User Manual VS2k-UMB / VS20k-UMB V 2.3 / 28.01.2020

2 Inhaltsverzeichnis

Inhaltsverzeichnis

1Read before use............................................................................................................. 4

1.1 Safety instructions................................................................................................... 4

1.2 Designated use....................................................................................................... 4

1.3 Guarantee............................................................................................................... 4

1.4 Incorrect use ........................................................................................................... 4

2Scope of delivery............................................................................................................ 5

3Part numbers.................................................................................................................. 5

3.1 VS2k-UMB / VS20k-UMB........................................................................................ 5

3.2 Accessories............................................................................................................. 5

3.3 Spare parts ............................................................................................................. 5

3.4 Additional documents and software......................................................................... 5

4Equipment description.................................................................................................... 6

4.1 Operation mode ...................................................................................................... 6

5Installation...................................................................................................................... 7

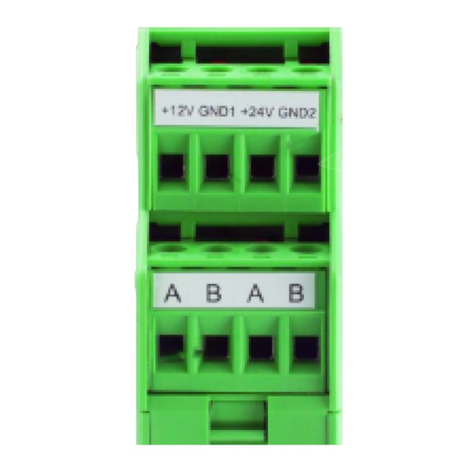

6Connections................................................................................................................... 8

6.1 Screw-in connector.................................................................................................. 8

6.2 Power supply........................................................................................................... 8

6.3 RS485 interface ...................................................................................................... 8

6.4 Current output......................................................................................................... 8

7Commissioning............................................................................................................... 9

8Configuration.................................................................................................................. 9

8.1 Factory settings....................................................................................................... 9

8.2 Configuration with PC software UMB Config Tool ................................................... 9

8.3 Firmware update..................................................................................................... 9

9Calibration / Adjustment ................................................................................................10

9.1 Preconditions .........................................................................................................10

10 Communication..........................................................................................................10

10.1 Binary-Protocol.......................................................................................................10

10.1.1 Framing...........................................................................................................10

10.1.2 Addressing with class and device ID...............................................................11

10.1.3 Examples for the formation of addresses ........................................................11

10.1.4 Example of a binary protocol request..............................................................11

10.1.5 CRC Calculation..............................................................................................12

10.2 ASCII Protocol........................................................................................................12

10.2.1 Composition....................................................................................................12