4CV IO&M B51161-003

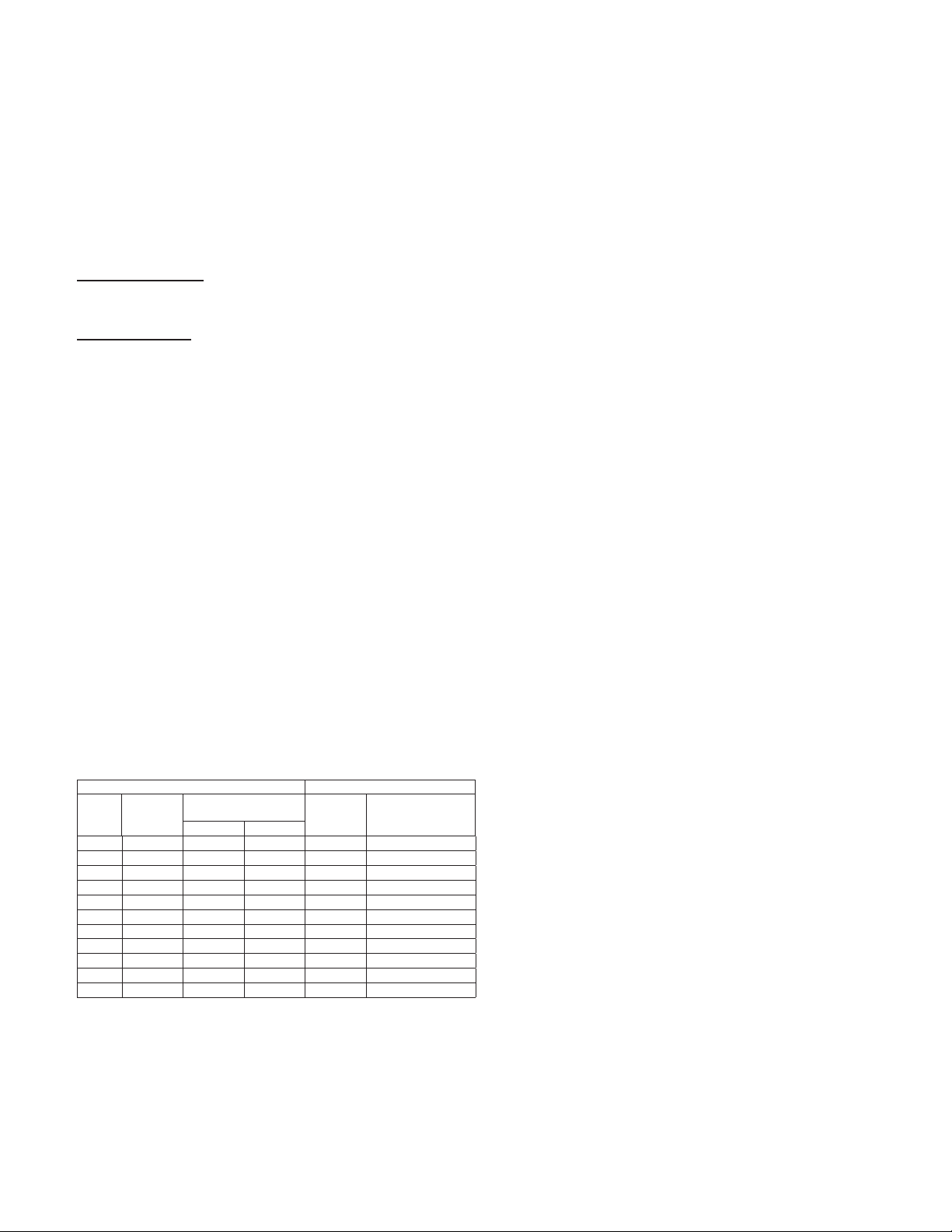

Bearings should be relubricated in accordance with the

conditions chart below.

Conditions Chart

RPM Temp °F Greasing Interval

Up to 1000 -30 to 120 6 months

120 to 200 2 months

1000 to 3000 -30 to 120 3 months

120 to 200 1 month

Over 3000 -30 to 120 1 month

120 to 200 2 weeks

Any Speed < -30 Consult Factory

Any Speed > 200 1 week

For moist or otherwise contaminated installations; divide the in-

terval by a factor of three. For vertical shaft installations divide

the interval by a factor of two.

For best results, lubricate the bearing while the fan is in

operation. Pump grease in slowly until a slight bead forms

around the bearing seals. Excessive grease can damage

seal and reduce life through excess contamination and/or

loss of lubricant.

In the event that the bearing cannot be seen, use no more

than three injections with a hand operated grease gun.

Motor Bearings

Motors are provided with prelubricated bearings. Any

lubrication instructions shown on the motor nameplate su-

persede instructions below.

Direct Drive 1050/1075, 1200, 1300 & 1500 RPM units

use a prelubricated sleeve bearing that has a oil saturated

wicking material surrounding it. The initial factory lubrica-

tion is adequate for up to 10 years of operation under nor-

mal conditions. However, it is advisable to add lubricant

after three years. Use only LIGHT grade mineral oil or SAE

10W oil up to 30 drops.

If the unit has been stored for a year or more it is ad-

visable to lubricate as directed above. For units in severe

conditions, lubrication intervals should be reduced to half.

Motors without sleeve bearings (as described above) will

have grease lubricated ball or roller bearings. Motor bear-

ings without provisions for relubrication will operate up to

10 years under normal conditions with no maintenance. In

severe applications, high temperatures or excessive con-

taminates, it is advisable to have the maintenance depart-

ment disassemble and lubricate the bearings after 3 years

of operation to prevent interruption of service.

For motors with provisions for relubrication, follow inter-

vals of the table below.

Relubrication Intervals

Service

Conditions

Nema Frame Size

Up to and

Including 184T 213T-365T 404T and Larger

1800

RPM

and

Less

Over

1800

RPM

1800

RPM

and

Less

Over

1800

RPM

1800 RPM

and Less

Over

1800

RPM

Standard 3 yrs. 6 months 2 yrs. 6 months 1 yr. 3 months

Severe 1 yr. 3 months 1 yr. 3 months 6 months 1 month

Motors are provided with a polyurea mineral oil NGLI #2

grease. All additions to the motor bearings are to be with

a compatible grease such as Exxon Mobil Polyrex EM and

Chevron SRI.

The above intervals should be reduced to half for vertical

shaft installations.

Inspection

Inspection of the fan should be conducted at the rst 30

minute, 8 hour and 24 hour intervals of satisfactory op-

eration. During the inspections, stop the fan and inspect as

per the following directions.

30 Minute Interval

Inspect bolts, setscrews, and motor mounting bolts. Ad-

just and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten as

necessary.

24 Hour Interval

Inspect belt tension. Adjust and tighten as necessary.

Maintenance

Establish a schedule for inspecting all parts of the fan.

The frequency of inspection depends on the operating

conditions and location of the fan.

Inspect fans exhausting corrosive or contaminated air

within the rst month of operation. Fans exhausting con-

taminated air (airborne abrasives) should be inspected ev-

ery three months. Clean the propeller and air inlets if ma-

terial build-up is excessive. Excessive build-up can cause

imbalance and failure of the propeller. Regular inspections

are recommended for fans exhausting non-contaminated

air. It is recommended the following inspections be

conducted twice per year.

• Inspect bolts and setscrews for tightness. Tighten as

necessary

• Inspect belt wear and alignment. Replace worn belts with new

belts and adjust alignment as needed. See Belt and Pulley

Installation, page 2

• Bearings should be inspected as recommended in the

Conditions Chart

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease on motor housing assures proper

motor cooling

Lubricants

Loren Cook Company uses petroleum lubricant in a lith-

ium base conforming to NLGI grade 2 consistency. Other

grades of grease should not be used unless the bearings

and lines have been ushed clean. If another grade of

grease is used, it should be lithium-based.

An NLGI grade 2 grease is a light viscosity, low-torque,

rust-inhibiting lubricant that is water resistant. Its tempera-

ture range is from -30°F to +200°F and capable of intermit-

tent highs of +250°F.

Fan Bearings

The fan bearings are provided prelubricated. Any spe-

cialized lubrication instructions on fan labels supersedes

information provided herein. Bearing grease is a petroleum

lubricant in a lithium base conforming to an NLGI #2 con-

sistency. If user desires to utilize another type of lubricant,

they take responsibility for ushing bearings and lines, and

maintaining a lubricant that is compatible with the installa-

tion.

An NLGI #2 grease is a light viscosity, low-torque, rust-

inhibiting lubricant that is water resistant. Its temperature

range is from -30°F to 200°F and capable of intermittent

highs of 250°F.