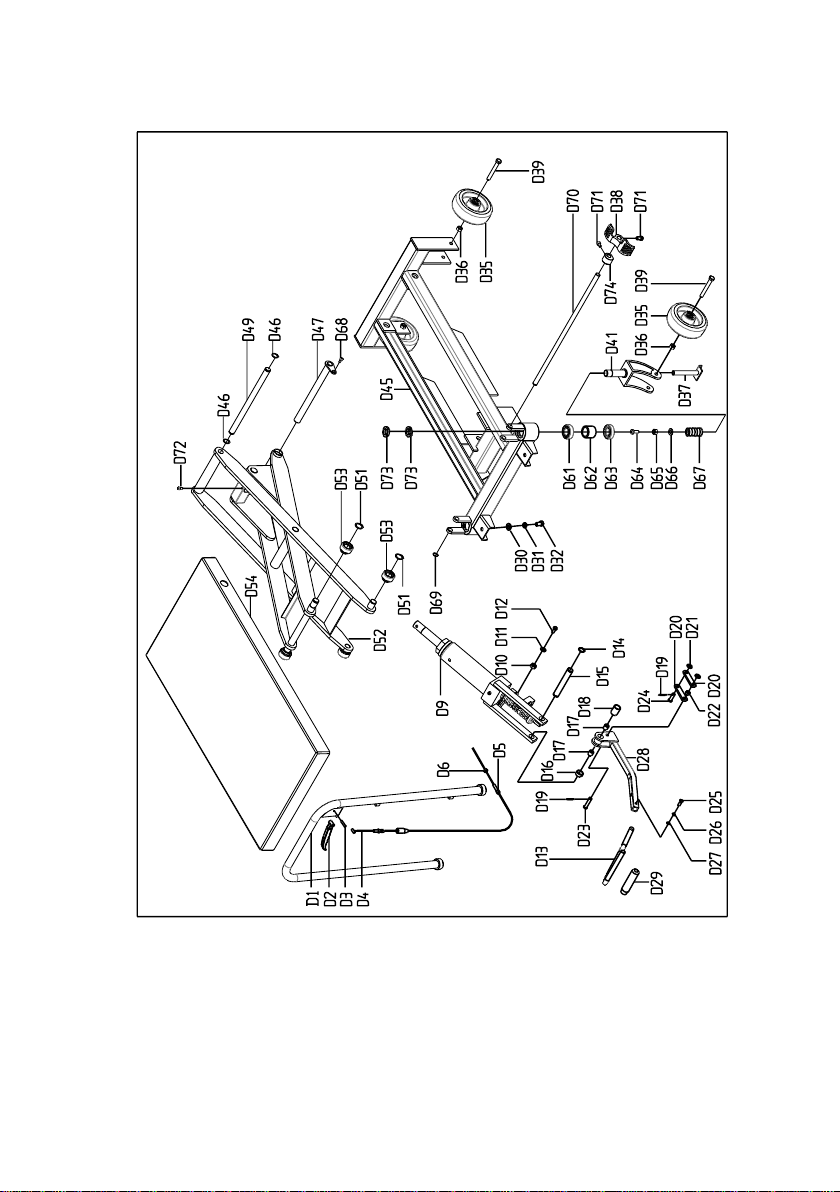

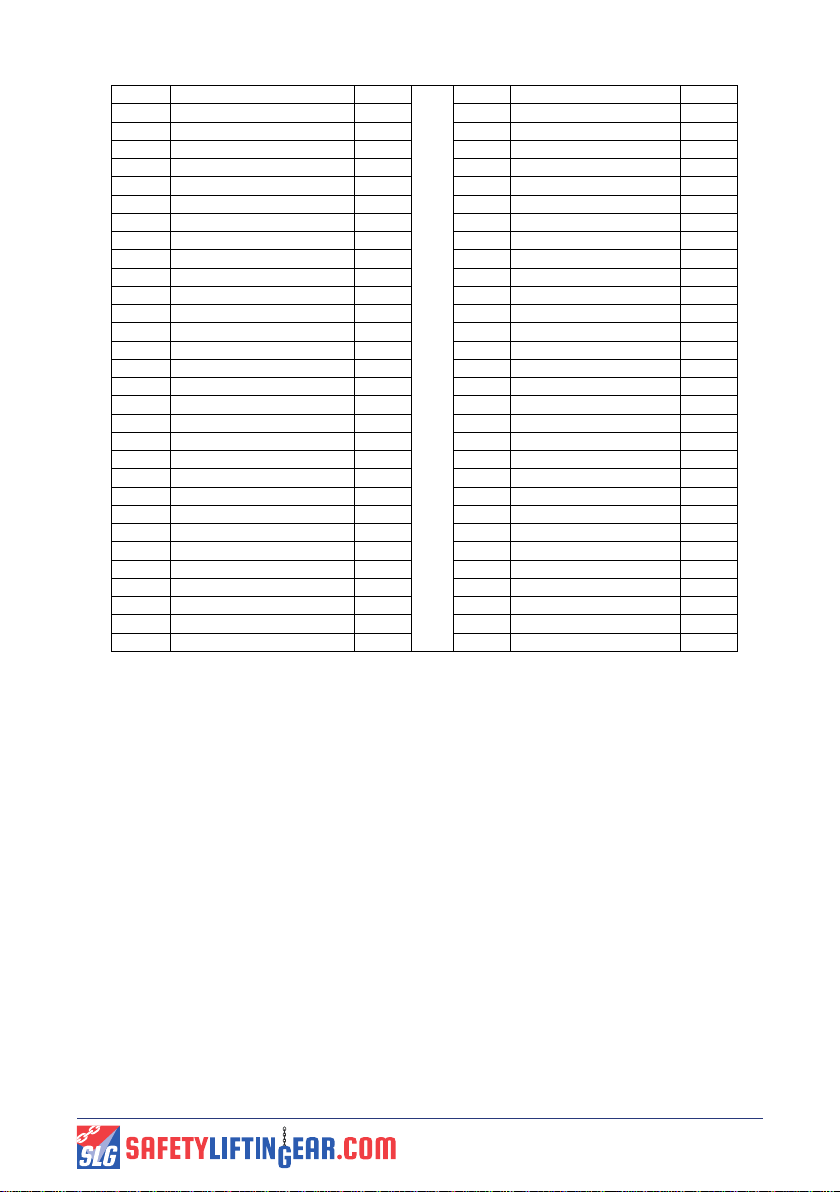

Ⅸ.Spare parts catalogue

1.PumpSpare parts catalogue (Type PT800A/PT1000A)

No.

Name

Qty.

No.

Name

Qty.

X910

Coverforspring

1

X935

O-ring

1

X911

Spring

1

X936

Washer

1

X912

Pump core

1

X937

Spring

1

X913

Dust ring

1

X938

O-ring

1

X914

Seal ring

1

X939

O-ring

1

X915

Pump cylinder

1

X940

Spring

1

X916

Washer

1

X941

Valve

1

X917

BigNylonwasher

2

X942

Valve

1

X918

SmallNylonwasher

1

X943

Strikepin

1

X919

Cylinder

1

X944

Strikepin base

1

X920

Retaining ring foraxle

1

X945

Ball

1

X921

Seal ring

1

X946

Spring base

1

X922

Piston

1

X947

Spring

1

X923

O-Ring

1

X948

O-ring

1

X924

Piston rod

1

X949

Screw

1

X925

Housing

1

X950

Nut

1

X926

Base

1

X951

Bolt

1

X927

Cylinder cap

1

X952

Retaining ring foraxle

1

X928

O-ring

1

X953

Pin

1

X929

Dust ring

1

X954

Ball

1

X930

Screw

1

X955

Ball

1

X931

O-ring

1

X956

Spring

1

X932

Valvecover

1

X957

Ball

1

X933

Valve

1

X958

Bolt

1

X934

Leverplate

1

5

2.PT800A/PT1000A sparepartscatalogue

6

No.

Name

Qty.

No.

Name

Qty.

D1

Handle

1

D35

Wheel

4

D2

Handleknob

1

D36

NutM12

4

D3

Springpin

1

D37

Breakpad

2

D4

BrakeLine

1

D38

Breaklever

2

D5

Screw

2

D39

Bolt

2

D6

Nut

2

D41

Baseforuniversalwheel

2

D9

Pump

1

D45

Washer

8

D10

Nut

1

D46

Frame

1

D11

Washer

1

D47

Nut

2

D12

Clampscrew

1

D49

Retainingringforaxle

6

D13

Foot lever

1

D51

Nut

4

D14

Retainingringforaxle

2

D52

Springwasher

4

D15

Shaft

1

D53

Washer

4

D16

Shortspacerbush

1

D54

Longshaft

2

D17

Bush

2

D61

Bearing

2

D18

Longspacerbush

1

D62

Spacerbush

2

D19

Cotter

2

D63

Bearing

2

D20

Link

2

D64

Screwm10X25

2

D21

Washer

2

D65

NutM10

2

D22

Spacerbush

1

D66

Washer 10

2

D23

pin

1

D67

Spring

2

D24

Pin

1

D68

ScrewM8X20

1

D25

Screw

1

D69

Retainingringforaxle 16

1

D26

Springwasher

1

D70

Brake rod

1

D27

Washer

1

D71

Screw M8X12

3

D28

Connectingrod

1

D72

Bolt M6X12

1

D29

Robbertube

1

D73

NutM24X1.5

4

D30

Washer

2

D74

Cam

2

D31

Springwasher

2

D32

ScrewM12X25

2

Unit R1D Rockingham Gate

Poplar Way West

Cabot Park

Bristol

BS11 0YW

Contact Us

Tel: 0808 123 69 69

Fax: 0117 9381 602

Email: [email protected]

This manual suits for next models

1

Other LoadSurfer Lifting System manuals

Popular Lifting System manuals by other brands

Bend-Pak

Bend-Pak HDS-18EA Installation and operation manual

Bohle

Bohle Liftmaster Quadro Brief instructions

Liko

Liko M220 Quick reference guide

E/D/E

E/D/E HLT1-520 operating instructions

STS

STS DTP05 Operation and maintenance manual

Titan Lifts

Titan Lifts HD2P-10000AC-D Installation, operation & maintenance manual

Challenger Lifts

Challenger Lifts 40200 Operation installation maintenance manual

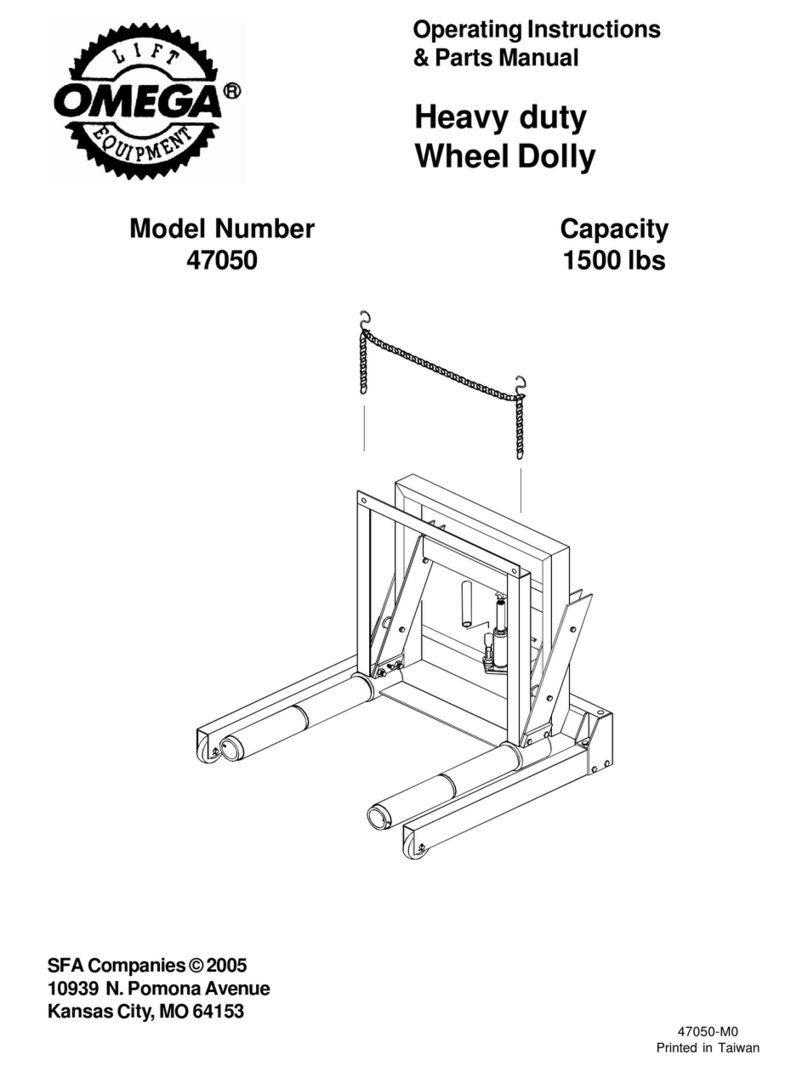

Omega

Omega 47050 Operating instructions & parts manual

EZ-ACCESS

EZ-ACCESS Modular Ramp Assembly manual

JLG

JLG T350 Service and maintenance manual

Harmar Mobility

Harmar Mobility AL055 Installation & owner's manual

Global Lift

Global Lift 450R owner's manual