IRS31Pro-UMB Operating Manual V10 / 01.2020

G. Lufft Mess- und Regeltechnik GmbH 3

Contents

1 Please Read Before Use ............................................................................................................................................ 5

1.1 Symbols Used ..................................................................................................................................................... 5

1.2 Safety Instructions .............................................................................................................................................. 5

1.3 Designated Use .................................................................................................................................................. 5

1.4 Incorrect Use ....................................................................................................................................................... 5

1.5 Guarantee ........................................................................................................................................................... 5

1.6 Brand Names ...................................................................................................................................................... 5

2 Scope of Delivery ....................................................................................................................................................... 6

3 Order Numbers ........................................................................................................................................................... 7

3.1 Accessories ......................................................................................................................................................... 7

3.2 Additional Documents and Software ................................................................................................................... 7

4 Equipment Description .............................................................................................................................................. 8

4.1 IRS31Pro-UMB Sensor ....................................................................................................................................... 8

5 Generation of Measurements .................................................................................................................................... 9

5.1 Current Measurement (act) ................................................................................................................................. 9

5.2 Average Value (avg) ........................................................................................................................................... 9

5.3 Sampling Rate .................................................................................................................................................... 9

6 Transmission of Measurements .............................................................................................................................. 10

6.1 Measurements .................................................................................................................................................. 10

7 Installation ................................................................................................................................................................ 14

7.1 Preparation ....................................................................................................................................................... 14

7.2 Installation ......................................................................................................................................................... 14

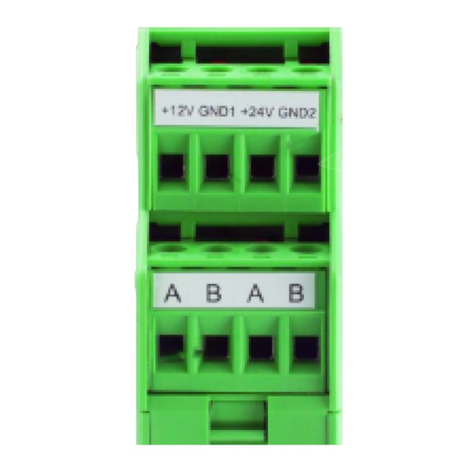

7.3 Connecting the Supply Cable............................................................................................................................ 16

7.4 Use of Surge Protection (8379.USP) ................................................................................................................ 20

7.5 Commissioning and Testing .............................................................................................................................. 21

8 Maintenance .............................................................................................................................................................. 22

8.1 Replacing the Sensor ........................................................................................................................................ 22

9 Connections .............................................................................................................................................................. 23

9.1 Supply Cable ..................................................................................................................................................... 23

10 Configuration and Testing ....................................................................................................................................... 25

10.1 Factory Settings ................................................................................................................................................ 25

10.2 Configuration with PC Configuration Software UMB Config Tool ...................................................................... 25

10.3 Function Test with the UMB Config Tool ........................................................................................................... 30

11 IRS31-UMB Compatibility mode .............................................................................................................................. 32

11.1 Important notes for using Sensor in compatibility mode .................................................................................... 32

11.2 Configuration possibilities ................................................................................................................................. 32

11.3 Examples for the Creation of Addresses ........................................................................................................... 33

11.4 Firmware-Update .............................................................................................................................................. 33

11.5 Overview channel list of an IRS31-UMB (IRS31Pro-UMB in IRS31-UMB compatibility mode) ......................... 34

12 Coupling with ARS31/ARS31Pro-UMB ................................................................................................................... 37

12.1 Configuration of coupling within IRS31Pro-UMB: .............................................................................................. 37

13 Technical Data .......................................................................................................................................................... 39

13.1 Measuring Range / Accuracy ............................................................................................................................ 39

14 Fault Description ...................................................................................................................................................... 41

15 Certifications ............................................................................................................................................................ 42

15.1 CE ..................................................................................................................................................................... 42

15.2 FCC .................................................................................................................................................................. 42

15.3 IC ...................................................................................................................................................................... 42

16 Disposal .................................................................................................................................................................... 43

16.1 Inside the EU .................................................................................................................................................... 43