4H-SERIES IO&M B51051-003

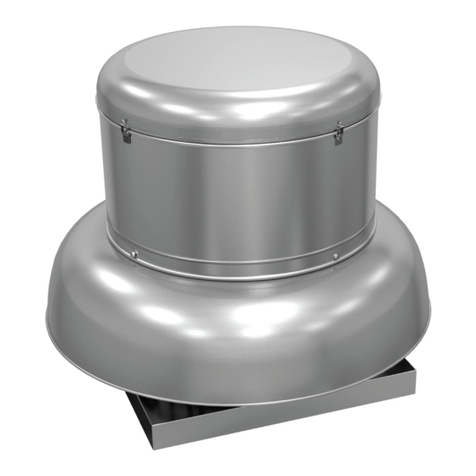

Fan Installation

The fan support (roof curb) should provide a level sur-

face for installation. If the roof is pitched more than 1/2:12,

a sloped curb must be used to correct the problem.

Place fan over roof opening. Secure the fan with lag

screws, anchor bolts, or other suitable fasteners.

Hood Assembly

Hoods for some non-ltered fans (size 42 and larger)

and some ltered fans (size 36 or larger) require eld as-

sembly. Assembly is accomplished using 1/2” and 9/16”

socket wrenches. Line-up punches and hand clamps will

speed up the assembly. Figure 4 shows the components

used to assembly the hood.

1. Place the hood halves (A) onto the hood supports (D).

Line up the hood anges and bolt the anges of the

hood ends (G) together. The top caps (B) must be in-

ter-locked for the anges to meet correctly.

2. Go under the hood and bolt the hood (angle ange) to

the hood supports (D) at the four overlapping locations.

3. Install the two perimeter angles (C), that were shipped

loose, inside each end of the hood.

4. If there is a gap between the top cap edges, loosen

the top cap bolts. Install a bolt in each end of the top

cap ange to pull the two top caps together. Tighten

the top cap bolts.

Filtered Fans

1. Place the two long lter retainers (E) (four on size 60)

and the two short lter retainers (F) on top of the base

and bolt the pieces together.

2. Bolt the long lter retainers (E) to the perimeter angles

(C) that are at the ends of each hood.

3. Install lters according to the lter schedule. Refer to

Filter Installation detail below. Insert edge of lters into

the lter retainer (E), swing lter into position and ip

the lter holding clip into position.

H-Series Fan Filter Sizes

Unit Size Type 1 Type 2

Length x Width No. Req. Length x Width No. Req.

20 14” x 14” 414” x 18-7/8” 6

24 18-1/4” x 30-1/8” 218-1/4” x 33-1/4” 4

30 20-7/16 x 18-1/16” 420-7/16” x 25-13/16” 6

36 22-1/4” x 21-1/16” 422-1/4” x 29-5/32” 6

42 24-1/16” x 29-1/2” 426-7/8” x 19-1/4” 8

48 27” x 27” 427” x 27” 8

54 29-1/8” x 20” 629-1/8” x 23-5/8” 10

60 37-11/16” x 21-7/8” 626” x 28-5/16” 10

Final Installation Steps

1. Inspect fasteners and setscrews, particularly fan mount-

ing and bearing fasteners, and tighten according to the

recommended torque shown in the table, Recommend-

ed Torque for Setscrews/Bolts.

2. Inspect for correct volt-

age with voltmeter.

3. Ensure all accessories

are installed.

4. Test the fan to be sure

the rotation is the same

as indicated by the arrow

marked Rotation.

Do not allow the fan to run in the wrong direction.

This will overheat the motor and cause serious

dam-age. For 3-phase motors, if the fan is running

in the wrong direction, check the control switch.

It is possible to interchange two leads at this lo-

cation so that the fan is operating in the correct

direction.

Operation

Pre-Start Checks

1. Lock out all the primary and secondary power sources.

2. Inspect fasteners and setscrews, particularly those

used for mounting the fan, and tighten if necessary.

3. Inspect belt tension and pulley alignment. (Remember,

if belt tension is correct, a loud squeal occurs as the

fan increases to full power.)

4. Inspect motor wiring.

5. Ensure the belt touches only the pulleys.

6. Rotate the propeller to ensure it does not rub against

the venturi.

7. Ensure fan and duct work are clean and free of debris.

Test the fan to ensure the rotation of the propeller is

the same as indicated by the rotation label (The HER

has a reversible propeller and can be operated in ei-

ther direction).

8. Close and secure all access doors.

9. Restore power to unit.

Recommended Torque for Setscrews/Bolts (IN-LB)

Setscrews Hold Down Bolts

Size

Key Hex

Across

Flats

Recommended

Torque Size Recommended

Torque

Min. Max.

#8 5/64” 15 21 3/8”-16 324

#10 3/32” 27 33 1/2”-13 780

1/4 1/8“ 70 80 5/8”-11 1440

5/16 5/32” 140 160 3/4”-10 2400

3/8 3/16” 250 290 7/8”-9 1920

7/16 7/32” 355 405 1”-8 2700

1/2 1/4“ 560 640 1-1/8”-7 4200

5/8 5/16” 1120 1280 1-1/4”-7 6000

3/4 3/8” 1680 1920 - -

7/8 1/2” 4200 4800 - -

19/16” 5600 6400 - -

Start Up

Turn the fan on. In variable speed fans, set the fan to its

lowest speed. Inspect for the following:

• Direction of rotation

• Excessive vibration

• Unusual noise

• Bearing noise

• Improper belt alignment or tension (listen for a continuous

squealing noise)

• Improper motor amperage or voltage

NOTICE! If a problem is discovered, immediately

shut o the fan. Lock out all electrical power and

check for the cause of the trouble. Refer to Trou-

bleshooting, page 7.

Inspection

Inspection of the fan should be conducted at the rst 30

minute, 8 hour and 24 hour intervals of satisfactory op-

eration. During the inspections, stop the fan and inspect as

per the following:

Filter

Schedule

Type 2

Type 2

Type 2

Type 2

Type 2

Type 2

Type 2

Type 2

Type 2

Type 2

Type 1

Type 1

Type 1

Type 1

Type 1

Type 1