ARS31(Pro)-UMB Operating Manual V9/03.2017

G. Lufft Mess- und Regeltechnik GmbH, Fellbach, Germany 3

Contents

1Please read before commissioning ........................................................................................................5

1.1 Symbols used.....................................................................................................................................5

1.2 Safety instructions ..............................................................................................................................5

1.3 Designated use...................................................................................................................................5

1.4 Guarantee...........................................................................................................................................5

1.5 Incorrect use.......................................................................................................................................5

1.6 Nomenclature .....................................................................................................................................5

2Order Numbers.......................................................................................................................................6

2.1 Accessories ........................................................................................................................................6

2.2 Additional Documents and Software ..................................................................................................6

3Differences between ARS31Pro-UMB/ARS31-UMB..............................................................................7

4Device description ..................................................................................................................................8

4.1 Method of operation ARS31Pro-UMB/ARS31-UMB...........................................................................8

4.2 Additional features of ARS31Pro-UMB...............................................................................................9

4.3 Availability of measurement values ....................................................................................................9

5Installation.............................................................................................................................................10

5.1 Preparation.......................................................................................................................................10

5.2 Installation.........................................................................................................................................10

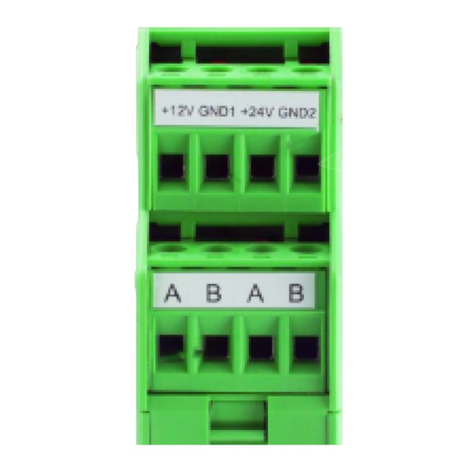

5.3 Connecting the cable........................................................................................................................14

5.4 Commissioning and testing ..............................................................................................................18

6Maintenance.........................................................................................................................................19

6.1 Replacing the sensor system ...........................................................................................................19

6.2 Connections......................................................................................................................................20

7Configuration ........................................................................................................................................22

7.1 Factory settings ................................................................................................................................22

7.2 Using PC configuration software......................................................................................................22

7.3 Firmware update...............................................................................................................................26

8Communication.....................................................................................................................................27

8.1 Binary protocol..................................................................................................................................27

8.2 ASCII protocol...................................................................................................................................29

8.3 Channel assignment for the data request ........................................................................................30

8.4 Mapping standards...........................................................................................................................32

9Technical data ......................................................................................................................................33

9.1 Measurements..................................................................................................................................33

9.2 Storage conditions (complete sensor)..............................................................................................33

9.3 Operating conditions.........................................................................................................................34

9.4 Electrical data...................................................................................................................................34

9.5Interfaces..........................................................................................................................................34

9.6 Mechanical data (excluding cable) ...................................................................................................34

10 EC Certificate of Conformity.................................................................................................................35

11 Troubleshooting....................................................................................................................................36

12 Service and maintenance.....................................................................................................................37

13 Disposal................................................................................................................................................37

14 Manufacturer.........................................................................................................................................38

14.1 Technical support .............................................................................................................................38

15 List of Figures.......................................................................................................................................39