3

© Lutz-Jesco GmbH 2015

Subject to technical changes.

150527

BA-70200-02-V01

Polymer preparing and dosing station EASYPURE Powder and Liquid Operating instructions

Table of Contents

1 Notes for the Reader ..........................................................4

1.1 General non-discrimination......................................................4

1.2 Explanation of the signal words ................................................4

1.3 Explanation of the warning signs ..............................................4

1.4 Identification of warnings.........................................................4

1.5 Instruction for action identification ...........................................5

2 Safety .................................................................................6

2.1 General warnings.....................................................................6

2.2 Hazards due to non-compliance with the safety instructions .....6

2.3 Working in a safety-conscious manner .....................................6

2.4 Personal protective equipment.................................................6

2.5 Personnel qualification.............................................................7

3 Intended Use ......................................................................8

3.1 Notes on product warranty .......................................................8

3.2 Intended purpose.....................................................................8

3.3 Device revision ........................................................................8

3.4 Prohibited dosing media...........................................................8

3.5 Water quality............................................................................8

4 Product description ...........................................................9

4.1 Scope of delivery .....................................................................9

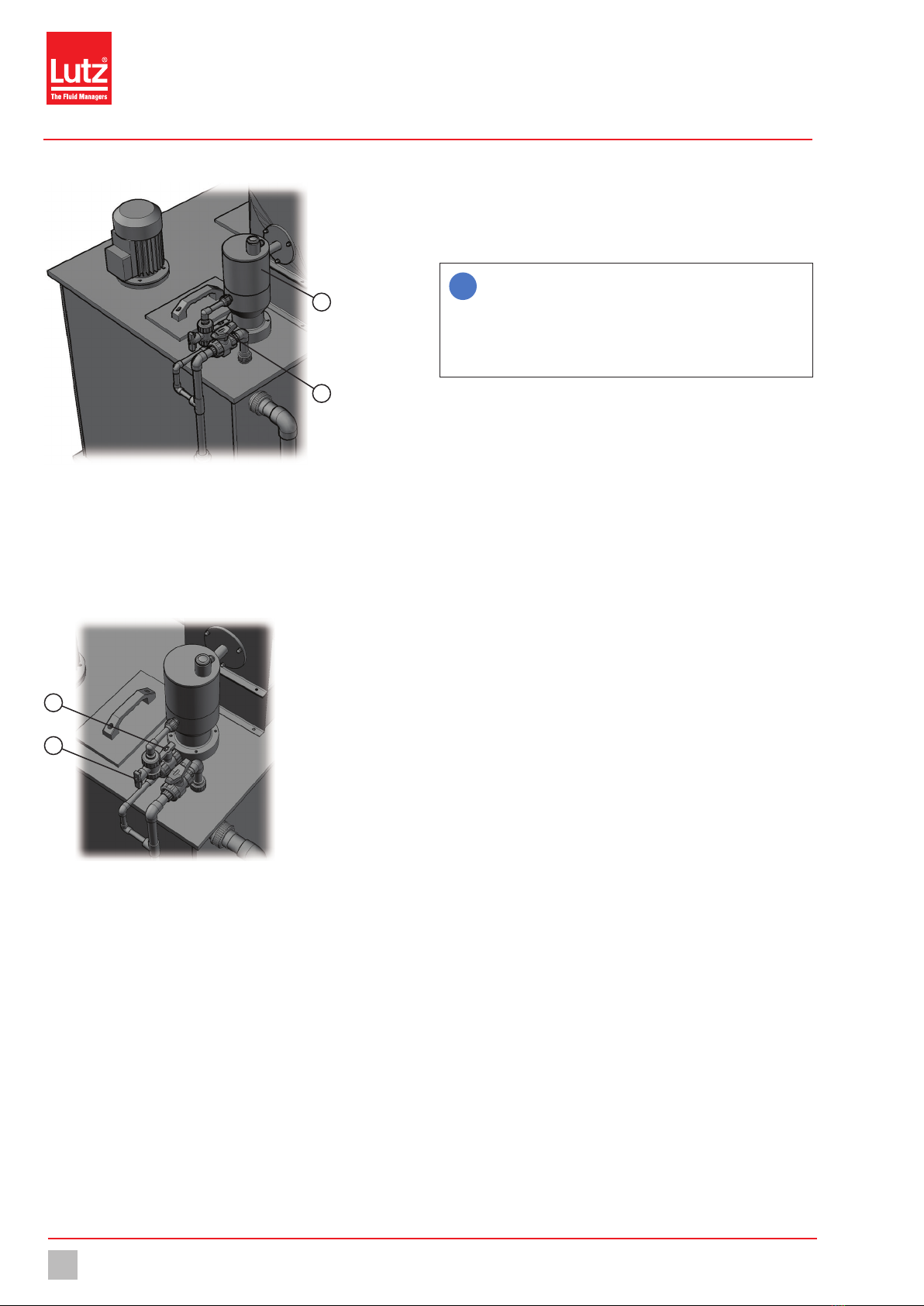

4.2 Design and function .................................................................9

5 Technical data..................................................................13

5.1 Output data............................................................................13

5.2 Operating conditions and limits ..............................................13

5.3 Electrical specifications .........................................................14

5.4 Connection dimensions..........................................................14

5.5 Components coming into contact with the media....................15

5.6 Other data .............................................................................15

6 Dimensions ......................................................................16

7 Installation .......................................................................17

7.1 Installation location................................................................17

7.2 Hydraulic installations............................................................17

7.3 Electrical installation..............................................................18

8 Control..............................................................................19

8.1 Control display.......................................................................19

8.2 Shutting down in an emergency .............................................19

8.3 Selection ...............................................................................20

8.4 Error messages .....................................................................22

9 Shutdown.........................................................................24

9.1 Short-term shutdown.............................................................24

9.2 Long-term shutdown .............................................................24

9.3 Storage .................................................................................24

9.4 Transportation........................................................................24

9.5 Disposal of old equipment ......................................................24

10 Maintenance ....................................................................25

10.1 Maintenance intervals..........................................................25

10.2 Finishing maintenance.........................................................26

11 Troubleshooting ...............................................................27

12 Spare parts.......................................................................28

12.1 Maintenance sets ................................................................28

13 EC declaration of conformity ...........................................29

14 Declaration of no objection..............................................30

15 Warranty claim.................................................................31