Version: IAE Visit us at www.lumingen.com or Call us at 1-604-371-4112

SLD-PK Area Flood LED Lighting

IMPORTANT SAFETY INSTRUCTIONS Mesures de Sécurité à Respecter

This product must be installed in accordance with the applicable installation code

by a person familiar with the construction and operation of the product and the

hazards involved.

Ce produit doit être installé selon le code d’installation pertinent, par une per-

sonne qui connaît bien le produit et son fonctionnement ainsi que les risques in-

hérents.

-

Convient aux emplacements mouillés.

Ne pas enlever l’ecran protecteur.

Mount ce

luminaire utilisant uniquement le support de montage fourni par le fabricant ou similaire.

----

Remplacer uniquement avec de nouveaux intempéries twist-on connecteurs de fils.

Les fils d’alimentation doivent convenir pour 90OC.

Attention—risque de choc.

Enlevé luminaire pour l’entretien.

Garder toujours la

plaque de protection en métal et les vis en place. Retirez uniquement si nécessaire.

Ne pas utiliser dans les logements.

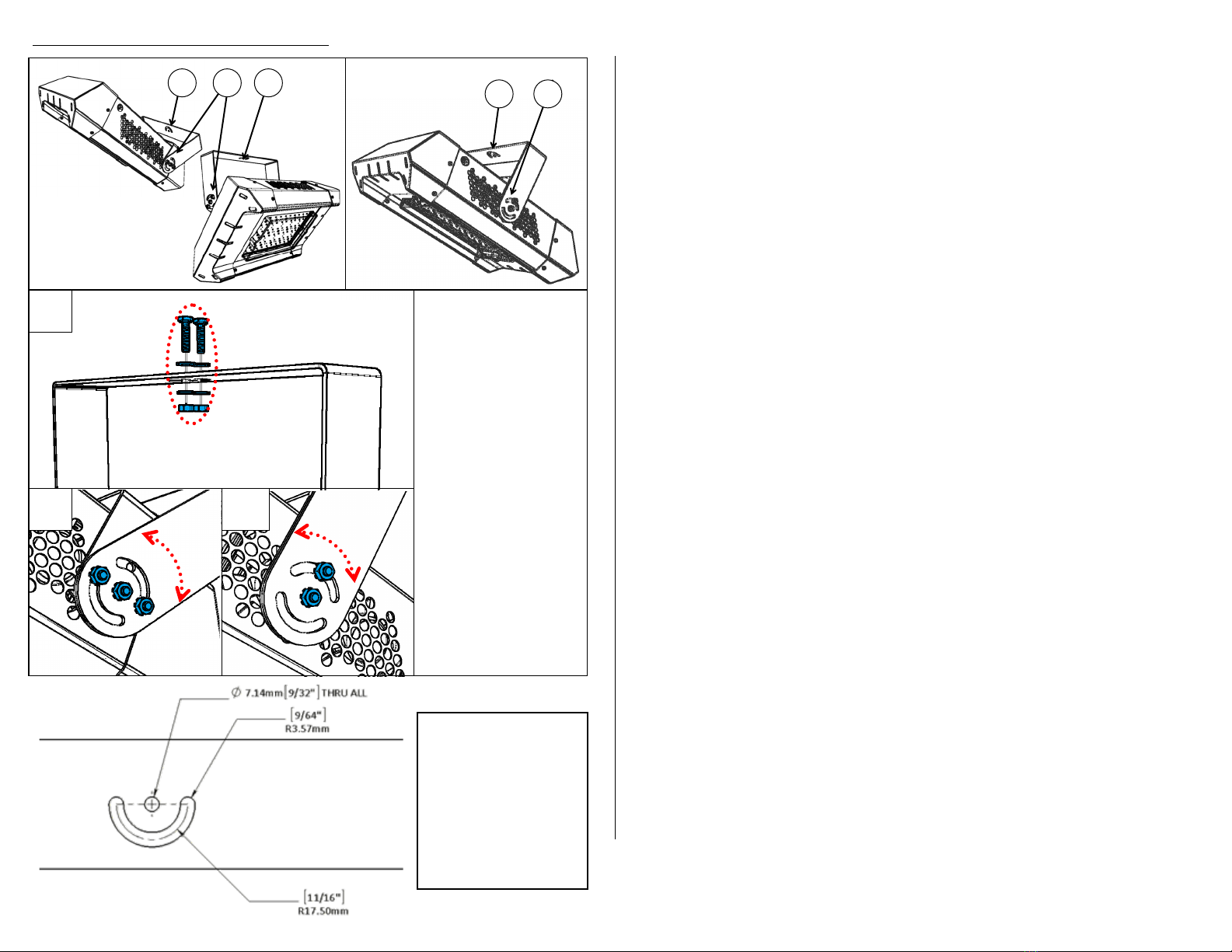

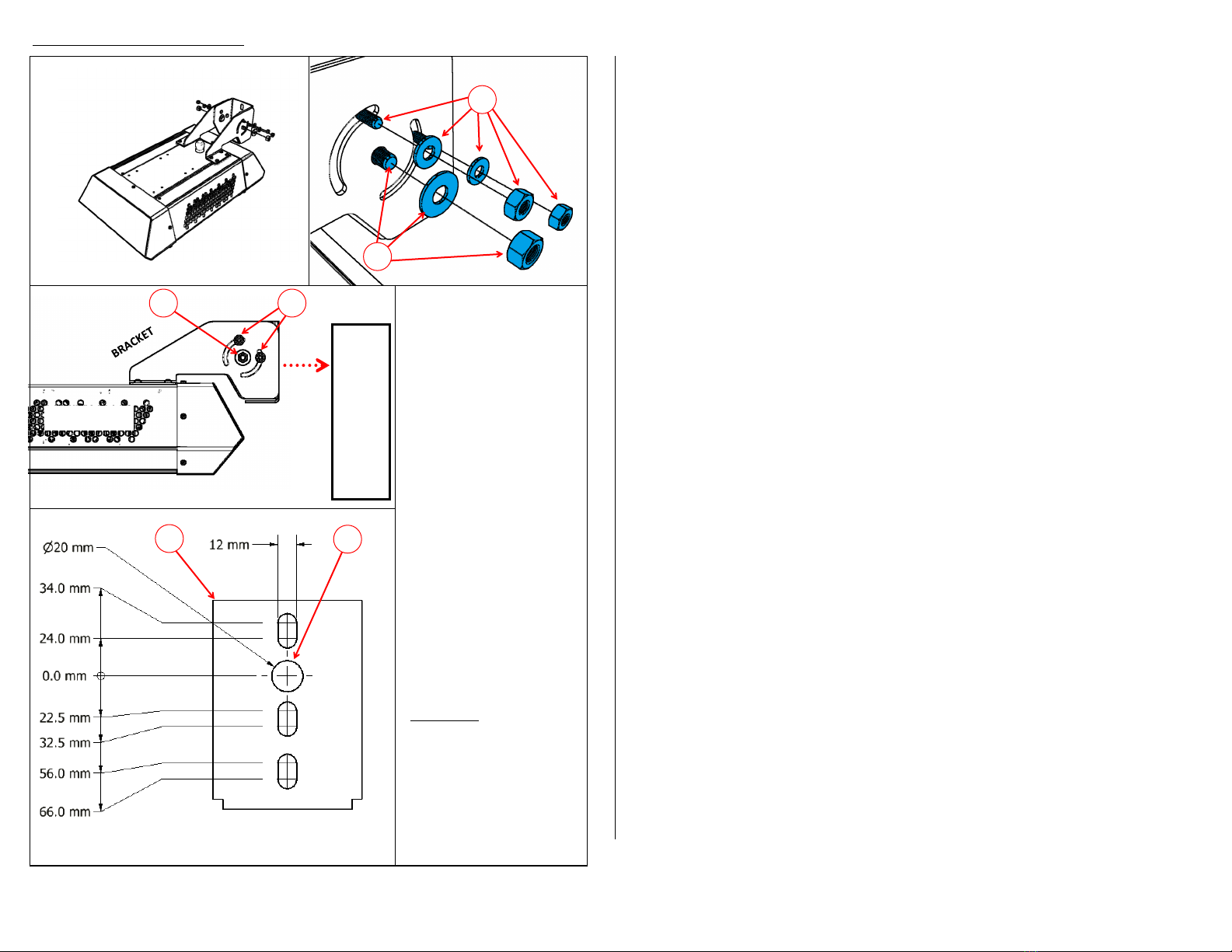

Ultra-versale high output lighng luminaire to be installed via Suspension, Surface/

Wall, Pole, or Pendant Stem.

264579

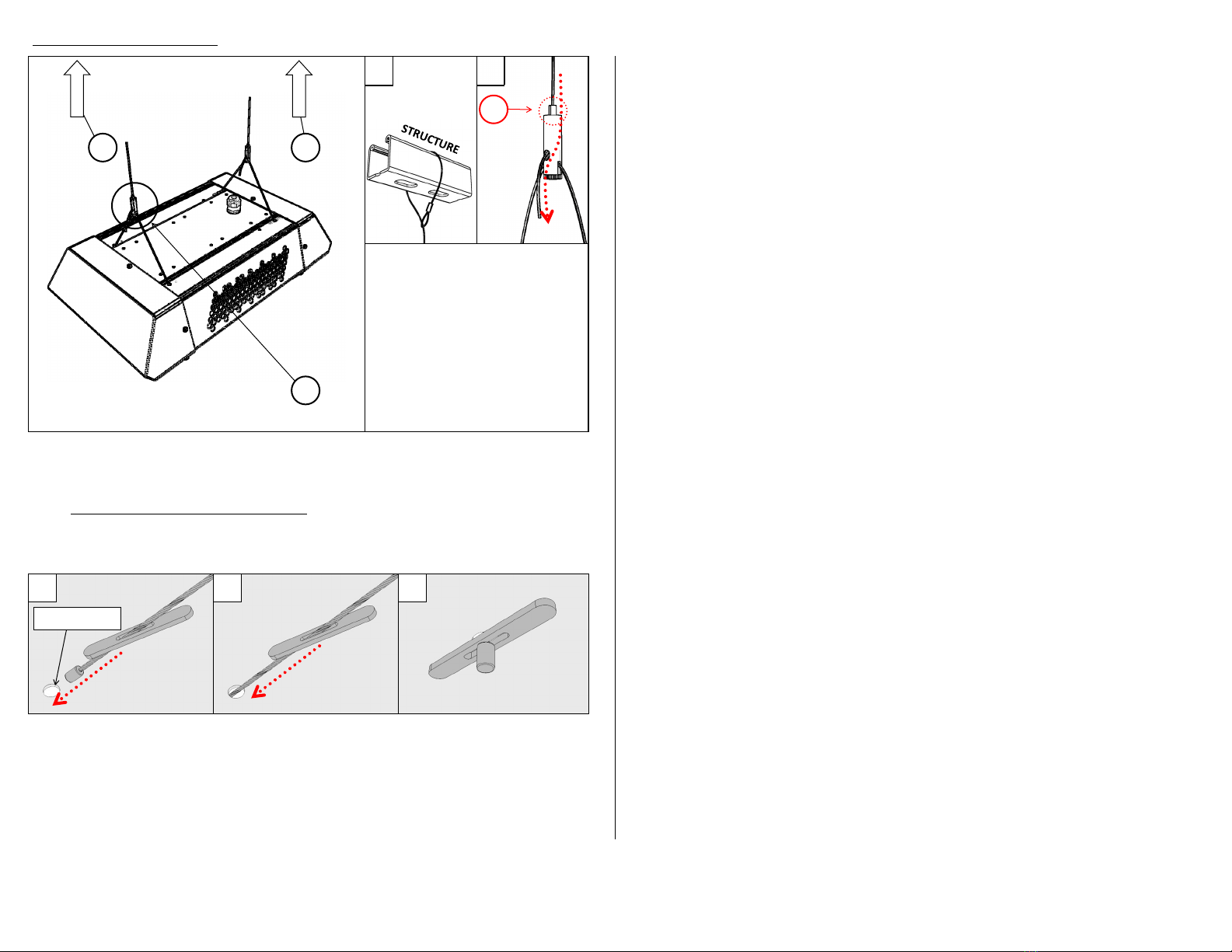

Wiring from LED Driver

to AC Supply, or LED

Driver Terminal Block

Colouring

Wiring for 0-10V

Dimming, from

Separate Cord

AC/Line Supply Connecon (Black)

AC/Neutral Connecon (White)

Earth Ground Connecon (Green)

Dim + Connecon (Violet/as Labeled)

Dim ‒ Connecon (Gray/as Labeled)

A

B

Your locaon

Holes (see point A) on the side of the housing allow for venlaon of heat from the housing. Do not mount

xture where this venlaon may be obstructed.

Lens cover (see point B) protects sensive LED components from water damage and is rated for IP67 appli-

caons. Do not remove lens cover, as this will compromise the water protecon of the xture.