CONGRATULATIONS!

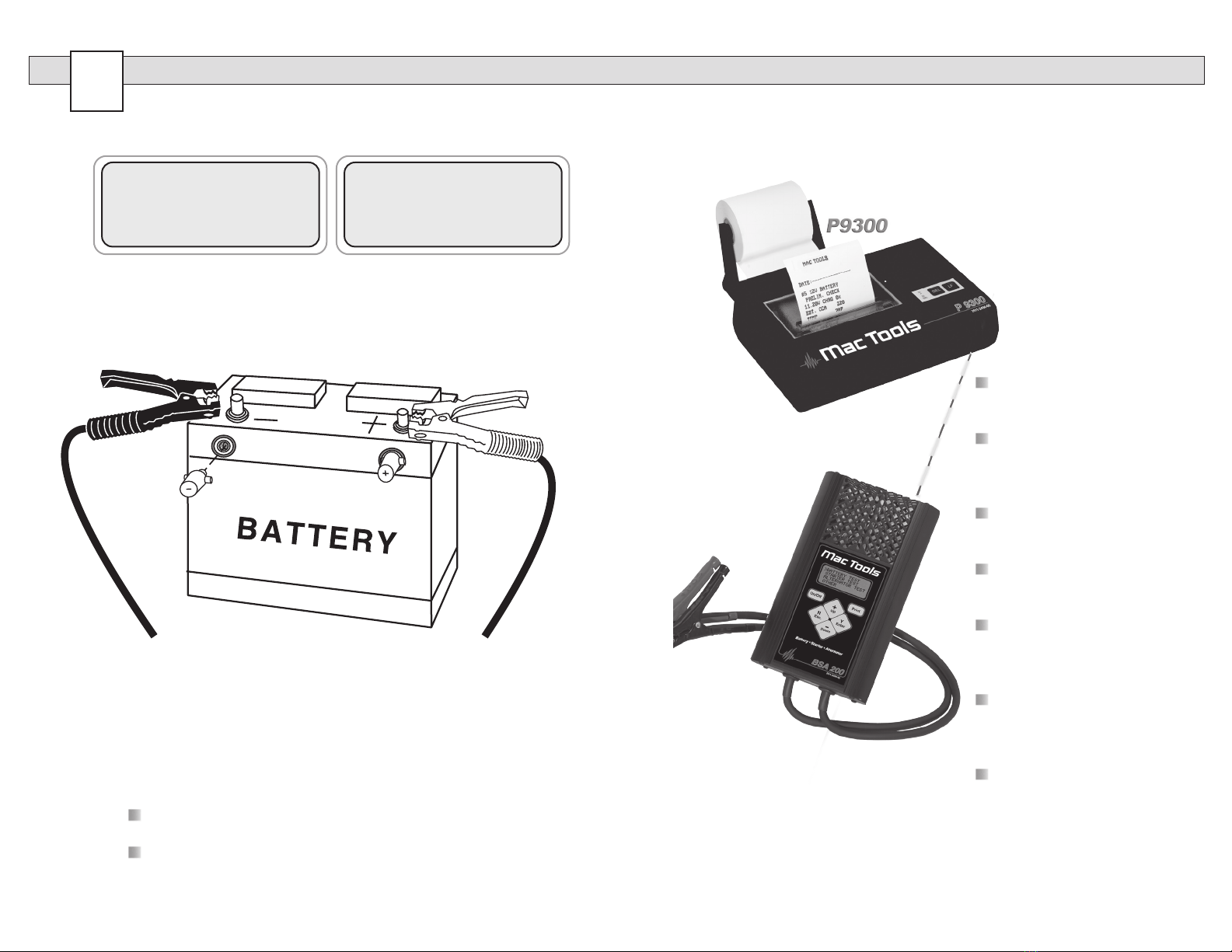

You have purchased one of MAC’s hand-held Charging System

Analyzers. It is designed to test each component of a vehicle's electrical

system with greater speed and accuracy. If you should have any

questions about your tester, testing procedures, or service see page 24

for contact information.

BVA 200s

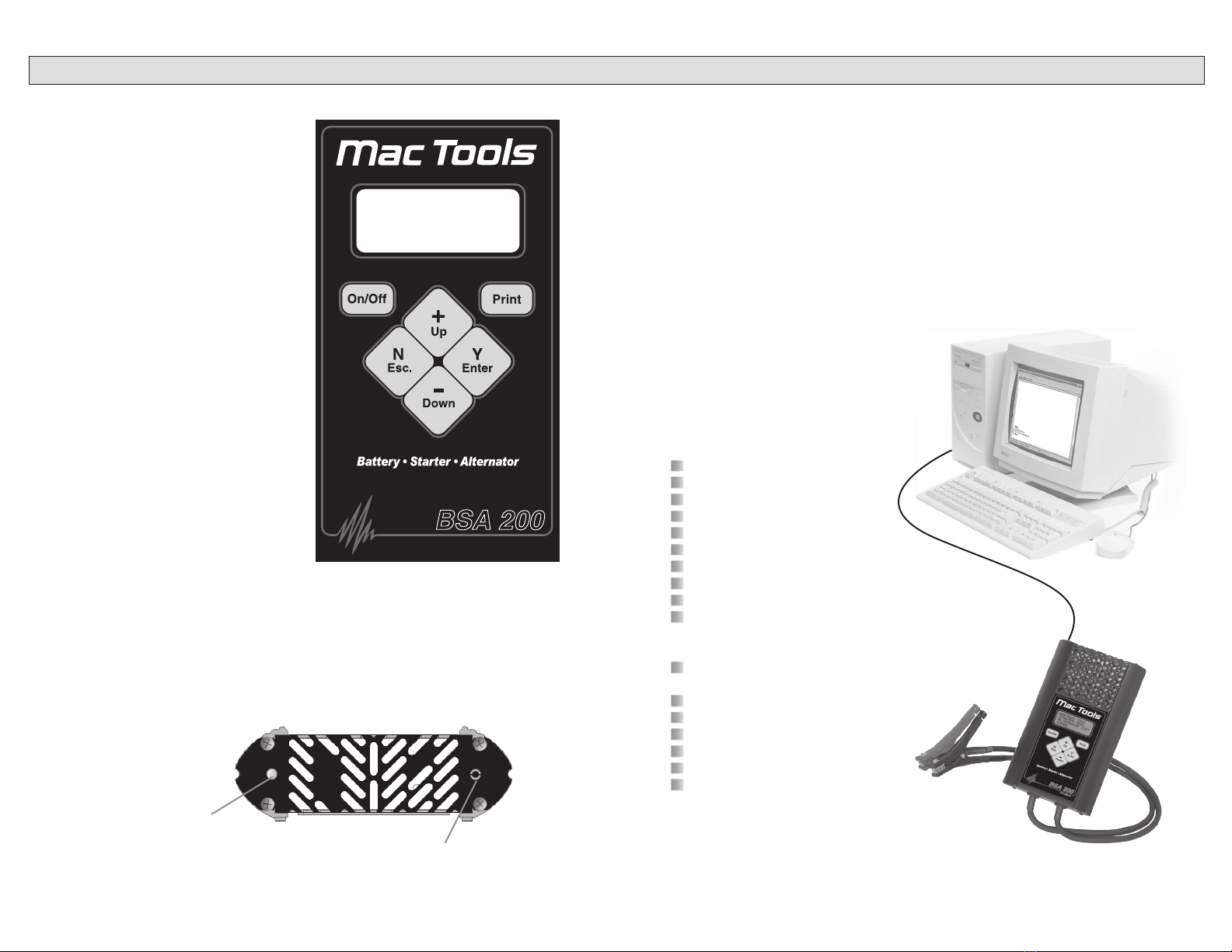

Load Test Capacity..................120 Amp

Battery sizes ...........................200-1600 CCA

Digital Back-Lit Display ..........1" x 2.5" - 4 line x 16 character

Volt Ranges.............................Digital 0-30

Cooling....................................Vented

Leads ......................................Load Amp-2 1/2 ft., 6 Gauge

Size .........................................5 7/8" x 9 1/2" x 1 7/8"

Memory ...................................stores the last 200 tests

Internal Battery........................9 Volt Alkaline

Optional P9300 .......................Infrared printer and carrying case

Optional CC100 ......................BSA200 Carrying case only

Optional AC-12 ......................PC Interface adapter cord

Weight.....................................4 lbs.

What to Expect from the BSA200:

Immediately recognize a bad battery and perform a complete

charging system analysis.The BSA200 is a portable full-featured

menu-driven battery tester and charging system analyzer that provides

quick, professional load results using Advanced DIgital Pulse Load

Technology. Quick battery checks will increase charging productivity.

The BSA200 is user friendly. It tells you what to do. The stator-

diode test automatically indicates open or shorted stator-diodes. It is

professionally accurate. Detailed test results are LCD displayed after

each test or can be reviewed and/or printed from memory.

Caution: The BSA200 grill may get hot after repeated use. Be sure to

hold the unit from the side grips only. Keep hands away from the grill.

LIMITED WARRANTY

12 MONTHS FROM DATE OF PURCHASE-

CABLES 90 DAYS

The manufacturer warrants to the consumer that this product

will be free from defects in material or workmanship for

a period of twelve (12) months from the date of original

purchase.

Products that fail within this 12 month warranty period will

be repaired or replaced at the manufacturer's option to the

consumer, when determined by the manufacturer that the

product failed due to defects in material or workmanship. This

warranty is limited to the repair or replacement of parts and

the necessary labor by the manufacturer to effect the repair or

replacement of the product. In no event shall the manufacturer

be responsible for special, incidental or consequential damages

or costs incurred due to the failure of this product.

Improper use, accident, water damage, abuse, unauthorized

repairs or alterations voids this warranty. The manufacturer

disclaims any liability or consequential damages due to breach

of any written or implied warranty on its test equipment.

WARRANTY AND SERVICE INFORMATION

Warranty claims to the manufacturer's service department

must be transportation prepaid and accompanied with dated

proof of purchase. This warranty applies only to the original

purchaser and is non-transferable. Shipper damage incurred

during return shipments is not covered under this warranty. It

is the responsibility of the shipper (the customer returning the

Test Equipment) to package the tester properly to prevent any

damage during return shipment. Repair costs for such damages

will be charged back to shipper (customer returning the Test

Equipment). Protect the product By shipping in original carton

or add plenty of over-pack cushioning such as crumpled up

newspaper.

For Service Please Contact:

Auto Meter Products, Inc.

413 West Elm Street

Sycamore, IL 60178

Phone: 866-883-8378

Fax: 815-895-6786

test_service@autometer.com