Printed on 26/04/12 10/15 U514986-e Revision 4

2. Installation

2.1. Reception

The meters are packed in packing designed for and adapted to protect the meters during transport.

However if, on arrival, the packaging appears to have been damaged, the customer should notify the

carrier of the damage and inform SATAM.

3. Installation

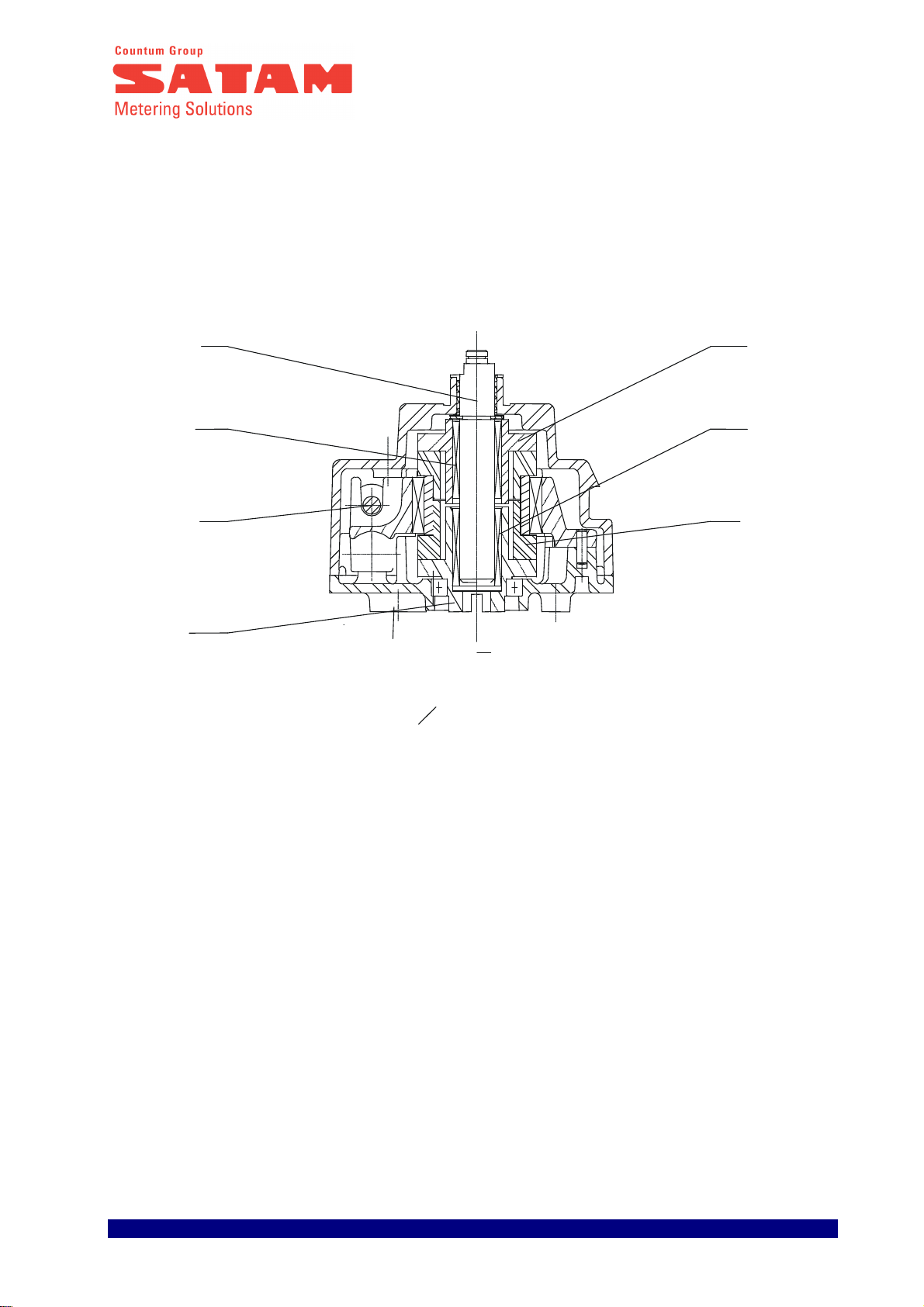

Counter flanges to be welded are supplied with the meter to enable the user to connect the meter to a 2”

horizontal installation (Ø 60.3).

Connect the meter to the piping ensuring the direction of flow is as indicated by the arrow on the cover of

the AB 40 transmission device.

All meters should be protected upstream by a strainer.

- Filtration for Jet A1 : 50 microns

- Filtration for Gasoline, Premium, Super : 70 microns

- Filtration for Diesel oil, Gas oil, FOD : 200 microns

4. Starting

Once the hydraulic installation has been completed, the meter may be put into operation.

To ensure this is carried out under optimal conditions, the following points should be strictly adhered to :

- Use clean product, devoid of any metallic particles

- All piping should be clean, rinsed, and completely dry

- Check the piping is free of air and put into operation progressively.

Important: Respect the maximum flow limit authorised for the meter.

For information on the Metrological inspection at operation start-up, refer to the next chapter.

4.1. Preset Operation

➥To display preset quantity required :

Stand in front of the preset. Press the “Set” button on the left to unlock the preset, then press each of the

5 push buttons until the quantity required is displayed in the windows. The quantity is indicated in litres.

For emergency stop, press the right hand “Stop” button.

➥To open the Preset Valve :

Pull the control lever towards yourself

4.2. Checking low flow initiation

For a ZC 17-24 or a 48 meter, low flow is initiated at approximately 30 litres from the end of delivery

(transfer from high to low flow at 30 litres from end of loading).

Low flow setting

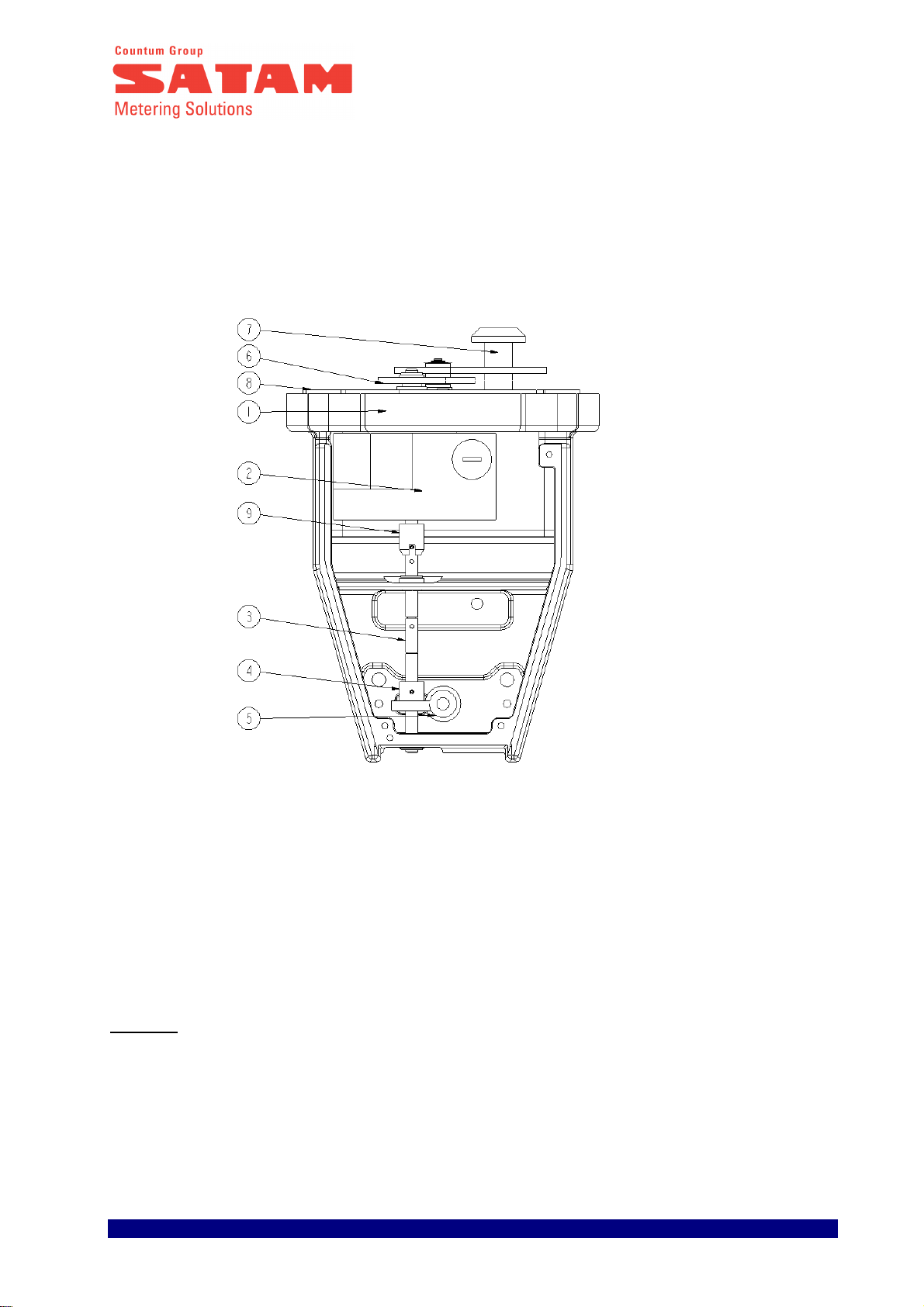

- Remove the cover (1)

- Adjust the setting by changing the position of the roller using the 19 mm flat spanner and a 10 mm

spanner.

- Rotate the eccentric in a clockwise direction to increase the low flow rate

- Rotate the eccentric in an anticlockwise direction to reduce low flow rate

- A non closing of the valve can be due to a too low set up of the low flow rate

- In stop state, there must be a clearance between the roller and the cam