M-Elec AL-II Series User manual

AL-ⅡSeries USB Master

AL2-02/USB

Instructions Manual

(For designers' use)

MN0199

Please ensure to read and understand this

Instructions Manual before using the Product.

Please keep this Instructions Manual at hand

so that it is always available for reference.

-2-

Introduction

This instructions manual explains the handling of "AL- Series USB Master AL2-02/USB",Ⅱ

emphasizing the specifications to enable proper and safe use.

The manual is thus intended for designers of control systems using servo motors and stepping motors.

Before using the product, read this manual carefully for better understanding.

Keep the manual handy so that you can read it whenever you want.

Description of safety

This product must be handled correctly.

Handling the product incorrectly may cause unexpected accidents resulting in personal injuries or

damage to your properties.

Many of those accidents can be avoided if you have advance information on dangerous situations.

This manual provides precautions where dangerous situations are predicted. The manual provides the

following alert marking and messages for this purpose:

This indicates a hazardous situation that could result in death or serious

WARNING

personal injury if you do not perform the procedure correctly.

This indicates a potentially hazardous situation that could result in personal

CAUTION

injury or physical damage if you do not perform the procedure correctly.

Before use

This product is not designed for use in the equipment related to nuclear power, aerospace equipment,■vehicles, marine vessels, medical equipment directly in touch with human body, equipment

anticipated to give a serious impact to properties, and other equipment required to provide high

reliability.

Take failsafe measures so that the whole system operates safely even if the input power causes an■error, a signal line is disconnected, or the main unit fails.

Be sure to use this product within the scope of the specifications described in this instruction manual■in accordance with the specification method described therein.

Set up the product before operating it.■Please refer to the Section 3, "Setting."

Please refer to separate manual "AL- series device driver manual for Windows" also when you■Ⅱ

handle this product.

AL2-02/USB

Instructions Manual

-3-

Introduction

Description of safety

Before use

Contents PAGE

Overview1.1-1. Features 4

1-2. Product configuration 5

1-3. Example of system configuration 5

1-4. Function block diagram 6

1-5. Externals of product 7

Specifications2.2-1. General specifications 8

2-2. Communication specifications 8

2-3. Master specifications 9

2-4. Input and output signal table 10

1 Serial communication connector J1 10() ( )

2 USB communication connector for ONLINE: J2, and for OFFLINE: J4 10() ( )

3 Power supply connector J3 10() ( )

2-5. Outside dimensions 11

Setting3.3-1. Setting of USB number S1 12()

3-2. Setting of AL- communication 12Ⅱ

1 Address setting of the AL- communication 12() Ⅱ

2 Baud rate setting of the AL- communication 12() Ⅱ

3 Retry setting of the AL- communication 12() Ⅱ

3-3. Setting of Extend-unit communication 12

Connection4.4-1. Connection of AL- communication system 13Ⅱ

1 Core connection of AL- communications cable 13() Ⅱ

2 Connection of terminator 13()

3 Wiring distance of AL- communication 13() Ⅱ

4 Power supply for communication 13()

OFFLINE5.5-1. Support environment of OFFLINE 14

5-2. OFFLINE specification 14

Maintenance6.6-1. Maintenance and inspection 16

1 Cleaning method 16()

2 Inspection method 16()

3 Replacement method 16()

6-2. Saving and disposal 16

1 Saving method 16()

2 Disposal method 16()

The main parts which revised by this manual

AL2-02/USB

Instructions Manual

-4-

AL2-02/USB

Instructions Manual

Overview1.

1-1. Features

The AL- series is a high speed serial communication system of original controlling the flexible stepping motor,●Ⅱ

servo motor which can cope easily as well and I/O in the decentralization of the device and supporting axial addition.

The AL- series is an insulation type high-speed serial communications of 20 Mbps/50 m or 10 Mbps/100 m.・Ⅱ

The wiring for the personal computer system can be omitted with USB of a personal computer general-purpose port.

The shift of board controller C-VX870 series Device-function for PCI made of our company and the USB series・()

Device-function and Unit-function is easy depending on the device driver function for Windows.()

The status of four axis batch reading and the command of four axis batch execution by the Unit-function is possible.●This Unit-function can perform a unit and AL- interface by one function execution from an application.Ⅱ

By this,

The time crunch can be done compared with accessed Device-function of each axis and I/O-function of・each I/O port.

The Unit-function writing suppresses the difference at time until it instructs time each axis and each I/O output・()

signal.

The Unit-function can reduce the load of the application.・It supports the Device-function, and can use the Device-function.・The Unit-function can be used together with the Device-function and the I/O-function.・

Access example in Device-function and I/O-function Access example in Unit-function

Time lag

Reading X-axis STATUS1 X-axis STATUS1

Reading Y-axis STATUS1 Y-axis STATUS1

Reading Z-axis STATUS1 Z-axis STATUS1

Reading A-axis STATUS1 A-axis STATUS1

Time lag Batch Reading

Reading X-axis Control I/O A Unit X-axis Control I/O()

Reading Y-axis Control I/O Y-axis Control I/O

Reading Z-axis Control I/O Z-axis Control I/O

Reading A-axis Control I/O A-axis Control I/O

General-purpose I/O General-purpose I/OReading

Reading Extend I/O 0 Extend I/O 0

n

Reading Extend I/O 1 Extend I/O 1

n

o

o

i

i

t

Time lag

Batch Writing X-axis DATA1 X-axis DATA1

t

a

Eachaxis X-axis DATA2 X-axis DATA2

a

c

()

X-axis COMMAND X-axis COMMAND

c

i

Batch Writing Y-axis DATA1 Y-axis DATA1

i

l

Eachaxis Y-axis DATA2 Y-axis DATA2

l

p

()

Y-axis COMMAND Y-axis COMMAND

p

p

Batch Writing Z-axis DATA1 Z-axis DATA1

p

A

Each axis Z-axis DATA2 Batch Writing Z-axis DATA2

A

()

Z-axis COMMAND Z-axis COMMAND()AUnit

Batch Writing A-axis DATA1 A-axis DATA1

Eachaxis A-axis DATA2 A-axis DATA2()

A-axis COMMAND A-axis COMMAND

Time lag

Writing X-axis Control I/O X-axis Control I/O

Writing Y-axis Control I/O Y-axis Control I/O

Writing Z-axis Control I/O Z-axis Control I/O

Writing A-axis Control I/O A-axis Control I/O

General-purpose I/O General-purpose I/OWriting

Writing Extend I/O 0 Extend I/O 0

Writing Extend I/O 1 Extend I/O 1

-5-

AL2-02/USB

Instructions Manual

AL2-02/USB is a master for the AL- series that can do the direct connection to the USB port of PC.●Ⅱ

The user controls the motor controller and I/O etc. of the AL- series by this master.Ⅱ

It conforms to USB2.0 FULL SPEED:12Mbps .・()

Shape is small in W24 H76.1 D94.4. And, it is a master unit that can be handled like HUB.・××

Confirming the operation of each axis of each slave unit and the I/O signal can do immediately without the user・program by the USB off-line application software that our company offers.

Moreover, the master can back up the setting data of each slave unit.

The setting data that this master backs up can transmit each slave automatically when the Initial-data-transfer-

function is executed. Also, it is possible to overwrite data from the user application.

1-2. Product configuration

Product name Rating Maker Quantity Remarks

Ⅱ()Master of AL- AL2-02/USB Melec Inc. 1 For USB Main Unit

()Connector 51103-0300 Molex 1 For power supply connector Accessory

()Contact 50351-8100 Molex 4 Accessory

1-3. Example of system configuration

AL- USB MasterⅡ

ONLINE :User application * 15 slave's unit can be connected by one Master board.AL2-02/USB

OFFLINE:Initial data edit/Kind operation AL- series Stepping or ServoⅡ

PC Slave Unit Driver Motor

USB AL- communication cable 2C-776Av1 etc. X-axis

ONLIE Ⅱ

20Mbps/50m or 10Mbps/100mOFFLINE

Terminator CB-54/R Y-axis

Extend I/O

Device driver Insert core CB-52/3232-MIL etc.※

MPL-45-01vx.xx/AL2W32 *1 ZCAT2032-0930 Z-axis●()

Windows 2000・

Windows XP 32 bit Extend I/O Interface cable・()

Windows Vista 32 bit A-axis・()

Windows 7 32 bit 32/32 points 5Mbps/1m or less・() ( )

Sensor

MPL-46-01vx.xx/AL2W64 *1 CWLM,CCWLM,ORG,NORG,EA/EB signal/ Each axis●

・()Windows XP 64 bit

・()Windows Vista 64 bit

・()Windows 7 64 bit

*1 Version No. Please confirm the latest version of vx.xx at the manual of the device driver.…

AL- series prepared connectable cables easily.・Ⅱ

Please refer to the "connection / others" instruction manual for details of connection of the AL- series.Ⅱ

Example of other AL- seriesⅡ

()Master Controller Controller with built-in driver General-purpose I/O Extend type and Slave type

AL2-01v1/PCI 2C-771v1 2CD-7710v1/ADB5F30 CB-53/1616-MIL 2CB-01v1/3232-MIL 2CB-02v1/1616-MIL2CD-7713v1/GDB5F40

Master for PCI 4-axes 2-axes for 5-phase 2-axes for 5-phase Extend type Slave type Slave type・・・・・・・

For stepping or stepping motor stepping motor In: 16-points In: 32-points In: 16-points・・・・

simple servo 0.75 A/phase 1.4 A/phase Out: 16-points Out: 32-points Out: 16-points・・・・・

RDY

J1 J2

MADEIN JAPA N

SENSOR/YSENSOR/X

S6 S5S4 S3

MOTOR/Y

MOTOR/X DC+24V/X DC+24V/Y

DC+24V

J8

J9

J6

J7

J3 J4 J5

SO

04

305OTC CTO 503

40

OS

J2J1

RDY

DC+24VJ5

SENSOR/YJ4SENSOR/X

J3

S3

S6 S4 S5

J7

MOTOR/X

J6

DC+24V/X S7

S10 S8 S9

J9

MOTOR/Y

J8

DC+24V/Y

J10

J11 MADEIN JAPAN

MADE IN JAPA N

OUT IN

DC+24V

J4J3 J2

J1

GND

8

OUT +24V

KP1516‑0A

MADEIN JAPAN

1

4

1

IN

+24VGND

3.5A

MADE IN JAPAN

J7J15 J17J9J14 J16J8 J6

J5 J3DC+24V

J4

J2

J1

INJ6OUTJ5

J2J1

MADEIN JAPAN DC+ 24VJ3

J4

OUT INJ7 J8

J4 J3DC+24V

MADE IN JAPAN

J1 J2

J5 OUT J6 IN

J1 J2

J3DC+24V

J5J4

RDY

J6 J7

J8 J9

J12 J10 J11

J13

MADEIN JAPAN

J14

MADE IN JAPAN

OUT IN

OUT IN

DC+24V

J5 J6

J4J3 J2J1

MADE IN JAPAN

J1

ONLINE

J2

OFFLINE

J4

PL

21S1

DC+24V

J3

-6-

AL2-02/USB

Instructions Manual

1-4. Function block diagram

AL2-02/USB

e

Serial interface

c

control block

a

t

f

E

e

i

r

l

N

c

n

e

o

I

a

U

ONLINE

t

r

L

f

B

n

t

r

e

S

I

Control block

n

N

e

v

U

o

O

t

a

B

C

I

n

l

S

T

I

S

U

A

Ⅱ

Ⅱ

Ⅱ

-

L

L

O

-

-

A

S

L

L

I

A

A

e

B

c

OFFLINE

Memory

S

a

)

U

f

(Slave Data back up

retnIBSU

ONLINE USB interface part()

This is an interface block with USB.

ONLINE USB is an universal serial bus port used when controlling from the user application.()

OFFLINE USB interface part()

This is an interface block with USB.

Setting and easy operation of each slave can be done by the application software for initialization.

* ONLINE and OFLINE cannot be controlled at the same time.

Execute it after stopping the application from ONLINE when you control from OFFLINE.

Control block

This is a control block between USB and the serial communications.

Serial interface control block

This department is control block for AL- serial communication.Ⅱ

The AL- serial communications interface department is insulated with +24 V power supply and internal powerⅡ

supply of AL2-02/USB.

Memory

The initial data of each slave unit by the application software for initialization is stored on the memory in master.

When the Initial-data-transfer-function is executed, master automatically sets the initial data to each slave unit.

-7-

AL2-02/USB

Instructions Manual

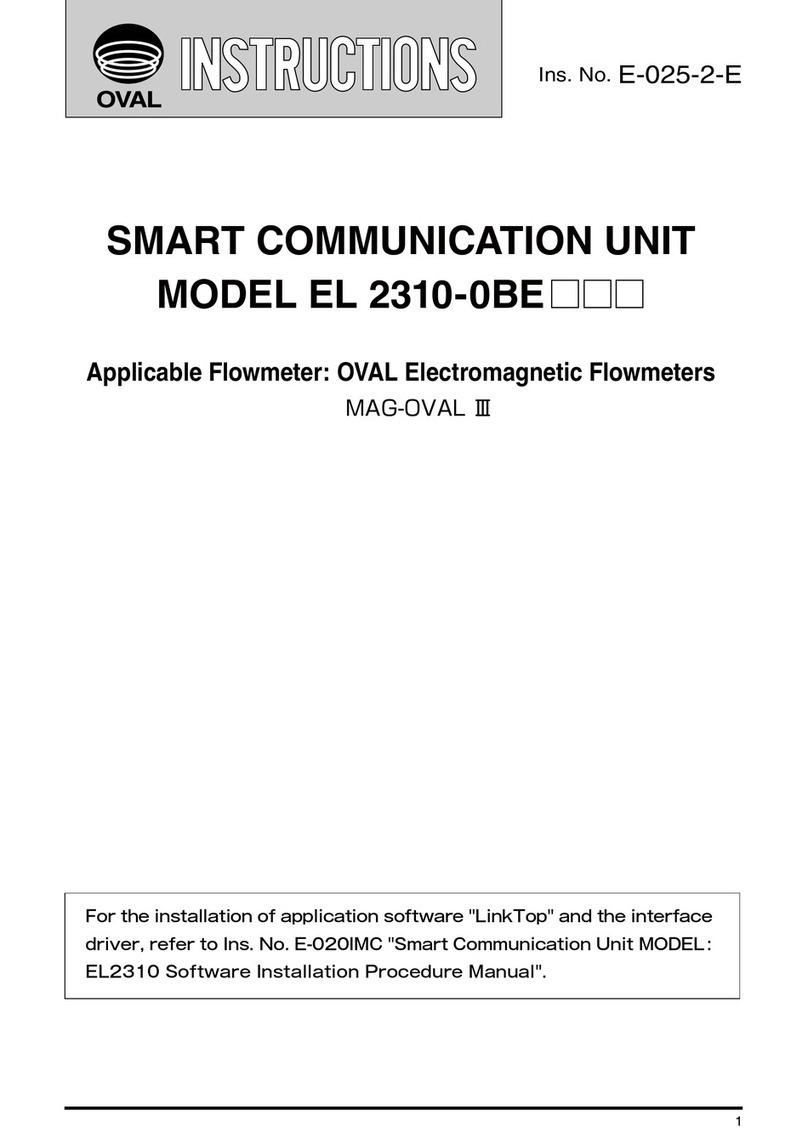

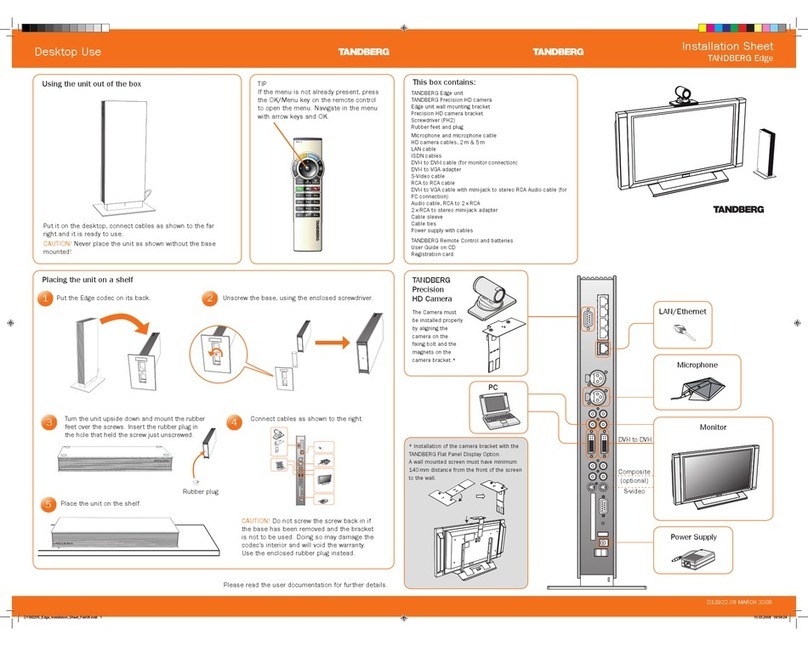

1-5. Externals of product

J1 This is a shield connector of the RJ-45 type to connect with the slave unit of the AL- series.Ⅱ

The terminator of the AL- communication is installing in this master by fixation.Ⅱ

J2 This is a USB connector connected with the personal computer at ONLINE user application control .()

()mini B type

J3 This is a connector connected for power supply +24 V of the main unit.

This is a USB connector connected with the personal computer at OFFLINE support application control .

J4 ()

()mini B type

S1 This is a dip switch to set for USB to be able to recognize the USB number.

This switch number must set for it not to overlap when two master are installed in PC.

PL1, PL2 These are LED for the monitor.

PL1 Red This LED lights when master detected abnormality of hard or abnormality of the・() …

AL- communication. This display is maintained even if it switches to OFFLINE.Ⅱ

PL2 Green This LED lights when the access from ONLINE is possible.・( )…

This LED is turned off when there is a control right on the OFFLINE side.

Cable clamp The USB cable pinching by this clamping is prevented from coming off.

()

Base install These are installation hole when the main unit is installed in the vertical direction. two places

-ation part Use the M3 screw.

Moreover, it is possible to install it in the DIN rail with a exclusive use DIN attachment lug.

Please refer to the connection/other manual for details.

()

Base install These are an installation hole when the main body is horizontally installed. two places

-ation part Use the M3 screw.

JP1 This is a connector for adjustment of the main unit.

Do not connect anything.

MADE IN JAPAN

J1

ONLINE

J2

OFFLINE

J4

PL

2

1

S1

DC+24V

J3

Made in Japan

21

ID S1

AL2‑02/USB

75700001

-8-

AL2-02/USB

Instructions Manual

Specifications2.

2-1. General specifications

No. Item Specifications

±%1 Supply voltage DC +24 V 10

2 Power consumption 70 mA or less

・℃〜+ ℃3 Operating ambient 0 40

・% ( )temperature and 80 RH or less without dew condensation

humidity

・℃〜+ ℃4055Storage temperature ・% ( )and humidity 80 RH or less without dew condensation

5 Installation Inside a well-ventilated cabinet installed indoor, free from direct sunlight.・

environment Not exposed to corrosive and flammable gasses, and not affected by oil mist,・dust, salt, iron powder, water, and chemicals.

Not subject to constant vibration or excessive shock.・Not affected by electromagnetic noise caused by power equipment.・Free of radioactive materials and magnetic fields, and not in vacuum.・

()6 Dimensions W24 × H76.1 × D94.4 mm

Vertical direction installation: pitch 88 mm , two points・()

Horizontal direction installation: 88 54 mm , two points・×()

7 Weight Approx. 0.15 kg

2-2. Communication specifications

No. Item Specifications

1 USB interface Conformity standard : USB2.0・

・()Baud rate : FULL SPEED 12 Mbps

Wiring distance : 5 m or less・USB connector : mini B type・connection number : 2 unit *1・

Ⅱ・ ()2 AL- interface Conformity standard : RS485 Insulation type

Transmission protocol : Protocol for AL- communication・Ⅱ

Slave connection number : 1 15 slave・〜

Master address: H ' 0 fixation・

・〜)Slave address setting range: H' 1 H' F

・()()Wiring distance/baud rate : 100 m 10 Mbps / 50 m 20 Mbps

*1 It is USB connection number of ONLINE sides that can be connected from one PC.

Connected number of OFFLINE sides is one.

-9-

AL2-02/USB

Instructions Manual

2-3. Master specifications

No. Item Specifications

1 Reading of slave informationConnected ・The slave type connected now can be read.

confirmation of slave

2 Error detection of Reading of error total number・

AL- The error total number detected in the AL- communication after the power supply isⅡⅡ

communication turned on can be read.

It is possible to use it for the evaluation of the communication environment.

When retrying is detected, it counts as an error.

The error total number can be counted 65535 times or less.

More than it do not update a count.

Clear of error total number・The value in which the error total number is counted can be cleared to 0.

Retry・It is a function to evade the stagnation of the entire system by retrying it when the influence

of the noise etc. is given to AL- communications.Ⅱ

The number of retrying is set by an Environment-set-function.

When retrying is made effective and the communication abnormality is detected, retrying is

automatically executed.

The setting of retrying is possible by the range from 0 non-retry to 3.()

3 Initialize Auto transmission of initialization・The master carries out initialization for all slaves automatically when user carries out an

Environment-set-function to a master.

Interlock・When an Environment-set-function is executed from the application, master executes

initialization a request to each slave.()

The slave product of the AL- series doesn't accept other requests until the initial-requestⅡ

sent from master is received after the power supply is turned on.

When other requests are received, an initial error is returned.

As a result, master notifies the application the answer back.

When the internal logic on the slave side was reset by the power failure etc. momentarily,

operation by the improper data can be stopped.

Please execute to master an Environment-set-function, after turning on slave's power supply.

4 Backup The backup can easily edit the parameter of each slave from USB by initialization editing soft・ware by the OFFLINE, and a master can back up the edited parameter Initial data .()

The initial data which a master backs up transmit a message for each slave at the time of the

practice of the Initial-data-transmission-function automatically.

5 ONLINE/OFFLINE As for the master, access are possible from ONLINE user application and OFFLINE・()

Function support application .()

The OFFLINE is a adjustment tool to offer the application that the function used USB to

enable machine adjustment without the application program development of the user

immediately for.

* ONLINE and OFFLINE cannot be controlled at the same time.

Execute it after stopping the application from ONLINE when you control from OFFLINE.

* Please refer to each slave unit manual about the specification of the slave unit executed by master.

-10-

AL2-02/USB

Instructions Manual

2-4. Input and output signal table

() ( )1 Serial communication connector J1

87654321

●()Connector :RJ-45 Shield type

●□□□□(〜)Recommended cable :KB-STP- L : length 30 m or less

()Made by Sanwa Supply: It is not an accessory.

No. Signal name DescriptionDirection

1 N.C Connection is prohibited.−

2 N.C Connection is prohibited.−

()3 I/O +AL Ⅱ+ side input/output signal of the serial data line driver positive logic

Ⅱ()4 O +V Power supply for AL- communication +6 V

−Ⅱ()5 -V GND for AL- communication 0 V

()6 I/O -AL Ⅱ- side input/output signal of the serial data line driver negative logic

7 N.C Connection is prohibited.−

8 N.C Connection is prohibited.−

() ( )2 USB communication connector for ONLINE: J2, for OFFLINE: J4

Connector : mini B type

12345 12345

●

●□□□□(〜)Recommendation cable: KU-AMB5 : length 5 m or less

()Made by Sanwa Supply: It is not an accessory.

No. Signal name DescriptionDirection

1 VCC USB bus power supply−

2 I/O -DATA - side input/output signal of USB communication

3 I/O +DATA + side input/output signal of USB communication

4 N.C Connection is prohibited.−

5 S.G GND of USB communication−

Reference

For more information about a cable preparing in the

AL- series and a recommended cable, refer to theⅡ

instruction manual of "connection / others" .

() ( )3 Power supply connector J3 ●()()Contact insertion side Connector : 53426-0310 Molex

●()Conformity connector : 51103-0300 Molex: accessories

●()Conformity contact : 50351-8100 Molex: accessories

●()Conformity crimp tool : 57295-5000 Molex

Acceptable wire : AWG28 AWG22●〜

(φ〜φ)Coating 1.15 1.8

Conformity cable : CE-76/003C10-51103●()1 m: It is not an accessories.

No. Signal name DescriptionDirection

1 I +24 V DC +24 V power supply

2 GND GND of +24 V power supply−

3 F.G Frame GND is connected with case.−

J1

ONLINE

J2 J4

OFFLINE

1123

J3

-11-

AL2-02/USB

Instructions Manual

2-5. Outside dimensions

General tolerance 0.5 mm or less±

Externals tolerance 1 mm or less±

112

MADE IN JAPAN

J3

DC+24V S1 12

PL OFFLINE

J4 J2

ONLINE J1

Made in Japan

79.6

88

94.4

6

24

71.3

76.1

75700001

AL2‑02/USB (J2) (J4)

S1

ID 12

88

54 10

(25)

MADE IN JAPAN

J1

ONLINE

J2

J4

OFFLINE

PL

2

1

S1

DC+24V

J3

Made in Japan

75700001

AL2‑02/USB

S1

ID 12

When DIN attachment lug (CP-14v1/AT2) is installed.

(Dimension of installation for user )

(Dimension of installation for user)

(Dimension of installation for user )

(Dimension of installation for user)

-12-

AL2-02/USB

Instructions Manual

Setting3. ()3-1. Setting of USB number S1

The USB number of this product is allocated by dip switch S1.

(( ) )By default When the shipment from the factory , the dip switch is USB number 0.

When the AL2-02/USB are used at one more, assign USB numbers such a way that no numbers are duplicated.

The following figure shows an example in which USB number 1 is assigned.

Switch No.

USBNo. 4321

ON side 0 OFF OFF OFF OFF Factory set←

1 OFF OFF OFF ON

Set is prohibited. OFF OFF ON OFF

Set is prohibited. ON OFF ON ON

Set is prohibited. ON ON ON ON

When turning on power, the setting of dip switch S1 becomes effective.・()

Set switch while turning off the power supply.

And, turn on the power supply after the setting change.

3-2. Setting of AL- communicationⅡ

AL2-02/USB does the following setting of AL- communications by executing Environment-set-function unlike theⅡ

switch setting done with other slave units.

1 Address setting of the AL- series() Ⅱ

The master address is H' 0 fixation.

And, please set not to overlap the address of each slave unit.

2 Baud rate setting of the AL- series() Ⅱ

As for the AL- communication baud rate, 10 Mbps/100 m or 20 Mbps/50 m can be selected.ⅡⅡTo transmission rate to set in AL2-02/USB, please set the transmission rate of all slave units connected on AL-

communication.

3 Retry number setting of the AL- series() Ⅱ

The setting of retrying is possible by the range from 0 non retry to 3.()

The address of the slave unit, the transmission rate setting become effective at the time of power supply injection.◆Please turn on the power supply again without fail.

And to the master execute an Environment-set-function after these setting changes.

Please refer to the device driver manual for Windows for details of function specification.

3-3. Setting of Extend Communication

When the Extend-unit is used, the address setting of the Extend-unit and the hard setting of the baud rate

setting etc. are unnecessary.

The Extend-unit is controlled by an Extend-unit-communication-set-function◆and an Extend-unit-communication-control-function.

Please refer to the details of function specifications at a device driver instruction manual for Windows.

S1

ID 12

O

N

1

2

3

4

-13-

AL2-02/USB

Instructions Manual

Connection4.

4-1. Connection of AL- communication systemⅡ

Operation not anticipated may cause damage of the machine and the product.

To prevent the malfunction by the noise, the AL- communications cable recommendsQAUTION Ⅱ

recommended cable.

1 Core connection of AL- communications cable() Ⅱ

Please install the core in the mastering side. As a result, the personal computer system including AL communications

is operated by stability. The core is prepared by our company.

Please refer to the "connection/other" manual.

2 Connection of terminator() AL2-02/USB mounts the terminator of the AL- communication, is connected, and the setting is unnecessary.Ⅱ

It is necessary to install AL2-02/USB to the AL- communication network edge.Ⅱ

Connect terminator CB-54/R with the slave unit arranged on the AL- communication network edge.() Ⅱ

Do not connect the terminator with other equipment.

AL- communication network TerminatorUSB Recommendation 3m or less()Core ⅡCB-54/R

PC AL2-02/USB 2C-776Av1 2CD-7710v1/ 2C-776Av1

Master etc. ADB5F30 etc. etc.()

Terminator Terminator Terminator Terminator

Always on Inside Unconnection Unconnection Connection()

3 Wiring distance of AL- communication() Ⅱ

The total wiring distance of the AL- communications cable is the following range including the multidrop wiring.Ⅱ

The USB communications cable is within recommend 3m max. 5m .・()

The wiring distance of Extend I/O doesn't relate to AL- communication baud rate RATE .・Ⅱ()

The wiring distance of Extend I/O from each slave is within 1 m.・

L1 / RATE

()Multi drop

Terminator Build-in Terminator()

Address Address Address Slave unit Address Address()

=0 =1 =2 =14 =15

L2()Master

()() ()()Extend I/O Extend I/O Extend I/O Extend I/O

AL- communication baud rate and wiring distance●Ⅱ RATE

Wiring distance 10 Mbps 20 Mbps

L1 AL- communication 100 m or less 50 m or less(Ⅱ )

L2 Extend I/O communication 1 m or less()

The number of slaves that can be connected directly with the AL- communication are 15 units or less.●Ⅱ

Extend I/O that can be extended directly from the slave unit is not included in the number of slaves.

4 Power supply and slave power supply for communication() The AL- communication power supply of each slave unit is supplied from the AL- master through theⅡ Ⅱ

communications cable so that the entire AL- communication network should not become unstable when theⅡ

power supply on each slave unit side is intercepted.

The reconnection of communications can be done by executing Environment-Function to the master when the power

supply of the main unit on the slave side is obstructed.

Master side Core:ZCAT2032-0930

The core is fixed with INSULOK.

Installs it within 40mm.

-14-

AL2-02/USB

Instructions Manual

OFFLINE5.As for AL2-02/USB, the access from ONLINE and OFFLINE is possible.

Confirming the operation of each axis of each slave unit and the I/O signal can do immediately without the user

program by the OFFLINE application software that our company offers.

* ONLINE and OFFLINE cannot be controlled at the same time.

Execute it after stopping the application from ONLINE when you control from OFFLINE.

5-1. Support environment of OFFLINE

(Ⅱ)Item MAP-19-01vx.xx Initial data edit software for AL- series

・()Support OS Microsoft Windows 7 32 bit version

・()Microsoft Windows Vista x86 version

・()Microsoft Windows XP 32 bit version

Microsoft Windows 2000 Professional SP4・

Support model IBM PC/AT Compatible・DOS/V・

・( )Communication USB 2.0 FULL SPEED: 12 Mbps

specification mini B type・

* The exclusive use USB driver is necessary to operation from OFFLINE with USB.

Install the USB driver attached to device driver MPL-34-01vx.xx/AL2W32 or MPL-35-01vx.xx/AL2W64 for

Windows of AL2-02/USB beforehand.

* Please download initial data edit software MAP-19-01vx.xx being offered from our homepage to the application

software for OFFLINE.

* Version No. Please confirm the latest version of vx.xx at the manual of the device driver,…and MAP-19 application.

5-2. OFFLINE specification

-15-

AL2-02/USB

Instructions Manual

The backup data of master●Thedataofthespecifiedfilecanbewrittentomaster.・It is possible to read out data from the master.・Moreover, data can be preserved by .AL2DAT TEXT file format.()

Data can be printed.・

The connection status of the slave unit connected with master can be confirmed.●

When the unit-number is specified, general-purpose I/O and Control I/O of the unit input is displayed.●Moreover, the level of the output can be reversed by clicking general-purpose I/O and Control I/O output button.

After the unit-number is specified, the communication of Extend I/O unit can be turned on and off with the●ON/OFF button of Extend I/O unit.

When Extend I/O communication is turned on, Extend I/O input status is displayed.・The level of the output can be reversed by clicking Extend I/O output button.・When the Extend communication is turned off with the output turned on, the output maintains the current state.

The following can be displayed by specifying the unit and the axis.●STATUS1 PORT of each axis of unit.・Value of ADDRESS COUNTER.・Present speed under output.・Status of input of sensor.・

Each data of specified SPEC INITIALIZE of the axis, SPEED PARAMETER, and ORIGIN PARAMETER is displayed●as the data that a present master stores.

It is possible to set it directly to master with each button of SPEC INITIALIZE, SPEED PARAMETER and ORIGIN

PARAMETER as backup data of the specified axis.

The axis of the specified unit can execute each drive by clicking each button of ORIGIN DRIVE, SCAN DRIVE,●INC INDEX DRIVE, and ABS INDEX DRIVE.

Moreover, the address counter is preset an arbitrary value.

●()()The drive can be stopped with the FSSTOP button immediate stop or the SLSTOP button deceleration stop

while executing the drive.

-16-

AL2-02/USB

Instructions Manual

Maintenance6.

Incorrect handling may lead to an electric shock.

Inspection and maintenance need to be conducted by an expert engineer only.QAUTION Before inspecting and maintaining this product, turn off the power.

An electric shock, injuries, and fire may be caused.

Do not make repair and modification such as product disassembly and partsQAUTION replacement.

6-1. Maintenance and inspection

1 Cleaning method() To use the product in a favorable condition, conduct cyclic cleaning as follows.

During the cleaning of the connector terminal plating part, wipe it with a dry, soft cloth.・If stain is not removed by the dry wiping, soak a cloth in a solution in which neutral detergent is diluted,・wring it out, and wipe off the stain with it.

Do not use a high-volatile solvent such as benzene and thinner, and a wipe.・This may deteriorate gold plating by transformation and oxidation.

2 Inspection method() To use the product in a favorable condition, conduct periodic inspection.

Usually conduct the inspection every six months or every year.

To use the product in an extremely hot and humid or dusty environment, shorten the inspection interval.

Inspection item Inspection details Criteria Inspection method

Environment state Check whether ambient and intra-device temperatures 0 + 40 Thermometer〜℃

are appropriate.

Check whether ambient and intra-device humidifies 10 80 RH Hygrometer%〜 %

()are appropriate. without dew condensation

Check whether dust is deposited. No dust Visual check

Installation state Check whether the product is firmly secured. Not loose 6 kg cm Torque wrench(・)

Check whether connectors are completely inserted. Not loose and removed Visual check

Check whether cables are to be removed. Not loose and removed Visual check

Check whether connecting cables are to be broken. Appearance is normal. Visual check

3 Replacement method() If the product becomes faulty, repair it immediately because the entire device system may be affected.

To make the repair smoothly, a spare product should be prepared.

To prevent an accident such as an electric shock during replacement, stop the device and turn off the power.・If poor contacting is assumed, wipe contacts with a clean cotton cloth that is wet with industrial alcohol.・Take a record of switch settings during replacement and return them to their state before the replacement.・After the replacement, confirm that the new product is normal.・For the faulty product replaced, have it repaired by returning it to the company with a・report indicating as much details on the failure as possible.

6-2. Saving and disposal

1Savingmethod() Save the product in the following environment.

・( )Indoor Place in which the product is not in the path of direct sunlight.

Place at ambient temperature and humidity within the specifications.・Place free of corrosive and inflammable gases.・Place free of dust, dirt, salt, and iron powder.・Place free of direct vibration and shock to the product body.・Place free of water, oil, and chemicals droplets.・Place where a person cannot ride or put objects on the product.・

2 Disposal method() Handle the product as industrial waste.

-17-

AL2-02/USB

Instructions Manual

The main parts which revised by this manual

Parts Content

None

Technical Service

TEL.(042)664‑5382 FAX.(042)666‑5664

E‑mail s‑support@melec‑inc.com

Sales and Service

TEL.(042)664‑5384 FAX.(042)666‑2031

URL:http://www.melec‑inc.com

Melec Inc. Control equipment marketing department

516‑10,Higashiasakawa‑cho,Hachioji‑shi,Tokyo 193‑0834,Japan

This Operating Manual is subject to change without prior notice

for the purpose of product improvement. C1108

Other manuals for AL-II Series

1

This manual suits for next models

1

Table of contents