Copyright © 2021, ASSA ABLOY Australia Pty Limited. All rights reserved. Reproduction in whole or

in part without the express written permission of ASSA ABLOY Australia Pty Limited is prohibited.

700002AU Rev 2 06/21

6

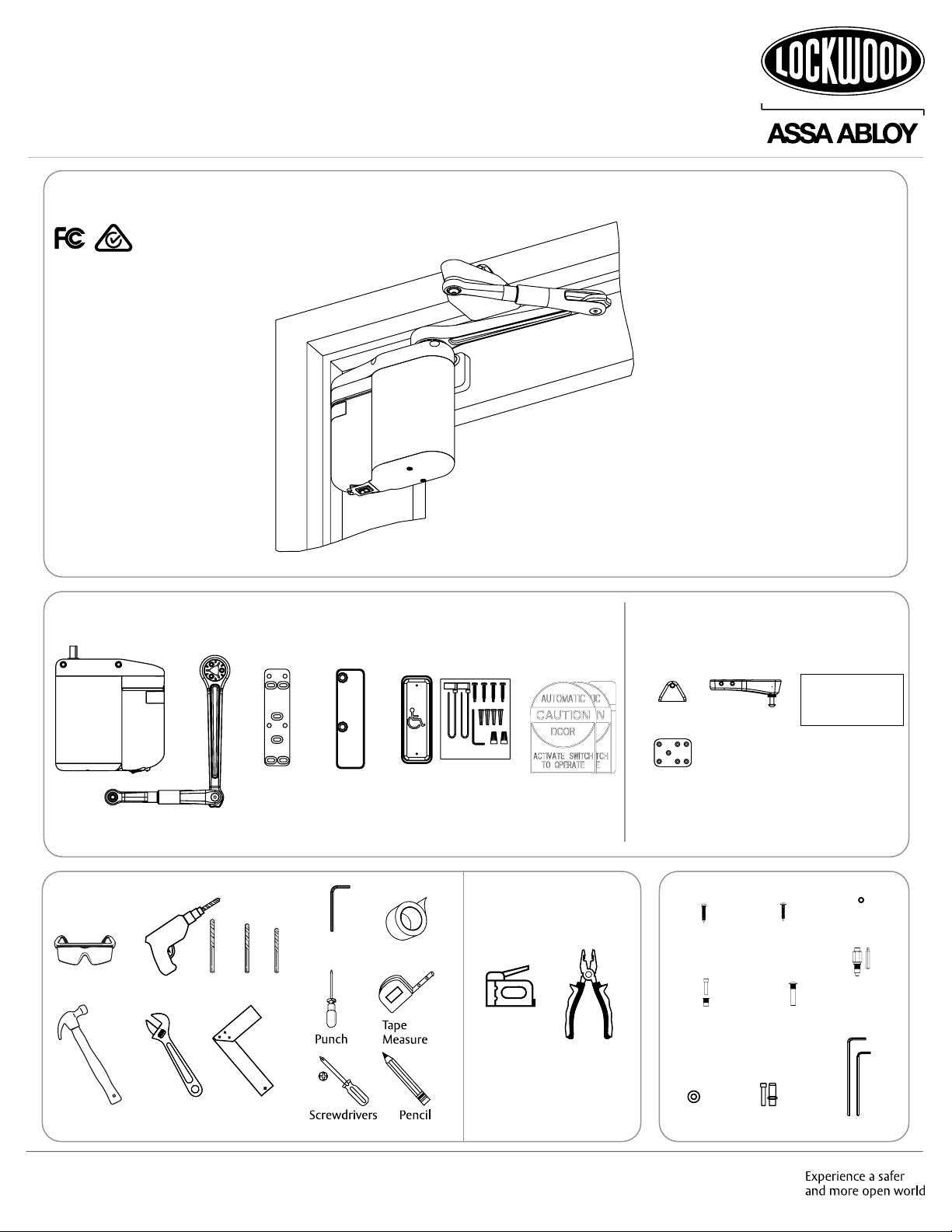

5831 Series Installation and Operating Instructions

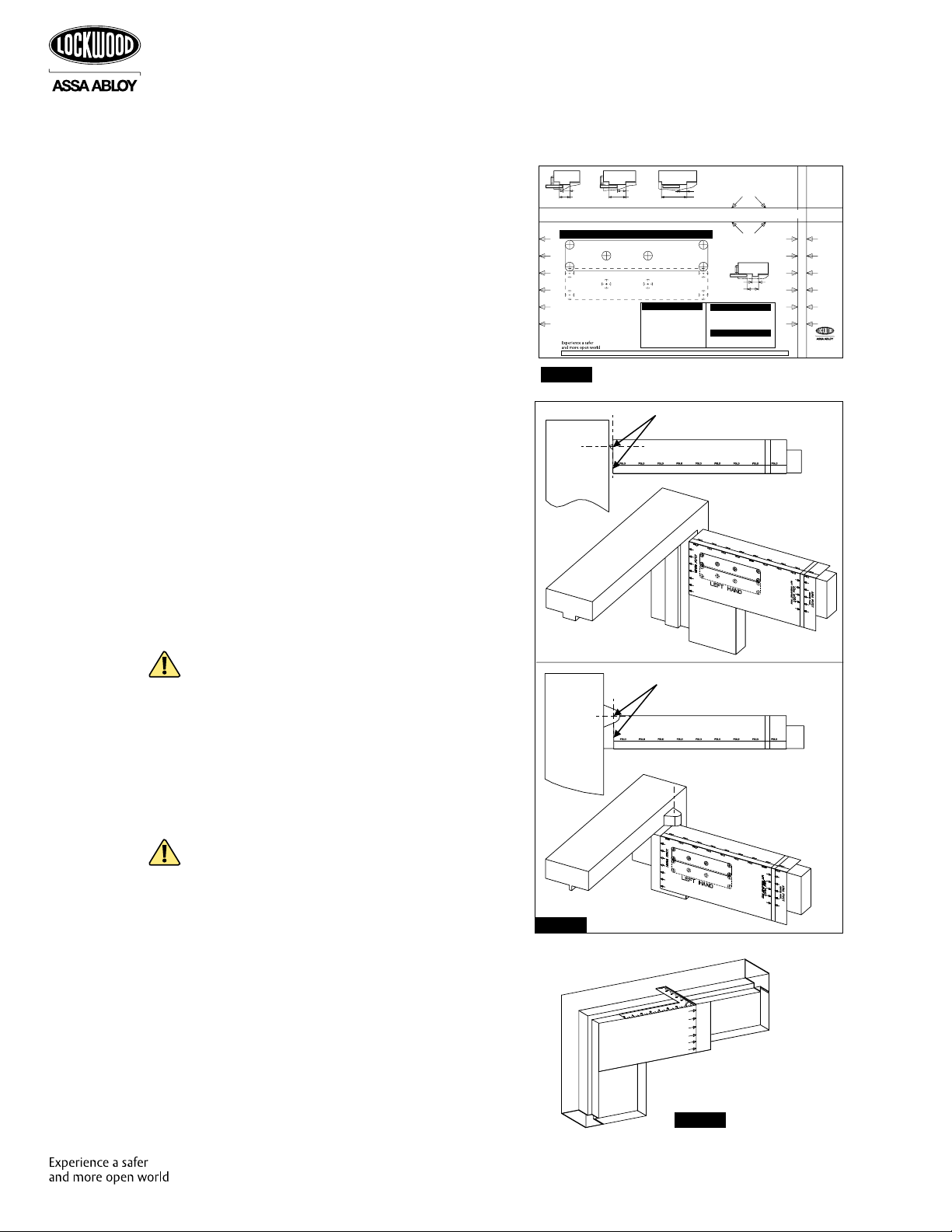

Align Template With Hinge Centerline

Top View

Butt Hinge

Top View

Offset Pivot Align Template With Hinge Centerline

EZ043

1. Select right hand or left hand template and

become familiar with information. (Figure 3)

NOTE: Refer to “Determine Door Handing and

Mounting Type” on page 5 to verify hand. A

push side operator always mounts on push-to-

open side of door at hinge.

2. Measure stop thickness and select fold line.

• If stop is greater than 38mm, use upper

fold line.

• If stop is 38mm or less, use lower fold line.

3. Determine type of door hinge (butt, offset

pivot, or center pivot) and align template at

centerline of door hinge or pivot. (Figure 4)

NOTE: Ensure template is at hinge centerline

NOT edge of door.

4. Measure stile and select mounting location.

• Narrow stile: Use solid line mounting

location.

• Other or Wood: Use dotted line mounting

location.

CAUTION: On an aluminum storefront door,

operator mounting holes must not be drilled

into top rail web, rail-to-stile tie rod(s), or rail-

to-stile junction.

5. Tape template into position and mark a

minimum of four (4) of the six (6) mounting

hole locations with a center punch and

hammer.

CAUTION: To ensure proper installation, at

least four (4) fasteners that will not interfere

with top rail web, rail-to-stile tie rod(s), or

rail-to-stile junction must be used. For heavier

doors, more fasteners are recommended.

6. With door closed, use a square to mark

centerline of arm mounting shoe onto

underside and face of frame header and door

stop. (Figure 5) This line is shown on template.

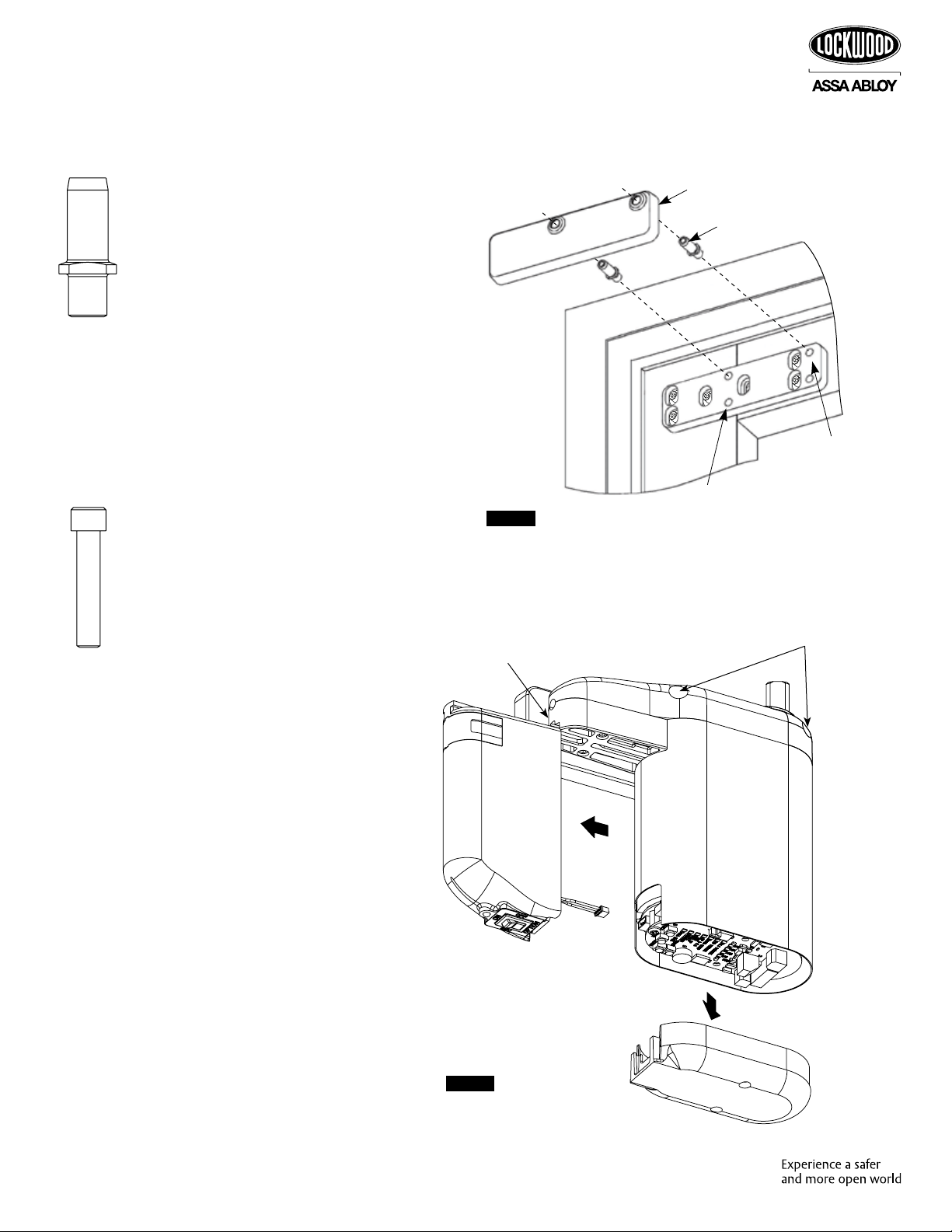

PUSH SIDE Operator and Arm Installation

Figure 5

Prepare Door and Frame

Figure 4

16mm Minimum

38mm Maximum

Greater than 38mm"

38mm Or Less

16mm Minimum

38mm Maximum

Operator Mounting Bracket

For Narrow Stile Doors

ADAEZ - LEFT HAND TEMPLATE - PUSH MOUNT

Operator Mounting Bracket

For All Other Doors

This device does not work with Swing

Clear hinges or Balanced Doors

Minimum Reveal - 40mm

Minimum Top Rail - 51mm

Stop Width - Reveal minus 25mm

Frame Face - No Minimum

0803AU-Rev 1

------------------------------------------------------------------------254mm - REFERENCE----------------------------------------------------------------------------

FOLD FOLD FOLD FOLD FOLD FOLD FOLD FOLD

FOLD FOLD FOLD FOLD FOLD FOLD FOLD FOLD

Centerline of Door Hinge or Pivot

NOT Edge of Door

16mm Minimum

387mm Maximum

Greater than 38mm

16mm Minimum

38mm Maximum

Greater than 38mm

Door Stop sizes greater

than 38mm width

Use this Fold Line

Fold Aligns with Top of Door

All other Door Stop sizes

Use this Fold Line

Fold Aligns with Top of Door

Door Arm Pivot Shoe Centerline

For Center Pivot Doors

Door Arm Pivot Shoe Centerline

For Butt Hung or Offset Pivot Doors

Copyright © 2020, ASSA ABLOY Australia Pty Limited. All rights

reserved. Reproduction in whole or in part without the express

written permission of ASSA ABLOY Australia Pty Limited is prohibited.

www.lockweb.com.au

CAUTION:

Desktop printers and

copiers can modify

scale if "actual size"

is not selected in

print or copy dialog.

Verify reference

dimension accuracy

before using.

RESETTING THE CONTROLLER

PROGRAMMING

PROGRAMMING TRANSMITTER

RESETTING THE CONTROLLER

1. and +PRESS HOLD “SELECT”

until 4 LEDs flash green.“ENTER”

door, “ENTER”2. CLOSE PRESS

door, “ENTER”3. OPEN PRESS

door, “ENTER”4. CLOSE PRESS

“ENTER”5. andPRESS HOLD

until LEDs go out

REFER TO MANUAL FOR MORE INFO

1. andPRESS HOLD “LEARN”

until 4 LEDs flash green.

2. the RF activation switch,PUSH

the LEDs shall flash green.

1. ,PRESS HOLD “ENTER”and

2. andPRESS RELEASE “RESET”

Figure 3