Replacement Kits ListReplacement Bowls List

THANK YOU!

You have just purchased a quality Lubricator from Master Pneumatic.

With care in its installation and maintenance, you can expect it to have a long and economical service life.

Before you go any further, please take a few minutes to look over this information,

then save it for future reference and for the useful service information it contains.

INSTALLATION:

1. Depressurize and lockout air pressure.

2. Upstream pipes must be free of excessive dirt and liquids.

3. Install the Lubricator as near as possible to the device it is to serve.

4. Install the Lubricator so that air flows from inlet to outlet as shown on the head.

5. The Lubricator must be installed vertically with Draincock at the bottom.

6. Lubricators should be installed downstream of any Filters or Regulators in the airline.

OPERATION:

1. To fill Lubricator with Oil, depressurize and lockout air pressure. Either remove Fill Plug or Bowl Assembly to add lubricant.

Use Light Spindle Oil 80-120 SSU at 100F. Do not use compound oils containing graphite’s, soap fillers, etc.

2. With air pressure on, the oil feed rate can be changed by turning the Adjusting Knob. Turn clockwise for less oil, or

counter-clockwise to increase oil delivery. The Sight Dome is used to monitor the oil feed rate (drops/min. etc.). Removal

of Adjusting Knob will make the Lubricator tamper resistant.

TO CLEAN OR REPAIR:

1. Depressurize and lockout air pressure.

2. If needed, the Fill Plug can be removed by turning counter-clockwise and cleaned.

3. Remove Bowl Ring and Bowl Assembly by turning counter-clockwise.

4. Both the Bowl Ring and Bowl Assembly can be cleaned.

5. If needed, the Cartridge Assembly can be removed by unscrewing the four Screws and replaced.

When replacing the Cartridge Assembly, hand start the screw. This will ensure that the self-tapping screw use the original

threads.

6. When re-assembling, be sure all seals are correctly located. Torque Bowl Ring hand tight.

7. If the Lubricator cannot be repaired by cleaning with soap and water, the parts should be replaced.

BL237D Installation and Maintenance

MASTER PNEUMATIC - DETROIT, INC.

6701 -18 Mile Rd. | Sterling Heights, MI 48314 | Phone: (586) 254-1000 | Fax: (586) 254-6055 | Email: mp@masterpneumatic.com

STU-5016

JAA 10-06-06

REV 05-12-08

(ECN 4400)

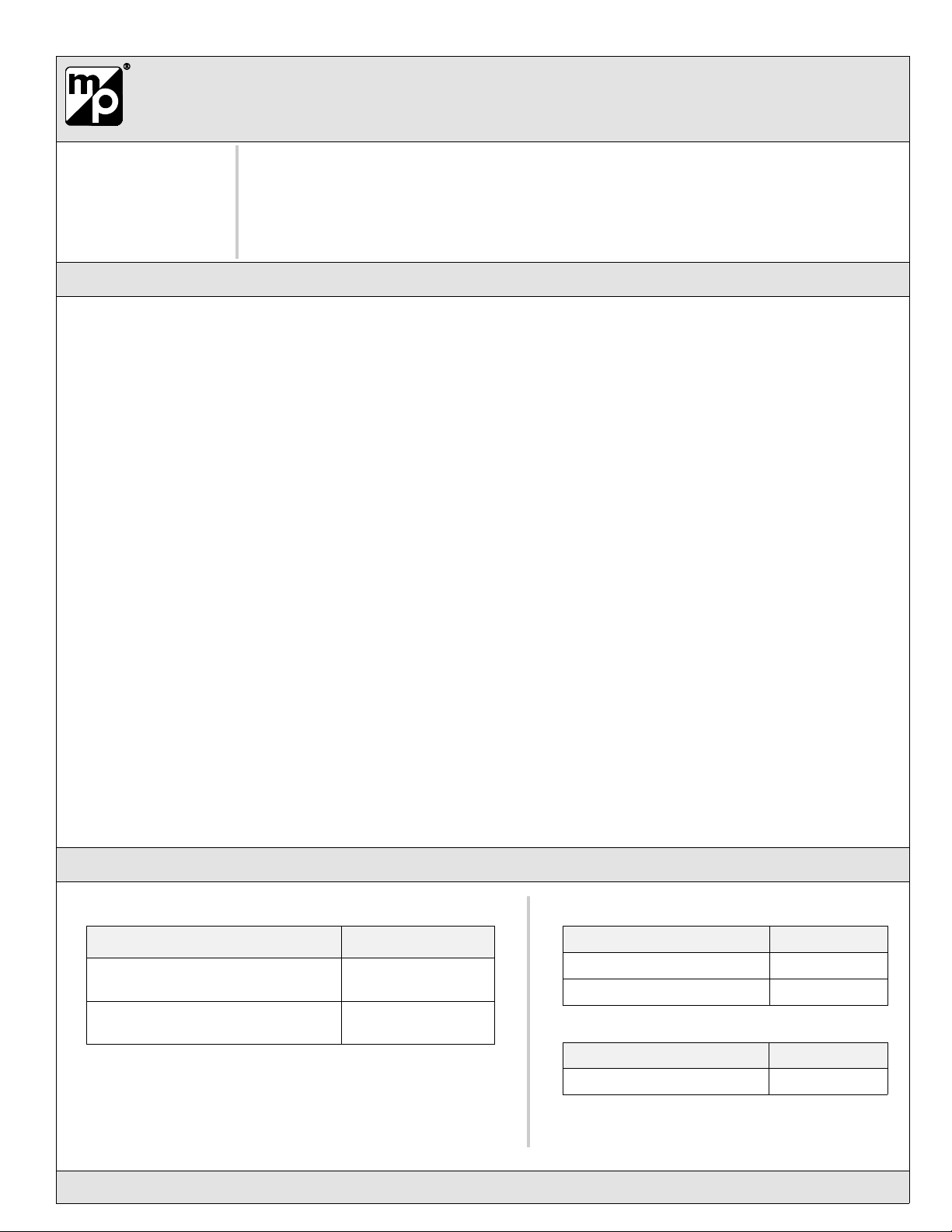

Replacement Parts

DESCRIPTION PART NUMBER

Fill Plug Kit A28-18

Cartridge Kit A29-20

DESCRIPTION PART NUMBER

Metal Bowl Assembly*OLD: ABL237-100

NEW: ABL237-105

Extended Metal Bowl Assembly*OLD: ABL237-100H

NEW: ABL237-105H Replacement Drain List

DESCRIPTION PART NUMBER

Manual Draincock 103-51SP

PRODUCT NUMBERS:

BL237D-6

BL237D-8

Installation & Operation Procedures

*Review Bowl Styles on Next Page.