31515694EN-02

2

Alfa LU-VE is a trademark registered and owned by LU-VE Group.

Alfa LU-VE reserves the right to change specifications without prior notification.

Index

1. Important information ............................................................................................................ 3

1.1 Disclaimer ................................................................................................................................. 3

1.2 Intended use ............................................................................................................................. 3

1.3 Where to nd product information ............................................................................................ 3

1.4 Warning symbols ...................................................................................................................... 3

1.5 Health, safety and hygiene ....................................................................................................... 4

1.6 Use of ammable gas ............................................................................................................... 4

1.7 Checks at delivery .................................................................................................................... 5

1.8 Return of unused heat exchangers .......................................................................................... 5

1.9 Guarantee ................................................................................................................................ 5

1.10 Disposal .................................................................................................................................... 5

2. Product description ............................................................................................................... 6

2.1 General information and application ......................................................................................... 6

2.2 Standard conguration ............................................................................................................. 6

2.3 Options ..................................................................................................................................... 6

2.4 Code description ...................................................................................................................... 7

3. Product labels ......................................................................................................................... 7

4. Transport and storage ........................................................................................................... 9

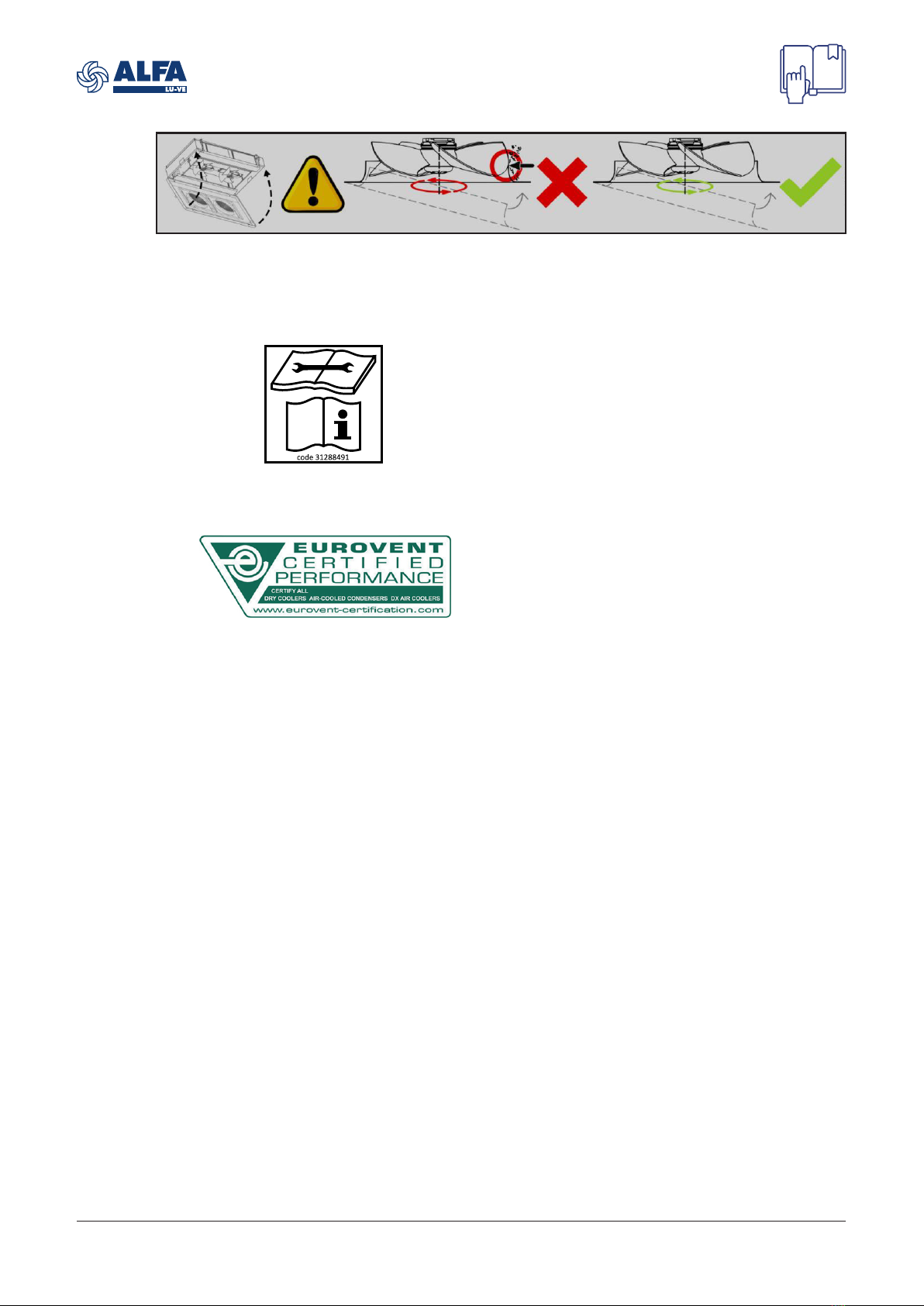

5. Unpacking and lifting ........................................................................................................... 10

6. Installation ............................................................................................................................ 12

6.1 Mounting dimensions ............................................................................................................. 12

6.2 Mounting bracket .................................................................................................................... 13

6.3 Technical spaces .................................................................................................................... 13

6.4 Refrigerant connections ......................................................................................................... 13

6.5 Cooler capacity test ................................................................................................................ 14

6.6 Drain line ................................................................................................................................ 14

6.7 Electrical connections ............................................................................................................. 15

6.8 Fan motors connections ......................................................................................................... 16

6.9 Fan motors connections ......................................................................................................... 16

6.10 Defrost .................................................................................................................................... 17

6.11 Electric defrost connections ................................................................................................... 18

7. Maintenance .......................................................................................................................... 19

7.1 Shut down periods .................................................................................................................. 19

7.2 Moisture in the refrigeration system ....................................................................................... 19

7.3 Cleaning and disinfecting ....................................................................................................... 19

7.4 Casing .................................................................................................................................... 19

7.5 Coil and drip tray .................................................................................................................... 19

7.6 Electric defrost elements replacement ................................................................................... 20

7.7 Fans ....................................................................................................................................... 21

7.8 Fan replacement .................................................................................................................... 21

8. Residual risks ....................................................................................................................... 22

9. Troubleshooting ................................................................................................................... 22

10. Spare parts ............................................................................................................................ 23