M3-98

Survey

Meter

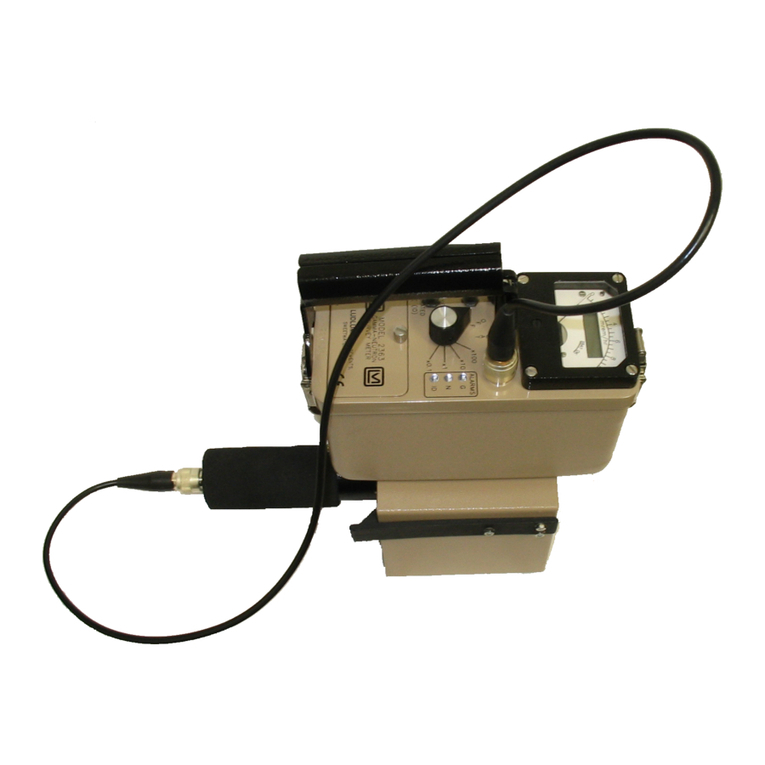

The Model 3-98

is

a portable survey instrument

with four linear ranges reading up to

500,OOO

CPM.

Theinstrumentfeaturesan internalpancaketube along

with the capability of utilizing an external probe by a

switch

on

the front panel labeled INT/EXT. Separate

high voltage adjustments for the internal and external

probes are provided. The high voltage power supply

is regulated and adjustable from 200 to loo0 volts.

Theunit body is made of cast aluminum, includingthe

meter housing. The can

is

0.090" aluminum. Other

operatingfeaturesof theinstrumentincludea unimorph

speaker mounted to the instrument can with an audio

ON-OFF capability, fast-slow meter response, meter

reset button, and a six-positionswitch for selecting

battery check or scalemultiplesof XO.

1,

X1, X10, and

X100. Each range multiplier has its own calibration

potentiometer.

Any G-M probe offered by the company will

operate

on

this

unit

as

well

as

many of the scintillator

type detectors. The externalhigh voltageis factory set

for 900 volts. For special requirements, it

may

be

adjustedfor operationwithany

G-M

or scintillatortube

between 200 and lo00 volts.

The

unit

is operated with two

"D"

cell flashlight

batteries for operation from 150°F to approximately

32°F. For temperature operation

to

O"F, either very

fresh alkaline or rechargeable NiCd batteries may

be

used.

Battery drain averages 17 milliamperes.

0

POWER: two standard

"D"

sizebatteries

0

RANGES: four linear range multiples of

XO.l, X1, X10, and X100; typically used in

combinationwith the 0-5k CPM meter dial,

0-500,OOO

CPM

is

achieved with the range multiplier.

0

l"UT

SENSITIVITY: 30 millivolts,

(f

10

mV)

0

AUDIO: built-in unimorph speaker with an

0

HIGH

VOLTAGE:externallyadjustablefrom

0

RESPONSE: Four or twenty-twoseconds for

0

LINEARJTY: plus or minus

5%

full scale

0

BATTERY

LIFE:

exceeds 600 hours with a

ON-OFF switch

200 to

lo00

volts

90%of final meter reading

fresh set of alkaline

"D"

cell batteries

BATTERY DEPENDANCE: Instrument

calibration change less than 3%within battery check

limits

on

meter

METER: lmA, 2 1/2-inchscale, with pivot-

and-jewel suspension

METER COMPENSATION: temperature

compensationis provided by thermistors

on

the Main

Board CONNECTOR: Series "C", 706 UIG; BNC

or MHV

may

also be provided

0

SIZE: 10.67cm (4.2")H X 8.9cm (3.5")W

X

21.6cm

(8.5")L,

exclusive of handle

WEIGHT: 1.36kg

(3

lbs.) less detector and

batteries

FINISH:

drawn-and-cast aluminum, with

computer-beigepolyurethaneenamel and silk-screened

nomenclature

3.

DESCRIPT.ION

OF

CONTROLS

AND

FUNCTIONS

0

Range Multiplier Selector Switch: A six-

position switch marked OFF, BAT, X100, X10, X1,

XO.

1.

Turning the range selector switch from OFF to

BAT position provides the operator a battery check of

the instrument.

A

BAT check scale

on

the meter

providesa visual means of checking the battery status.

Moving the range selector switch to one of the range

multiplier positions (XO.

1,

X1, X10, X100) provides

the operator with an overall range of 0-5OOk CPM

(typical meter dials is

0-5k

CPM). Multiply the scale

reading by the multiplier for determining the actual

reading.

0

AUD ON-OFF' Toggle Switch:

In

the ON

position, the switch energizes the unimorph speaker,

located

on

the left side of the instrument. The

frequency of the clicks is relative to the rate of the

incoming pulses. The higher the rate, the higher the

audio frequency. The audio should be turned OFF

when not required to reduce battery drain.

F-S

ToggleSwitch: Providesmeter response.

Selecting the fast, "F", position of the toggle switch

provides 90% of the final meter reading in four

seconds.

In

slow,

"S",

position,

90%

of the final

meter reading takes 22 seconds. In "F"position there

is fast response and large meter deviation. In

"S"positionthere is a slow response and damped meter

deviation.

RESET Pushbutton: When depressed,

provides a rapid

means

to drive the meter to zero.