Regulatory Models

Lumencor utilizes regulatory model names for all certified and CE marked products. The regulatory model names are

traceable to all regulatory documentation, third party reports and certifications.#

“Regulatory Model: Spectra” is used as a representative model for all certified and CE marked Spectra Products.#

Emissions

This equipment has been tested and found to comply with the limits of EMC directive 2014/30/EU. These limits are de-

signed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.#

Safety Certifications

TUV SUD America, CB Certification (IEC 61010-1:2010)#

TUV SUD America, NRTLus Certification (UL 61010-1:2012-05/R:2015-07)#

TUV SUD America, cNRTL Certification (CAN/CSA-C22.2 No. 61010-1:2012/U1:2015-07)#

TUV SUD America, EN Certification (EN 61010-1:2010)#

CE Marking

Low Voltage Directive (2014/35/EU)#

EMC Directive (2014/30/EU)#

RoHS Directive (2011/65/EU+2015/863/EU)#

REACH Regulation (EC) No. (1907/2006/EC)#

EU Declarations of Conformity can be found at https://lumencor.com/company/compliance#

For EU customers discarding end-of-life Lumencor electrical and electronic equipment: Please submit an RMA request

with “Recycle product under WEEE” in the Description of Issues field.#

For disposal in countries outside of the European Union: This symbol is only valid in the European Union (EU). If you wish

to discard this product, please contact your local authorities or dealer and ask for the correct method of disposal.#

Lumencor, Inc. | 14940 NW Greenbrier Parkway | Beaverton, OR 97006 USA | 503.213.4269 |www.lumencor.com#

Document Number 57-10006#

Revision B#

091421#

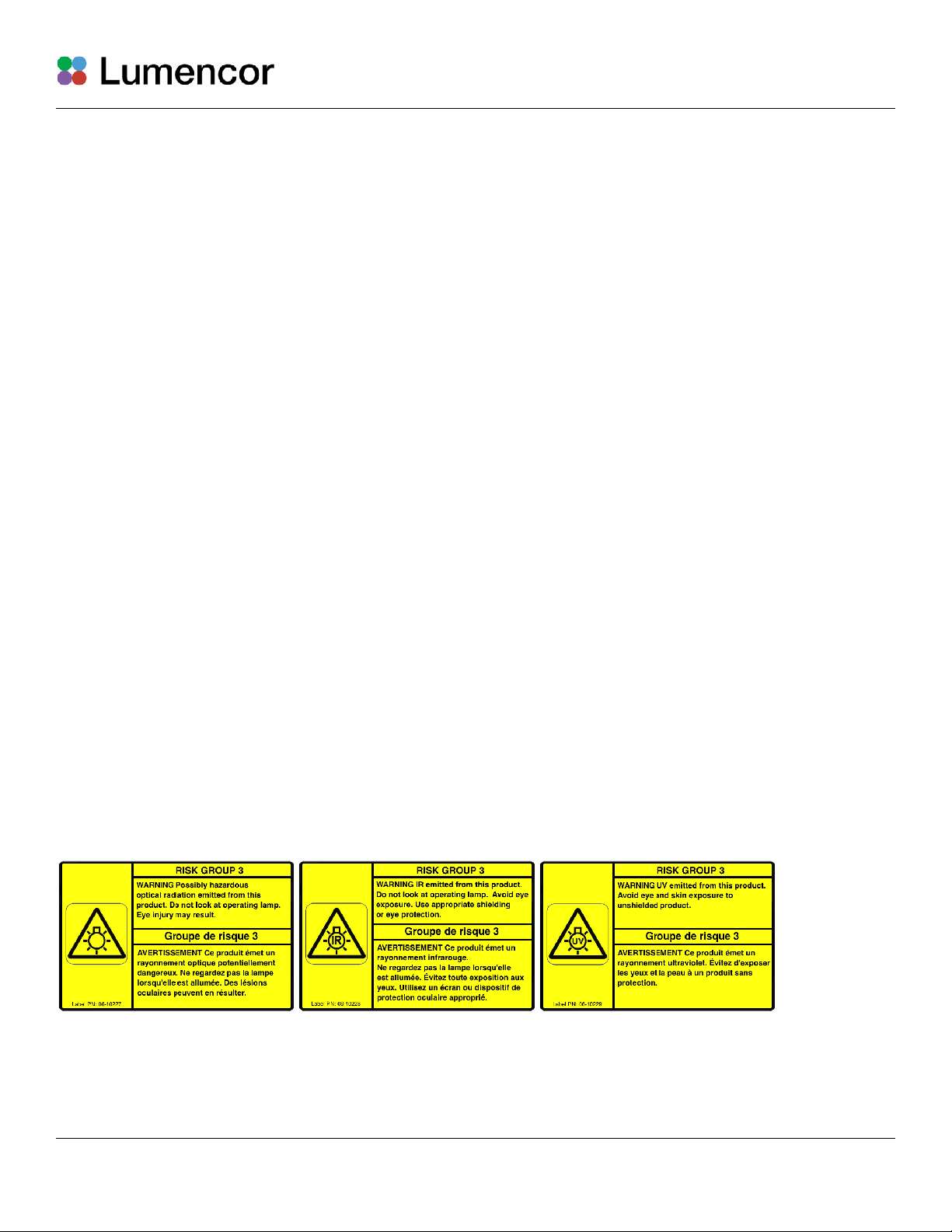

Lumencor Light Engines as supplied, and as represented in this manual, meet safety and regulatory require-

ments"For Research Use Only."If the light engine is incorporated into an instrument or system for a specific end-

use application, it is the responsibility of the system integrator to verify that the light engine, and the system into

which it is incorporated, meet all safety and regulatory requirements of that end-use application.