CONTENTS

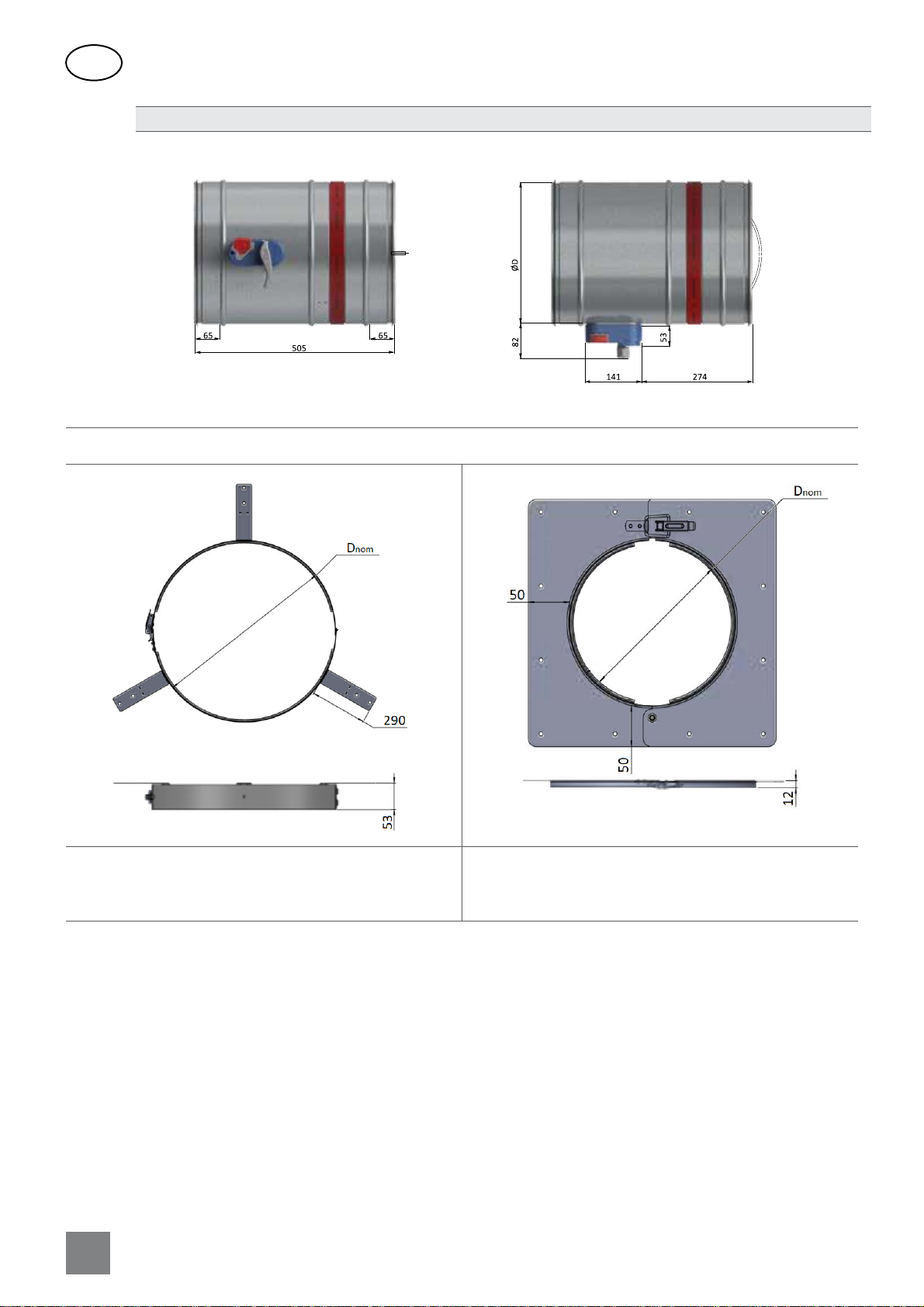

1. FIRE DAMPER DESIGN AND DIMENSIONS...........................................................................................................................3

2. INSTALLATION METHODS ..................................................................................................................................................5

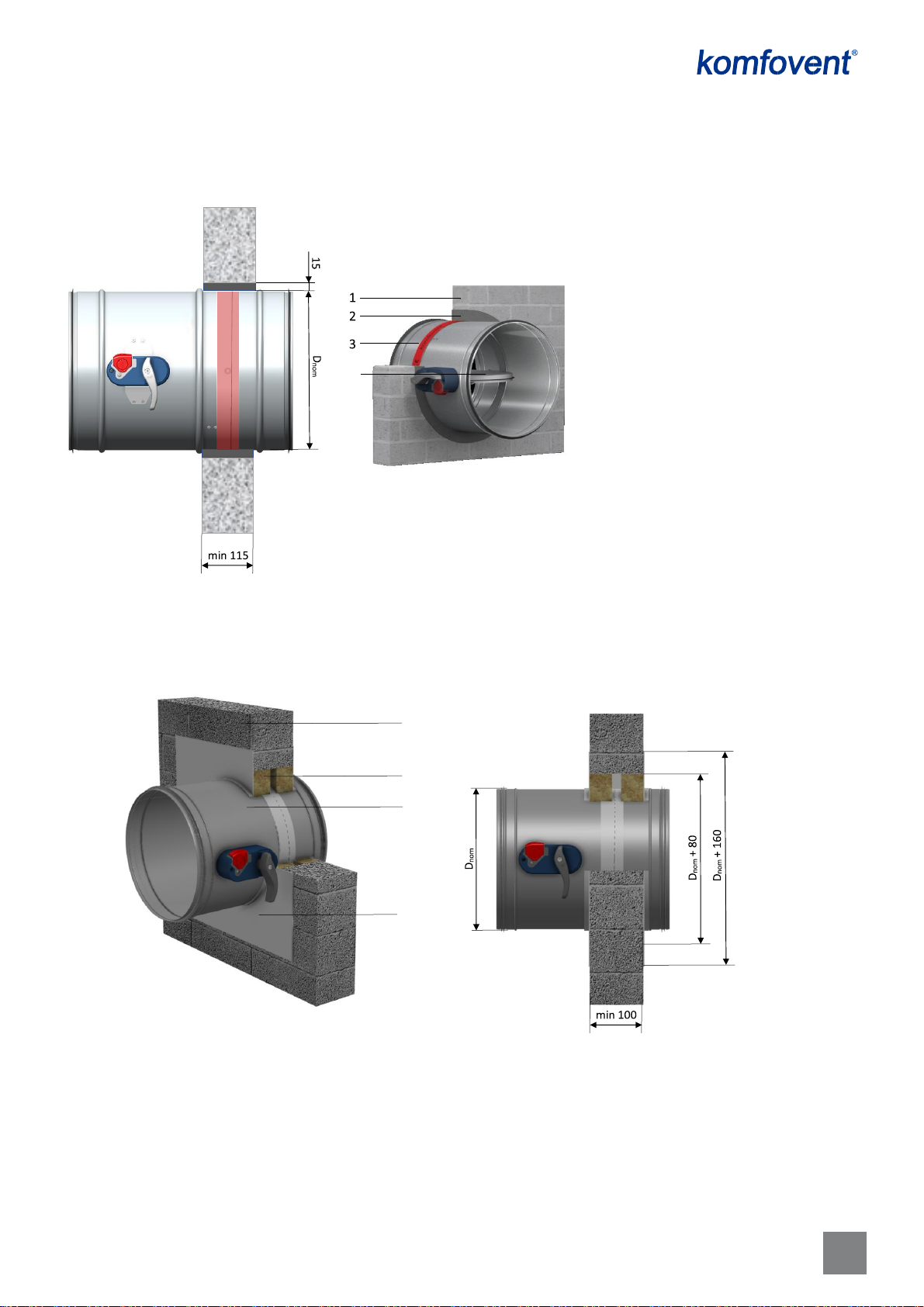

2.1. Mortar - based installation in a solid wall ..................................................................................................................5

2.2. “Fire batt” - based installation in a solid wall .............................................................................................................5

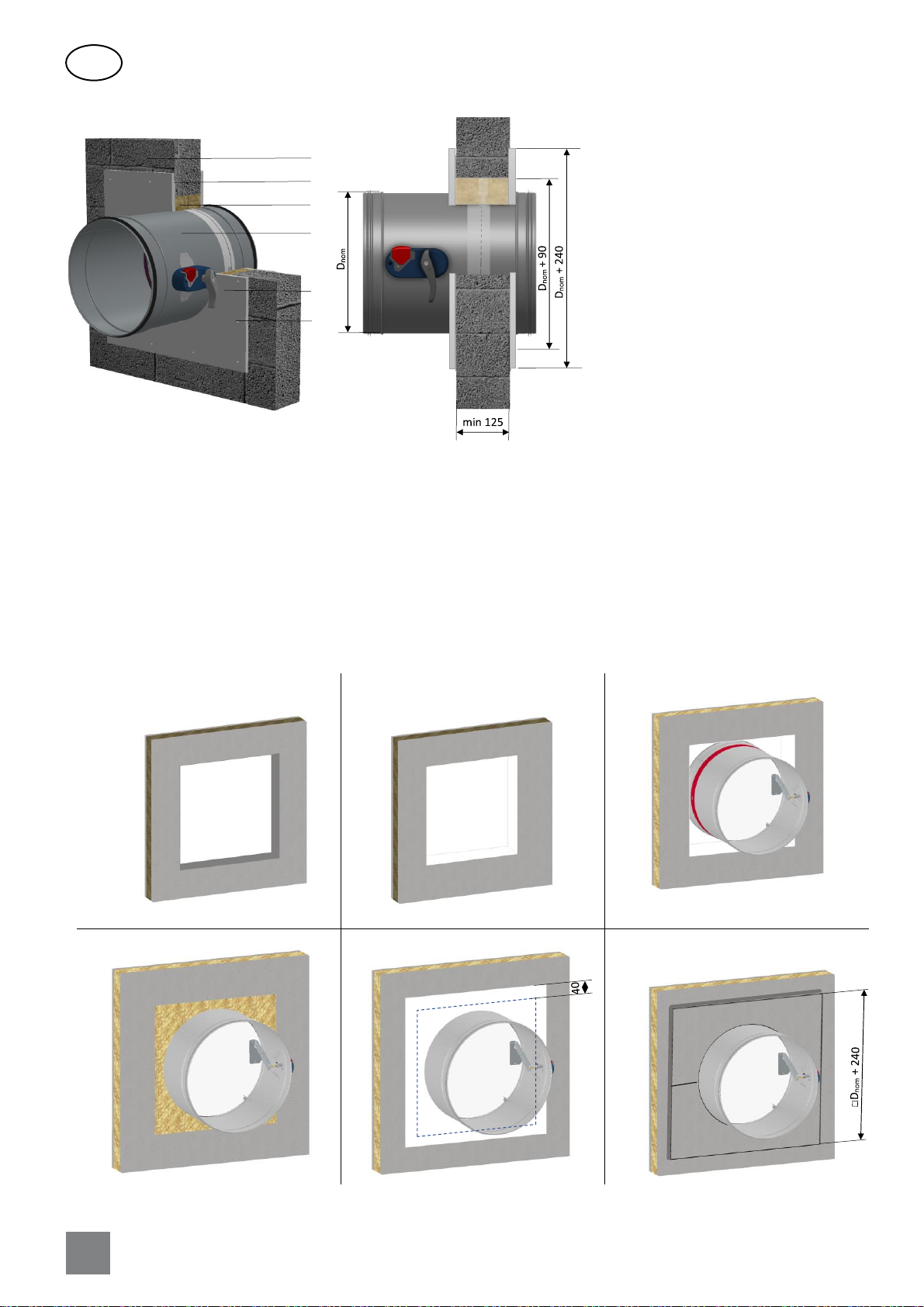

2.3. “Dry montage” installation kit - based installation in a solid wall ...............................................................................7

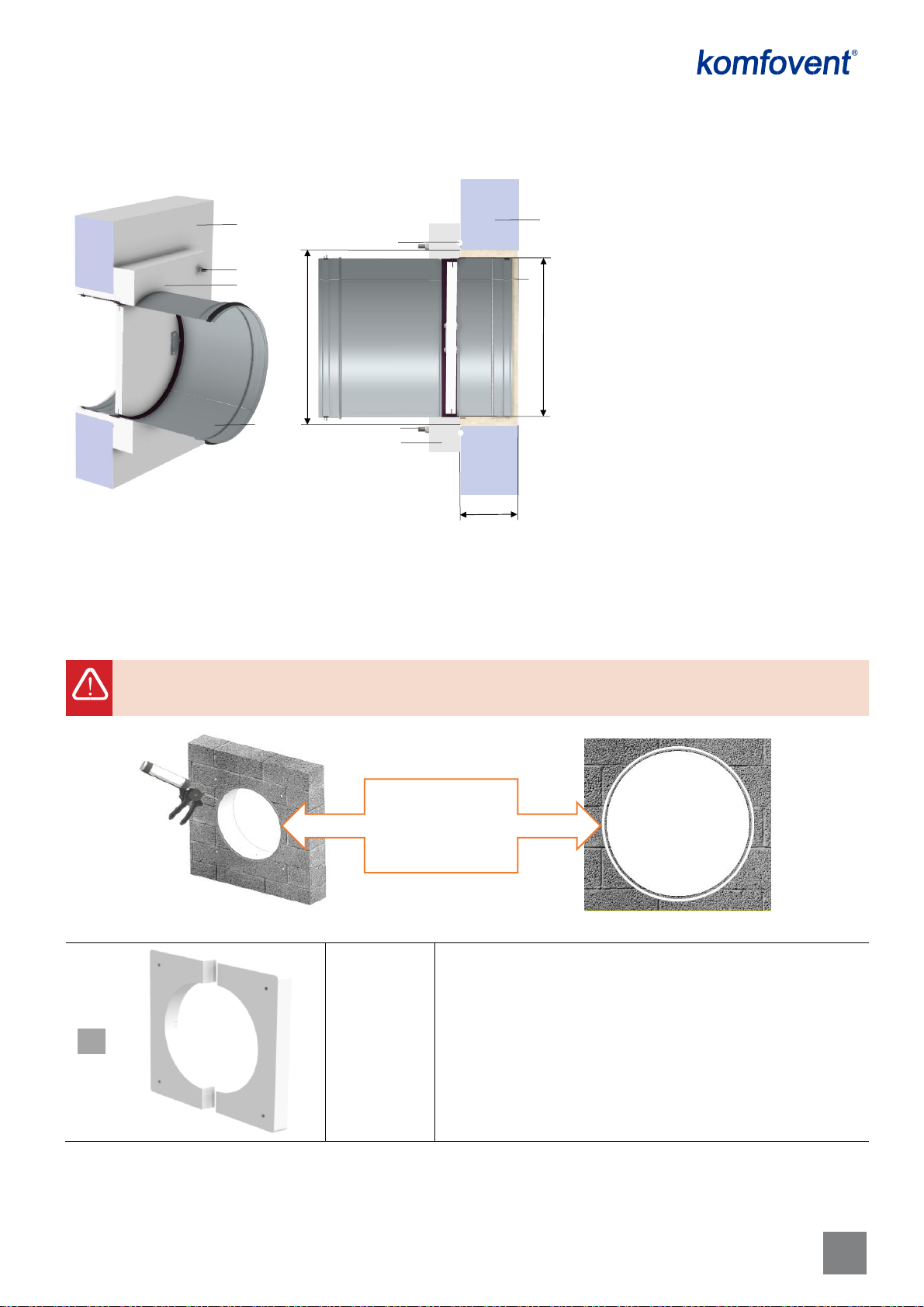

2.4. Installation in a flexible wall (metal stud drywall) ......................................................................................................9

2.5. Installation in a solid ceiling ....................................................................................................................................10

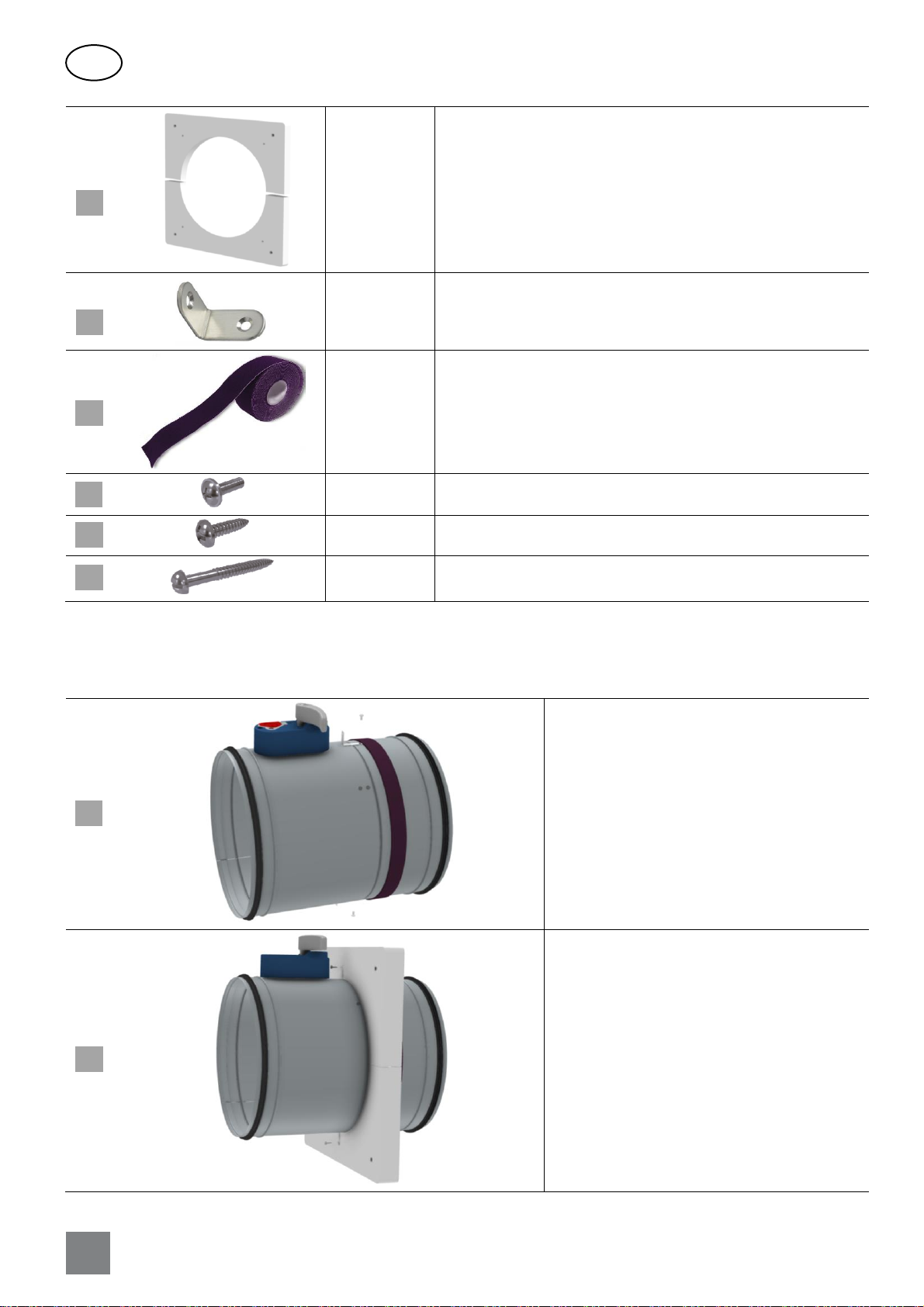

2.6. Application of the montage accessories ..................................................................................................................11

2.7. Installation methods consolidation..........................................................................................................................13

3. SAFETY REQUIREMENTS ..................................................................................................................................................15

4. INSTALLATION STEPS.......................................................................................................................................................16

4.1. Signaling devices (switches) installation instructions ...............................................................................................19

5. PERIODICAL INSPECTIONS ...............................................................................................................................................21