Trico Opto-Matic 30078 User manual

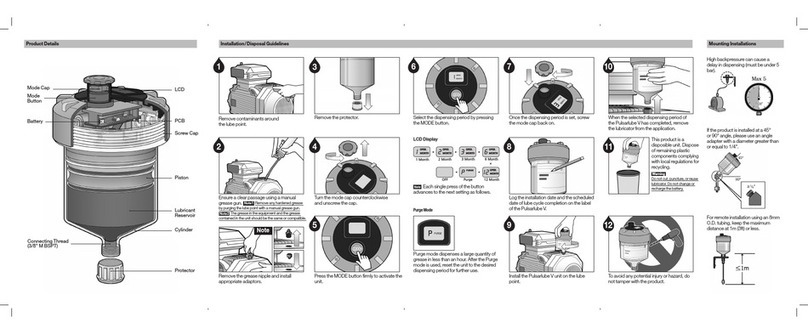

Read Instructions Before Installing

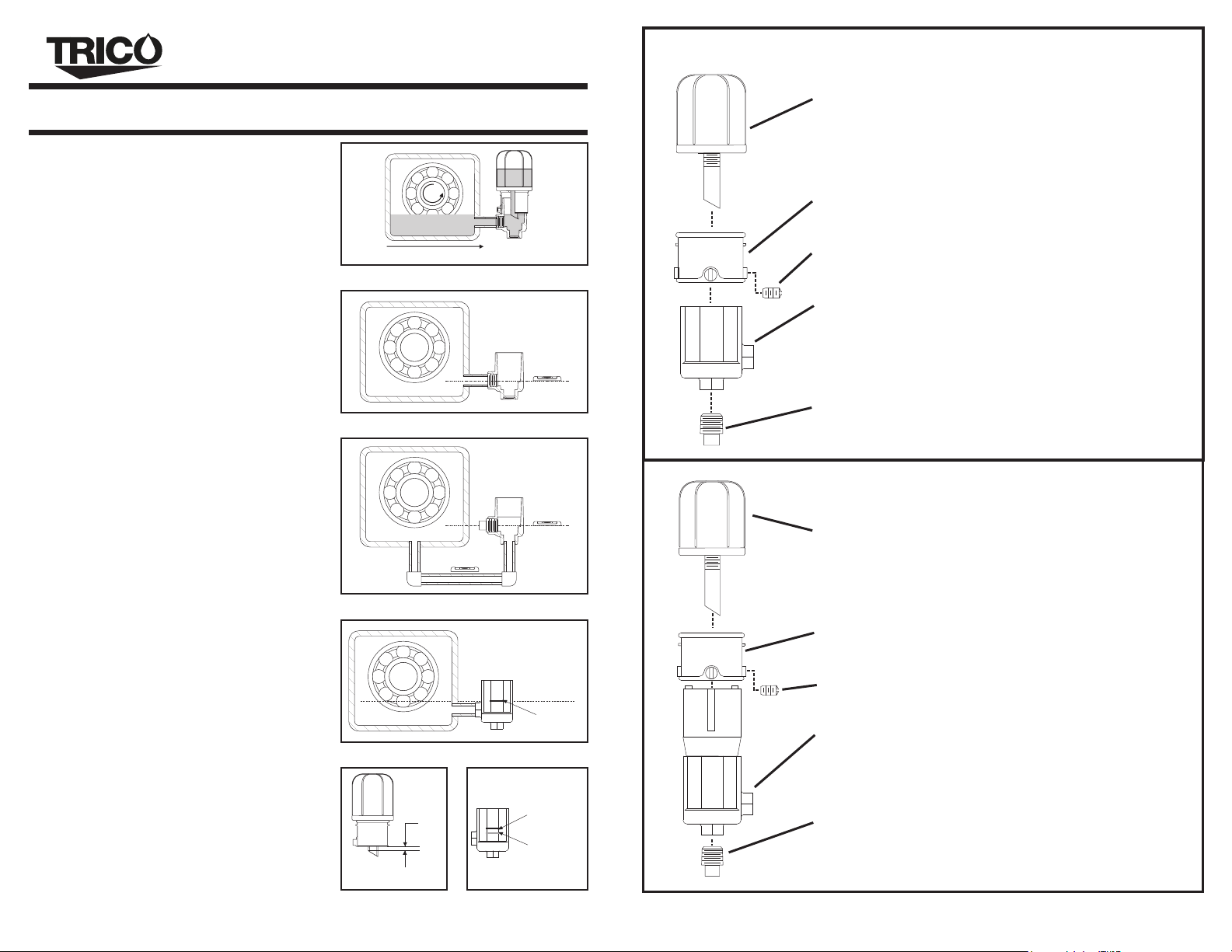

Plastic Opto-Matic Oilers

Spirit

Level

Fig. 2

Spirit

Level

Fig. 3

TRICO CORPORATION 1235 Hickory St., Pewaukee, WI 53072 Phone: (262) 691-9336

www.tricocorp.com 61402 02/19

RESERVOIR FOR

4 oz. (120 ml.)Oilers - 20283R

All types and sizes - 20315R

UPPER CASTING WITH SET SCREWS FOR

SET SCREW ONLY

8 oz. (240 ml.) Oilers - 20284R

All types and sizes - 10310

LOWER CASTING FOR

2 oz. (60 ml.) Oilers - 20282R

Type “E” with ¼ NPT side hole only - 10304

Type “E” with ¼ BSPT side hole only - 14243

PIPE PLUG FOR

Type “EB” ¼ NPT - 10321

Type “EB” with ¼ NPT side and bottom holes - 10306

Type “EB” with ¼ BSPT side and bottom holes - 14241

Type “EB” ¼ BSPT - 14201

“E” & EB” OPTO-MATIC

REPLACEMENT PARTS LIST

LOWER CASTING FOR

Type “EH” with ¼ NPT side hole only - 20330R

Type “EH” with ¼ BSPT side hole only - 22544R

Type “EHB” with ¼ NPT side and bottom holes - 20331R

PIPE PLUG FOR

Type “EHB” ¼ NPT - 10321

2 oz. (60 ml.) Oilers - 20327R

RESERVOIR FOR

8 oz. (240 ml.) Oilers - 20329R

4 oz. (120 ml.) Oilers - 20328R

UPPER CASTING WITH SET SCREWS FOR

SET SCREW ONLY

All types and sizes - 10310

All types and sizes - 20315R

“EH” & EHB” OPTO-MATIC

REPLACEMENT PARTS LIST

3. Loosen set screws on reservoir assembly. Remove

reservoir assembly from lower casting.

4. Be sure all connecting hardware is free from

contaminants (burrs, chips, dirt, etc.) to prevent

clogging or damage to the equipment to be lubricated.

5. Connect lower casting to bearing chamber either

through the side connection, Type E and EH oilers

(Fig. 2) or the bottom connection, Type EB and

EHB oilers (Fig. 3). Use thread compound on

threaded areas.

6. Verify the lower casting is level and parallel with

desired oil level (Fig. 2 and 3). Make necessary

adjustments if needed until lower casting is level.

2. Determine proper oil level, which may be indicated

on the equipment with an arrow. If that is not the case,

engineering drawings or the equipment’s operator

manual can provide the information. Indicate proper

oil level on equipment using a marking device such

as; a marker, scribe, paint, etc.

7. From the oil level mark indicated on the equipment,

use a level to put a mark on the outside of the Opto-

Matic lower casting to indicate where the oil level

should be (Fig 4).

8. Measure the distance between Opto-Matic Oiler

casting edge and top edge of spout angle (Fig 5).

Mark this distance above the original line made in

step 7 on the outside of the Opto-Matic lower casting

(Fig. 6). Now the bottom of the reservoir assembly

can be used as an indicator of oil level.

9. Fill the equipment bearing chamber through the lower

casting until the oil level reaches just below the mark

made in step 7 on the lower casting. DO NOT fill at

or above this mark as it will cause your equipment to

have a high oil level.

10. Use a funnel to fill the reservoir assembly 2/3rds

with the recommended oil.

11. Place thumb over reservoir spout, invert, and insert

on lower casting assembly at the point where the

bottom edge of the reservoir assembly is at the level

“X” mark from step 8. Quickly tighten set screws on

the side of the reservoir assembly.

12. Start up equipment to verify proper oil level is

being maintained.

1. Prior to installing the Opto-Matic Oiler, shaft rotation

direction must be determined, typically indicated by an

arrow on the casting of the equipment. Install oiler on

the side of the equipment facing the direction of shaft

rotation to prevent misfeeding of the oiler (Fig 1).

Fig. 4

Level Line

Oil Level

Fig. 5

X

Fig. 6

Mark from

step 7

Mark Level “X”

TRICO CORPORATION 1235 Hickory St., Pewaukee, WI 53072 Phone: (262) 691-9336

www.tricocorp.com

Fig. 1

Direction of shaft rotation

Read Instructions Before Installing

Plastic Opto-Matic Oilers

Spirit

Level

Fig. 2

Spirit

Level

Fig. 3

TRICO CORPORATION 1235 Hickory St., Pewaukee, WI 53072 Phone: (262) 691-9336

www.tricocorp.com 61402 02/19

PIPE PLUG FOR

Type “EB” with ¼ BSPT side and bottom holes - 14241

Type “EB” ¼ NPT - 10321

Type “EB” ¼ BSPT - 14201

SET SCREW ONLY

Type “E” with ¼ NPT side hole only - 10304

Type “EB” with ¼ NPT side and bottom holes - 10306

UPPER CASTING WITH SET SCREWS FOR

2 oz. (60 ml.) Oilers - 20282R

All types and sizes - 20315R

LOWER CASTING FOR

Type “E” with ¼ BSPT side hole only - 14243

8 oz. (240 ml.) Oilers - 20284R

RESERVOIR FOR

4 oz. (120 ml.)Oilers - 20283R

All types and sizes - 10310

“E” & EB” OPTO-MATIC

REPLACEMENT PARTS LIST

2 oz. (60 ml.) Oilers - 20327R

RESERVOIR FOR

4 oz. (120 ml.) Oilers - 20328R

Type “EHB” with ¼ NPT side and bottom holes - 20331R

Type “EH” with ¼ NPT side hole only - 20330R

Type “EH” with ¼ BSPT side hole only - 22544R

All types and sizes - 10310

UPPER CASTING WITH SET SCREWS FOR

LOWER CASTING FOR

8 oz. (240 ml.) Oilers - 20329R

All types and sizes - 20315R

SET SCREW ONLY

PIPE PLUG FOR

Type “EHB” ¼ NPT - 10321

“EH” & EHB” OPTO-MATIC

REPLACEMENT PARTS LIST

3. Loosen set screws on reservoir assembly. Remove

reservoir assembly from lower casting.

4. Be sure all connecting hardware is free from

contaminants (burrs, chips, dirt, etc.) to prevent

clogging or damage to the equipment to be lubricated.

EHB oilers (Fig. 3). Use thread compound on

threaded areas.

5. Connect lower casting to bearing chamber either

through the side connection, Type E and EH oilers

(Fig. 2) or the bottom connection, Type EB and

6. Verify the lower casting is level and parallel with

desired oil level (Fig. 2 and 3). Make necessary

adjustments if needed until lower casting is level.

2. Determine proper oil level, which may be indicated

on the equipment with an arrow. If that is not the case,

engineering drawings or the equipment’s operator

manual can provide the information. Indicate proper

oil level on equipment using a marking device such

as; a marker, scribe, paint, etc.

7. From the oil level mark indicated on the equipment,

use a level to put a mark on the outside of the Opto-

Matic lower casting to indicate where the oil level

should be (Fig 4).

8. Measure the distance between Opto-Matic Oiler

casting edge and top edge of spout angle (Fig 5).

Mark this distance above the original line made in

step 7 on the outside of the Opto-Matic lower casting

(Fig. 6). Now the bottom of the reservoir assembly

can be used as an indicator of oil level.

9. Fill the equipment bearing chamber through the lower

casting until the oil level reaches just below the mark

made in step 7 on the lower casting. DO NOT fill at

or above this mark as it will cause your equipment to

have a high oil level.

10. Use a funnel to fill the reservoir assembly 2/3rds

with the recommended oil.

11. Place thumb over reservoir spout, invert, and insert

on lower casting assembly at the point where the

bottom edge of the reservoir assembly is at the level

“X” mark from step 8. Quickly tighten set screws on

the side of the reservoir assembly.

being maintained.

12. Start up equipment to verify proper oil level is

1. Prior to installing the Opto-Matic Oiler, shaft rotation

direction must be determined, typically indicated by an

arrow on the casting of the equipment. Install oiler on

the side of the equipment facing the direction of shaft

rotation to prevent misfeeding of the oiler (Fig 1).

Fig. 4

Level Line

Oil Level

Fig. 5

X

Fig. 6

Mark from

step 7

Mark Level “X”

TRICO CORPORATION 1235 Hickory St., Pewaukee, WI 53072 Phone: (262) 691-9336

www.tricocorp.com

Fig. 1

Direction of shaft rotation

This manual suits for next models

1

Other Trico Lubrication System manuals

Popular Lubrication System manuals by other brands

Groeneveld

Groeneveld MultiLine SFi Operation & maintenance manual

Graco

Graco Spindl-Gard 24B219 instructions

Bijur Delimon

Bijur Delimon TMD-5 manual

Perma

Perma CLASSIC Series operating instructions

Bijur Delimon

Bijur Delimon V5 60444 Technical data

Schneider Airsystems

Schneider Airsystems FP-M Original operating manual