-16-

English

Table of Contents

1Signs and symbols .........................................................................................................17

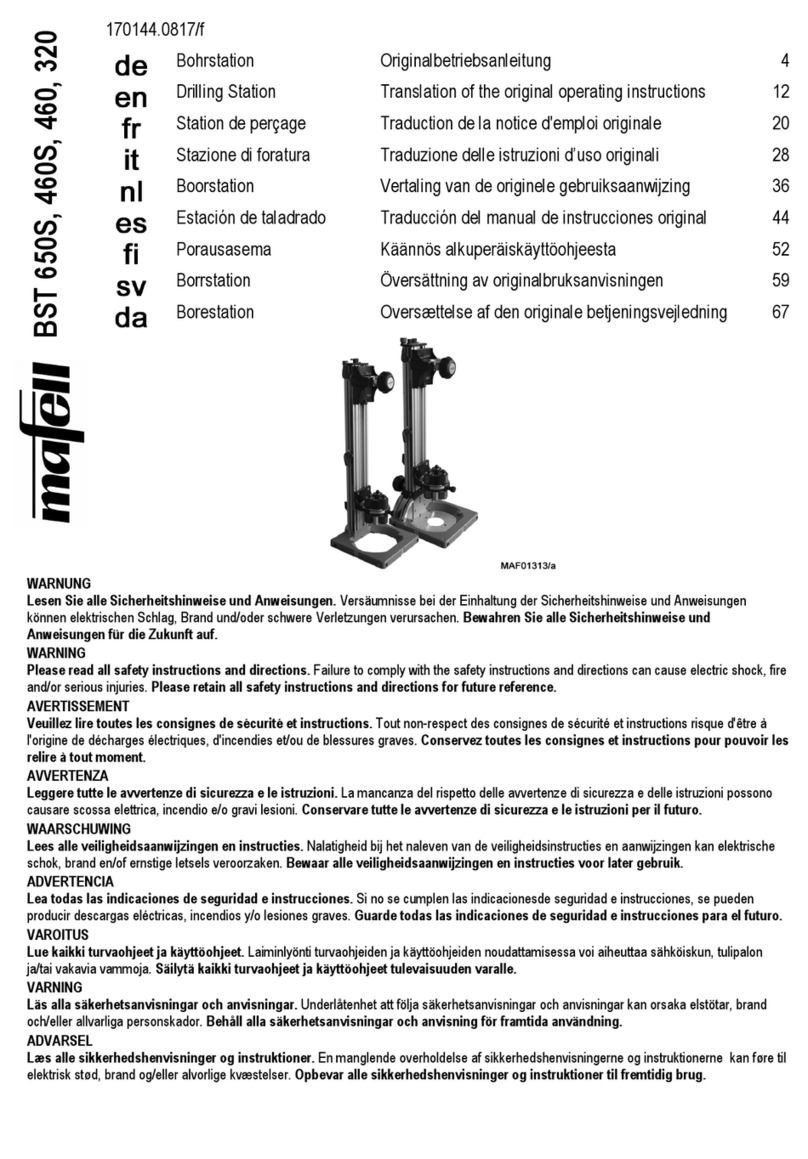

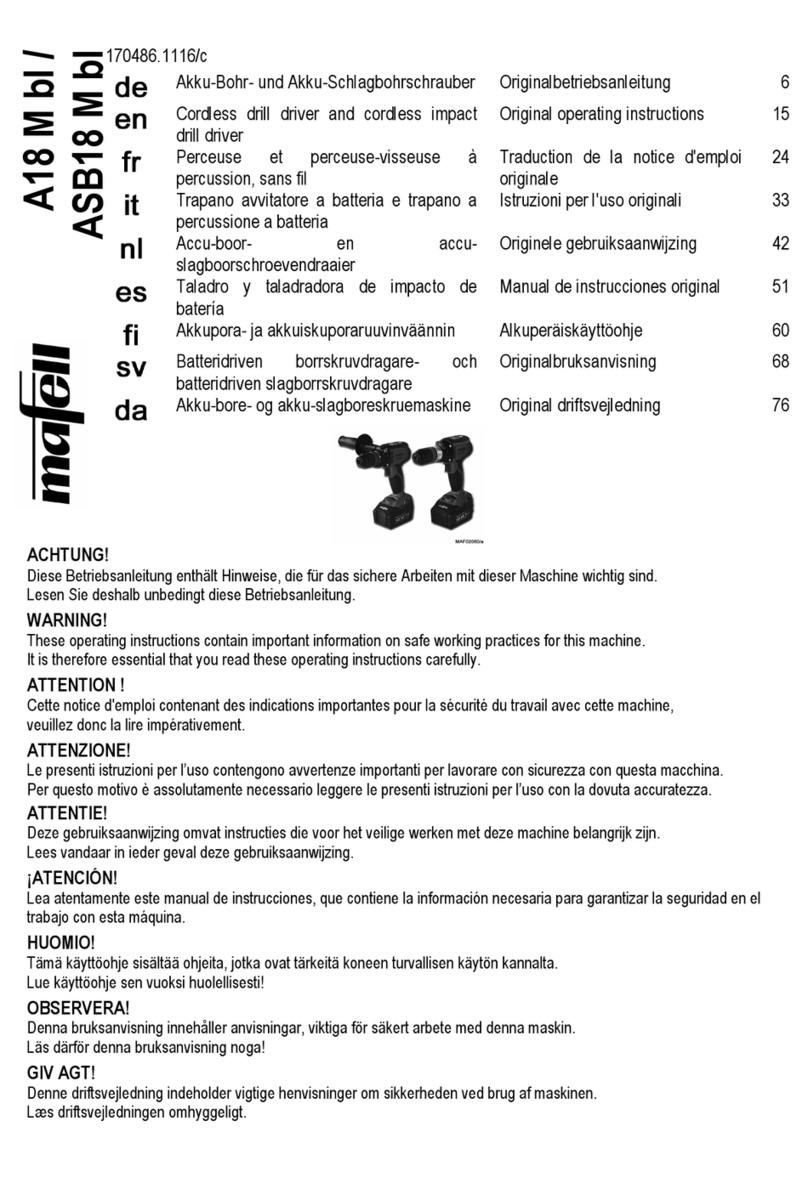

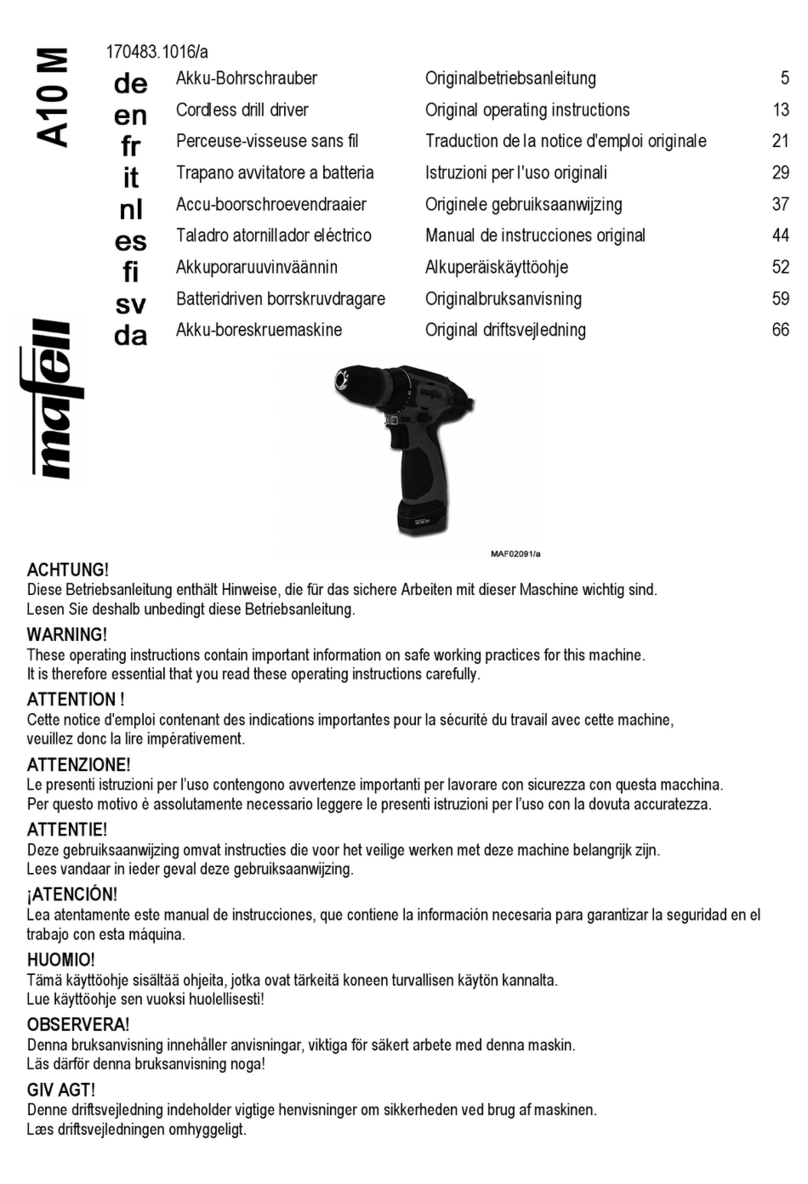

2Product information ........................................................................................................17

2.1 Manufacturer´s data ....................................................................................................... 17

2.2 Machine identification.....................................................................................................17

2.3 Technical data ................................................................................................................ 18

2.4 Emissions....................................................................................................................... 18

2.5 Scope of supply.............................................................................................................. 19

2.6 Use according to intended purpose................................................................................19

3Safety information ..........................................................................................................19

3.1 Safety instructions for all types of work ..........................................................................19

3.2 Safety instructions for the use of long drill bits ............................................................... 19

3.3 Additional safety instructions..........................................................................................20

4Layout............................................................................................................................. 20

4.1 Depicted components.....................................................................................................20

4.2 Symbols..........................................................................................................................20

5Operation........................................................................................................................20

5.1 Rechargeable battery, capacity and signal display ........................................................20

5.2 Removing and inserting the rechargeable battery..........................................................21

5.3 Sense of rotation, transport lock.....................................................................................21

5.4 Selecting the gear speed................................................................................................ 21

5.5 Setting drilling or impact drilling mode............................................................................ 21

5.6 Setting the torque, impulse function ...............................................................................21

5.7 Switching on/off, setting the speed.................................................................................21

5.8 Tool change....................................................................................................................21

5.9 Switching the LED light on/off ........................................................................................ 22

5.10 Belt clip...........................................................................................................................22

5.11 Bit adapter......................................................................................................................22

5.12 Optical alignment (spirit level) ........................................................................................22

6Service and maintenance...............................................................................................22

6.1 Storage...........................................................................................................................23

6.2 Transport........................................................................................................................23

6.3 Disposal of rechargeable batteries/batteries ..................................................................23

7Troubleshooting..............................................................................................................24

8Optional accessories ......................................................................................................25

9Exploded drawing and spare parts list ........................................................................... 25