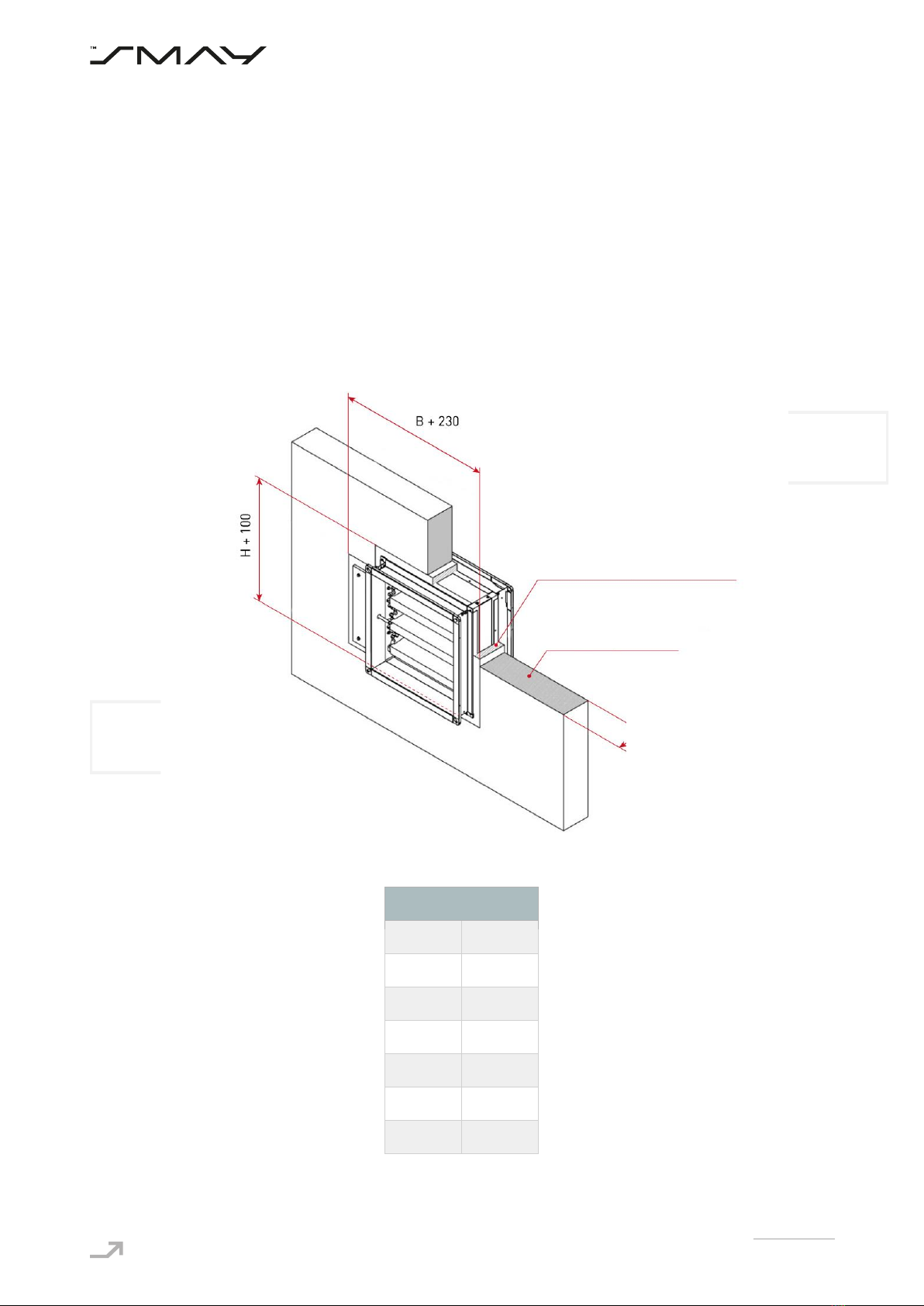

INSTALLATION TECHNOLOGY

Before installing the fire dampers, make sure that there are no damage, during transport or storage, that could block

the baffle.

Check that the baffle can be opened and closed (full opening and closing position). To open fire dampers WKP-O use

the actuator key.

The opening and closing must proceed smoothly (not stepwise).

Do not pull by baffle to open or close fire damper, it may cause permanent damage, not covered by the warranty.

Before installation verify dimensions of the gap between bottom blade and inside part of the housing under the blade,

and between top blade and inside part of housing above blade. The dimension of the gap cannot be lower than 4 mm.

Before installing, secure the fire damper, by dust and dirt, using a foil or other screening material. It can prevent

components of fire damper by damage.

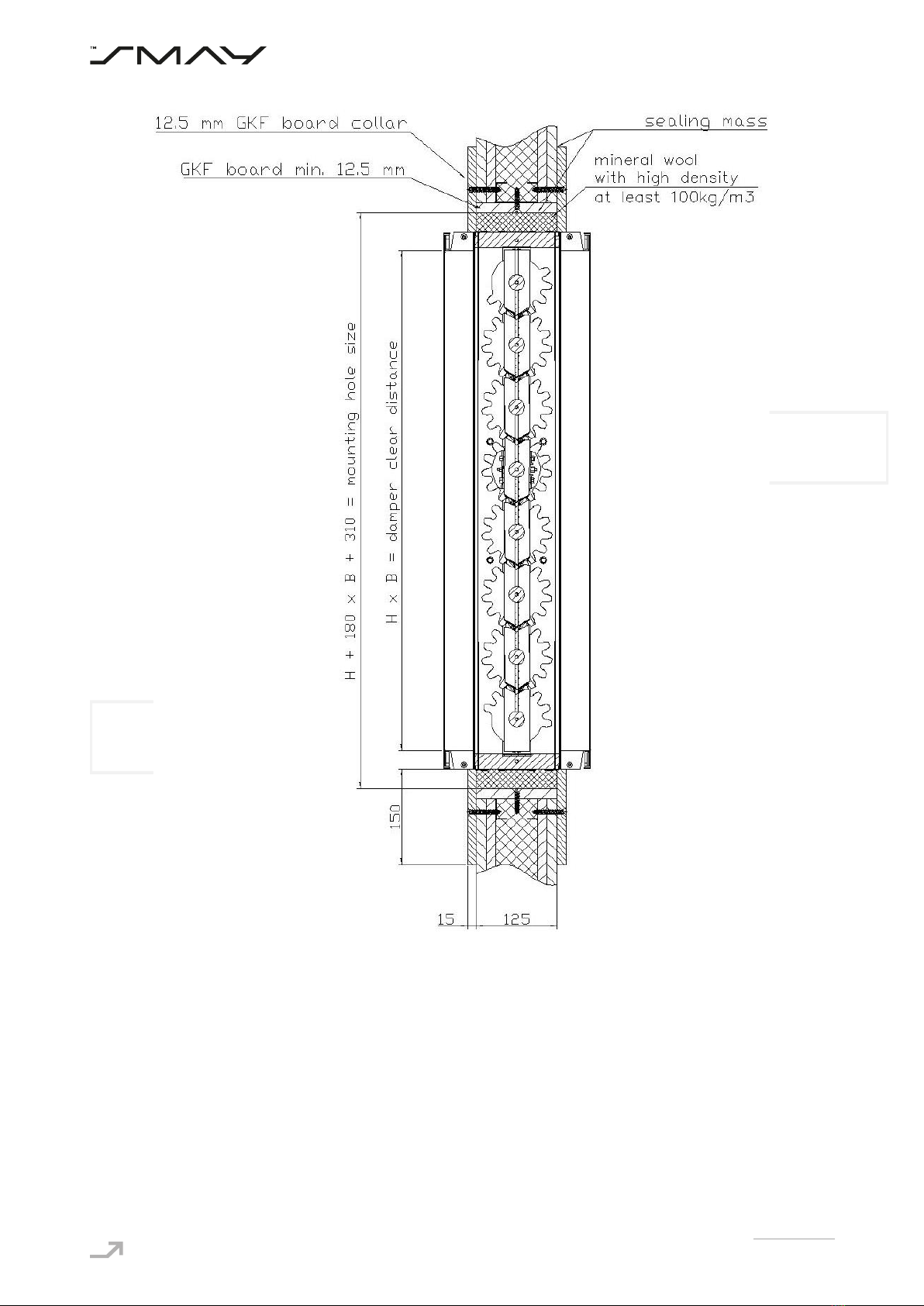

Dampers to preserve of the declared resistance, insulation and smoke leakage EIS120, EIS90, should be installed on

wall, which was classified as EIS120, EIS90.

It is allowed to install WKP-O dampers in wall with other fire-resistance, should be remembered that fire-resistance in

this situation is resistance of lowest classified (in this regard) element in this system.

Ducts made of flammable and non-flammable materials can be connected to the damper. Ducts should be installed

that they cannot load the damper during fire. Ducts lengthening during fire can be compensated by support and knee.

ATTENTION: Distance between fire dampers or fire damper and construction elements must be compatible with

standard 1366-2:

a. Minimal 200 mm between fire damper, which are installed in different ventilating wires,

b. Minimal 75 mm between fire damper and construction element (wall/ceiling).