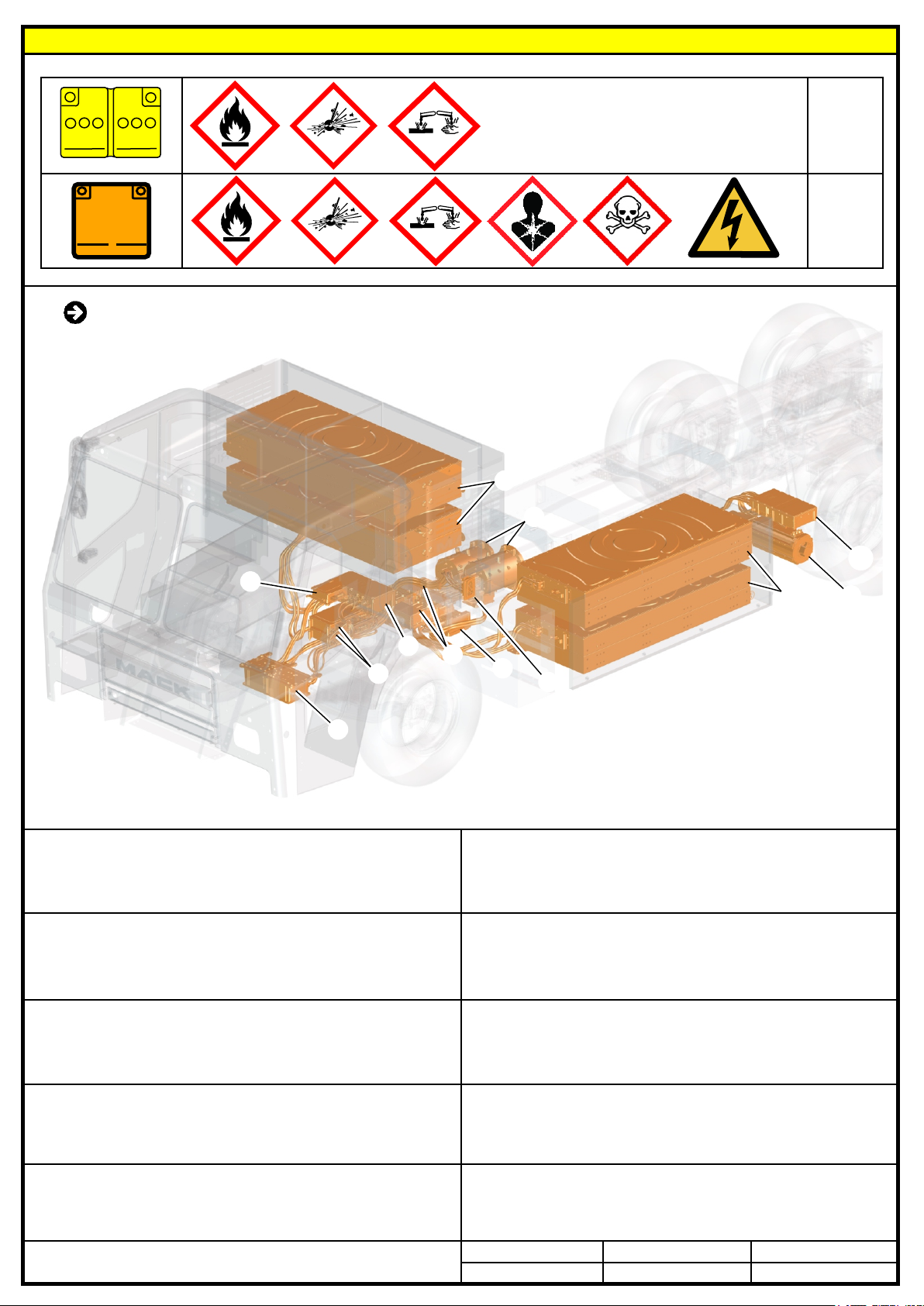

5.Storedenergy/liquid/gases/solid

12 V

Identiicationnumber Versionnumber Pagenumber

800077265 06/2021 7

600 V

2

1

1

7

3

4

4

5

8

9

10

1. Traction Battery: Four Li-ion battery packs supply a

maximum of 738V at 110A. Battery electrodes are made of

Carbon, Lithium, Nickel, Manganese and Cobalt.

2. Charging switch unit (CSU): The primary function of the

Charging Switch Unit (CSU) is to act as a circuit breaker for

the charging plug.

6

3. DC/DC converter: The DC/DC converter converts the

traction voltage of 600 V DC to 24 V DC. In electric trucks, the

DC/DC converter charges the 12 V batteries and handles the

loads connected to the 24 V system.

4. Traction Voltage Junction Box (TVJB): The TVJB has 2

variant combinations depending on the number of

high-current and low-current connection interfaces.

The TVJB distributes power in the electric propulsion system.

5. Electric Motor Drive (EMD): The EMD converts 600V DC

to three-phase AC. The EMD runs the electric motor and

controls the speed, torque and calibration.

8. Electric Motor: 2 three-phase AC motors with 400kW to

334 kW capacity power the truck.

9. Electric motor, hydr. ePTO: Three-phase Ac motor with

70kW power the hydraulic pump.

10. Electric Motor Drive (EMD)- hydr. ePTO: The

EMD- ePTO converts 600V DC to three-phase AC. The EMD

runs the electric motor and controls the speed, torque and

calibration.

6. Charging inlet, CCS 1 type : The CCS inlet is used for

600V DC charging. The CCS inlet is equipped with an

actuator that prevents accidental disconnection of the

charging plug on truck side.

7. Traction Voltage Monitoring Unit (TVMU): The TVMU

performs measurements in the traction voltage system,

detects any potential hazardous situation and communicates

this to the HPCU (Hybrid Powertrain Control Unit).

High-voltage component location