MODEL9-3 TechnicalManual Section2

Ludlum Measurements, Inc. Page 2-2 June 2018

Instrument Test

Note:

The Model 9-3 has two options for chamber wall voltage. An

internal jumper may be selected to allow continuous voltage on

the chamber wall with the instrument turned off. This option

allows a faster, three-minute settling time when the instrument is

frequently used. If the instrument is infrequently used, it is

recommended that this option not be used, because of battery

drain. Battery life with the continuous wall voltage on and

instrument off is approximately six months.

Without this option, the battery drain is zero with the instrument

OFF. When the instrument is turned on, a settling time of 5

minutes is required for a reading of less than 0.2 mR/hr, 10

minutes for less than 0.1 mR/hr, and several hours for readings

near zero.

The instrument will be shipped with the chamber wall voltage

turned on when the instrument is turned off.

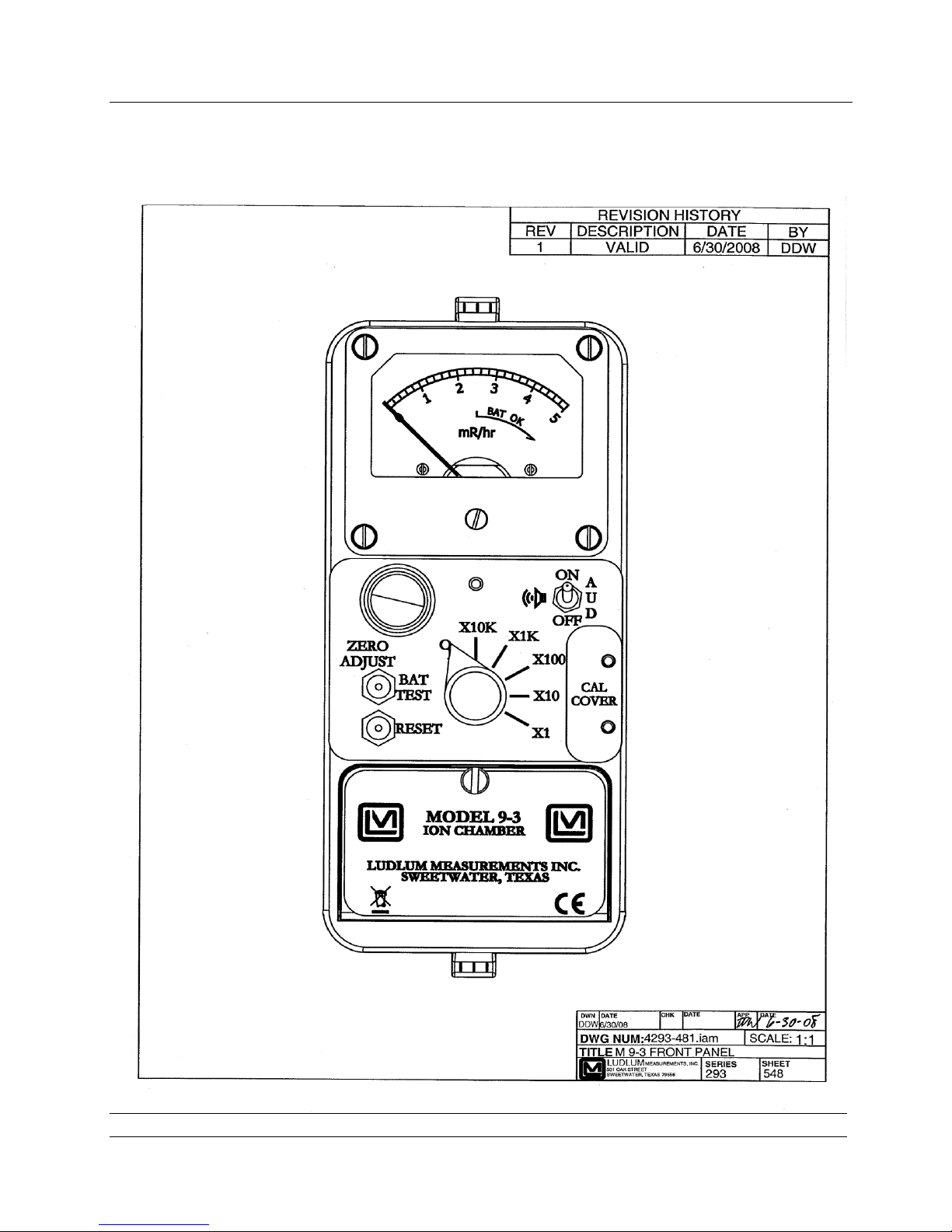

After checking the batteries with the range switch on the ×10K position, turn

the instrument range switch to the ×1 position. Note that as the selector switch

moves from ×100 to ×10, a meter transient will occur. This transient is caused

by an internal range relay and is normal. Allow time for the ×1 scale to stabilize.

Open the beta shield slide. Switch the AUD ON OFF switch to ON. Expose

the chamber window to a check source. Observe that the audio click frequency

increases as the meter reading increases.

Note:

The RESET circuit discharges the chamber and opens the

chamber connection to the electrometer. This causes a transient

on the ×1 and ×10 scales. The meter will indicate full scale and

count-down for five seconds when the RESET switch is pressed

and released. For near zero reading on ×1 scale, allow several

more seconds for setting time after RESET is released.