Operating Manual V8.2/03.2017 Non Invasive Road Sensor

G. Lufft Mess- und Regeltechnik GmbH, Fellbach, Germany 3

Contents

1Please Read Before Use.............................................................................................................................................5

1.1 Symbols Used .....................................................................................................................................................5

1.2 Safety Instructions...............................................................................................................................................5

1.3 Designated Use...................................................................................................................................................5

1.4 Incorrect Use.......................................................................................................................................................5

1.5 Guarantee............................................................................................................................................................5

1.6 Brand Names.......................................................................................................................................................5

2Scope of Delivery........................................................................................................................................................6

3Order Numbers............................................................................................................................................................7

3.1 Accessories.........................................................................................................................................................7

3.2 Spare Parts..........................................................................................................................................................7

3.3 Additional Documents and Software....................................................................................................................7

4Equipment Description...............................................................................................................................................8

4.1 Road Surface Temperature.................................................................................................................................8

4.2 Water Film Height................................................................................................................................................8

4.3 Ice Layer Thickness.............................................................................................................................................8

4.4 Road Condition....................................................................................................................................................8

4.5 Ice Percentage ....................................................................................................................................................8

4.6 Freezing Temperature.........................................................................................................................................8

4.7 Saline Concentration ...........................................................................................................................................9

4.8 Snow Height ........................................................................................................................................................9

4.9 Friction.................................................................................................................................................................9

4.10 Sensor Technology NIRS31-UMB.....................................................................................................................10

5Generation of Measurements...................................................................................................................................11

5.1 Current Measurement (act)................................................................................................................................11

6Operation Modes.......................................................................................................................................................11

6.1 Normal Operation..............................................................................................................................................11

6.2 Energy Saving Mode .........................................................................................................................................11

7Measurement Output ................................................................................................................................................12

7.1 Measurements...................................................................................................................................................12

7.2 Additional Sensor Information............................................................................................................................15

8Installation.................................................................................................................................................................17

8.1 Fastening...........................................................................................................................................................17

8.2 Aligning the Sensor............................................................................................................................................18

8.3 Selecting the Installation Location .....................................................................................................................19

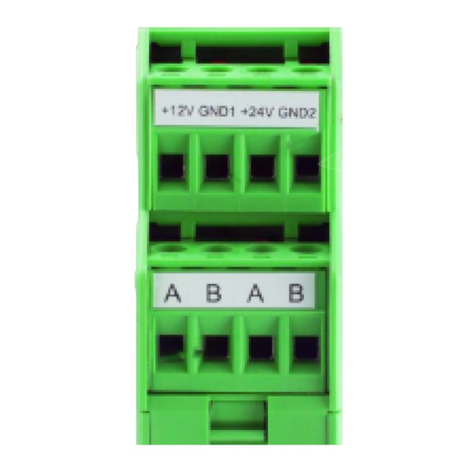

9Connections ..............................................................................................................................................................22

9.1 Equipment Connector........................................................................................................................................22

9.2 Pin Assignment..................................................................................................................................................22

9.3 Supply Voltage ..................................................................................................................................................22

9.4 RS485 Interface.................................................................................................................................................22

9.5 Connection to ISOCON-UMB (8160.UISO).......................................................................................................23

9.6 Use of Surge Protection (8379.USP).................................................................................................................23

10 Commissioning.........................................................................................................................................................24

10.1 Conditions for the Initial Commissioning............................................................................................................24

10.2 Important Instructions for Commissioning..........................................................................................................24

11 Sensor Adjustment...................................................................................................................................................25

11.1 Readjustment using the UMB Config Tool.........................................................................................................25

11.2 Adjustment during Operation.............................................................................................................................25

12 Configuration and Testing........................................................................................................................................26

12.1 Factory Settings.................................................................................................................................................26

12.2 Configuration with the UMB Config Tool............................................................................................................26